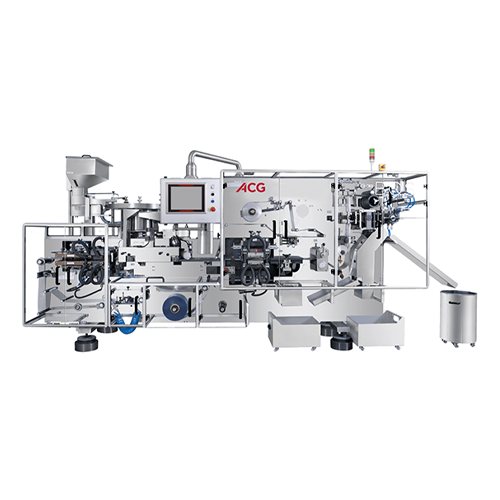

Flat-sealing continuous-motion blister packaging solution

Enhance your blister packaging with precise, high-speed sealing and comprehensive film compatibility, making it an adaptable choice for pharmaceutical and nutraceutical production lines.

Forms, Seals, and Punches Blister Packs

The BQS from ACG is a continuous blister packaging machine designed for pharmaceutical and nutraceutical applications. It efficiently forms, seals, and punches blister packs for solid dosage forms, including tablets and capsules. Powered by servo technology, the BQS ensures precise control and reliability, enhancing productivity on the packaging line. It accommodates a variety of thermoform films and cold-form foils, providing flexibility for different packaging requirements. Operating at high speeds, it achieves up to 45 thermoforming cycles per minute and 35 cold-forming cycles per minute, with a maximum forming area of 240 mm x 180 mm. The BQS is fully PLC-controlled with ACG SMART CONNECTED technology for remote monitoring and real-time performance insights. It conforms to CE/EAC/UL certifications, ensuring compliance with international standards. Its ergonomic balcony design facilitates easy access and cleaning, minimizing downtime during changeovers. With its capacity to integrate seamlessly with cartoning machines, the BQS supports efficient downstream operations, making it a versatile choice for packaging lines aiming for high throughput and efficiency.

Benefits

- Enhances productivity with high-speed, continuous blister packaging.

- Reduces changeover time with easy access and cleaning.

- Increases packaging yield with edge-to-edge blister-pack punching.

- Ensures compliance with global standards through CE/EAC/UL certification.

- Provides real-time monitoring and reduced maintenance costs with SMART CONNECTED technology.

- Applications

- Soft gelatine capsules, Hard capsules, Pharmaceutical tablets

- End products

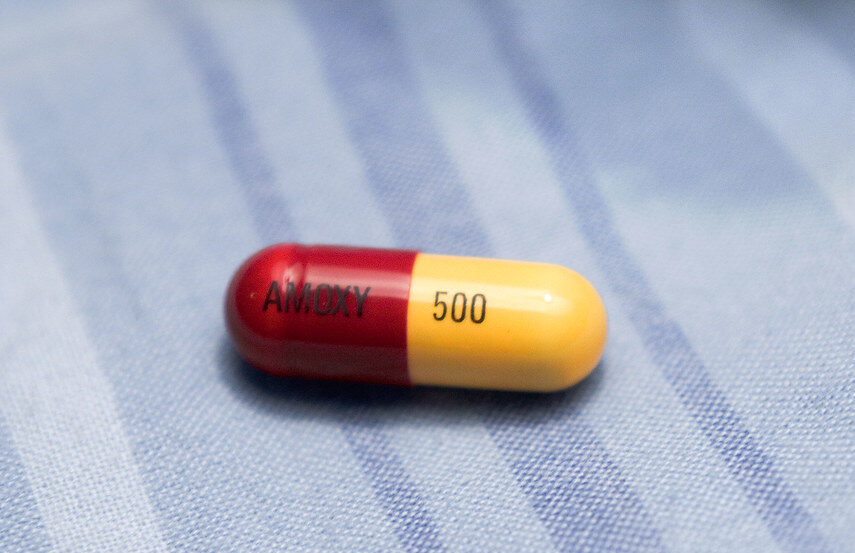

- Ibuprofen tablets, Omega-3 gel capsules, Vitamin d capsules, Antihistamine tablets, Fish oil softgels, Amoxicillin capsules, Multivitamin tablets, Paracetamol tablets

- Steps before

- Formulation, Tablet compression, Capsule filling

- Steps after

- Cartoning, Vision inspection, Aggregation, Label serialisation

- Input ingredients

- thermoform films, cold-form packaging foils, PVC, PVC/PVdC, Aclar, Triplex (PVC/PE/PVdC), cold-form foil (Alu), lidding materials, push-through foil, child-resistant foil, peelable foil

- Output ingredients

- blister packs, packaged tablets, packaged hard capsules, packaged soft gelatine capsules

- Market info

- ACG World is known for manufacturing capsules and capsule filling machines, providing integrated pharmaceutical solutions with a strong reputation for innovation, quality, and comprehensive service offerings in the pharmaceutical manufacturing industry.

- Forming cycle - Thermoforming

- Up to 45 cycles/min

- Forming cycle - Cold-forming

- Up to 35 cycles/min

- Forming depth - Thermoforming

- Up to 12 mm

- Forming depth - Cold-forming

- Up to 9 mm

- Maximum forming area

- 240 mm x 180 mm

- Forming materials

- PVC, PVC/PVdC, Aclar, Triplex (PVC/PE/PVdC), cold-form foil (Alu)

- Lidding materials

- Push-through foil, child-resistant foil, peelable foil

- Blister width

- Up to 127 mm

- Working mechanism

- Flat-sealing, continuous-motion

- Automation level

- SERVO technology

- Remote monitoring

- ACG SMART CONNECTED technology

- Customization capability

- High flexibility for specific requirements

- Changeover time

- Hassle-free

- Thermoform films

- PVC, PVC/PVdC, Aclar, Triplex (PVC/PE/PVdC)

- Cold-form packaging foils

- Aluminum (Alu)

- Lidding materials

- Push-through foil, child-resistant foil, peelable foil

- Blister packaging material

- Thermoform films, cold-form foils

- Dosage forms

- Tablets, hard capsules, soft gelatine capsules

- CE marking

- Yes

- UL certification

- Yes

- EAC certification

- Yes

- Blister width

- Up to 127 mm

- Maximum forming area

- 240 mm x 180 mm

- Forming depth - Thermoforming

- Up to 12 mm

- Forming depth - Cold-forming

- Up to 9 mm

- Compliance,Certifications

- CE/EAC/UL

- Control Panel Type

- ACG SMART CONNECTED technology

- Integration Possibilities

- Effortless downstream integration with cartoning machines

- Customization Flexibility

- Highly flexible for custom requirements

- Rotary Indexing

- Suitable for large blister sizes, up to 127 mm width