Blender for whole bean roasted coffee

Achieve precise coffee blend consistency and protect delicate roasted beans with an advanced blending and pneumatic conveying system, ideal for specialty coffee production.

Blends and Conveys Roasted Coffee Beans

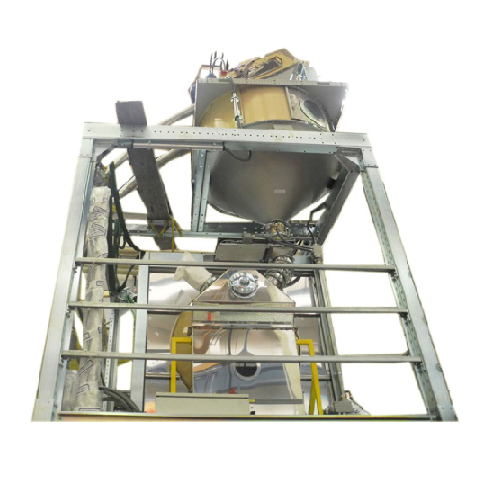

The Pneumatic Conveying and Blending System from Scolari Engineering is designed to enhance your coffee production line with precision and care. This system delicately handles fragile roasted coffee beans using pneumatic pulse conveyors, ensuring the quality of whole bean coffee is maintained. Suitable for coffee roasting businesses and industrial coffee manufacturers, it efficiently blends and conveys roasted beans for various end products, including specialty coffee blends and espresso beans.

The system employs a discontinuous mixing process, allowing precise batching and blending for consistent product quality. With options to seamlessly integrate into your existing production line, it provides automated operation through electronic speed control and programmable batching schedules, optimizing workflow from roasting to final packaging.

Constructed from durable materials to withstand processing rigors, the equipment is available with multiple roasted coffee silos accommodating different batch sizes. The flexibility of bypassing blending stages allows for streamlined operations, whether proceeding directly to grinding or packing.

Customization options are available, supported by expert engineering consultation, ensuring the system meets your specific production requirements.

Benefits

- Ensures gentle handling to preserve the integrity of fragile roasted coffee beans.

- Increases efficiency by automatically managing blending and conveying processes.

- Supports versatile production with options to skip stages for direct packing or grinding.

- Customizable to meet specific production needs with expert engineering support.

- Minimizes labor requirements through electronic speed control and programmable operations.

- Applications

- Coffee blends, Ground coffee, Coffee beans, Roasted coffee

- End products

- Artisan roasted coffee, Espresso coffee beans, Specialty coffee blends, Whole bean coffee packaging, Filter ground coffee

- Steps before

- Roasting, Batching

- Steps after

- Grinding, Packing, Blending

- Input ingredients

- roasted coffee beans

- Output ingredients

- whole bean roasted coffee, blended roasted coffee, ground coffee, packed coffee

- Market info

- Scolari Engineering is known for designing and manufacturing custom-engineered drying systems and equipment, particularly for the food and agricultural industries, leveraging innovative technology and a strong reputation for quality and reliability.

- Silos Capacity

- From 4 to 18 silos each battery

- Pneumatic Pulse Conveyor Control

- Electronic speed control

- Batching Program

- Roasted batching program

- Rotary Blender Function

- Handles roasted beans carefully

- Blender Exclusion Feature

- Possible to exclude blender for direct processing

- Automation

- Computer-controlled scheduling

- Weighing and Batching Machine

- Part of the system

- Discontinuous Mixers

- Fed from a batching unit

- Working Mechanism

- Pneumatic pulse conveyor

- Batching System

- Roasted batching program

- Automation Level

- Computer-controlled blending

- Blend Scheduling

- Computer-generated schedule

- Careful Handling

- Fragile roasted beans

- Batch vs. Continuous Operation

- Batch

- Exclusion Function

- Blender exclusion option

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- CIP

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–1.5 g/cm³ / 100–500 µm

- Tank size

- 4 to 18 silos

- Feed/discharge method

- Pneumatic pulse conveyors

- Control panel type

- Electronic speed control

- Control panel type

- Electronic speed control