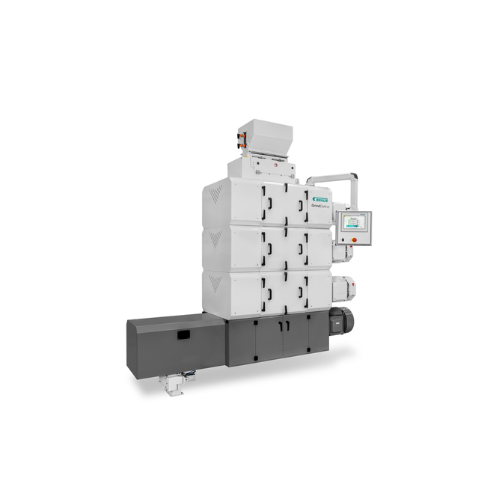

Industrial coffee grinder for consistent particle sizes

Achieve precise, consistent coffee grinds essential for specialized brews with advanced roller gap control and temperature regulation, ensuring optimal flavor profiles across a range of coffee products.

Grinds Coffee Precisely for Consistent Particle Size

The GrindDefine™ Coffee Grinder from Bühler Group is engineered to provide superior grinding precision and 24/7 reliability for industrial coffee production. Its unique roller grinding mechanism maintains precise gap settings and roll temperature control, ensuring optimal particle size distribution for various coffee products, including espresso, filter, and instant coffee. The grinder’s modular design accommodates diverse applications, and its high throughput supports large-scale operations within the food, beverage, and coffee industries. With a robust and durable construction, including Bühler’s double-layered centrifugal die-cast rollers that are re-corrugatable, it minimizes downtime and maintenance. Equipped with an intuitive HMI and smart process control, the GrindDefine integrates seamlessly into existing operations, offering remote monitoring capabilities and enhanced user interaction. This grinder prioritizes product quality and safety, enhancing efficiency in demanding grinding environments.

Benefits

- Ensures consistent coffee quality with precise particle size control.

- Operates 24/7 to meet high production demands.

- Minimizes maintenance disruptions with durable, re-corrugatable rollers.

- Simplifies operation and monitoring with intuitive touch-screen controls.

- Enables quick product changeovers with a hygienic design and easy access.

- Applications

- Filter coffee, Espresso coffee, Coffee, Ultrafine coffee, Instant coffee

- End products

- Espresso grind, Specialty coffee grind, Coffee capsules, Espresso pods, Instant coffee powder, Turkish coffee, Ground coffee, Filter coffee blend

- Steps before

- Roasting, Dehulling

- Steps after

- Packing, Weighing, Palletizing, Sifting, Grading

- Input ingredients

- coffee beans

- Output ingredients

- ground coffee, instant coffee, filter coffee, espresso, ultrafine coffee

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Accuracy

- Total gap control and roll parallelism

- Temperature Control

- High-performance roll temperature control

- Operational Mode

- 24/7 production

- Automation

- Touch screen and process control software

- Roller Material

- Double-layered centrifugal die-cast

- Particle Size Distribution

- Tailor-made settings

- HMI Type

- Touch screen

- Hygienic Design

- Stainless steel processing zone

- Working mechanism

- Roller grinding

- Integrated steps

- Grind size control, temperature control

- Automation level

- Touch screen, PLC control

- Batch vs. continuous operation

- Continuous

- Changeover time

- Fast changeover capability

- CIP/SIP

- Easy cleaning access

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Roller design

- Double-layered centrifugal die-cast

- Open service doors

- Large, easy opening

- Processing zone material

- Stainless steel

- Control panel type

- Touch screen

- Modular set-up

- Yes, allows wide application range

- HMI interface

- Intuitive

- Control panel type

- Touch screen HMI

- Process control software

- Intuitive and customizable

- Integration possibilities

- Remote control room access

- Tailor-made grinding settings

- Particle size distribution customization

- Roller package design

- Modular and adaptable