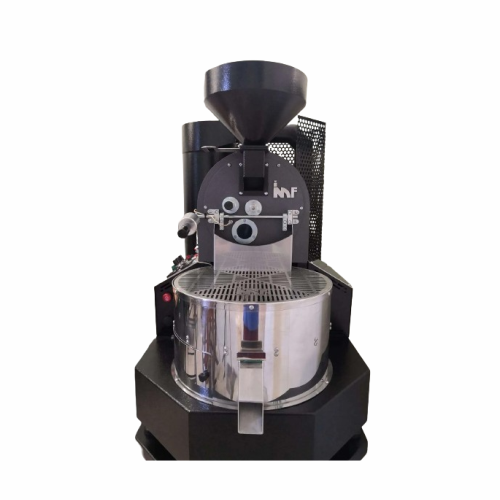

Small batch coffee roaster for specialty coffee shops

Achieve consistent, artisanal coffee roasts with this precision-controlled roaster, designed for small-scale operations to explore unique flavor profiles and cater to coffee connoisseurs.

Roasts and Air Circulates Coffee Beans

The RM2 Electric and Gas Drum Coffee Roasters from IMF s.r.l. offer precision roasting through indirect flame and forced hot air technologies. Uniquely designed for cafes and specialty coffee shops, these roasters deliver consistent quality for espresso beans, cold brew, and artisan blends. Operating with a processing capacity of 2.5 kg per cycle and up to 10 kg/h output, they ensure flexibility with batch and manual operation modes. The electric model requires 8 kW, while the gas model combines 14 KW of fuel power and 2 kW of electric power. Integration into your production line is simplified via USB connectivity and adjustable fan and drum speed, enhancing control over roasting profiles. Constructed to maintain energy efficiency and robust performance, they suit small-scale operations aiming for tailored roasting solutions, while offering optional engineering support for customization.

Benefits

- Ensures consistent coffee quality with precise temperature and air control.

- Supports flexible production schedules with efficient batch operation.

- Enhances flavor development through adjustable fan and drum speeds.

- Reduces energy costs with optimized power usage for both electric and gas models.

- Allows seamless data integration and roasting profile management via USB connectivity.

- Applications

- Specialty coffee, Coffee shops, Cafes

- End products

- Café-exclusive roasts, Artisan coffee blends, Single-origin coffee, Espresso beans, Cold brew coffee beans

- Steps before

- Sorting, Weighing, Grinding, Blending

- Steps after

- Cooling, Degassing, Packaging, Labeling

- Input ingredients

- green coffee, natural gas, LPG

- Output ingredients

- roasted coffee

- Market info

- IMF Italy is recognized for its expertise in manufacturing innovative industrial induction furnaces and foundry equipment, known for high quality, technical proficiency, and customization according to client needs in the metallurgical industry.

- Model

- RM2 Electric / RM2 Gas

- Capacity per Cycle

- 2.5 kg

- Output

- 10 kg/h

- Cycle Time

- 12/18 min

- Electric Power

- 8 kW (Electric) / 2 kW (Gas)

- Power

- 14 kW (Gas)

- Fuel Type

- Natural gas / LPG

- Roasting Technology

- Indirect flame, Forced hot air, Perforated drum

- Burner Type

- Modulating burner

- Connectivity

- USB port connection

- Working mechanism

- Indirect flame, Forced hot air

- Batch vs. continuous operation

- Batch (kg/cycle)

- Modulating burner

- Yes

- Fan speed control

- Yes

- Ground speed control

- Yes

- USB port connection

- Yes

- Fuel type

- Electric or Natural gas / LPG

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Drum size

- Perforated drum

- Roasting technology

- Indirect flame, Forced hot air

- Fuel type

- Natural gas / LPG

- Output capacity

- 2.5 kg/cycle, 10 kg/h

- Cycle time

- 12-18 min per cycle

- Control method

- USB port connection

- Power consumption

- Electric

- Fan speed

- Modulating

- Burner type

- Modulating burner

- Connection type

- USB port connection

- Cycle size

- 2.5 kg

- Output

- 10 kg/h

- Cycle time

- 12/18 min