Leak detection unit for coffee pods

Ensure the integrity of your coffee pods with precise leak detection, vital for maintaining freshness and quality before reaching consumers.

Performs Leak Detection on Coffee Pods

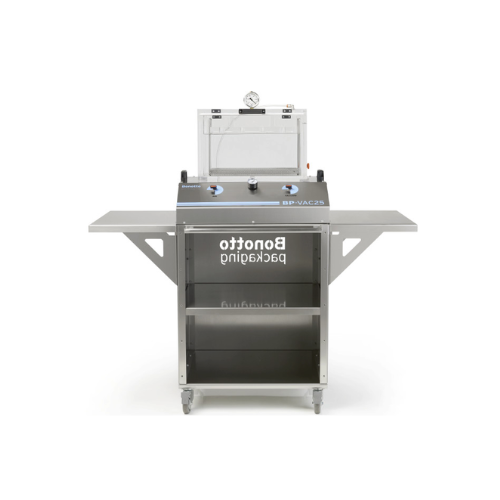

The BP-VAC25 Leak Detection Unit from Bonotto Packaging is designed for coffee pod manufacturers seeking robust packaging quality assurance. This bench-top unit specializes in detecting leaks within coffee pods, ensuring the integrity of seals and maintaining the aroma and freshness of the blends, whether Arabica, Robusta, or flavored variants. Operating on a simple yet effective vacuum test principle, it identifies even minute seal failures, critical for maintaining high standards in coffee production. Ideal for lab environments, it supports both manual and automated processes, seamlessly integrating into existing testing workflows. Engineered for the food and beverage sector, it caters to the specialized needs of packaging and quality control departments. Its user-friendly design allows easy operation and maintenance, and its compact size makes it perfect for limited space environments. Configurations to accommodate different pod sizes are available upon request, ensuring this unit meets diverse operational needs.

Benefits

- Ensures product integrity by identifying small leaks that can compromise coffee freshness.

- Increases quality assurance through accurate seal testing, reducing the risk of defective pods reaching the market.

- Space-efficient design fits seamlessly into lab environments, ideal for manufacturers with limited space.

- Customizable configurations support different pod sizes, allowing for versatile production requirements.

- Enhances operational efficiency by integrating smoothly into existing testing workflows, minimizing disruption.

- Applications

- Espresso capsules, Coffee pods

- End products

- Flavored coffee espresso pods, Single-origin coffee espresso capsules, Coffee pods with arabica blend, Decaffeinated espresso capsules, Coffee pods with robusta blend

- Steps before

- pod sealing, pod production

- Steps after

- quality assurance, packing

- Input ingredients

- coffee pods, espresso pods

- Output ingredients

- sealed coffee pods, verified espresso pods

- Market info

- Bonotto Packaging is known for its expertise in designing and manufacturing custom-engineered packaging machinery for various industries, recognized for innovative solutions and reliability in delivering high-quality, tailored equipment to meet specific client needs.

- Leak detection method

- Vacuum

- Application

- Coffee pods

- Automation level

- Automated system

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Product Type

- Coffee Pods

- Container Type

- Capsules

- Integration possibilities

- Automated packaging solutions

- Control panel type

- To be customized as per customer's needs

- HMI type

- Customizable for specific applications