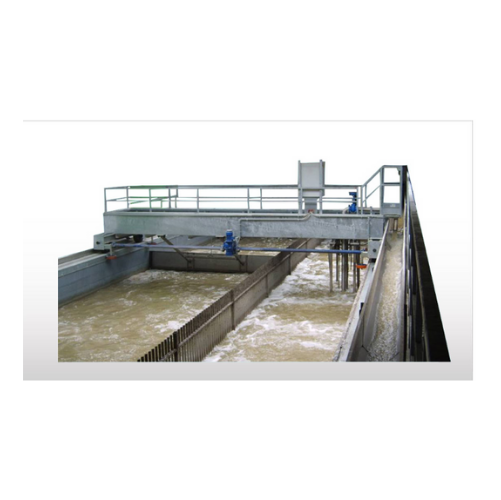

Grease and grit removal system for wastewater treatment

Efficiently streamline your wastewater treatment process with this system designed to remove grease and grit, ensuring clean effluent and environmental compliance.

Removes Grease and Grit from Wastewater

The Travelling Bridges for Grease and Grit Removal PVD from WAMGROUP offers a robust solution for wastewater treatment, designed for municipal and industrial applications. This system operates with a dual scraper setup—comprised of surface and bottom scrapers—facilitated by a movable truck on traction trolleys. An air injection system optimizes separation, directing scum to the grease collection channel while ensuring efficient grit settling, enhancing end-product purity such as treated water and processed sludge. The system caters to up to 50m long and 8m wide tanks and is built with hot-dip galvanized carbon steel or stainless steel options for enhanced corrosion resistance. With quick installation and low maintenance, it streamlines operations in industries ranging from tannery effluent processing to clean water treatment. Designed for automated continuous operation, the equipment integrates seamlessly into existing systems, featuring a centralized gearbox for efficient scraper operation and available options like cable holding chains and rail-based travelling systems for tailored engineering support.

Benefits

- Enhances treatment efficiency by effectively separating grease and grit for cleaner output.

- Minimizes labor requirements with automated operation and centralized control systems.

- Lowers maintenance overheads with durable construction and simple installation processes.

- Adapts to various environmental conditions with corrosion-resistant material options.

- Ensures regulatory compliance for wastewater discharge, supporting sustainable operations.

- Applications

- By-products processing, Animal by-products handling, Industrial waste water treatment, Industrial solid waste handling, Processing, Sludge treatment, Treatment, Clean water treatment, Environmental technology, Pulp, Starch, Municipal waste water treatment, Paper processing, Dyeing works, Tanneries

- End products

- Bleached paper pulp, Treated municipal water, Processed industrial waste residues, Processed animal by-products, Potable water, Refined paper products, Processed wastewater for environmental compliance, Treated dye wastewater, Treated industrial water, Treated tannery effluents, Processed sludge, Processed starch derivatives

- Steps before

- Screening, Primary Settling

- Steps after

- Sludge Treatment, Final Clarification, Disinfection

- Input ingredients

- municipal wastewater, industrial wastewater, oil, sand, grit, grease

- Output ingredients

- cleaner water, collected grit, collected grease, scum, floating particles

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Tank Width

- Up to 8m

- Tank Length

- Up to 50m

- Material

- Hot dip-galvanised carbon steel / 304 L / 316 L SS

- Automation

- Central gearbox operated

- Grit Removal Device

- Included

- Scum Removal Device

- Included

- Control System

- Control panel

- Options

- Cable holding chain, Travelling system on rails

- Air Injection System

- Not supplied

- Voltage and Frequency

- Alternative available

- Motor Protection Degree

- Alternative available

- Operating Mechanism

- Movable truck on traction trolleys

- Scraper Type

- Surface and bottom scrapers

- Automation Level

- Gear motor operated

- Grit and Grease Removal Method

- Circular movement and scrapers

- Air Injection System

- Not supplied

- Tank Structure

- Divided for grit settling and grease collection

- Installation Type

- Quick installation

- Travelling System

- Wheels or railway option

- Material Option

- 304 L / 316 L SS

- Abrasion resistance

- Highly resistant

- Corrosive resistance (e.g. acids)

- 304L/316L Stainless Steel

- Cleanability

- Hot dip-galvanised

- Density/particle size

- Suitable for various wastewater particulates

- Machine footprint

- Up to 8m wide, 50m long

- Tank shape

- Rectangular

- Material

- Hot dip-galvanised carbon steel / 304 L / 316 L SS

- Discharge method

- Surface and bottom scrapers

- Travelling system

- Trolleys with drive wheels

- Control panel type

- Available

- Cable management

- Festooned cables / Cable holding chain

- Customization options

- Alternative voltage and frequency, Travelling system on rails

- Control panel

- Available