Coffee drum roaster px 120 for industrial use

Optimize your coffee roasting with precise control over batch size and heating, ensuring consistent quality and energy efficiency for a diverse range of premium coffee products.

Roasts and Cools Coffee Beans Efficiently

The Px 120 Drum Coffee Roaster from PROBAT SE is a cutting-edge solution designed to enhance the efficiency and quality of large-scale coffee roasting operations. Featuring a horizontally oriented drum equipped with a rotary drive, this roaster utilizes both conduction and convection heating methods to deliver uniform roasting for batch sizes ranging from 60 to 120 kg. It is especially suited for producing espresso, cold brew, and artisan coffee varieties, tackling challenges in specialty coffee production with unmatched precision.

The Px 120 integrates seamlessly into existing production lines, being fully automated and optimized for energy efficiency. The inclusion of a high-efficiency cyclone ensures effective chaff separation while significantly reducing exhaust air volume through its partial recirculation system. With the capability of operating on natural gas, propane, or hydrogen, the Px 120 offers flexibility in energy sourcing.

Equipped with the PILOT 2020 ROASTER control system, this machine allows users to manage roasting profiles with an intuitive, touch-optimized HMI, ensuring reproducible results and real-time access to all critical production data. Compliance is enhanced with PROBAT’s modular exhaust air treatment systems, addressing environmental standards and emissions reductions, while its robust design minimizes heat loss and maximizes safety.

Customization options include flexible recipe management and energy monitoring with heat recovery options, catering to unique operational requirements. Whether producing barista-grade coffee or specialty blends, the Px 120 stands out for its reliability and innovative engineering.

Benefits

- Increases energy efficiency with partial recirculation, reducing operational costs.

- Ensures consistency in coffee quality across diverse batch sizes and roast profiles.

- Minimizes exhaust emissions, supporting compliance with environmental regulations.

- Enhances production flexibility with adaptable heating options, including renewable hydrogen.

- Simplifies maintenance and cleaning with optimized design features like the high-efficiency cyclone.

- Applications

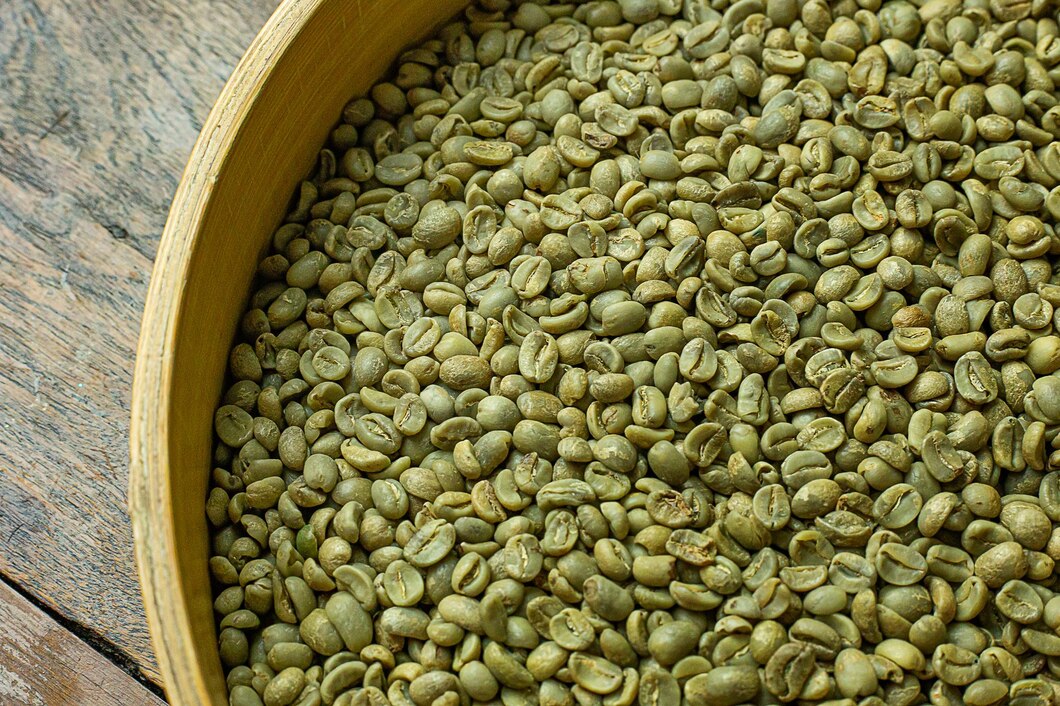

- Specialty coffee, Green coffee, Coffee beans, Dark roasts

- End products

- Blended coffee varieties, Single-origin specialty coffee, Espresso roast, Artisan roasted coffee, Barista-grade coffee, Fair trade certified coffee, Decaffeinated coffee, Flavored coffee beans, Cold brew coffee, Espresso beans, Organic coffee beans, Turkish coffee, French roast coffee, Specialty pour-over coffee

- Steps before

- Green coffee preheating, Coffee bean selection, Sorting, Weighing, Cleaning

- Steps after

- Cooling, Chaff separation, Quality control, Packaging, Flavor analysis

- Input ingredients

- green coffee beans, natural gas, propane, hydrogen

- Output ingredients

- roasted coffee beans, exhaust air, chaff, heat energy

- Market info

- Probat is renowned for its expertise in manufacturing coffee processing equipment, particularly coffee roasters. The company has a strong reputation for engineering solutions in industrial coffee roasting, blending, and grinding technology.

- Batch Size

- 60–120 kg

- Roasting Time

- 6–20 min

- Roasting Capacity

- 480 kg/h

- Heating

- Natural gas, propane, hydrogen

- Control System

- Fully automatic with PILOT 2020

- Energy Efficiency

- Optimized with CFD analytics

- Chaff Separation

- High-efficiency cyclone

- Exhaust Air Treatment

- Partial recirculation system

- Cooling Performance

- Increased

- Roasting mechanism

- Drum Roasting

- Roasting drum type

- Horizontally lying with rotary drive

- Roasting batch size range

- 60-120 kg

- Roasting time

- 6-20 minutes

- Energy consumption

- Reduced with partial recirculation system

- Control system

- Web-based PILOT 2020 ROASTER with touch-optimized HMI

- Automation level

- Full automatic with flexibility for manual adjustments

- Heating options

- Natural gas, propane, hydrogen

- Recirculation of exhaust air

- Partial

- Cooling efficiency

- Increased cooling performance

- Flexibility in batch processing

- Increased through extended batch size range

- Chaff separation method

- High-efficiency cyclone

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Touchscreen / Web-based

- Discharge method

- Rotary drive

- Drum size

- Not specified

- Capacity

- 60–120 kg per batch

- Heating method

- Natural gas / Propane / Hydrogen

- Control panel type

- Touchscreen HMI

- Integration possibilities

- Web-based application

- Heating options

- Natural gas, propane, hydrogen

- Batch size flexibility

- 60–120 kg

- Recirculation system

- Partial recirculation