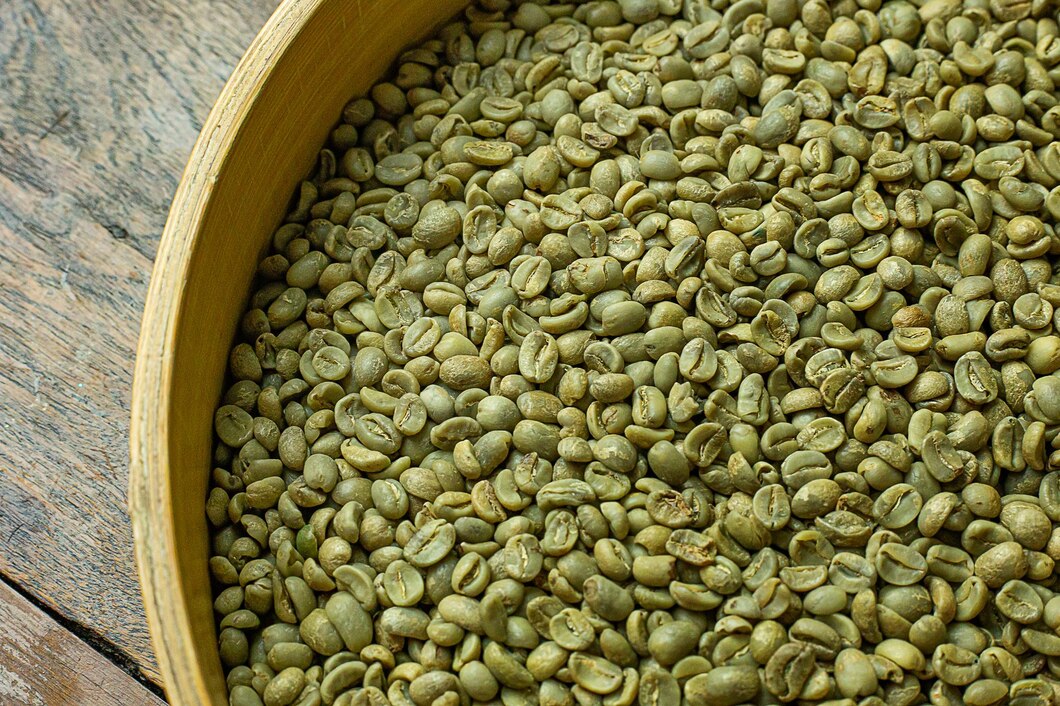

Cleaning system for green coffee beans

Ensure optimal purity in your coffee production with a system designed to remove impurities, batch with precision, and maintain traceability, setting a new standard for quality green coffee bean handling.

Processes and Cleans Green Coffee Beans

The Cleaning Machine Green Coffee from Scolari Engineering is specifically designed to enhance the cleaning and processing of green coffee beans. It efficiently unloads, cuts, and cleans the beans, employing a comprehensive system that includes a bag cutter and a dust collecting unit to manage different forms of coffee delivery. Ideal for use in coffee processing plants, it supports both manual and automatic operations, facilitating accurate weighing, batching, and traceability of coffee beans. Notably, the system’s integration allows seamless operation from the unloading stage to precise batching into green coffee silos. The machine emphasizes efficient energy usage and operational control, ensuring reduced operator error and enhanced batch management. Constructed to cater to food and beverage industry standards, it offers customization options to suit different operational scales and requirements, making it a versatile solution for coffee roasters, producers, and importers.

Benefits

- Ensures precise batching and traceability, minimizing coffee blend inconsistencies.

- Streamlines unloading and cleaning processes, reducing manual labor requirements.

- Integrates seamlessly with existing production lines, enhancing operational efficiency.

- Mitigates cross-contamination risks with safeguards against incorrect silo loading.

- Optimizes energy use during processing, contributing to lower operational costs.

- Applications

- Green coffee, Coffee beans

- End products

- Coffee bean blends, Roasted coffee beans, Ground coffee, Green coffee beans

- Steps before

- Green coffee reception, Bags unloading, Code entry, Batching

- Steps after

- Weighing, Batching, Blends selection, Roasting

- Input ingredients

- green coffee bags, loose green coffee, palletized green coffee

- Output ingredients

- cleaned green coffee, weighed green coffee

- Market info

- Scolari Engineering is known for designing and manufacturing custom-engineered drying systems and equipment, particularly for the food and agricultural industries, leveraging innovative technology and a strong reputation for quality and reliability.

- Automation

- PLC-controlled

- Batch documentation

- Auto recording

- Batch size

- Variable based on system and operator input

- Bag type

- Loose, Pallets, Individual bags

- Dust collecting system

- Included

- Safety system

- Prevents cross-contamination of different products

- Weighing Accuracy

- Net weight measurement

- Loading system

- Telescopic conveyor, mechanical hand

- System longevity

- Over 10 years in operation

- Customizability

- Easy to modify pre-programming

- Blending options

- Multiple blends and qualities pre-programmed

- Roasting curve control

- Automatic based on product or blend code

- Batch vs. continuous operation

- Batch

- Automation level

- PLC

- Cleaning method

- CIP / Manual

- Energy efficiency

- Unknown

- Changeover time

- Unknown

- Air incorporation control

- Unknown

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Feed method

- Loose bags or pallets

- Discharge method

- Telescopic conveyor belt

- Control panel type

- Electronic

- Control panel type

- Electronic panel

- Integration possibilities

- Pre-programmed blends menu

- Batch traceability

- Yes

- Roasting curve automation

- Automatic setting by product/blend code