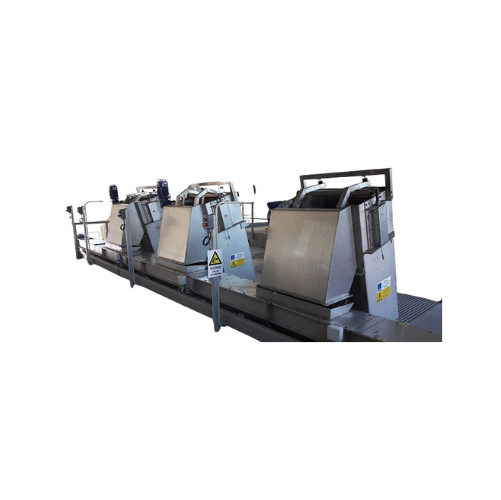

Sub-vertical mechanical bar screens for wastewater treatment

Optimize your wastewater treatment process by capturing coarse solids efficiently with sub-vertical mechanical bar screens, designed to enhance filtration and ensure continuous operation in demanding environments.

Screens and Removes Coarse Solids from Wastewater

The Sub-vertical Mechanical Bar Screens GVL from WAMGROUP is engineered to streamline coarse screening in municipal and industrial wastewater treatment facilities. Designed to address the rugged demand of environments such as abattoirs, food processing, and beverage industries, this equipment effectively captures solids with chain-driven rakes, transferring them to discharge points. The GVL screens use precision laser-cut raking tines and a stainless steel bar frame for enhanced durability and corrosion resistance. Operating with a 75-degree incline angle, they accommodate channel widths from 400 to 1,200 mm, ensuring efficiency in high-volume applications. Automation is seamless through a PLC-controlled setup, minimizing manual intervention and maintenance needs. Optional conductive level probes offer improved operational control, while integrated systems ensure quick and efficient serviceability without removing screens from their channels. Capable of reducing service requirements, GVL offers a cost-effective solution to handle wastewater challenges in diverse industries, supporting processes to produce treated effluents, sanitized food products, and more.

Benefits

- Enhances operational efficiency by capturing and removing solids with minimal manual intervention.

- Reduces maintenance needs with a no sprocket, no lower bearings design.

- Adapts to various channel widths, supporting scalability in treatment facilities.

- Minimizes labor costs with automated chain-driven raking and PLC control.

- Supports diverse industry applications from municipal to industrial effluent management.

- Applications

- Manure treatment, Industrial waste water, Clean water treatment, Paper processing, Vegetable processing waste water, Industrial solid waste handling, Tannery waste water, Starch by-products processing, Municipal waste water, Animal by-products processing, Catering waste water, Animal by-products handling, Beverage industry waste water, Pulp processing, Plastics recycling industry waste water, Abattoirs, Dyeing works, Food processing waste water, Livestock breeding, Fruit processing waste water

- End products

- Potable water, Starch derivatives, Refined paper, Treated industrial effluents, Vegetable by-products, Treated tannery water, Effluent-free beverages, Treated municipal water, Processed animal fat, Paper pulp, Meat by-products, Fertilizer from manure, Sanitized catering water, Treated manure, Recycled plastic pellets, Protein meal, Dye pigments, Sanitized food products, Juice by-products, Processed solid waste

- Steps before

- Waste Collection, Initial Screening, Debris Removal

- Steps after

- Solid Waste Compacting, Waste Conveying, Waste Disposal

- Input ingredients

- municipal waste water, industrial waste water, sludge treatment, abattoir waste water, beverage industry waste water, food processing waste water, catering waste water, fruit processing waste water, vegetable processing waste water, pulp processing waste water, paper processing waste water, starch processing waste water, dyeing works waste water, tannery waste water, plastics recycling waste water, livestock breeding waste water, clean water treatment

- Output ingredients

- coarse screened waste, solids, screenings, municipal water treatment effluent, industrial water treatment effluent, clean water, processed water

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Screen spacing

- 10mm ~ 40mm

- Cleaning rakes

- 2 or more

- Channel width

- 400 ~ 1, 200 mm

- Incline angle

- 75 degrees

- Material

- Galvanized steel

- Working Mechanism

- Sub-vertical Mechanical Bar Screen

- Cleaning Method

- Chain-driven rakes

- Operation Incline Angle

- 75-degree

- Material Flow Type

- Coarse screening

- Integrated Steps

- Screening, Raking, Discharge

- Spacing

- 10mm ~ 40mm

- Channel Width

- 400 ~ 1, 200 mm

- Automation Level

- Manual / Automatic

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Channel width

- 400 ~ 1, 200 mm

- Spacing

- 10mm ~ 40mm

- Incline angle

- 75 degrees

- Frame material

- Steel

- Transmission chain

- Galvanized steel

- Filtration zone

- Individually replaceable bars

- Spacing

- 10mm ~ 40mm

- Incline angle

- 75-degree

- Channel width

- 400 ~ 1, 200 mm