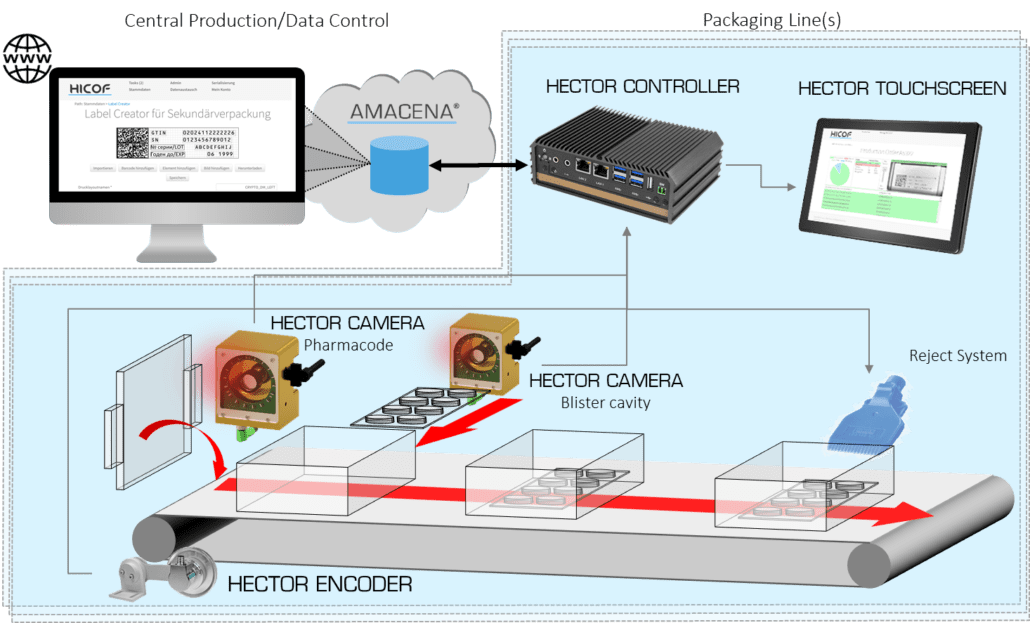

Serialization and aggregation inspection system

Including serialization and aggregation inspection systems to packaging lines helps manufacturers to make the distribution chain more efficient while ensuring consumer safety. Having different systems that handle serialization, aggregation and visual inspection can require different training and be time-consuming. A single system that can manage all three fuctionalities in one could be a solution to reduce effort, time, and cost.

Complete track and trace solution for serialization, aggregation and quality inspection

The Hector system from Hicof is a system with a complete track and trace system for serialization, aggregation and quality inspection. It can manage the process of serial numbering with different printing systems such as Thermo Inkjet, Continuous Inkjet or Laser printing. The Hector system has a controller that can be connected to cameras for the print inspection process. Its integrated register allows tracking processes through machines based on encoder signals. Hector system features a wide range of optical systems that helps in managing the aggregation of serialized products over multiple packaging levels. It can create individual identifiers of the aggregated container by connecting to label printing systems. Hector manages the visual quality inspection process as Pharmacode reading, filling control of Blister cavities, and quality inspection of tablets and molded products.

Benefits

- Hector system can be integrated into any industrial machine

- More than 4 CPU cores controller

- Hector cameras can be customized based on the application

- Stand-alone touch screens

- Integrated to the Hicof AMACENA Software