Weighing system for 100% inspection of capsules and tablets

Ensure precise quality control with a format-free system that performs 100% weight inspection of tablets and capsules, seamlessly managing diverse product sizes while enhancing process reliability and reducing maintenance time.

Weighs and Inspects Solid Dosage Forms

The OmniControl from Harro Höfliger is a versatile weighing and inspection system designed for the pharmaceutical industry’s rigorous demands. Utilizing a patented rotary star principle, it ensures 100% inspection of tablets, capsules, and coated pills with format-free operation. This system handles up to 65,000 products per hour, providing seamless integration into continuous, high-speed production lines. Equipped with advanced automation, OmniControl optimizes dosing feedback loops to maintain precise fill weights, reducing waste and enhancing production efficiency. Its format-independent design accommodates various product sizes and shapes, offering quick setup and minimal cleaning times. Constructed for durability, it supports compliance with GMP standards, making it ideal for applications in pharmaceutical, medical device, and biotechnology sectors. With options for customization and engineering support, OmniControl is designed to meet your specific production needs.

Benefits

- Ensures flawless quality control by providing 100% inspection of solid dosage forms.

- Increases operational efficiency with high-speed throughput up to 65,000 products per hour.

- Minimizes labor involvement and error with automated weight feedback and sorting mechanisms.

- Reduces setup and cleaning times, resulting in higher production efficiency.

- Adapts easily to product variations with format-free handling, reducing the need for additional investment.

- Applications

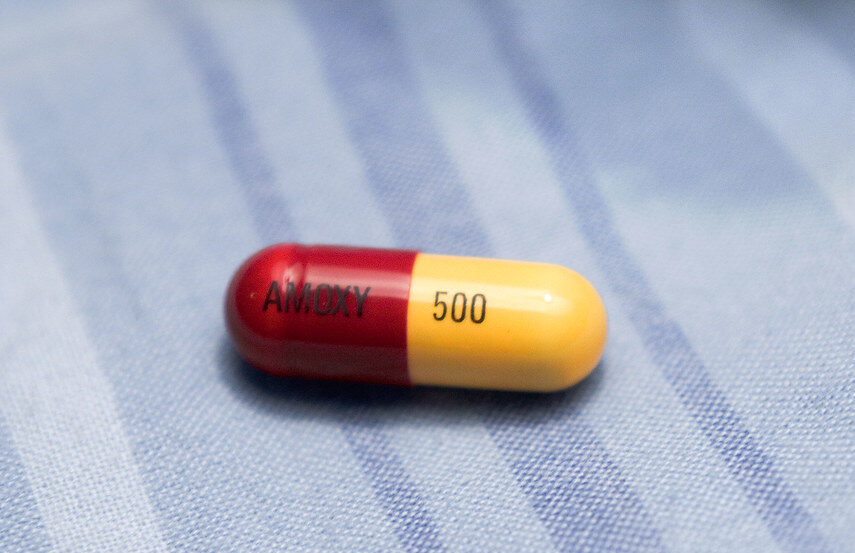

- Customized products, Capsules, Pharmaceutical tablets, Coated pills

- End products

- Paracetamol tablets, Amoxicillin capsules, Ibuprofen coated pills, Omega-3 customized capsules

- Steps before

- Capsule Filling, Tablet Coating, Product Customization

- Steps after

- Sorting and Quality Control, Sterilization, Packaging

- Input ingredients

- capsules, tablets, coated pills, customized products

- Output ingredients

- 100% weighed capsules, 100% weighed tablets, 100% weighed coated pills, 100% weighed customized products, good products, bad products

- Market info

- Harro Hoefliger is known for its expertise in manufacturing custom, engineered-to-order packaging and production equipment, particularly for the pharmaceutical, healthcare, consumer goods, and chemical industries, with a reputation for precision, innovation, and quality engineering solutions.

- Output

- 32, 500 to 65, 000 products/h

- Design

- 6 to 12 grooves

- Measuring Range

- 0 - 2, 000 mg

- Measuring Accuracy

- ± 2 mg

- Feeding Design

- 6-groove and 12-groove

- Product Type

- Capsules, Tablets, Coated Pills, Customized Products

- Transport Method

- Vacuum suction wheel

- Sorting Method

- Rotary Star Principle

- Process Automation

- Feedback Loop for trend regulation

- Working Mechanism

- Patented rotary star principle

- Integrated Steps

- Weight determination and product sorting

- Batch vs. Inline Flow

- Format independent / Continuous

- Automation Level

- Automatic feedback loop with dosing system

- Changeover Time

- Minimal setup and cleaning times

- CIP/SIP

- Manual cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type

- Capsules, tablets, coated pills

- Product variety

- Customizable products

- Machine footprint

- Compact design

- Feed method

- Format free feeding

- Discharge method

- Rotary star sorting

- Transport mechanism

- Vacuum suction wheel

- Groove design

- 6-groove and 12-groove

- Integration possibilities

- MES, ActiveDirectory, OPC

- Groove design

- 6-groove / 12-groove