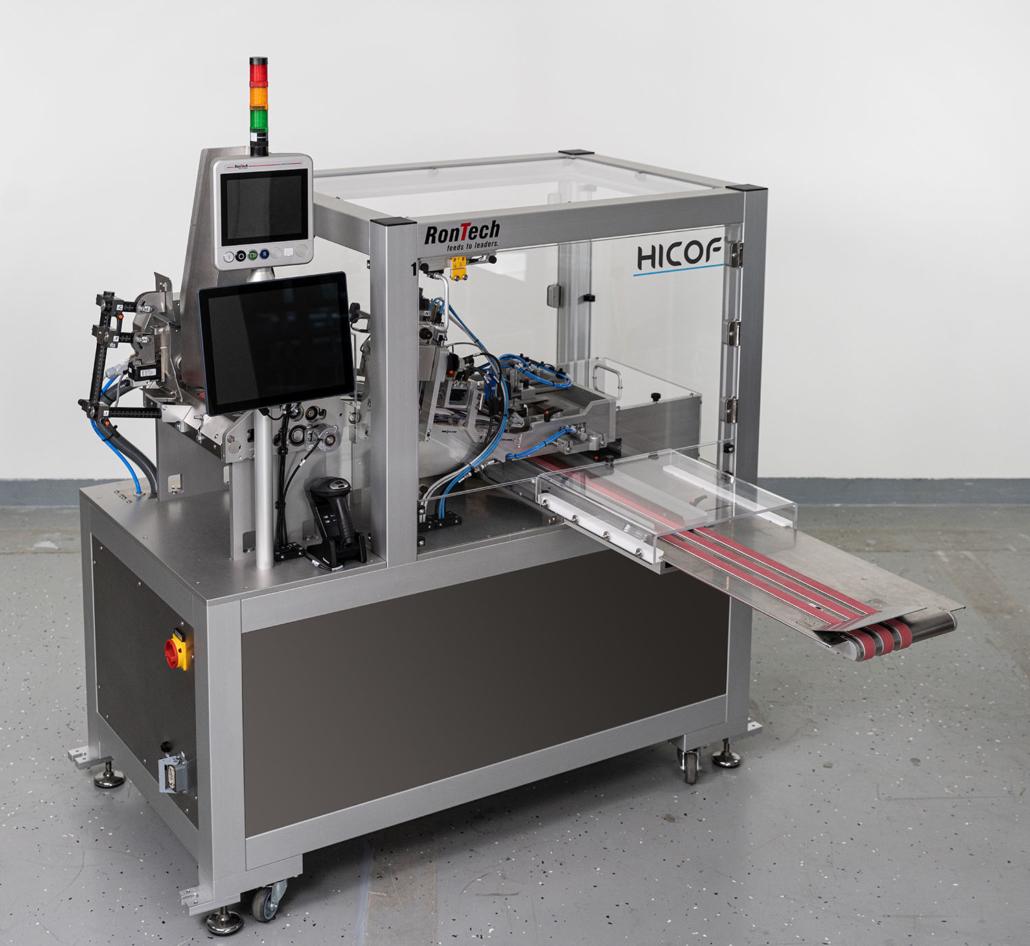

Flat carton coding machine

The coding process is an essential step in the production line as it can provide trusted supply chain and product information. However, companies sometimes cannot expand existing packaging lines with serialization stations due to space limitations. A solution to this issue can be taking the marking operation off-line.

Compact serialization station marking up to 300 pieces per minute

The AMAPLAN-150 from Hicof is a compact serialization station providing up to 300pcs/min with a wide range of formats. The products are fed via an upper and lower guide passing the printer and the Hicof Goldeneye camera. When in the machine, the movement of the product is very controlled as it is guided from all sides. A very constant product speed can be obtained by the closed loop servo controlled movement and thus gives you optimal marking results. Finally, the product is shingled on an output belt for drying purposes of the marking. The shingling of the product makes the drying time longer, thus preventing smears of the freshly marked flat cartons. AMAPLAN-150 can make a format change within less than 5 minutes by the quick adjustment of the settings.

Benefits

- Up to 300 pcs/min

- Laser technology or inkjet for printing

- Substandard marking of products rejected automatically

- Shingle belts with space-saving property

- Hicof Goldeneye camera qualifies the marking according to ISO15415, OCR and OCV