Tablet and capsule counting system

Need precise counting and filling of solid doses like tablets and capsules in your production line? This system efficiently separates and delivers exact quantities into containers, ensuring accuracy and preventing cross-contamination.

Counts and Fills Tablets and Capsules

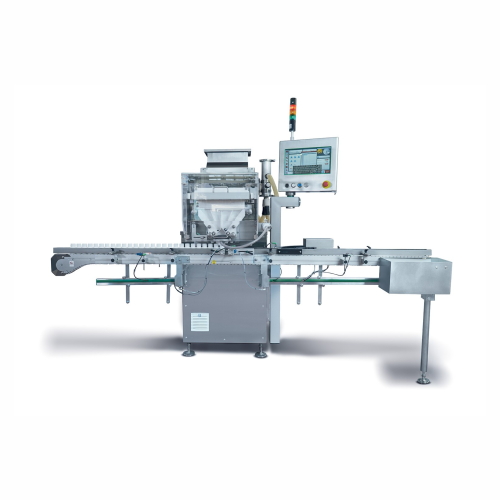

The FTC-24 from Marchesini Group is a high-precision intermittent motion counting machine designed for the pharmaceutical and nutraceutical sectors. It utilizes electronic counting with 3 vibrating trays and 12 channels for each counting group to ensure accurate tablet and capsule counts. Integrating seamlessly into packaging lines, it supports the handling of various solid forms including paracetamol tablets and vitamin D soft gel capsules. With a capacity of up to 150 bottles per minute, it features automatic adjustments and a self-learning system for quick adaptation to different product recipes. Constructed in compliance with cGMP norms, the machine offers clear separation of filling and capping areas to prevent cross-contamination. Its design includes a balcony style conveyor belt for easy inspection and maintenance, enhancing operational efficiency. The FTC-24 supports both plastic and glass bottle formats, making it a versatile choice for diverse production needs.

Benefits

- Enhances counting accuracy, minimizing product waste and ensuring precise dosage.

- Increases production efficiency with up to 150 bottles filled per minute.

- Minimizes cross-contamination risks through clear separation of filling and capping zones.

- Applications

- Coated tablets, Supplements, Pharmaceutical tablets, Hard gelatine capsules, Soft gelatine capsules, Lozenges

- End products

- Omega-3 fish oil capsules, Ibuprofen coated tablets, Vitamin d soft gelatine capsules, Cough lozenges, Multivitamin supplements, Paracetamol tablets

- Steps before

- Purification, Drying, Tablet Pressing

- Steps after

- Sterilization, Packing, Capping

- Input ingredients

- tablets, coated tablets, dragees, hard gelatine capsules, soft gelatine capsules, lozenges

- Output ingredients

- bottles with tablets, bottles with capsules, bottles with lozenges

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Production speed

- Up to 150 bottles/min

- Bottle diameter

- 20 mm to 100 mm

- Bottle height

- 55 - 185 mm

- Tablet diameter

- 5 - 20 mm

- Capsule size

- 000 - 5

- Motion type

- Intermittent motion

- Counting group

- 3 vibrating trays at 12 channels

- Automation

- Electronic counting and self-learning system

- Synchronization control

- Integrated electronics

- Conveyor belt

- Balcony style, automatic adjustment

- Working mechanism

- Intermittent motion

- Automation level

- PLC-controlled

- Changeover time

- Quick size changeover without tools

- Automation

- Self-learning system for product recipes

- Synchronization control

- Integrated in the electronics

- Cleaning method

- Clear separation to avoid cross-contamination

- Bottle handling

- Automatic adjustment of bottle height

- Conveyor belt type

- Balcony style, easy to inspect

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Capsule size

- 000 to 5

- Container type

- Glass / Plastic bottles

- Product diameter (Tablet)

- 5 - 20 mm

- Container size

- Diameter 20 mm to 100 mm, Total height 55 - 185 mm

- Product type

- Tablets, coated tablets, hard, soft gelatine capsules, lozenges

- Discharge method

- Balcony style bottles conveyor belt

- Control panel type

- PC display with self-learning system

- Control panel type

- PC with display integration

- Adjustments

- Automatic or guided, millimeter scales and digital indicators

- Conveyor belt adjustment

- Automatic

- Product control system

- 2D product control system prearrangement