Making Dyes

Find innovative production technology for making dyes and connect directly with world-leading specialists

Dyes lend color to the things we consume. The foods we eat, the clothes we wear, and even the keyrings that separate your bunch all have a splash of dye added. Historically, colors were extracted from the natural world, but that process has been replaced by processing technology. Dye manufacturing equipment produces colors that are high in definition and consistency.

Select your dyes process

Tell us about your production challenge

Combine the base chemicals in a reactor

Dyes are born in a reactor. A colorless chemical substance – a chromogen – is synthesized with a light-absorbing molecule – a chromophore. Chromogens such as benzene, naphthalene, and anthracene are safe for application in consumer products.

Chromophores range from carbon and nitrogen acids to azo compounds and sulfur acids. The combination of chromogens and chromophores produces the chemical classification that makes dye manufacturing repeatable.

Synthesize dye chemicals with additives to build substrate affinity

Dyes are distinct from pigments because they are soluble. While the latter remains in particle or crystalline form, dyes are designed to attach to other materials.

To develop this substrate affinity, the chromogen-chromophore combination is reacted with a class of atoms like amine, hydroxyl, and carboxyl. These auxochromes provide a higher affinity for the substrate than water, so the colorants are retained after the material is dried off.

Adjust dye manufacturing for wet and light fastness

Besides affinity, different dye classifications modify the wet and light fastness of colorants. Vat dyes, for example, include an insoluble complex of molecules to resist fading in water. One of the most popular dyes made with this process is indigo.

Acid dyes, on the other hand, do not hold particularly well in washing. But the sulfuric acid dyestuff makes them sufficiently light fast and are often used for dyeing textiles like wool and silk.

Separate the dye mixture from the solvent under vacuum filtering

Once the dye is chemically composed, the production process shifts to its physical attributes. Filter the dye mixture from solvents using a vacuum filter and purify the solution by chromatography or distillation.

The color ingredient is now isolated, but the production line involves more dye manufacturing equipment to standardize the end product. Treat the purified mixture to high temperatures to reduce moisture content. Finally, grind the dry material in a ball mill or roller mill to produce a homogeneous particle size.

Processing steps involved in dyes making

Which dyes technology do you need?

Versatile cone mill for uniform size reduction

Achieve precise particle size consistency and gentle deagglomeration across...

Air classifier mill for ultra-fine powder grinding

Optimize your milling operations with precision particle size control ...

High shear plough mixer for powders, granules, and pastes

Achieve rapid and efficient blending with high shear mixers de...

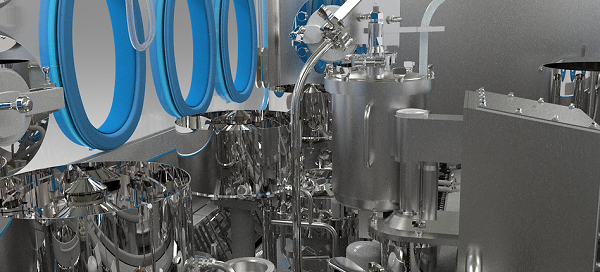

High-pressure homogenizers for liquid products

Achieve consistent emulsions and stable dispersions with high-pressure homo...

High-pressure homogenizer for food and pharmaceuticals

Achieve unparalleled consistency and stability in emulsions and di...

Homogenizers for high-pressure applications

Achieve unparalleled product consistency and stability with precision-engineer...

Industrial homogenizer for food and pharmaceutical applications

Ensure product consistency and stability with high-press...

High-pressure homogenizers for dairy and food products

Achieve consistent texture and stability in your liquid products w...

High-pressure homogenizers for dairy and juice processing

Ensure superior texture and stability in your liquid formulati...

High-speed pulverizer for carbon black production

Achieve consistent particle size and optimal homogenization with high-s...

Coaxial mixer for high viscosity liquids

Achieve seamless blending of high-viscosity materials with a coaxial mixer designe...

Heavy duty analytical sieve shaker for coarse-grained materials

Need precise particle size distribution for large minera...

Vertical pharma vacuum blender for bulk solids

Optimize your mixing of fine chemicals and pharmaceutical powders with high...

Crossflow filtration with sieve filter for difficult suspensions

Achieve precise separation and recovery in challenging ...

Laboratory crossflow filtration test system

Efficiently test and determine optimal filtration parameters with this portabl...

Pressure drum filter for fine-grained products

Achieve exceptional precision in fine particles processing with this pressu...

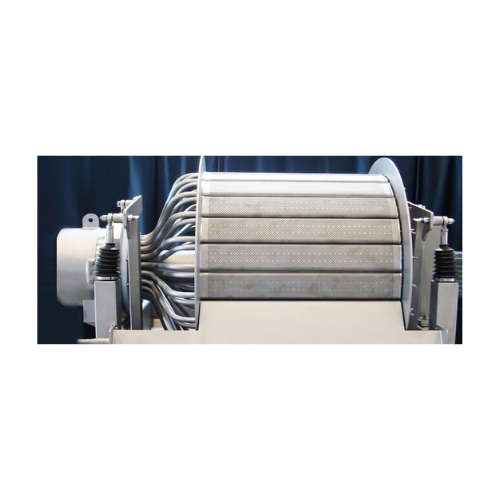

Industrial drum vacuum filter for filtration and washing

Efficiently manage filtration, washing, and dewatering tasks wit...

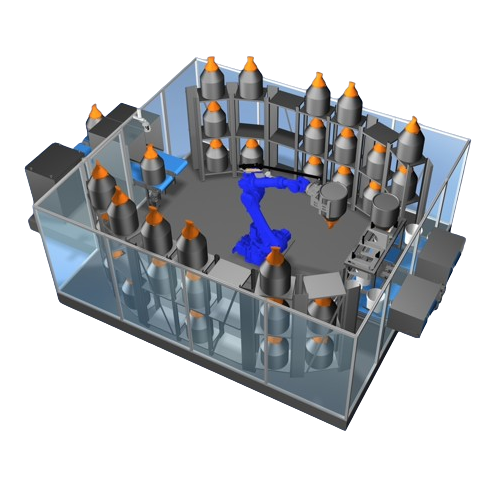

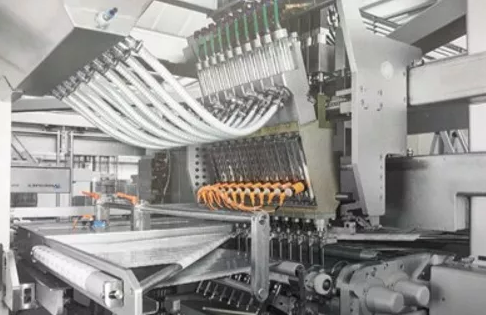

Robotic dosing system for accurate micro quantities

Achieve precise and reproducible micro dosing of challenging raw mate...

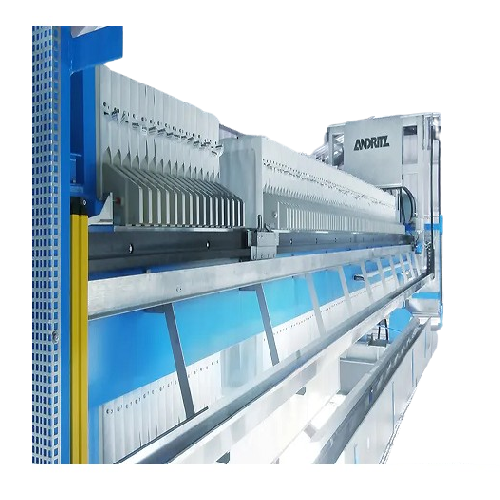

Industrial filter press for dewatering and filtration

Optimize your dewatering and filtration needs with a highly adaptab...

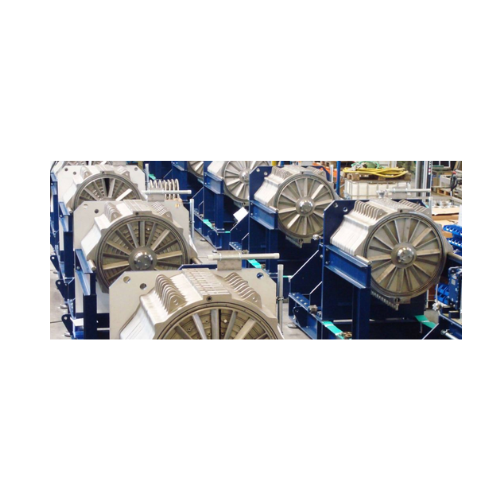

Vacuum drum filter for solid/liquid separation

Optimize your solid/liquid separation process with a versatile vacuum drum ...

Flash dryer for high-moisture bulk materials

Tackle high-moisture challenges head-on with rapid drying solutions that effi...

Disposable containment system for solid dosage material

Ensure safe and dust-free transfer of hazardous materials with ou...

Mixing vessel for liquid, sauce, and cream products

Maximize efficiency in your production line with a versatile solution...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

Industrial rapid turbulent mixer for homogeneous mixing

Achieve unparalleled homogeneity with rapid turbulent mixing, ess...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Horizontal shaft mixer for free-flowing materials

Achieve consistent mixing of diverse free-flowing materials with a reli...

Efficient ribbon mixers for precise powder blending

Achieve consistent and uniform blending with this advanced U-Trough m...

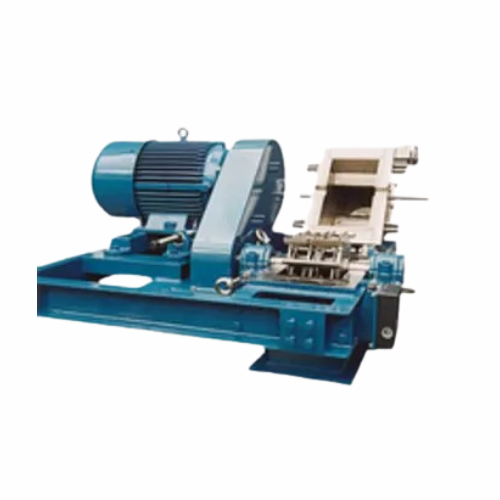

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

Pressure vessel for hazardous and non-hazardous liquids and gases

Ensure safety and compliance when handling hazardous ...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Industrial blenders for powder and granule mixing

Optimize your production line with advanced mixing solutions designed f...

Pv mixing vessels for industrial hire

Optimize your production mix with vessels that ensure precise blending, heating, and ...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

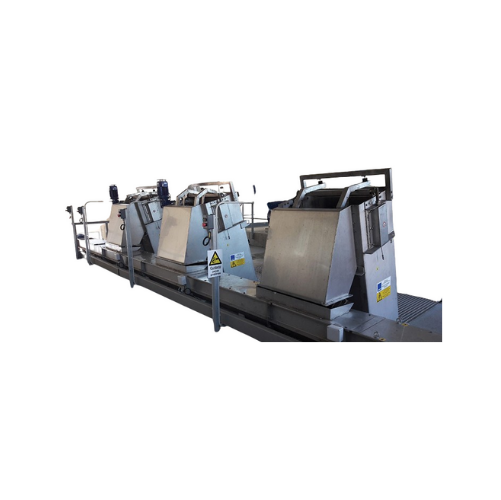

Rotary drum screens for efficient wastewater treatment

Ensure optimal separation and de-watering of solids in wastewater ...

Step screens for fine wastewater screening

Enhance your wastewater treatment with step screens that efficiently separate f...

Shafted washer compactors for wastewater treatment

Effectively compact and dewater waste streams while reducing volume by...

Fine belt screens for wastewater treatment

Efficiently screen and convey solids from wastewater with in-channel fine belt ...

Fine drum screens for wastewater treatment

Streamline your wastewater treatment process by seamlessly integrating a rotati...

Externally fed drum screen for wastewater treatment

Optimize your wastewater treatment with advanced drum screening techn...

Peripheral traction clarifiers for waste water treatment

Efficiently addressing the challenge of biological sludge and sc...

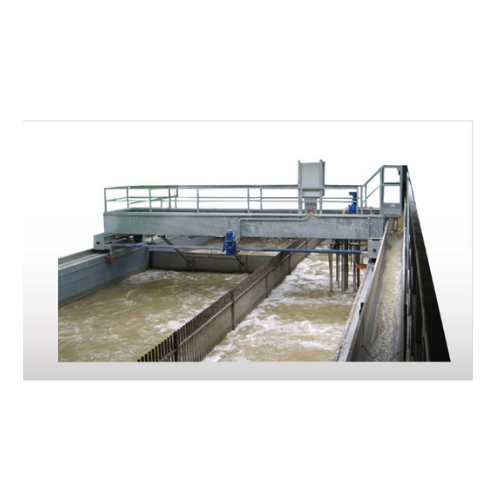

Travelling bridges for grease and grit removal in wastewater treatment

Ensure efficient grease and grit removal in wast...

Grease and grit removal system for wastewater treatment

Efficiently streamline your wastewater treatment process with thi...

Travelling bridges for sludge removal in wastewater treatment plants

Efficiently removing sludge and scum is crucial in...

Internally fed rotating drum screen for wastewater treatment

Streamline your wastewater management with this advanced fi...

Peripheral traction clarifier with sludge suction for wastewater treatment

Optimize your wastewater management with a ...

Peripheral traction clarifier for sludge suction

Effectively manage sludge and scum removal with this clarifier, designed ...

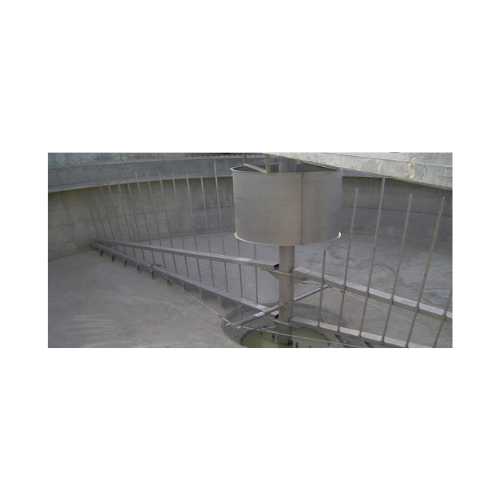

Central traction clarifiers for wastewater sludge removal

Efficiently handle waste challenges with precision-engineered ...

Penstock for wastewater treatment

Efficiently control and isolate water flow in your wastewater treatment facility, ensurin...

Sludge thickeners for wastewater treatment plants

Optimize your wastewater treatment process with a reliable solution tha...

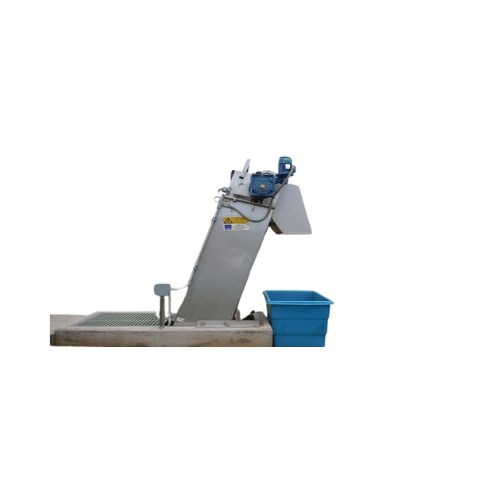

Industrial grit classifier for wastewater treatment

Achieve efficient grit removal and sediment separation in wastewater ...

Mechanical fine bar screens for wastewater treatment

Efficiently capture and remove solids from wastewater streams with s...

Sub-vertical mechanical bar screens for wastewater treatment

Optimize your wastewater treatment process by capturing coa...

Sub-vertical perforated screens for wastewater treatment

Optimize your wastewater treatment with robust mechanical screen...

Sub-vertical mechanical perforated screens for wastewater treatment

Optimize your wastewater treatment process with adv...

Grit classifier for wastewater treatment

Optimize your wastewater treatment process with a grit classifier that efficiently...

Screenings compactor for waste water treatment

Achieve efficient waste management by reducing the volume of screenings by ...

Big-bag unloading station for bulk materials

Facilitate seamless integration into your production line with efficient bulk...

Explosion-proof bead mill for industrial grinding applications

For manufacturers seeking precise particle size control, ...

High-pressure hydrogenation reactor for chemical labs

Achieve precise high-temperature hydrogenation with integrated on-d...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

Efficient grinding and drying mill

Transform your production line with a versatile mill that simultaneously grinds, dries, ...

Self-cleaning bead mill for highly viscous materials

To prevent blockages, clogging, and cross-contamination coming from ...

Horizontal disc bead mill for liquid chemicals

Processing toxic chemicals requires high compliance with safety standards a...

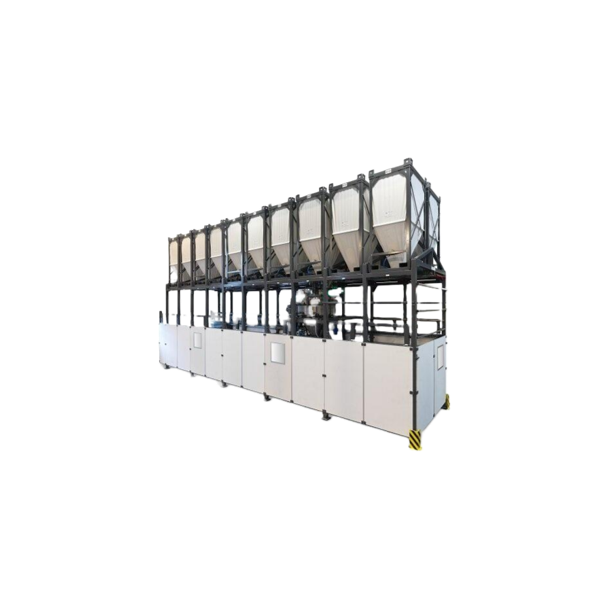

Accurate multiple dosing system for powders

Dosing multiple powders in a batch process is time inefficient, especially whe...

Powder micro-dosing system

Pharmaceutical powders in metered doses demand maximum filling precision. This is particularly ch...

Non-Destructive Crack Detection Vessel Testing

Using traditional types of inspection methods when inspecting vessels may p...

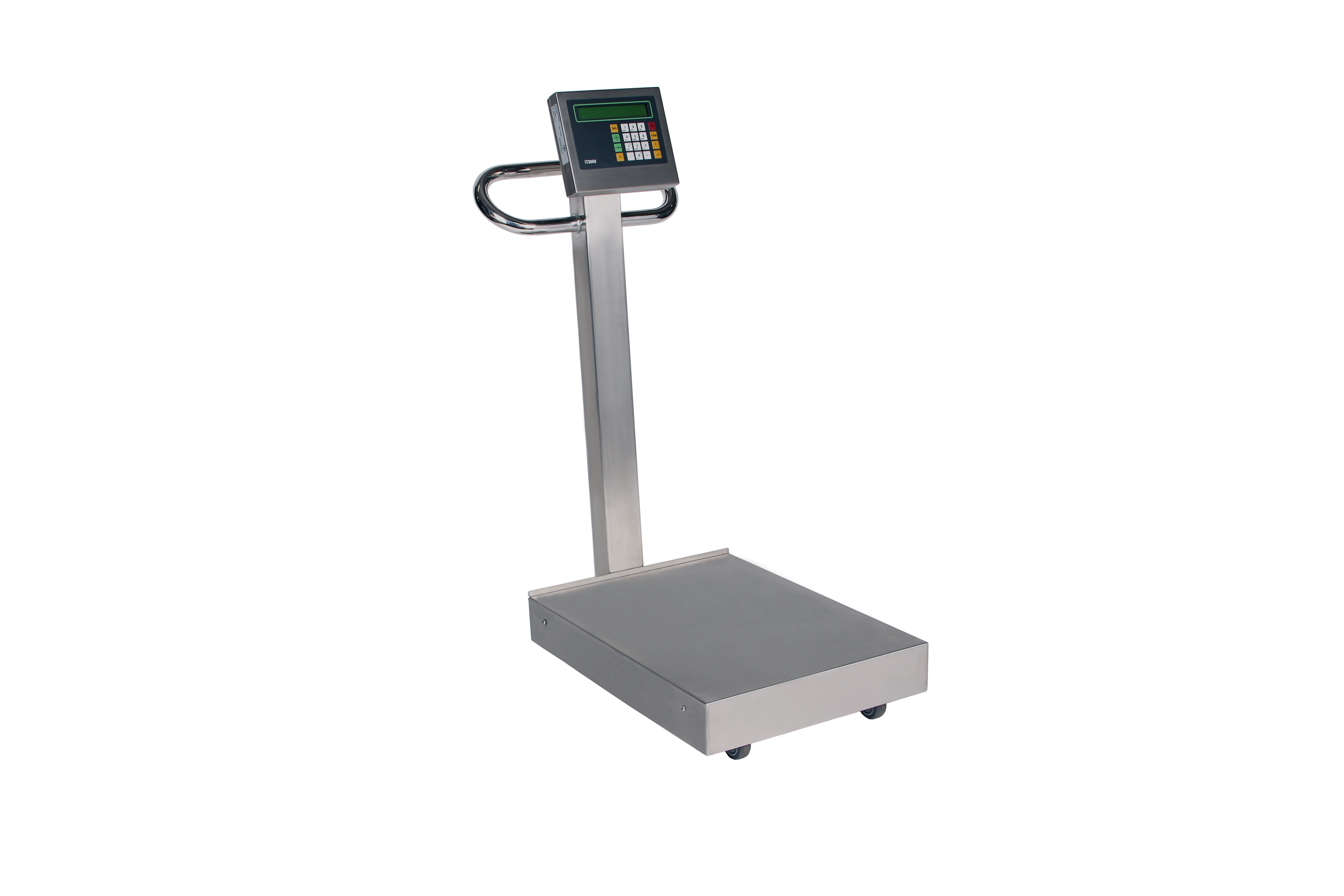

Hygienic mobile scale

Having a reliable and accurate weighing and measuring solution is absolutely essential, especially in t...

Airshocking hammer

Silos, hoppers, bins, and other containers can build up a layer of powdered product on the internal walls....

In-process weighing system for mills

When you need a throughput weigher for modern flour/grain milling applications, the we...

High-capacity bulk weighers

A checking weigher recognized for receiving and shipping bulk materials, typically in mills and ...

Robot palletizer

Palletize up to 1,800 large industrial bags per hour at a multi-pick-up configuration.

Open-mouth baggers for free flowing powders

For bagging free flowing materials into open mouth bags, this system is ideal....

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...