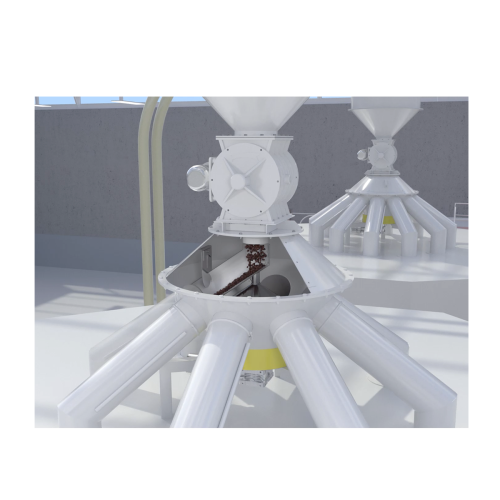

Roasted coffee handling and conveying system

Ensure the gentle handling of roasted coffee with versatile conveying solutions that preserve aroma and quality, seamlessly integrating into your production line to minimize breakage and optimize storage efficiency.

Handles and Conveys Roasted Coffee Efficiently

IMA Coffee Petroncini’s Roasted Coffee Handling and Conveying Systems provide a comprehensive solution for maintaining the quality and integrity of roasted coffee products. Featuring a flexible pneumatic and mechanical design, these systems gently weigh, handle, and convey roasted coffee, preventing breakage and ensuring optimal aroma preservation. They incorporate pneumatic transport with options like bucket elevators for short distances and tubular drag conveyors for longer routes. With capacities designed to suit different production needs, the systems efficiently integrate into existing facilities. They include self-regulating options based on coffee weight and state-of-the-art receiving cyclones and rotary distributors, minimizing product degradation. These systems are ideal for applications in coffee producers and beverage manufacturers aiming to optimize production efficiency and product quality while reducing maintenance requirements.

Benefits

- Preserves coffee flavor and aroma with gentle handling and minimal breakage.

- Enhances operational flexibility with pneumatic and mechanical options tailored to plant needs.

- Lowers maintenance costs through robust design and self-regulating systems.

- Optimizes space and resource use by integrating seamlessly into existing production lines.

- Increases efficiency with flexible routing options and multiple discharge points.

- Applications

- Ground coffee, Coffee beans, Roasted coffee

- End products

- Espresso roast coffee, Instant coffee powder, Cold brew coffee concentrate, Drip coffee grounds, French press coffee

- Steps before

- Roasting, Destoning

- Steps after

- Weighing, Storing in Silos, Preservation

- Input ingredients

- roasted coffee, destoned coffee

- Output ingredients

- weighed coffee, handled coffee, conveyed coffee

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Conveying System

- Pneumatic / Mechanical

- Pneumatic Transport Type

- Compression / Aspiration

- Suction Pipe Length

- Up to 60 m

- Receiving Cyclones,Rotary Distributors Material

- Special Materials

- TPA System

- Pneumatic Transport in Aspiration

- Multiple Discharge Capability

- Yes

- Flexibility

- High

- Chain Conveyor

- Long distances aroma protection

- Bucket Elevator

- Gentle conveying

- Handling method

- Pneumatic/Mechanical

- Conveying method

- Bucket Elevator/Drag/Chain Conveyor

- Conveying flexibility

- Multiple routes/discharges

- Capacity

- Plant-specific

- Pneumatic transport distance

- Up to 60 m

- Product preservation

- Aroma protection

- Maintenance requirement

- Reduced for Pneumatic

- Adaptable orientation

- Ground/Ceiling Fixed

- Breakage control

- Maximum care in conveying

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Handling method

- Pneumatic or Mechanical

- Conveyor type

- Bucket / Tubular Drag

- Handling method

- Pneumatic / Mechanical

- Discharge method

- Multiple Discharges

- System installation

- Ground / Ceiling Mounted

- Discharge method

- Multiple discharges, 2-way valves

- Installation options

- Ground or ceiling fixing

- Route flexibility

- Multiple routes inside production area

- Handling distance

- Up to 60 m of suction pipes

- Conveying method

- Bucket elevator, Tubular drag conveyor, Chain conveyor, Pneumatic conveying