Sub-vertical perforated screens for wastewater treatment

Optimize your wastewater treatment with robust mechanical screening, reducing maintenance and ensuring efficient removal of solids from a variety of industrial and municipal effluents.

Captures and Cleans Wastewater Solids Efficiently

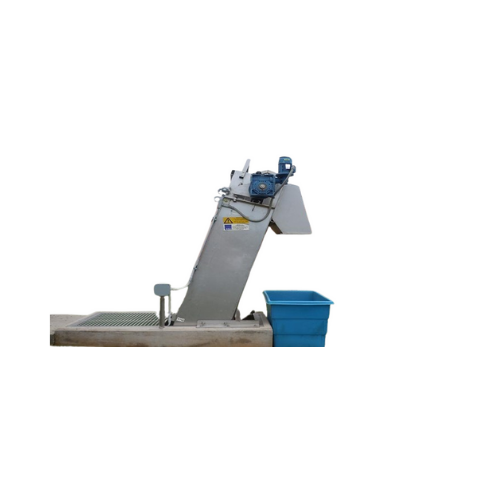

The GVS Sub-vertical Mechanical Perforated Screens from WAMGROUP offer an efficient solution for fine screening in municipal and industrial wastewater treatment facilities. Designed with a robust steel frame and customizable perforated plate filters, these screens excel in capturing solids from diverse effluent streams. The chain-driven system utilizes brushes and wiper blades to maintain clean filters, ensuring seamless operation and minimal maintenance disruptions. Applicable across industries such as beverage production, food processing, and pulp manufacturing, the GVS Screens promote treated and recycled water, refined solids, and compostable by-products. With channel widths spanning 400 to 2,000 mm and incline angles adjustable from 75 degrees to vertical, they integrate simply into existing infrastructures. Built from hot dip galvanized or stainless steel (304L/316L), these screens resist corrosion while meeting strict environmental compliance standards. Effortless blade and wiper replacements minimize downtime, making this equipment a versatile and reliable choice for diverse waste management applications.

Benefits

- Ensures continuous operation with minimal maintenance due to no sprocket or bearing needs.

- Reduces downtime with easy-to-replace wipers and brushes bolted to the rake mechanism.

- Handles varying effluent types with customizable screen perforations and incline adjustments.

- Offers durability and corrosion resistance with stainless steel construction options.

- Integrates seamlessly into existing frameworks with versatile channel width and angle configurations.

- Applications

- Fruit processing wastewater, Manure treatment, Municipal sludge treatment, Clean water treatment, Paper processing, Beverage industry wastewater, Tanneries, Municipal wastewater, Industrial solid waste handling, Starch processing, Animal by-products handling, Catering wastewater, Incinerators, Pulp processing, Food processing wastewater, Plastics recycling wastewater, Dyeing works, Industrial wastewater, By-products processing, Livestock breeding, Vegetable processing wastewater

- End products

- Frozen vegetable packs, Manure fertilizers, Finished paper products, Industrial waste aggregates, Recycled industrial water, Dyed textiles, Tanned leather products, Purified drinking water, Treated municipal water, Treated municipal sludge, Combusted waste by-products, Processed foods, Clean livestock facilities, Processed animal by-products, Biogas from manure, Bottled beverages, Packaged ready meals, Modified starches, Recycled plastic products, Refined pulp, Canned fruit products

- Steps before

- Initial Wastewater Collection, Preliminary Screening, Coarse Filtration, Primary Sedimentation

- Steps after

- Sludge Treatment, Fine Filtration, Wastewater Aeration, Clarification, Disinfection

- Input ingredients

- wastewater, sewage, process water, municipal waste, industrial waste

- Output ingredients

- screened solids, clean water, discharged materials

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Perforation size

- 3mm ~ 6mm

- Cleaning blades and wipers

- 4 or more

- Channel width

- 400 ~ 2, 000 mm

- Incline angle

- 75 degrees

- Screen material

- Hot dip galvanized steel

- 304 L / 316 L SS

- Power supply options

- Alternative voltage and frequency

- Screening type

- Fine screening

- Flow direction

- Sub-vertical

- Cleaning mechanism

- Brush and wiper blades

- Incline angle

- 75 degrees

- Automation level

- Manual / PLC

- Maintenance requirement

- Low maintenance costs

- Installation depth

- Very deep channels

- Material discharge method

- Dumpster, conveyor or compactor

- Corrosion resistance

- Hot dip galvanised steel

- 304 L / 316 L SS

- Abrasion resistance

- Yes

- Cleanability

- Chain-driven brushes and wiper blades

- Biological compatibility

- Suitable for waste water, municipal and industrial

- Screen angle

- 75–90 degrees

- Machine Footprint

- Variable, depending on channel width

- Incline Angle

- 75 degrees, adjustable up to 90 degrees

- Channel Width

- 400 ~ 2, 000 mm

- Perforation Size

- 3mm ~ 6mm

- Material

- Hot dip galvanised steel

- 304 L / 316 L SS

- Discharge Method

- Discharge into dumpster, conveyor or compactor

- Screen type and size

- Alternative types and sizes

- Material type

- Hot dip galvanized steel

- 304 L / 316 L SS

- Incline angle

- 75 degrees, adjustable up to 90 degrees with goose neck

- Voltage and frequency

- Alternative options available

- Motor protection degree

- Alternative degree options available

- Control panel

- Customizable