Automated coffee bean roaster

Optimize your coffee roasting with precision control, ensuring consistent quality in every batch. Designed to handle multiple roasting profiles, it’s perfect for experimenting with specialty coffee blends while reducing downtime with its continuous, computerized operation.

Roasts and Monitors Coffee for Consistent Quality

The Roaster automatic HYC 100 from Scolari Engineering is a highly efficient industrial coffee roasting solution designed for the intricate demands of coffee producers and specialty manufacturers. This system employs a computerized control platform optimized for espresso and specialty coffee roasting, ensuring precise medium to dark roast profiles. It integrates seamlessly into your processing line, automating roasting, weighing, and sampling processes to maintain consistent output quality across three-shift operations. Equipped with a modular skid construction, the HYC 100 allows for rapid assembly and flexible integration. Its advanced control software, compatible with Microsoft® Windows 7/10, enables real-time monitoring and adjustment, addressing challenges such as power interruptions with minimal downtime. Enhanced by a pneumatic sampling system, it facilitates QC testing post-roast, ensuring only high-quality products like espresso beans and specialty coffee packs proceed to market.

Benefits

- Ensures consistent roast quality with computerized precision.

- Minimizes operational disruptions with automated alarm systems.

- Enhances productivity across continuous three-shift operations.

- Facilitates rapid assembly and integration with modular design.

- Supports quality assurance with systematic sampling and testing.

- Applications

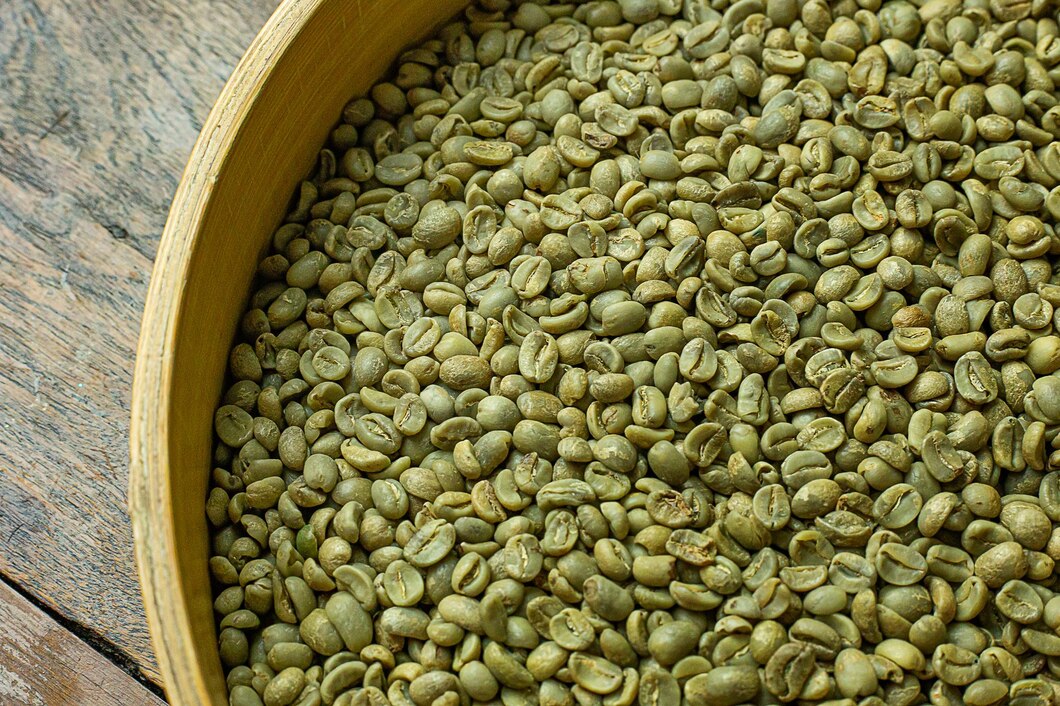

- Green coffee, Ground coffee, Roasted coffee

- End products

- Coffee blends, Dark roast coffee, Medium roast coffee, Espresso beans, Ground espresso, Specialty coffee packs

- Steps before

- Green Coffee Sorting, Weighing, Pre-heating

- Steps after

- Cooling, Quality Control Testing, Packaging

- Input ingredients

- green coffee

- Output ingredients

- roasted coffee

- Market info

- Scolari Engineering is known for designing and manufacturing custom-engineered drying systems and equipment, particularly for the food and agricultural industries, leveraging innovative technology and a strong reputation for quality and reliability.

- Automation

- Computerized

- Operating System

- Microsoft® Windows 7/10

- Programming Language

- Microsoft® C, C Sharp

- Roasting Control

- Espresso, Medium to Dark Roasting

- Modular Construction

- Skid Construction for Rapid Assembly

- Operational Shifts

- Three Shifts

- Weighing Cycle

- Automated with Alarm for Irregularities

- Sampling System

- Pneumatic Sampling System

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Batch

- Integrated steps

- Pneumatic sampling system

- Working mechanism

- Computerized roasting systems

- CIP/SIP

- User requirement-based (e.g., varies depending on cleaning needs)

- Cleaning method

- Manual intervention during alarm

- CE marking

- Yes

- FDA materials

- Potentially

- EHEDG certification

- Possible

- Modular construction

- Skid

- Batch operation

- Computerized roasting system

- Control Software

- Developed for "espresso" coffee

- Operating System

- Microsoft® Windows 7/10

- Programming Language

- Microsoft® "C" language, Microsoft® "C Sharp" language

- Modular Construction

- Skid

- Shift Operation

- Three shifts

- Roaster Supervisor

- Aid man interface