Making Ground Coffee

Find innovative production technology for making ground coffee and connect directly with world-leading specialists

Any coffee-drinker can agree that a cup of coffee in the morning can brighten up their day. As the most convenient way of making coffee, many people choose to make coffee at home. Whether you want to make Moka coffee or filtered coffee, you need ground coffee that is grind appropriately for the coffee brewing method of your choice. These ground coffee are manufactured by roasting and grinding processes.

Stories about ground coffee

Select your ground coffee process

Tell us about your production challenge

From green beans to the roasting and grinding process – check your equipment for making filter coffee!

Manufacturing the ground coffee starts from choosing and ordering the type and origin of green beans of your choice. Then, you need to roast these green beans with a recipe depending on the flavor profile of the coffee you desire to manufacture.

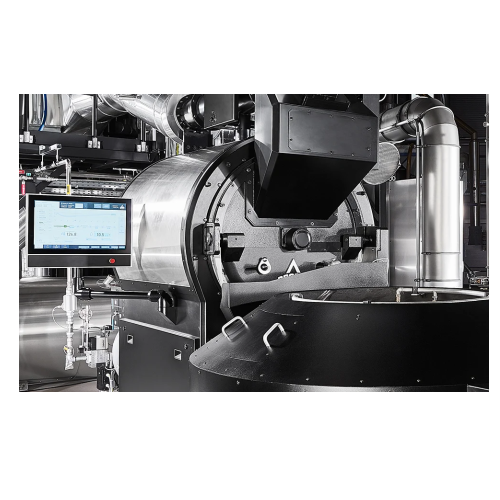

First, you put these beans into a green bean loader which can hold up to 30kg. This loader then carries the green beans through the pipe to the pre-load hopper. From this hopper, the beans are transferred to the drum roaster, which is a hot air roaster – meaning the beans are roasted through the hot air released in the drum. With this roaster, you can control the recipe of the roasting conditions – such as the air temperature forced into the beans, the drum’s rotation speed, the speed of the airflow, or how agitated the beans are in the hot air. Here, more or less heat and temperature can affect the aroma and the taste of the coffee, so it is important to maintain the specific temperature and heat level for your coffee.

When beans are roasted, they fall on the cooling tray and cool down a bit. After this process, the beans go into the destoner – filtering and cleaning process – which sucks the beans upward and leaves rocks, metal, and nails on the bottom. Then, spending on the coffee mix you would like to manufacture, you can put these beans in the blender silo. Here, destoned beans are gathered to make a coffee blend of your choice. If you intend to manufacture single-origin coffee, you can skip this step.

When you are done with the roasting process, you can transfer the destoned roasted beans into the grinder silo, which is connected to the grinder itself. Usually, this process incorporates the roller mill grinders, a machine that grinds coffee by putting beans in between two rotating grooved steel cylinders. In this process, you can choose the particle size of your ground coffee (coarse to fine), depending on the end product you desire to manufacture.

Grinding different sizes of bean particles for different brewing methods

The grinding process is an essential part of making ground coffee. This is because depending on the size of the coffee particle size, the flavor, depth, and body of your coffee can change. The particle size of the ground coffee can affect the extraction process – the general extraction time, and the time that water is intact with the coffee particles, the amount of surface area that the water is touching during the extraction. This explains why the finer the particle of the coffee beans are, the stronger the coffee comes out.

The particle sizes can range as extra-coarse – coarse – medium-coarse – medium – medium-fine – fine – extra-fine. And these particle size varies according to the different extraction method you intend to make a product for or what your target customer is looking for. Extra-coarse beans are often used for cold brew coffee, and coarse coffee is for french press extraction. You can use medium-coarse ground coffee for pour-over coffee such as Chemex or V60, and medium coffee can be used for Siphon or filter coffee machine. Medium-fine size is for Aeropress, and fine coffee can be for espresso machine and Moka pot. Lastly, extra-fine coffee is for Turkish coffee.

Packaging for the ground coffee – keep ‘em fresh!

The key to coffee packaging is to keep the oxygen out of the roasted beans and simultaneously release the CO2 created from the roasted beans. When coffee is roasted, the beans emit CO2 for a few days after the process. If you don’t consider this factor in the packaging process and accidentally seal the coffee in the vacuum pack within a few days after the roasting, the packaging will explode due to the gas of the beans. Hence, it is important to wait for a few days after the roasting process – for your beans to stop releasing gas and be ready for the vacuum sealing.

It is crucial to know that when the coffee beans meet oxygen, they oxidize and lose their aroma and flavor. To solve this issue, many coffee producers use airtight bags with one-way valves. This circular-shaped valve allows the gas to go out but simultaneously, no air can enter the bag. Hence, packaging with this valve is often sealed without removing any gas. This is the most efficient way if you would like to pack the freshest bean. However, it is noted that this valve packaging will be still affected by moisture and heat in a long term. If you are producing coffee on a larger industrial scale and are concerned about the longevity of the coffee, you can also consider waiting for the beans to degas and proceed with the vacuum or semi-vacuum packing.

Processing steps involved in ground coffee making

Which ground coffee technology do you need?

Perforated plate sieves for particle size determination

Optimize your particle size separation with high-stability stainl...

Industrial coffee roaster for mid to large-scale production

Optimize your coffee’s aroma with precision control ov...

P series coffee roasting system

Optimize your roasting precision and flexibility with customizable batch sizes, ideal for ac...

Coffee drum roaster px 120 for industrial use

Optimize your coffee roasting with precise control over batch size and heati...

Tangential coffee roaster for diverse roasting profiles

Achieve unparalleled precision and flexibility in coffee roasting...

Large scale coffee drum roaster

Enhance your coffee production with a versatile drum roaster designed for precise control an...

Industrial drum roaster for gourmet coffee

Achieve consistent gourmet coffee flavor profiles with precise heat transfer an...

Centrifugal coffee roaster for uniform roasting

Achieve consistent and precise coffee roasting with advanced centrifugal t...

Commercial coffee grinder for industrial use

Achieve precision in coffee grinding with this solution, offering optimal con...

Sample roaster for green coffee bean quality grading

Achieve precise roasting control and enhance quality assurance with ...

Medium batch coffee roaster for flexible production

For coffee roasters seeking precision and flexibility, this medium ba...

Color measurement tool for ground coffee

Ensure accurate coffee color measurement with a reflection-based system, vital for...

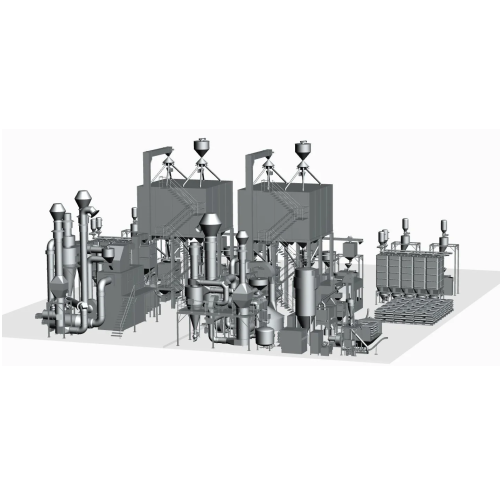

Custom coffee roasting plant solutions

Optimize your coffee production line with scalable plant solutions that integrate se...

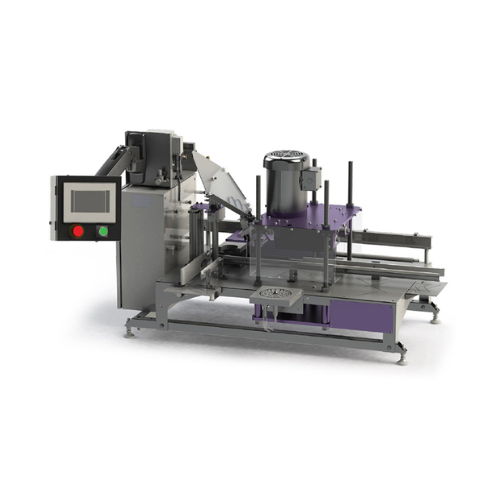

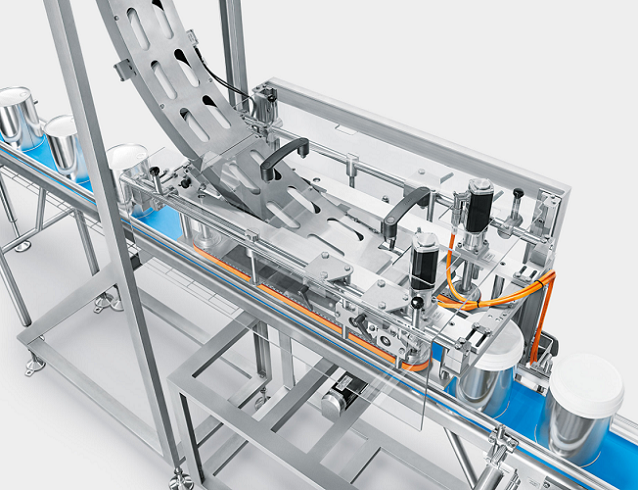

Coffee bean and ground coffee filling system

Efficiently fill tins and jars with coffee beans or ground coffee while ensur...

Filling system for ground coffee in tins

Achieve precise weight control and enhanced throughput with a high-speed filling s...

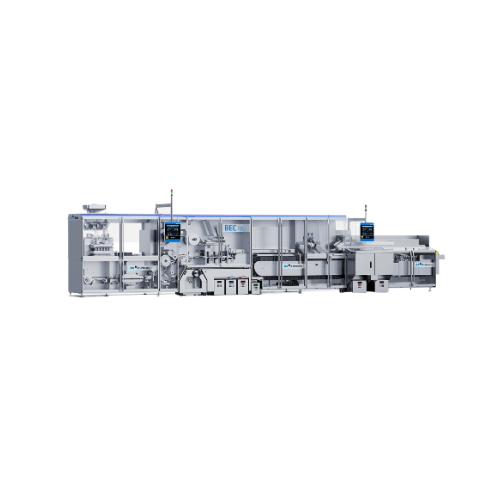

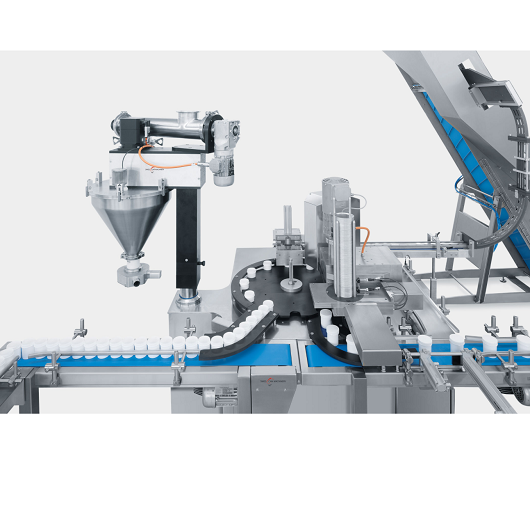

Filter paper pod production system

Streamline your production of single-serve beverages with precise weight control and sea...

Industrial coffee roaster for high-capacity coffee production

Enhance your coffee production line with high-speed roasti...

Automatic shop roaster for small and medium roasteries

Enhance your coffee production with advanced roasting technology d...

Industrial coffee roaster 480kg batch capacity

Optimize your coffee production with precision roasting for up to 480 kg pe...

Multilane vertical packaging for stick sachets

Optimize your packaging line with high-speed, multilane machines designed f...

Coffee roasting solution for small-scale industrial applications

This innovative roasting solution offers complete contr...

Specialty coffee roaster for small batch production

Enhance your coffee roasting precision with advanced heat control and...

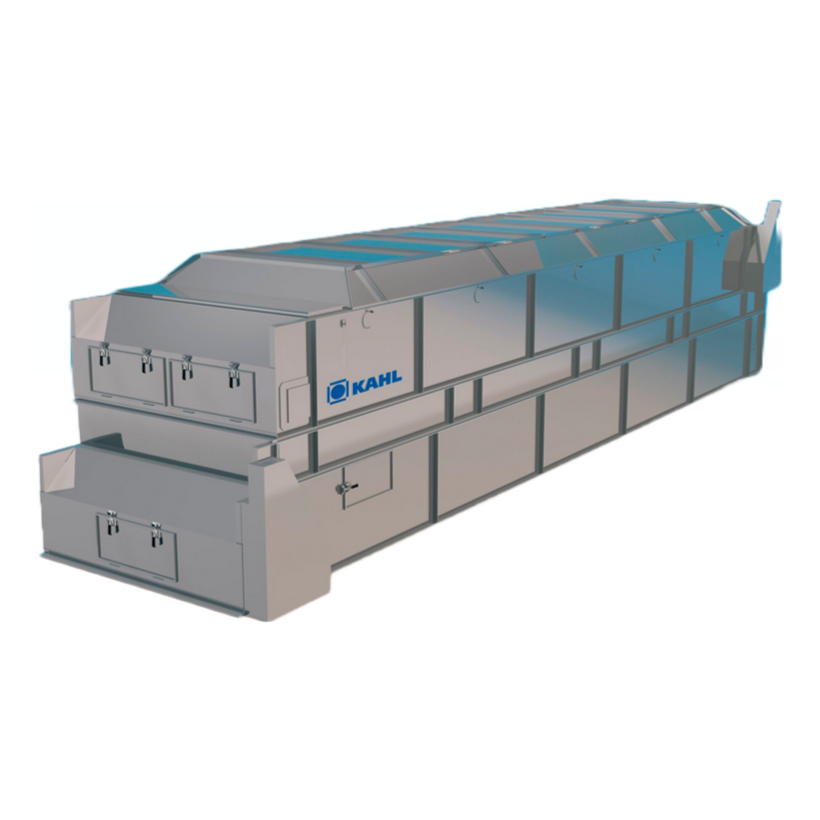

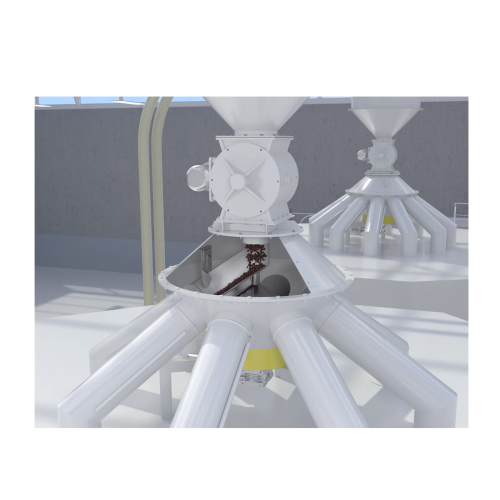

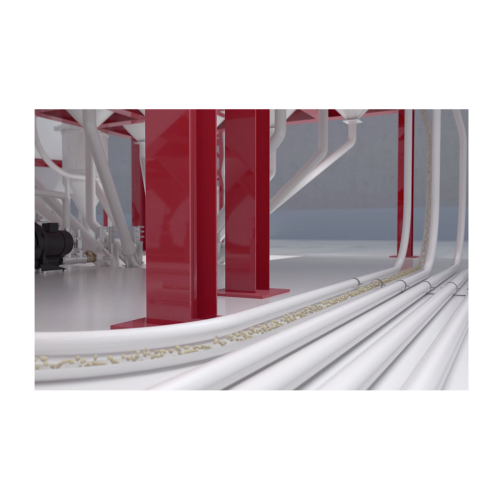

Roasted coffee handling and conveying system

Ensure the gentle handling of roasted coffee with versatile conveying solutio...

Roasted coffee weighing and blending system

Achieve precision and consistency in your coffee blends with cutting-edge weig...

Hard pod packaging system for coffee

Optimize your coffee production with a compact system designed for high-speed packagin...

Green coffee handling and conveying systems

Efficiently handle and convey green coffee beans to maintain product integrity...

Green coffee storaging and dosing system

Optimize your coffee production with a flexible and modular solution designed for ...

Industrial coffee grinders for optimal particle size

Achieve precise coffee grinding with advanced control over particle ...

Ground coffee handling and conveying system

Enhance your coffee production with precise handling systems that ensure aroma...

Small batch coffee roaster

Achieve consistent flavors and precision in small-batch coffee roasting with this versatile roast...

Large-scale coffee roaster for wholesale production

Elevate your coffee roasting with precision and efficiency, ensuring ...

Mid-sized coffee roaster for specialty coffee shops

Optimize your coffee roasting process with precision control and vers...

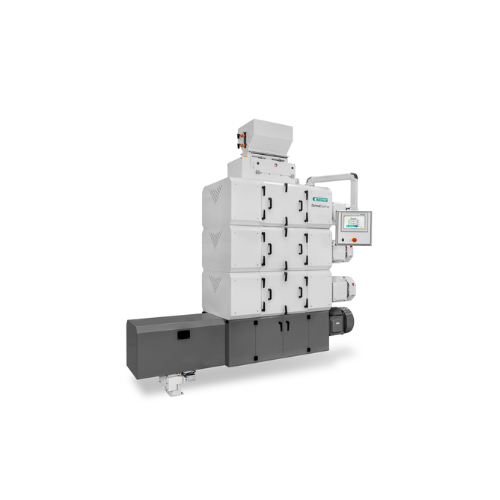

Electrostatic filter for coffee roasting emissions

Mitigate unwanted odors and emissions in coffee roasting with high-eff...

Catalytic emission cleaner for coffee roasters

Optimize your coffee roasting process by effectively reducing emissions wit...

Coffee destoner

Ensure the integrity and quality of your roasted coffee beans by efficiently removing stones and foreign mater...

External cyclone for coffee roasting chaff collection

Simplify your coffee roasting process by efficiently collecting cha...

Sample roaster for coffee beans testing and profiling

Optimize your coffee roasting process with a versatile sample roast...

Modular silo system for coffee bean storage

Optimize your coffee production with a fully customizable modular silo system ...

Industrial coffee roaster for large-scale production

Designed for coffee producers aiming to enhance their roasting capab...

Intermediate coffee roaster for small to middle roasteries

For roasteries expanding production, this versatile roaster o...

Optical sorter for coffee, grains, nuts, and plastic flakes

Ensure precise defect detection and foreign material removal...

Optical sorter for grains, coffee, nuts, and plastics

Ensure consistent product quality and minimize waste with advanced ...

Industrial coffee roaster

Achieve optimal coffee flavor with precise roasting control and energy efficiency, perfect for pus...

Industrial coffee grinder for consistent particle sizes

Achieve precise, consistent coffee grinds essential for specializ...

Coffee processing system for integrated coffee production

Enhance your coffee production with a versatile system that in...

Continuous freeze drying solution for coffee and food pieces

Achieve optimal moisture removal in heat-sensitive products...

Coffee roasting system

Optimize your coffee production from green beans to finely ground espresso with this versatile system,...

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure...

Wet grinding system for coffee flavor preservation

Achieve unparalleled coffee flavor and aroma by integrating a low-temp...

Industrial coffee extraction system for high yields

Maximize coffee yield and quality with precision-controlled extractio...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Stick pack packaging for powders and liquids

Streamline your packing process with high-speed, servo-driven stick pack mach...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

Automatic pour over coffee brewer

Streamline your pour over coffee experience with precision brewing, ensuring perfect extr...

Automatic pour over coffee maker

Enhance your coffee and tea offerings with seamless brewing precision, optimizing pour-over...

Sachet powder filling machine

Optimize your packaging line with this efficient solution for precise powder filling, ensuring...

Commercial coffee beans roaster

Maximize your coffee’s flavor profile with precise control over roasting variables, ensuring...

Industrial roaster for coffee, nuts, and cocoa beans

Optimize your roasting processes with a versatile solution designed ...

Rotating sieve for roasted coffee

Optimize your coffee production with a rotating sieve specifically designed to handle del...

Catalytic converter for industrial coffee roasting

Optimize your coffee roasting with precise control and efficiency, ens...

Automatic lab roaster for 1 kg coffee batches

Perfect for coffee roasters aiming to refine roast profiles, this lab roaste...

Automated coffee bean roaster

Optimize your coffee roasting with precision control, ensuring consistent quality in every bat...

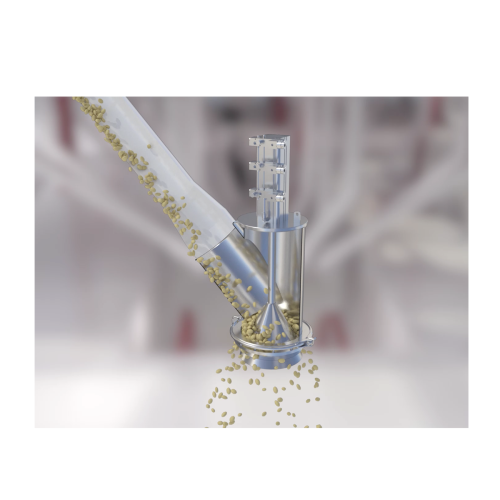

Compression pneumatic line for green coffee handling

Streamline your coffee production with a compression pneumatic line ...

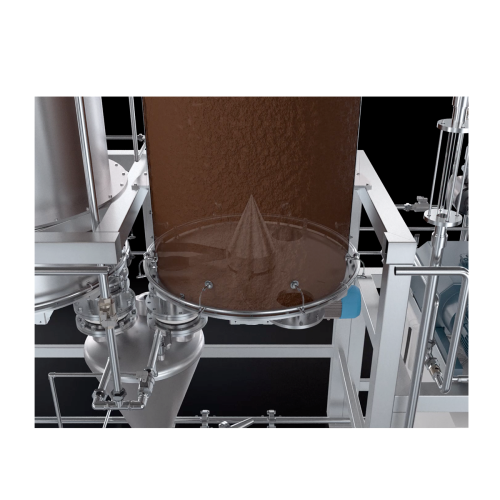

Degassing system for ground coffee

Optimize your coffee production with a robust degassing solution designed to preserve fl...

Industrial coffee grinder for ground coffee production

Enhance your coffee production line with precise grinding capabili...

Chaff conveying system for coffee roasters

Efficiently manage coffee chaff with an integrated solution that transports, co...

Dosing feeder for coffee production

Streamline your coffee production with precision control, ensuring consistent packing l...

Pelletizer for chaff

Transform chaff and agricultural byproducts into valuable energy pellets with precision and efficiency, ...

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

Leak tester for vacuum packaging

Roasted coffee beans, as well as grounded coffee, rapidly diminish in flavor. The oxyge...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

Capping machine for plastic lid oatmeal tins

Some products ask for a plastic reusable lid after the can has been sea...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Wraparound case packer

Packaging companies need to pay attention to personalization in shape and design in addition to the at...

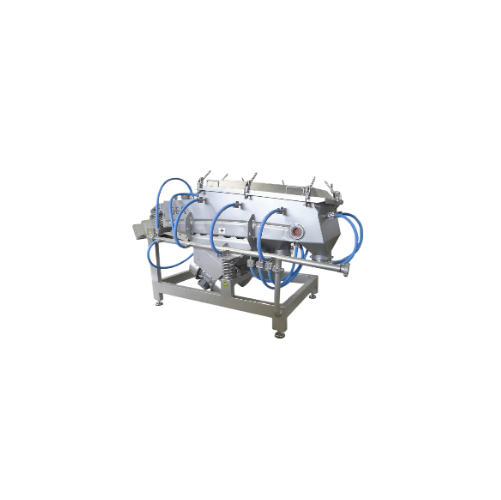

Vibrating screening machine for coffee

Coffee bean separation is one of the important steps during bulk coffee production. ...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

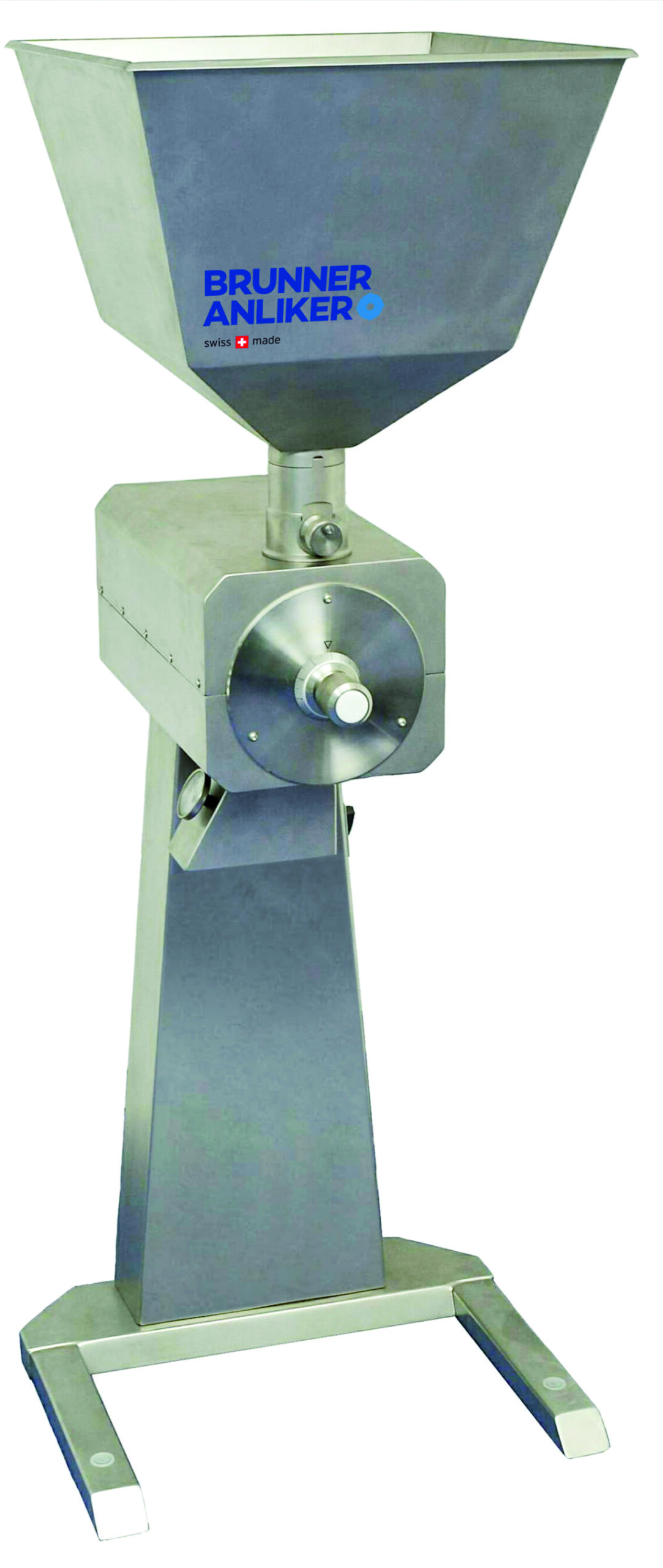

Grinder for spices and coffee

Gentle grinding of coffee down to all grades from coarse to fine requires high precision proce...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

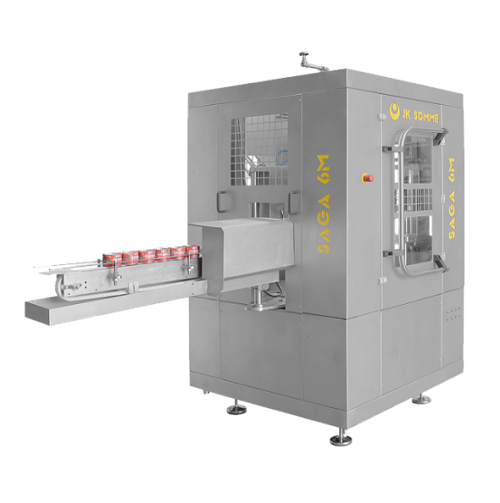

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Tumbler sieve for classifying and dedusting granular materials

For the classification of delicate granular material, scr...

High volume particles separation sieve

For large scale production processes in the chemicals or food industries that requir...

Multifrequency sieve for separation of difficult particles

Separating particles in difficult-to-process materials for pr...

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...

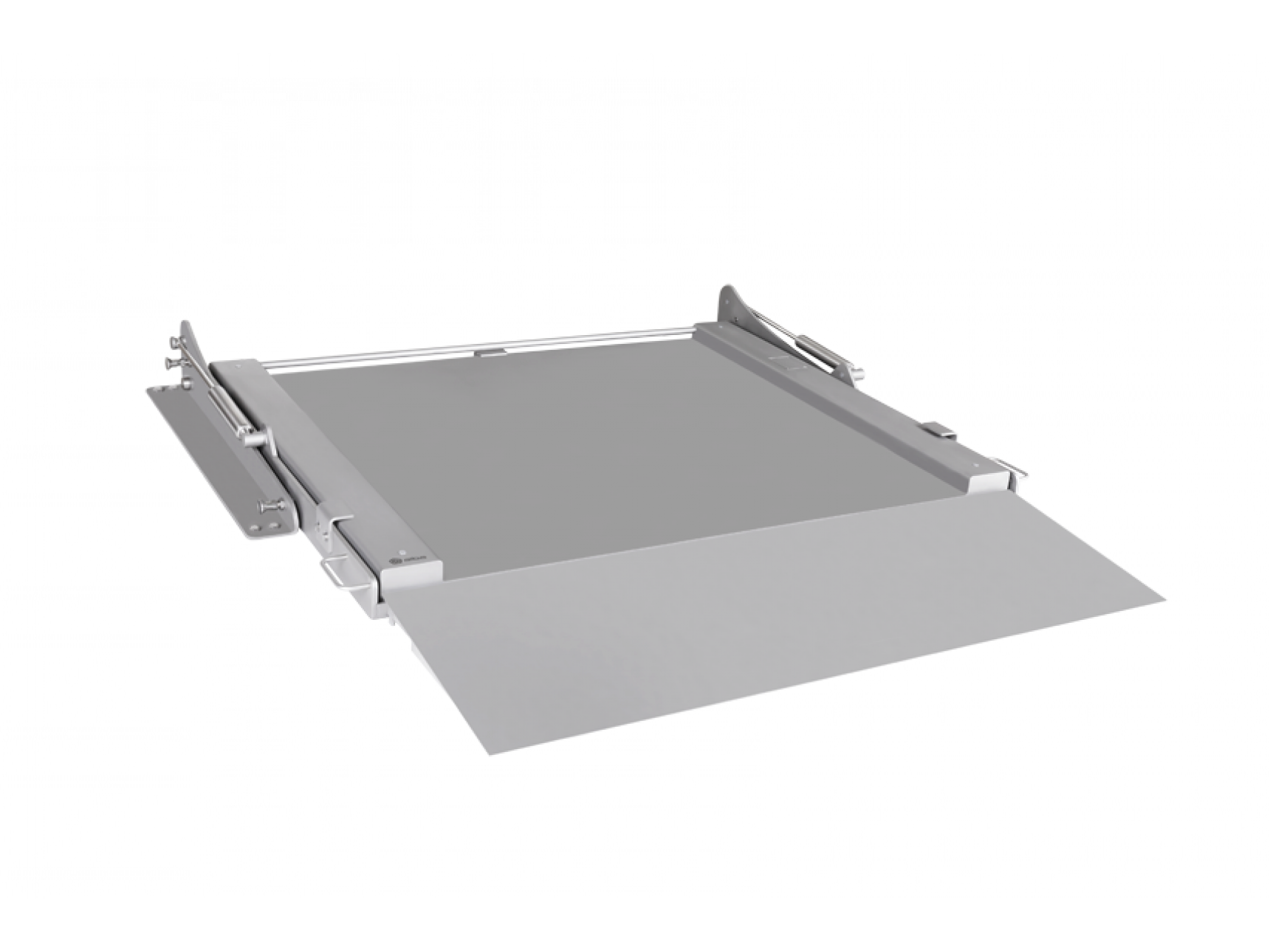

Hygienic floor scale with lifting device

The food and pharmaceutical industries require maintaining high levels of sanitati...