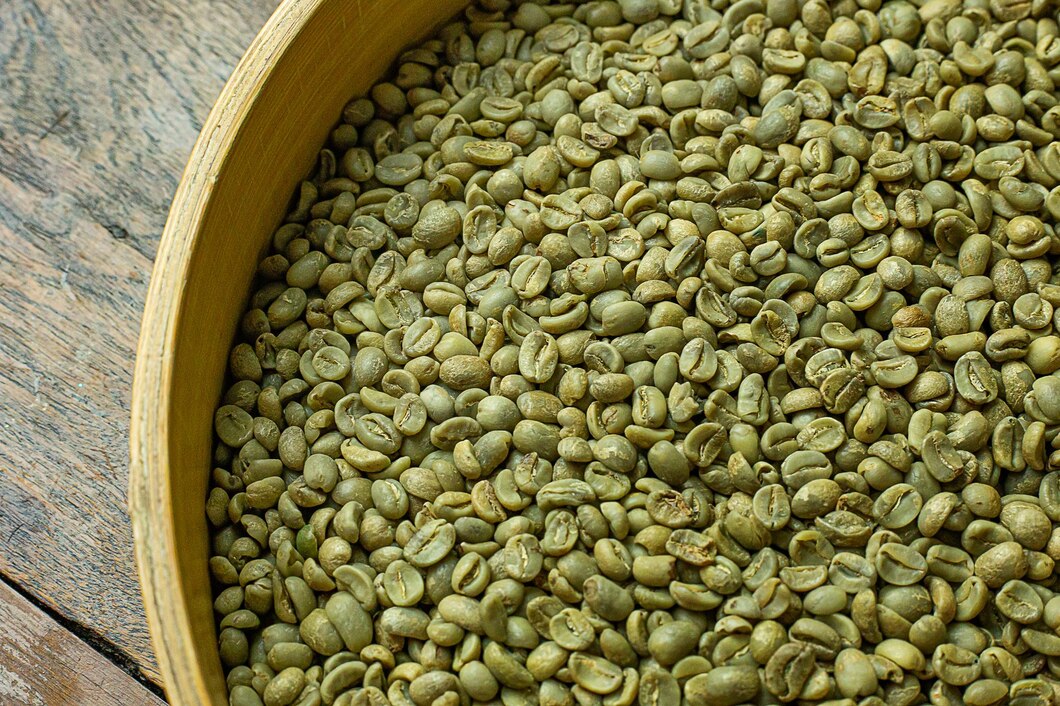

Green coffee preheating system

Optimize your coffee roasting process by utilizing waste heat for preheating, reducing energy consumption and enhancing flavor development through uniform heat distribution.

Preheats and Mixes Green Coffee Beans Efficiently

The RKV Green Coffee Preheating System by PROBAT is a sophisticated energy-saving solution designed for industrial coffee roasters. This system creatively repurposes waste heat from exhaust air to preheat green coffee beans, significantly reducing energy demands and cycle times. It ensures uniform heat distribution through mechanical mixing, achieving consistent roasting patterns. Suitable for various applications, from specialty roasted coffee to instant coffee granules, it optimizes the roasting process by minimizing the time between preheating and aroma development. Operating in continuous, automated modes, it integrates seamlessly into large-scale coffee production lines. The system promises up to a 20% increase in energy efficiency, catering to the needs of environmentally-conscious coffee processing facilities striving for lower energy consumption and CO2 emissions.

Benefits

- Enhances energy efficiency by reclaiming excess heat for preheating.

- Cuts roasting cycle times, boosting overall throughput.

- Lowers energy consumption and CO2 emissions for sustainable operations.

- Ensures consistent coffee quality with uniform heat distribution.

- Integrates seamlessly into existing production lines with automated operation.

- Applications

- Green coffee beans, Coffee

- End products

- Filter coffee, Coffee blends, Espresso coffee, Specialty roasted coffee beans, Instant coffee granules

- Steps before

- Green coffee loading, Exhaust air treatment

- Steps after

- Roasting, Browning reactions, Aroma formation

- Input ingredients

- green coffee, cleaned exhaust air

- Output ingredients

- preheated coffee beans, reduced CO2 emissions

- Market info

- Probat is renowned for its expertise in manufacturing coffee processing equipment, particularly coffee roasters. The company has a strong reputation for engineering solutions in industrial coffee roasting, blending, and grinding technology.

- Exhaust Temperature

- 320–860 °C

- Preheating Temperature

- Approx. 100 °C

- Energy Efficiency Improvement

- Up to 20%

- Cooling Time

- N/A - Integrated with Roasting

- Mixing Mechanism

- Mechanical Mixing

- Capacity Increase

- Higher Processing Capacity

- Roasting System Compatibility

- Drum Roaster NEPTUNE 1500

- Energy Source

- Reused Exhaust Air

- Energy recovery

- Yes

- Preheating process

- Exhaust air reuse

- Uniform heat transfer

- Mechanical mixing

- Automation level

- Integrated with roasting system

- Batch vs. continuous operation

- Continuous preheating

- Temperature control

- Approx. 100°C preheating

- Efficiency improvement

- Up to 20%

- Environmental impact

- Reduced CO2 emissions

- Integration

- Upstream of the roaster

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat exchange unit size

- Customized as per exhaust system

- Preheating chamber

- Incorporated upstream of the roaster

- Temperature control

- Approx. 100°C for preheating

- Mechanical components

- Includes mechanical mixing

- Control panel type

- Digital / HMI

- Integration possibilities

- Compatible with roasting systems

- System configuration

- Customizable to existing roaster models