Making Hard Gelatin Capsules

Find innovative production technology for making hard gelatin capsules and connect directly with world-leading specialists

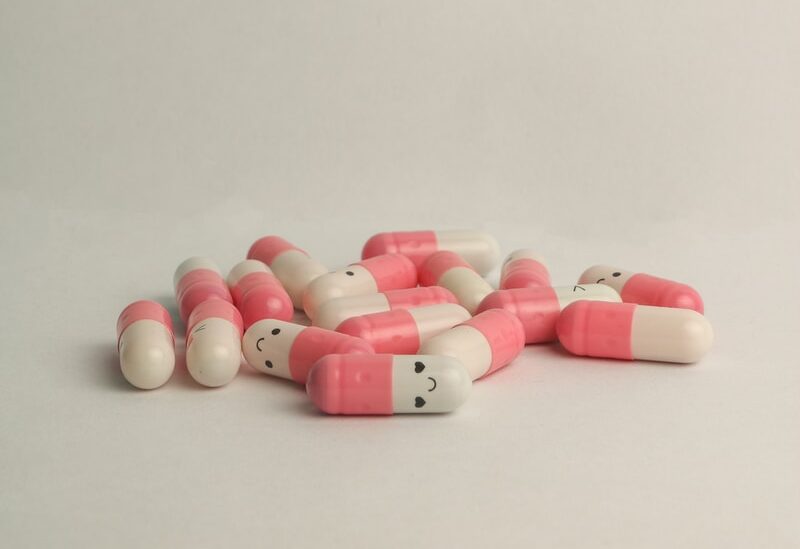

The two-piece capsule is a visual shorthand for all types of medical remedies. Advances in technology have made the production of hard-gelatin capsules a convenient delivery method for drugs and other ingested substances. But the simple solution requires micrometric precision to be manufactured to the proper pharmaceutical standards.

Select your hard gelatin capsules process

Tell us about your production challenge

Dosing accuracy is key to manufacturing hard gelatin capsules

The bright colors that hard-gel capsules are synonymous with come from dyes and edible colorings. However, the main ingredients of the shell are gelatin and plasticizers, which combine at a typical ratio of 1:0.4 using precise dosage technology.

Compared with softgel capsules, the hard gelatin alternatives require fewer components to produce. But your standard formula will also include sugars, an opacifier, and preservatives.

Hygroscopic ingredients weaken the hard-shell structure

The flexibility of hard-gel caps and their relatively long shelf-life make them an ideal solution for the delivery of various drugs. Two-piece capsules can hold a range of powder formulations, tablets, and semisolid solutions.

But hygroscopic agents may lead to cracks in the shell over time, making the production of hard gelatin capsules unsuitable for materials such as silicon dioxide and magnesium carbonate.

Production of hard gelatin capsules is largely impacted by the water content

The mixture to manufacture hard gelatin capsules consists of 14% to 16% demineralized water. Achieving this delicate proportion is key to ensuring that your shells have the proper elasticity to hold their structure and protect the filling.

Too little water will result in brittle capsules, while too much of it risks destabilizing the drug content inside.

Plant-based gelatin alternatives follow the same manufacturing process

Gelatin has been the industry standard in manufacturing hard capsules for nearly a century. But currents drifting away from animal-based ingredients are spurring research into vegetarian alternatives. Substitute materials like starches and carrageenan can be handled with minor modifications to existing technology.

HPMC capsules have emerged as a prime contender to produce plant-based encapsulation formulas. An edible natural polymer, HPMC is made from plant-extracted cellulose. Unlike gelatin, which is non-allergenic foodstuff, HPMC is considered an additive (E460).

Processing steps involved in hard gelatin capsules making

Which hard gelatin capsules technology do you need?

High throughput capsule filling system

Achieve precise, high-speed capsule filling with versatility, ensuring product integ...

Capsule filling system for high volume production

Maximize your capsule production efficiency with a system designed to s...

Tablet and capsule counting system

Need precise counting and filling of solid doses like tablets and capsules in your produ...

High-containment diverter for continuous tablet and capsule filling

Enhance your production line with a versatile solut...

Empty capsule sorting system

Streamline your capsule production by efficiently removing empty and defective capsules, ensuri...

Capsule polisher for pharmaceutical production

Enhance capsule quality and safety by effectively polishing, dedusting, and...

Capsule polisher for pharmaceutical capsules

Ensure your capsules are free from dust and perfectly polished with a solutio...

Tablet and capsule diverter

Streamline your tablet and capsule production with precise container filling and flexible config...

Automatic capsule filling machines

Efficiently fill capsules with precise doses of powders, liquids, and tablets to enhance...

Electronic tablet counter for tablets and capsules

Optimize your production line with precise counting solutions for a wi...

Integrated counting system for tablets and capsules

Streamline your packaging line with a highly versatile system that se...

Capsule selection and feeding unit

Enhance your capsule filling process with precise selection and feeding, ensuring only t...

Capsule filler for pharmaceutical applications

Need precise capsule filling for pharmaceuticals and nutraceuticals? This s...

Precision weight-checking for pharmaceutical capsules

Ensure exact capsule and tablet dosage with high-speed precision we...

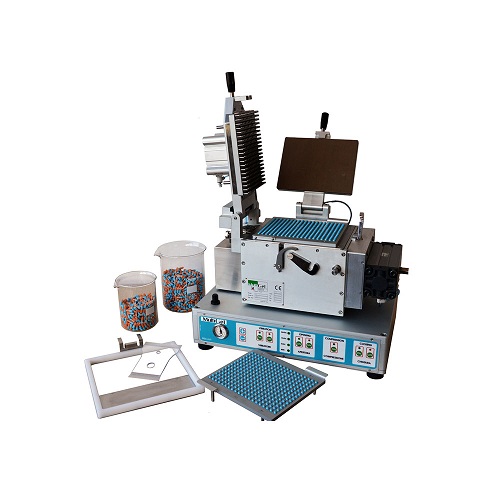

Table-top capsule filler for micro-dosing

Achieve precise micro-dosing for pharmaceutical powders and pellets with a user-...

Capsule banding system for tamper-evident sealing

Ensure tamper-evident integrity for capsules by utilizing a precise ban...

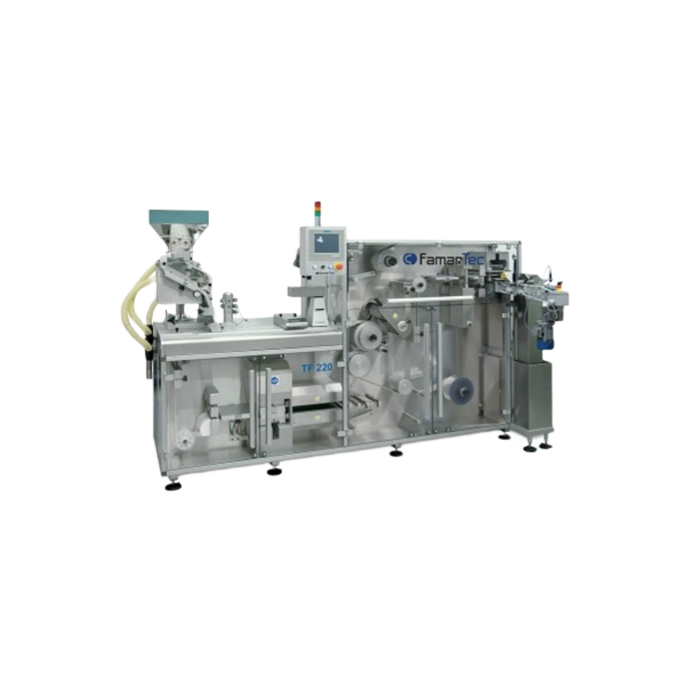

High-speed blister packaging with integrated cartoner

Optimize your blister packaging process with a solution that seamle...

Capsule filler for multi-product dosing

Achieve precision and flexibility in capsule filling with a system designed for hig...

High-speed capsule weighing system for quality assurance

Ensure precise capsule weight monitoring and sorting with a syst...

In-process weighing system for capsules and tablets

Ensure precise dosing and consistent quality with a format-free syste...

Powder dosing system for development and small batches

Streamline lab-scale pharmaceutical production with a versatile po...

Commercial capsule filling for small scale production

Efficiently fill and dose capsules with precision, ensuring flawles...

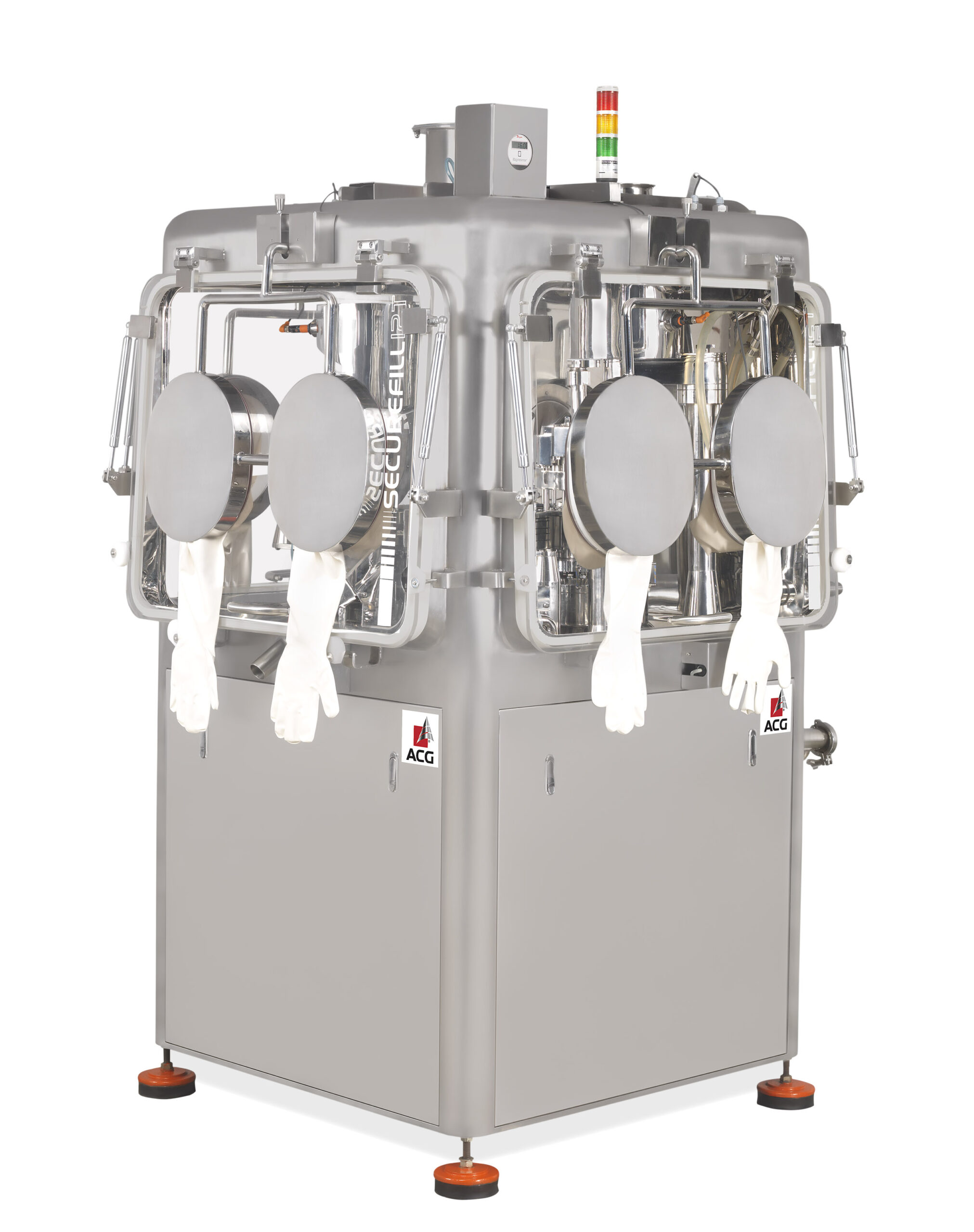

High-containment capsule dosing and filling system

Achieve precise dosing and optimal containment for pharmaceutical prod...

Capsule filling system for powder, pellets, and tablets

Optimize capsule production with rapid dosing changes, minimizing...

Containment capsule filling system for lab and small batch production

Designed to ensure maximum safety in pharmaceutic...

Versatile capsule filler for pharmaceuticals

Effortlessly switch between powder, pellet, and liquid dosing with this adapt...

Empty capsule transfer system

Ensure seamless capsule filling operations by eliminating manual handling and preventing produ...

Filled capsule conveyor system for pharmaceutical production

Ensure gentle and efficient conveying of filled capsules in...

Capsule conveyors for gentle capsule transfer

Streamline your capsule production line with a system designed for high-spee...

Laboratory film coating system for development and clinical batches

Achieve precision in tablet coating with a versatil...

Linear tablet and capsule counter

Ensure precise and efficient bottle filling with a cutting-edge counting system that guar...

Integrated bottling center for pharmaceutical tablets and capsules

Enhance your production line with versatile bottling...

Tablet counting solution for pharmaceutical industry

Maximize dosing precision and reduce miscounts in high-speed pharmac...

High speed blister packaging for pharmaceuticals

Need efficient packaging with quick format changeovers for various capsul...

High-speed strip packaging for tablets and capsules

Optimize your high-speed pouching operations with precise four-side s...

Pharmaceutical roller compaction solution

Optimize your pharmaceutical tablet production with precision granulation and co...

Capsule filling solution for small to medium batch sizes

Achieve precise and efficient capsule filling up to 3,400 units ...

Capsule filling system for pharmaceutical production

Efficiently fill and lock capsules of various sizes with exceptional...

Tablet and capsule visual inspection system

Achieve unparalleled precision in tablet and capsule inspection with a high-sp...

Tablet coater for batch sizes up to 250 liters

Enhance your tablet production process with high-speed coating solutions de...

Tabletop granulation system for small batches

Enhance R&D capabilities with this innovative solution designed for gra...

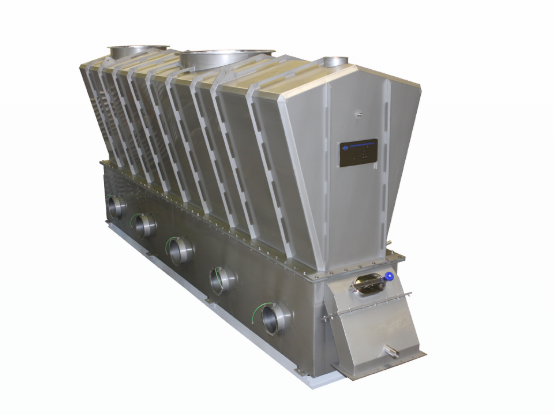

Advanced fluid bed for pharmaceutical granulation

Achieve precise granulation and drying for pharmaceutical powders with ...

Fluid-bed granulator for top-spray applications

Need precise granulation and drying for sensitive materials? This fluid-be...

Fluid-bed drying and granulation system

Optimize your production line with high-speed batch processing for efficiently dryi...

Liquid capsule filling for r&d and pilot-scale production

Optimize liquid capsule production with a compact machine that...

High-speed capsule filler for large batch production

Achieve higher yields and reduce powder waste with a capsule filling...

Capsule filler for high-speed, dust-free capsule production

Enhance your production efficiency with a solution designed ...

Fluid bed dryer with granulation and coating

Enhance your processing efficiency with a versatile system capable of combini...

Flat-forming blister packager for small production batches

Ideal for pharmaceutical and nutraceutical firms seeking effi...

Tabletop blister packaging for clinical trials

For R&D facilities conducting clinical trials or feasibility studies, ...

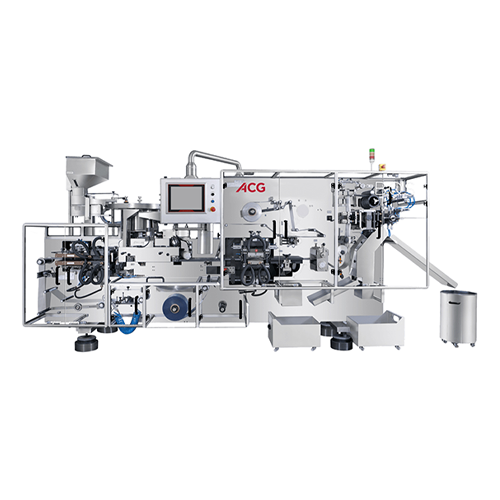

Containment blister packaging for highly potent Apis

Ensure operator safety during the blister packaging of highly potent...

Rotary blister packaging for tablets and capsules

Optimize your blister packaging with high-performance rotary forming an...

Blister packaging for solid dosage forms

Optimize your packaging line with high-speed, continuous blister packaging that en...

Capsule band sealer for liquid-filled hard capsules

Seamlessly seal liquid-filled hard capsules to enhance product integr...

Semi-automatic de-blistering solution for Pvc and alu blister packs

Streamline your packaging operations by swiftly rec...

Automatic capsule checkweigher for statistical weight control

Ensure precise weight control of capsules with automatic s...

Capsule de-dusting and polishing system

Ensure precision in capsule production with continuous de-dusting and polishing, en...

Empty capsule sorting system for pharmaceutical manufacturing

Expedite your capsule production with a high-speed system ...

Filled capsule elevator for seamless process integration

Efficiently streamline the transfer of filled capsules across va...

Automated powder and pellet product conveying system

Optimize your encapsulation process effortlessly with this fully aut...

Capsule sorter elevator for encapsulation processes

Ensure uninterrupted encapsulation by efficiently removing defective ...

Metal contamination detection for tablets and capsules

Ensure product integrity by detecting and separating metal particl...

Flat forming and sealing blister packaging solution

Enhance your blister packaging process with a solution that ensures p...

Flat-sealing continuous-motion blister packaging solution

Enhance your blister packaging with precise, high-speed sealin...

Fully automatic hard capsule filling machine

Enhance pharmaceutical production with precise capsule filling, ensuring opti...

Capsule filling for pharmaceuticals and nutraceuticals

Enhance your capsule production capabilities with modular filling ...

Online tablet counter inspection system

Ensure product integrity by precisely inspecting and rejecting defective tablets an...

Capsule printer for pharmaceutical applications

Experience precise dual-color printing with high-speed efficiency for caps...

H-track ink printing solution for tablets and capsules

Ensure precise ink printing on tablets and capsules with high-spee...

Tablet and capsule ink print and laser marking system

Streamline tablet and capsule identification with a high-speed syst...

Tablet and capsule ink printer

Achieve precise and high-speed printing on tablets and capsules, ensuring clear product ident...

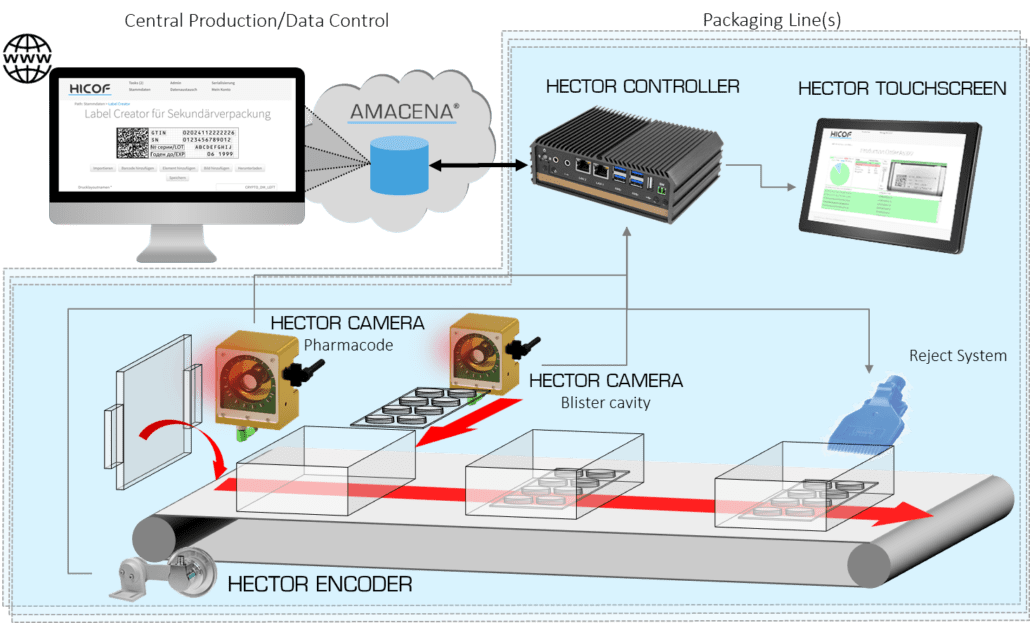

Serialization and aggregation inspection system

Including serialization and aggregation inspection systems to packaging li...

Pharmaceutical data management software

A typical pharmaceutical production handles numerous work flow activities like mana...

Flat carton serialization station

The packaging lines in the pharmaceutical industry handle several flat cartons. Manual pa...

Blister inspection system

The pharma and healthcare industries widely use blister thermoforming machines to package a variet...

Cold forming aluminum blister machine for capsules

Aluminum blisters are mainly used for packaging products that are sens...

Easy to validate capsule filler

Staying competitive in today’s highly dynamic and highly regulated pharmaceutical prod...

High speed bottle filler with inspection

Medicines in tablet, capsule, or soft gel forms undergo various processes before r...

Effective Visual Inspection System for Capsules

The attribute of capsule packing is a critical parameter that controls the...

Lifter and De-duster for Tablets

The use of several different tools for lifting, de-dusting, and polishing in the pharmaceut...

High Speed Visual Inspection System for Tablets

In order to ensure quality and standard specifications of tablets, capsule...

Contained Visual Inspection System

In the medicine industry, it is important to ensure there are no defects in tablets or c...

Tablet counting machine

Production of pharmaceutical solid dosage forms usually require complete accuracy, flexibility, and c...

Pharmaceutical bottle unscrambler

Pharmaceutical packaging industry requires the ability to quickly manage the process yet ...

Dessicant inserting machine

Desiccant canisters play an important role in the pharmaceutical and nutraceutical industries. T...

Metal detector for bottles

For metal contamination detection in finished products that are bottled, traditional solutions re...

Metal detector for tablets and capsules

Identification of metallic contaminants is a vital part of pharmaceutical quality c...

Semi-automatic capsule filler

Hard gelatin capsules are a popular format for delivering a wide variety of pharmaceutical dos...

Automatic filling line for solid doses

For medium-scale production of solid doses such as tablets, capsules, and softgels t...

Electronic capsule counter

For lab work or small batch production, hand counting of solid doses into dispensing containers i...

Semi-automatic case packer

Pharmaceutical products require complete traceability throughout the production cycle. For smalle...

Laboratory capsule filler for liquid solutions

A recent important change in the industry is the trend toward providing liq...

Automatic laboratory capsule filler

Innovators in the highly regulated and highly dynamic pharmaceutical market place need ...

Automatic capsule filler

Capsule filling should be a worry-step in pharmaceutical and nutraceutical manufacturing. The right...

Industrial capsule checkweigher

Pharmaceutical manufacturing demands the highest quality standards and completely consistent...

Capsule checkweigher

The production of pharmaceutical capsules requires that individual doses are checked for accuracy. In a ...

Stand-alone aggregation station

The aggregation of pharmaceutical products for tracking purposes is already compulsory in ma...

Serialization coding and labeling equipment

In the pharmaceutical industry, product serialization is the cornerstone of al...

Automatic capsule filler for liquid solutions

Use of liquid filled hard capsules is increasingly popular with today’...

Contained capsule filler

For pharmaceutical formulations that are highly active specialized capsule filling equipment is ofte...

High-yield capsule filler

Pharmaceutical manufacturers require maximum yield from their encapsulation process for efficient ...

High capacity capsule filler

In the highest volume pharmaceutical production environments, capsule filling needs to be extre...

Scale up capsule filler

For higher production volumes of pharmaceutical capsules, speed, accuracy and reliability of producti...

Entry level capsule filler

For the production of pharmaceutical doses in capsule form complete accuracy of fill is paramount...

High capacity weight sorter for tablets & capsules

By employing a weight sorter that is fully flexible and able to ha...

Versatile weight sorter for tablets & capsules

Saving costs and improved production efficiencies are possible by opti...

R&D semi-automatic capsule filler

Semi-automatic filling machine suitable to open, fill and close empty hard gelatin capsul...

R&D hard gelatin capsule sealing machine

When encapsulating products at temperatures up to + 80°C, these tend to solidify a...

R&D electronic counter for capsules and tablets

This machine has been designed to offer an ever-precise and reliable count...

R&D automatic capsule filler

Automatic capsule filling machine for powders, pellets, tablets, mini-tablets, capsule in capsu...

R&D capsule orientater

A semi-automatic orienter for capsules with an output speed up to 6000 capsules.

Entry-level blister machine

A start-up solution for contract packing and generics manufacturing with an easy-to-get upgrade ...

Checkweigher for capsules

The new interactive indicator unit allows for even easier use. High-rigidity weighcells have been ...

Checkweigher

A check weigher that is equipped with high speed/high accuracy force balance load cell. It meets stringent accura...

High-sensitivity metal detection system

Highly efficient metal detector with enhanced quality control and reporting capabil...

Entry-level X-ray inspection system

Without compromising on performance, if you need an entry level x-ray inspection system...