High-speed capsule cartoning solution

Optimize your capsule packaging line with a versatile cartoning machine that accommodates various capsule types and configurations while ensuring high-speed operation and gentle handling to maintain product integrity.

Packs and Cartons Beverage Capsules Efficiently

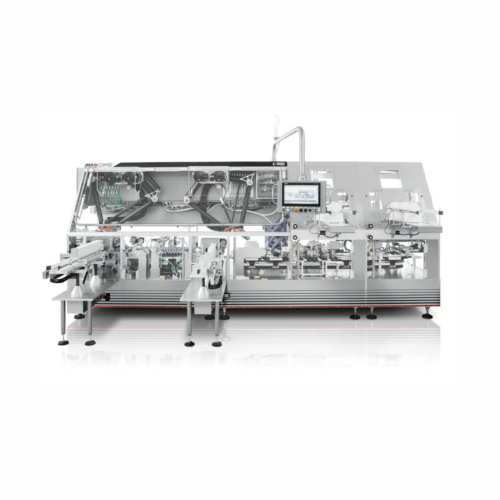

The IMA Group’s C-900 embodies a high-speed solution for coffee producers and beverage manufacturers, engineered to handle any market-available capsule with ease and precision. This capsule cartoning machine is fitted with an advanced capsule transfer feeding system that features a buffer and recirculation unit, ensuring gentle handling and preventing capsule damage. Capable of processing up to 900 capsules and packaging up to 90 cartons per minute, the C-900 is a cornerstone for flexible production lines.

Ideal for secondary packaging tasks, it caters to espresso, latte, green tea, and herbal infusion capsules, including compostable and recyclable varieties. Choose from a range of carton styles, such as nested arrangements or multi-layered packs, complemented by a variety of closure options including tamper-evident systems. The fully servo-driven technology ensures high-speed, continuous operations, and quick size changeovers for seamless integration into existing setups. Its energy-efficient motorization minimizes power waste, sharing kinetic energy across modules, and supports sustainable packaging with its ability to handle recyclable materials.

Benefits

- Enhances efficiency by packing up to 90 cartons per minute, maximizing output.

- Maintains product integrity with gentle handling, reducing capsule damage.

- Saves packaging material and shelf space with optimized carton configurations.

- Supports sustainability efforts by accommodating compostable and recyclable materials.

- Lowers energy consumption through efficient motorization and kinetic energy redistribution.

- Applications

- Beverage capsules, Secondary packaging, Coffee capsules, Compostable capsules, Carton packaging, Recyclable capsules

- End products

- Variety pack cartons for beverage capsules, Espresso coffee capsules, Green tea capsules, Latte macchiato capsules, Multi-layered carton packs for capsules, Compostable espresso capsules, Tamper evident beverage capsule packs, Herbal infusion capsules, Nested arrangement cartons for capsules, Flip top closure carton packs for coffee capsules, Recyclable tea capsules

- Steps before

- Capsule filling, Capsule transfer feeding

- Steps after

- Carton packing, Carton closing

- Input ingredients

- capsules, flat blank cartons

- Output ingredients

- packed cartons, cartons with capsules

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Production speed

- up to 90 cartons/min

- Capsule feed rate

- up to 900 capsules/min

- Average power consumption

- 15 kW

- Operating Pressure

- 6 bar

- Maximum air consumption

- 800 Nl/min

- Weight

- 5000 kg

- Automation

- Fully servo-driven movement

- Carton styles

- Variety including tubes

- Changeover time

- Quick size changeover

- Carton filling configuration

- Single or multi-layer with interlayers/inlays

- Closure options

- Top Flap, Additional lateral flaps, Flip Top closure

- Automation level

- Fully Automated / Servo-driven

- Capsule handling method

- Pick, Place / Gripper-suction cup

- Size changeover

- Quick changeover

- Carton feeding method

- Flat blank carton magazine

- Feeding system

- Bucker chain / Capsules recirculation

- Efficiency

- Optimized carton space / Material saving

- Speed

- 900 capsules/min, 90 cartons/min

- Modularity

- Single or double magazine option

- Carton closure types

- Top Flap / Flip Top

- Motorization

- Energy-efficient / Kinetic energy recovery

- Compostable material compatibility

- Yes

- Recyclable material compatibility

- Yes

- Recycled material compatibility

- Yes

- Capsule arrangement

- Alternated / Nested

- Carton styles

- Single / Multi-layer / Tubes

- Closure options

- Top Flap / Flip Top / Lateral flaps

- Material compatibility

- Compostable / Recyclable

- Changeover time

- Simple size changeover

- Carton magazine

- Single / Double flat blank