Manufacturing Active Pharmaceutical Ingredients (Api)

Find innovative production technology for making active pharmaceutical ingredients (api) and connect directly with world-leading specialists

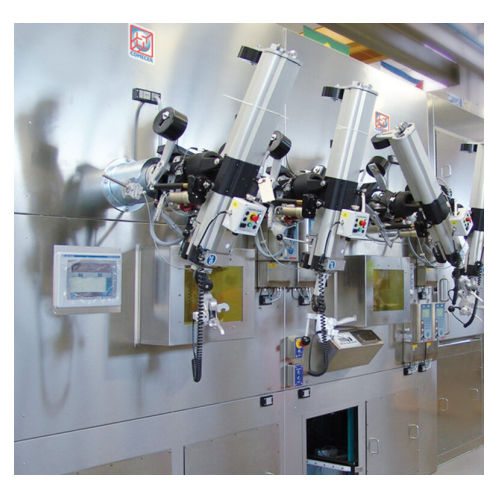

API making equipment must observe rigorous quality control standards across the entire manufacturing process. The pharmacodynamic properties of active pharmaceutical ingredients API make them highly sensitive to their environment, making API manufacturing and production a tightly regulated field.

Top technology picks for making API

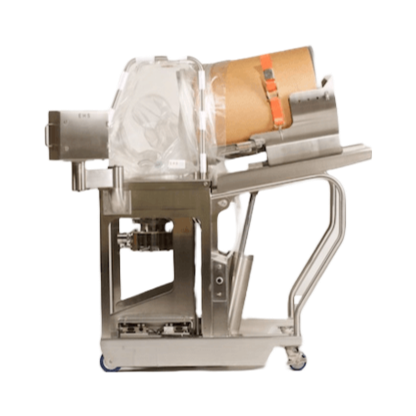

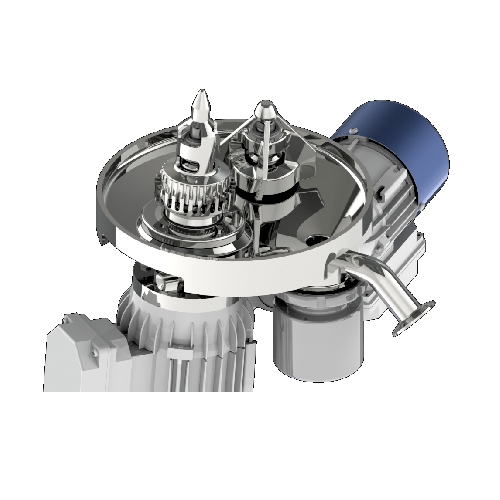

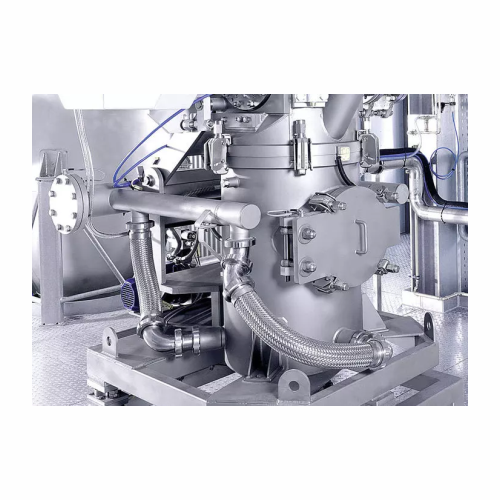

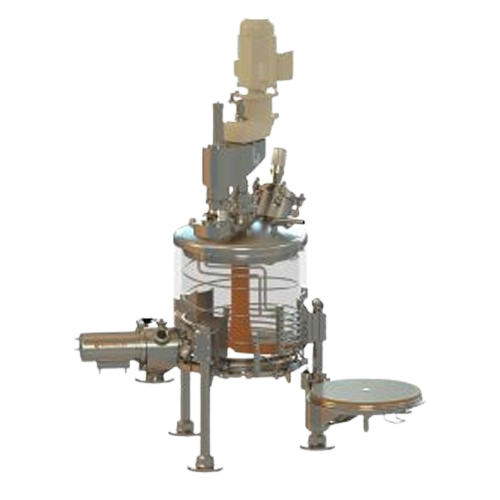

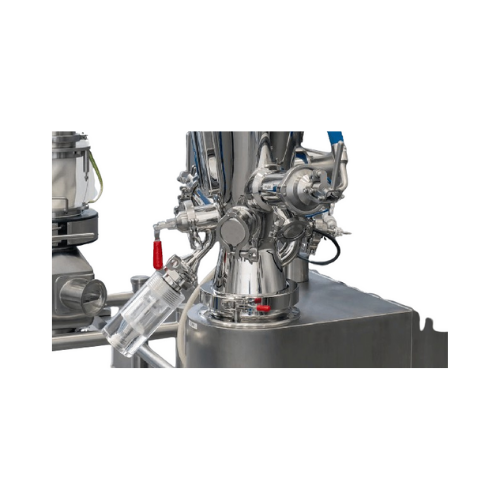

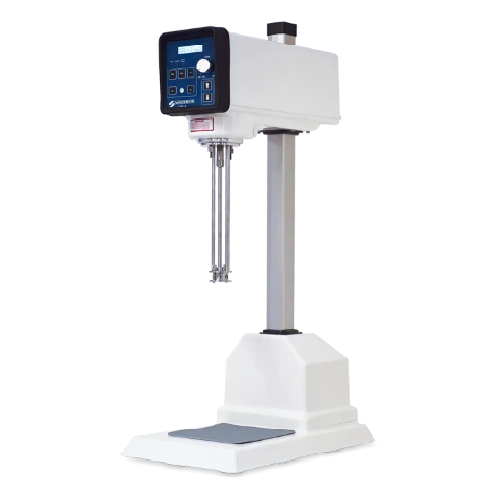

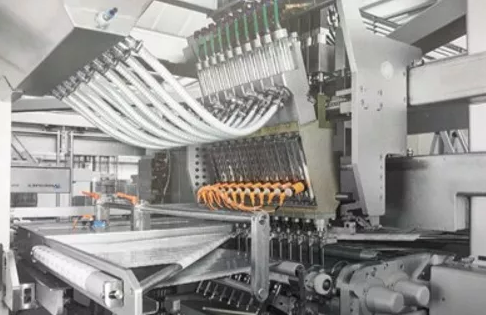

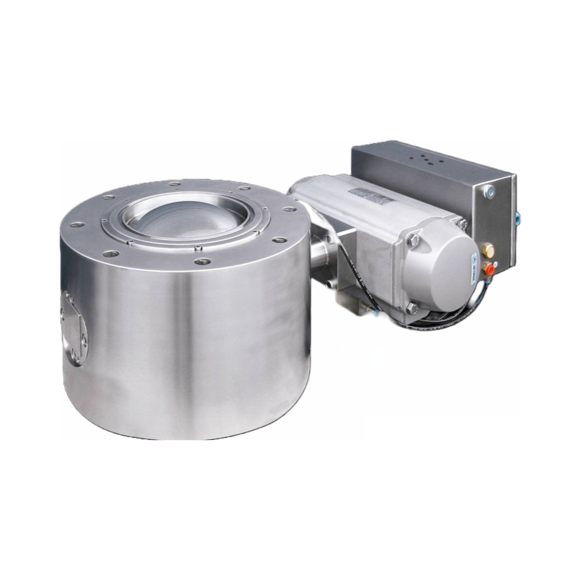

Agitator bead mill for API

To achieve precisely defined API properties and safe and reproducible production, rigorous implem...

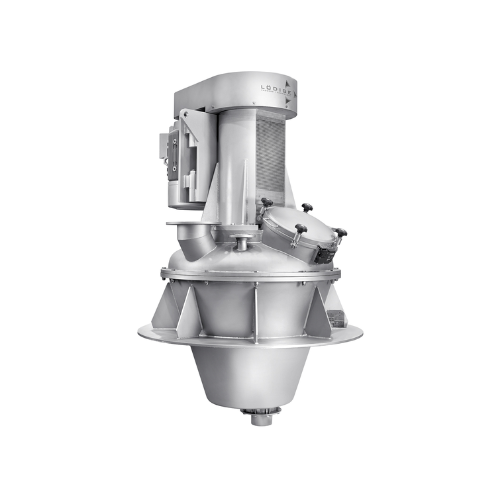

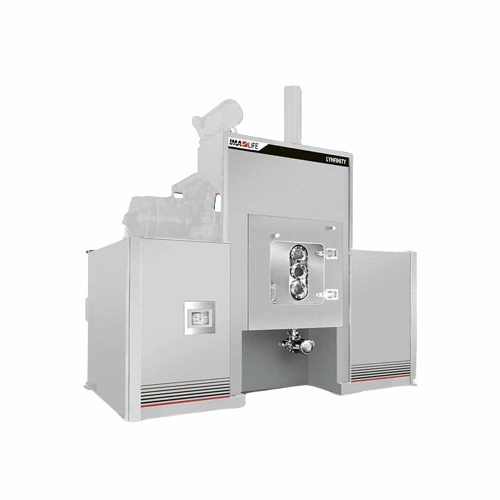

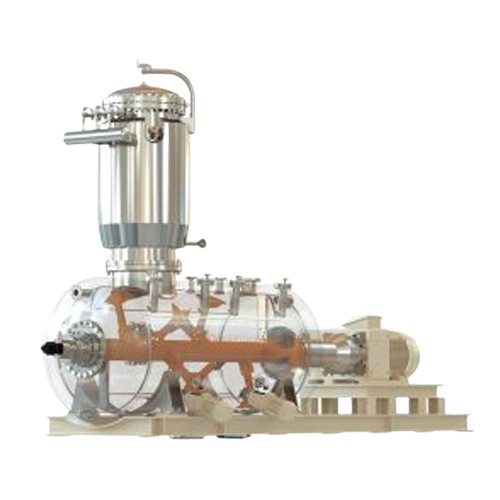

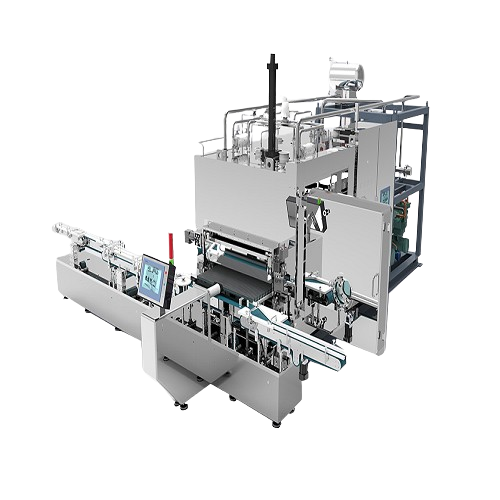

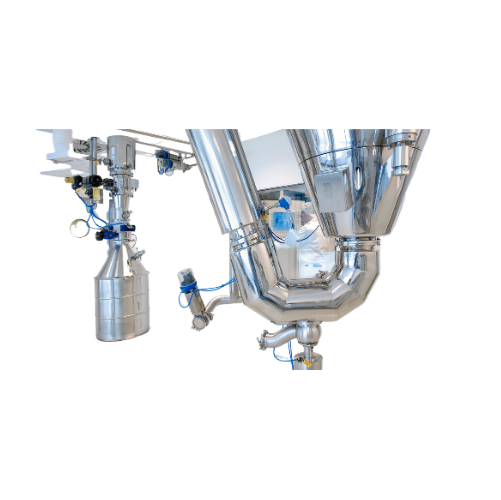

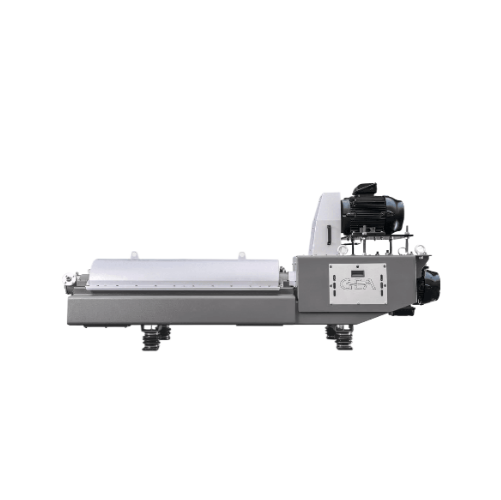

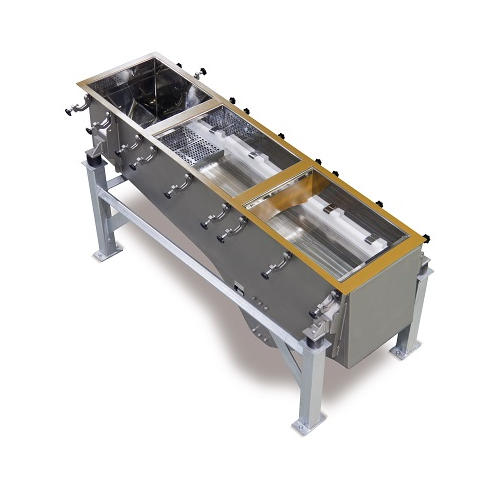

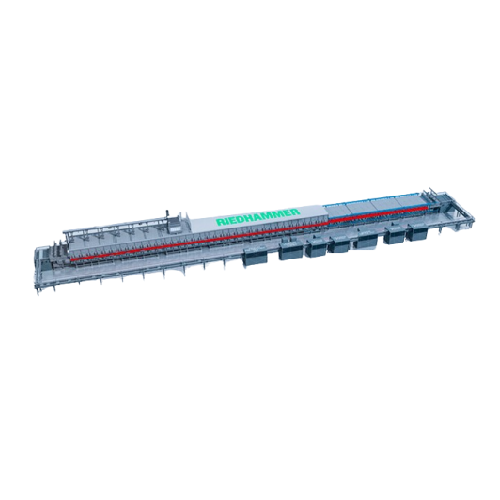

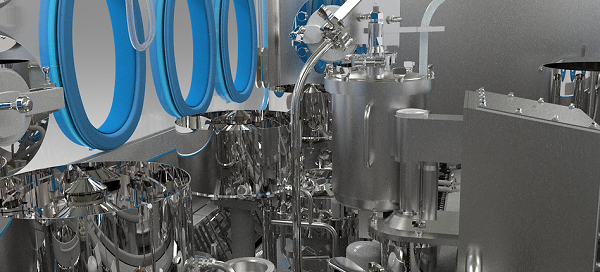

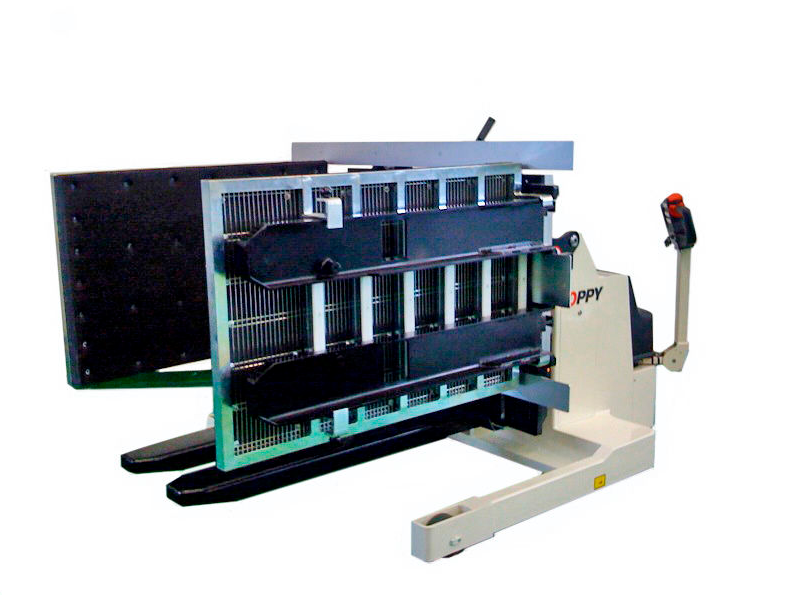

Continuous wet granulator and dryer for R&D

Pharmaceutical laboratories need compact equipment to handle and produce small...

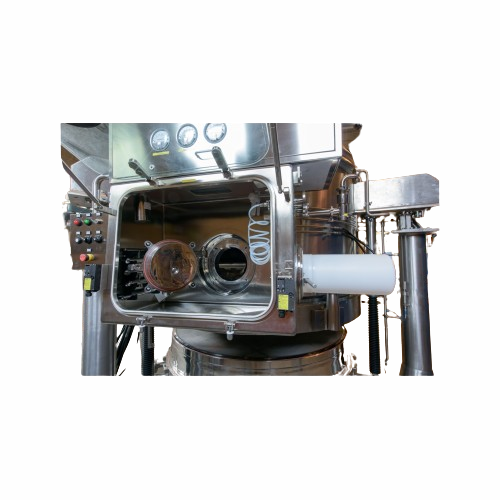

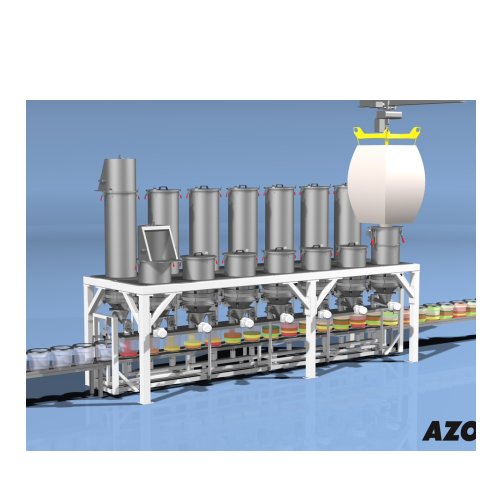

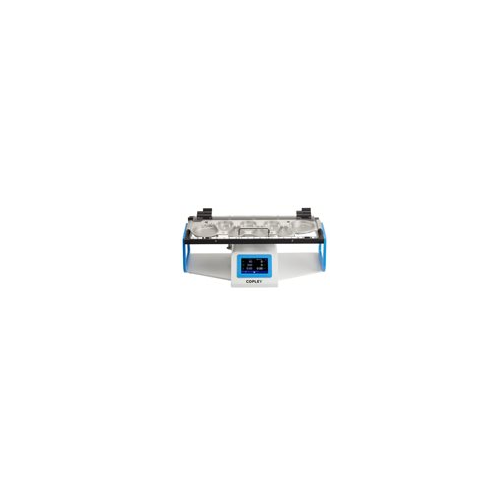

Automatic tablet coater for lab scale

The ability to coat tablets in an even and controlled way is an important stage in th...

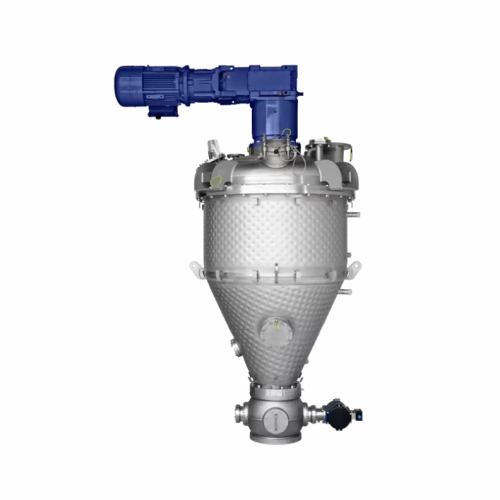

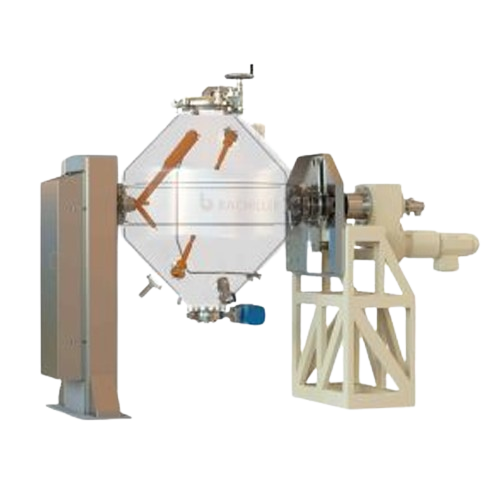

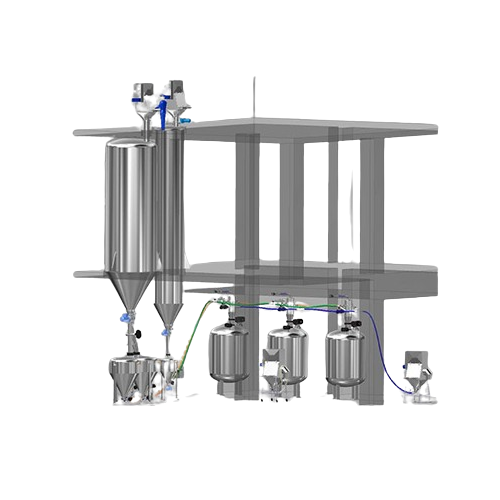

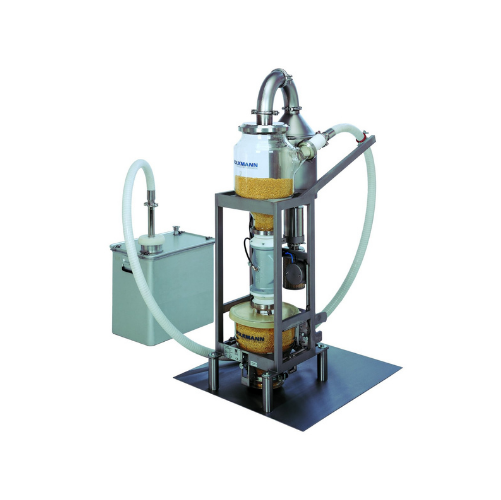

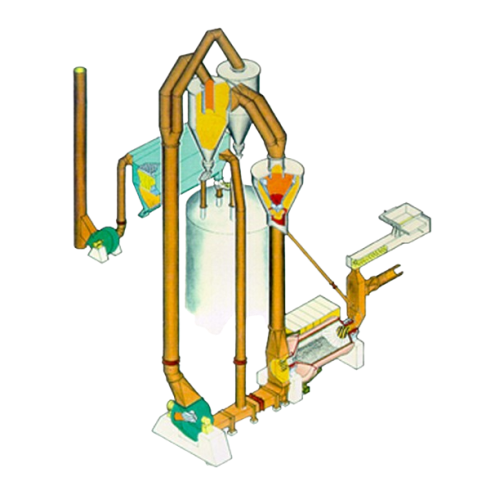

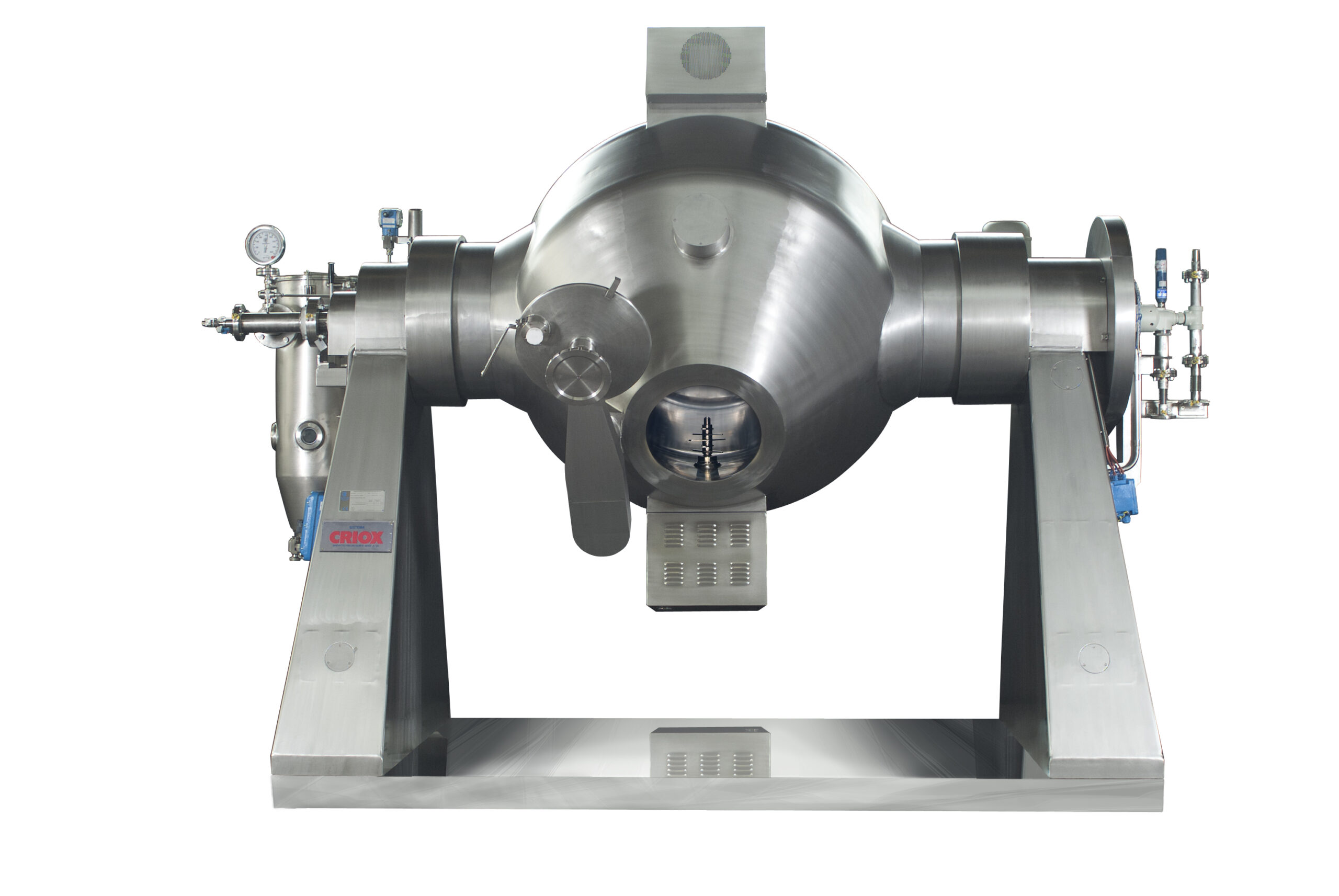

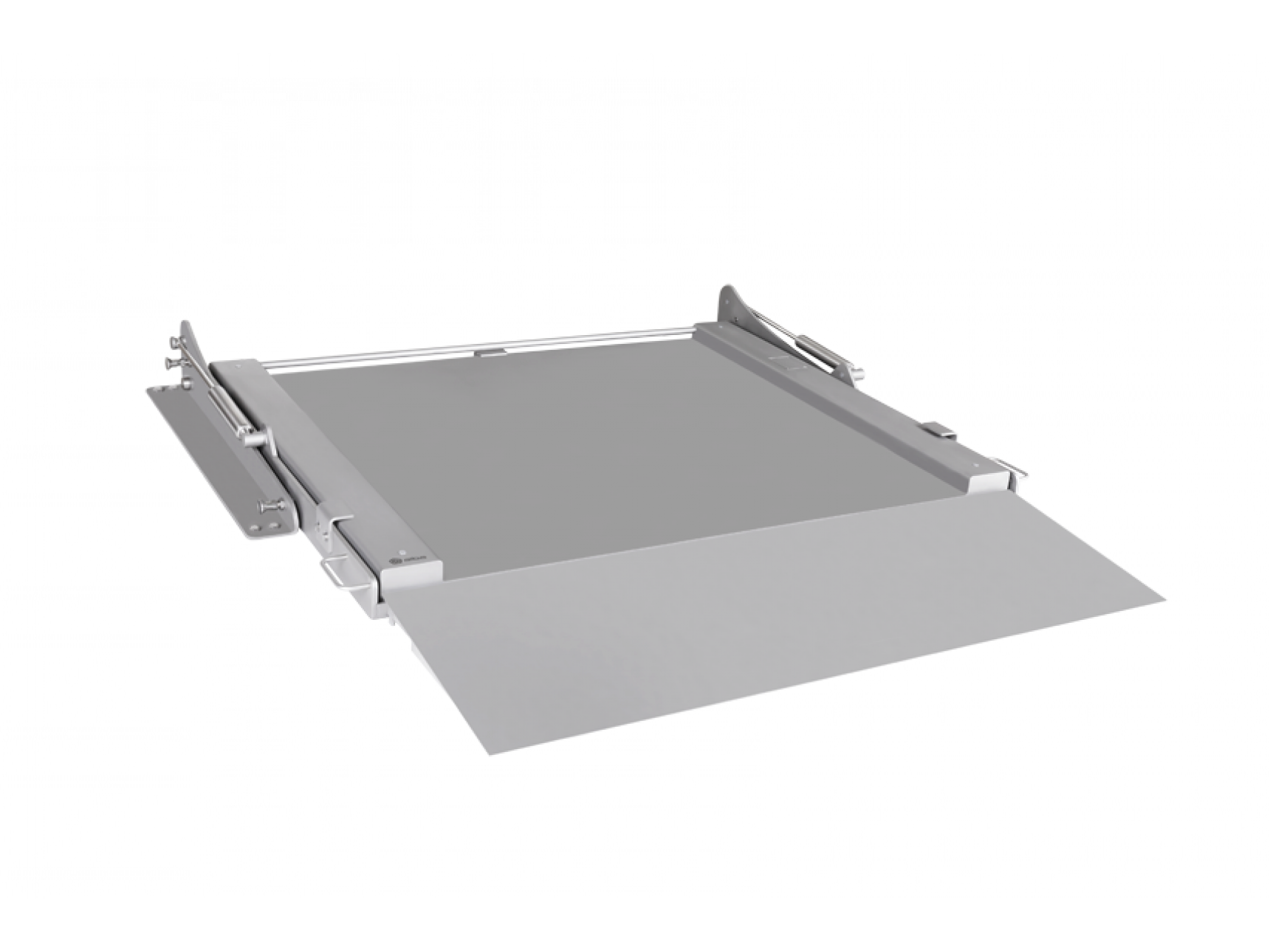

3D powder mixer for active pharmaceutical ingredients

Proper mixing and homogenization are essential to achieve a reliabl...

Stories about active pharmaceutical ingredients (api)

Scientifically tested continuous drying for your tablets

Aim your safety standards high, while granulating dry

Discover the best mix for your blending application

Wet milling: The revolution in the API production

Closing the containment loop in HPAPI manufacturing

Lowering heat stresses on API by reducing friction

Select your active pharmaceutical ingredients (api) process

Tell us about your production challenge

Manufacturing API from a natural, synthetic, or semi-synthetic base

Synthetic APIs are developed from chemical conversions in a lab. Natural APIs, on the other hand, are derived from plants or animals and then purified. Semi-synthetic options stand somewhere in between. They are extracted from natural sources but then biochemically converted into the final Active Pharmaceutical Ingredient API.

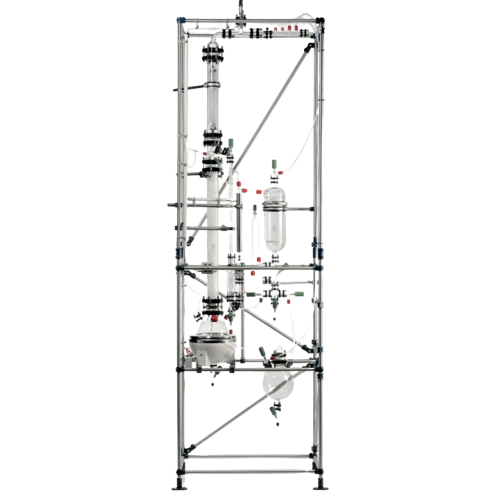

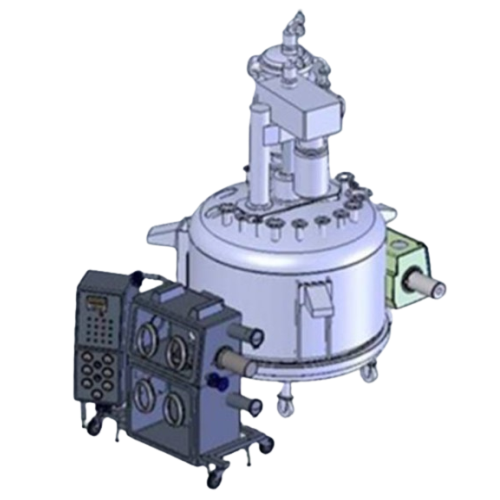

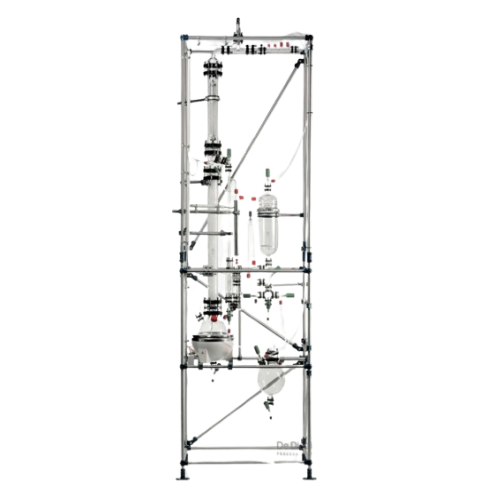

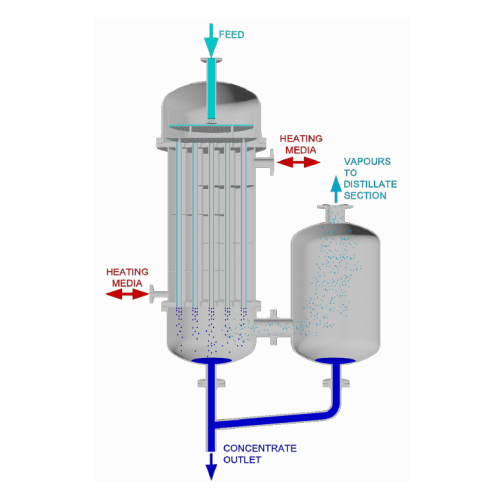

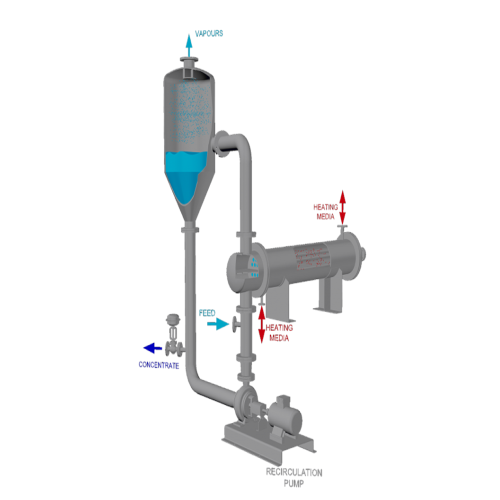

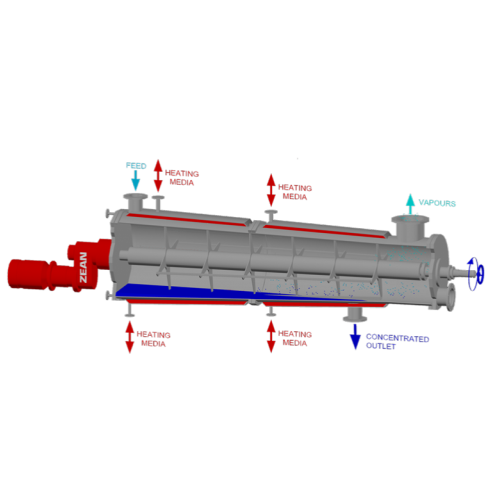

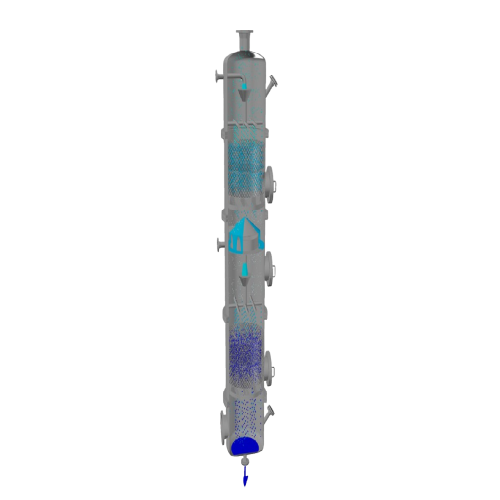

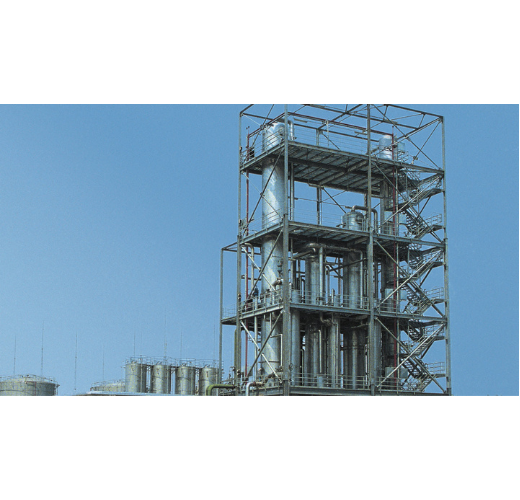

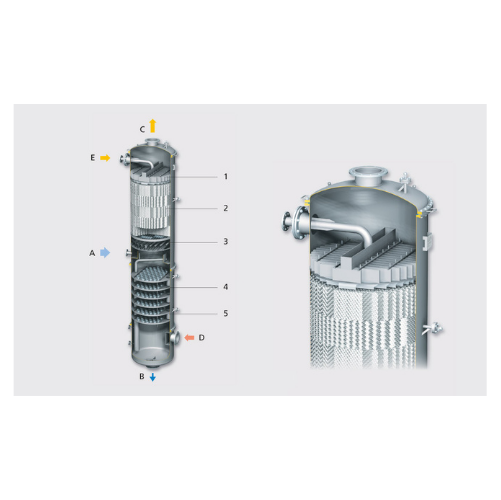

The three main groupings of active pharmaceutical ingredients, however, employ similar extraction methods. The intermediaries are extracted from raw materials in a reactor before passing through a series of filtering and centrifuges for isolation and purification. Depending on the finished products, API are milled or freeze-dried before packaging. Distillation is also a key process used in the manufacturing of APIs. The distillation process is used to purify and isolate the desired compound from a complex mixture of chemicals.

Follow GMP standards for your API making equipment

Your API processing equipment must have official certification for reaching production standards.

There are multiple protocols, but Good Manufacturing Practices (GMP) are the global benchmark in pharmaceutical product certification. The World Health Organization (WHO) issues guidelines in this department but other jurisdictions such as China, the EU, and Canada have developed their own GMP.

Classification of API must be clearly displayed on your product label

There are hundreds of active pharmaceutical ingredients used for a wide range of finished pharmaceutical products. Orphenadrine, for example, is the main API found in muscle relaxants, while antivirals are composed of oseltamivir carboxylate. The pharmacological effects of antidepressants are driven by active ingredients such as memantine, amitriptyline, and citalopram. APIs come in various forms such as powders, liquids, tablets and capsules.

The WHO keeps and updates a catalog of all API, ensuring common application and labeling across all pharmaceutical manufacturing markets. The names of these ingredients are non-proprietary and must be displayed under the brand names of packaged pharmaceutical products.

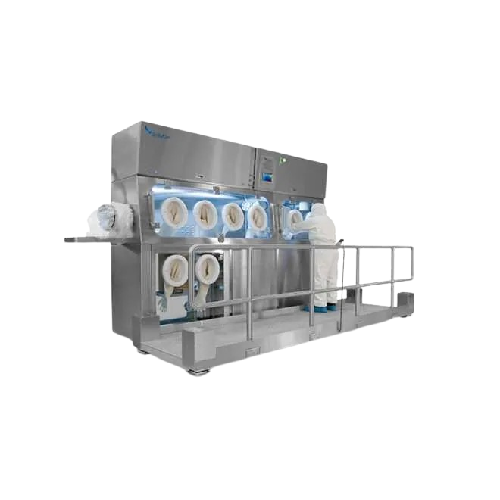

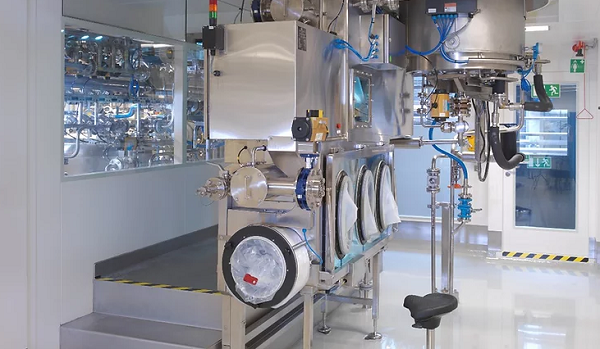

HPAPI manufacturing requires expert containment solutions

The API sector is moving in the direction of highly potent active pharmaceutical ingredients (HPAPI). These special components deliver a stronger drug efficacy than regular API and at a reduced dose. Medicines made from HPAPI minimize side effects and are an important development in the treatment of chronic conditions.

Manufacturing HPAPI, however, raises a series of considerations. Producers must ensure strict handling and cleansing procedures to adhere to occupational exposure limits (OEL) and rigorous quality control to keep their workers safe.

Processing steps involved in active pharmaceutical ingredients (API) making

Which active pharmaceutical ingredients (api) technology do you need?

Separators for pharma extraction

Optimize your pharmaceutical extraction process with innovative centrifugal separation tech...

Pharma extraction clarifier

Achieve superior purity in pharma extraction with efficient separation of solids and liquids, se...

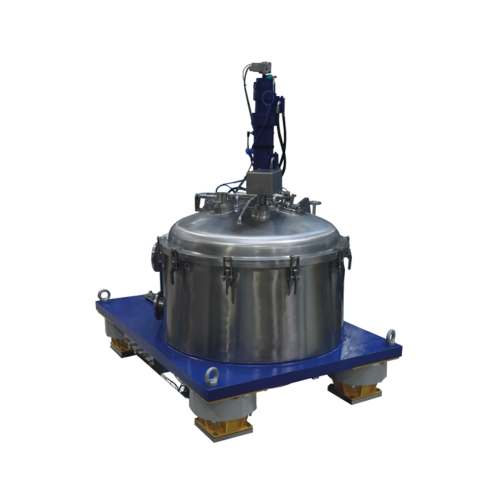

batch centrifuge for solid-liquid separation

Achieve precise solid-liquid separation in high-demand environments with a ma...

Vertical batch centrifuge for solid-liquid separation

Optimize your solid-liquid separation process with high-speed centr...

Horizontal batch centrifuge for chemical industry

Optimize your solid-liquid separation with a centrifuge designed for pr...

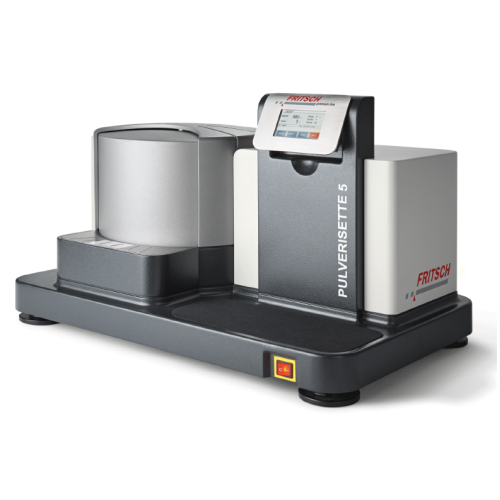

Planetary ball mills for fine grinding of materials

Optimize particle size and surface area in your samples with high-ene...

Ultra centrifugal mill for size reduction of soft and medium-hard materials

Achieve precise particle size reduction an...

Drum mills for fine grinding of large volumes

Achieve consistent and precise pulverization of large sample volumes with dr...

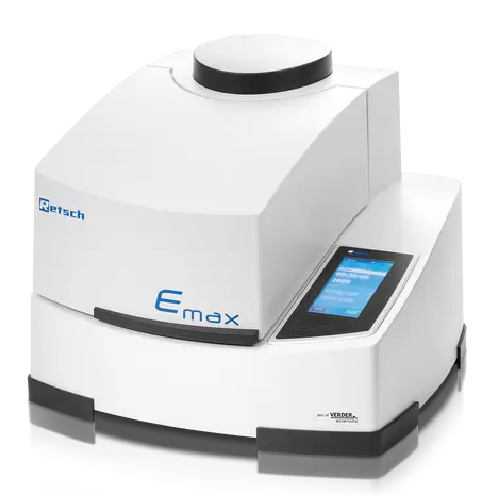

High energy ball mill for ultrafine grinding

Achieve nanoscale precision and unmatched particle uniformity with high-energ...

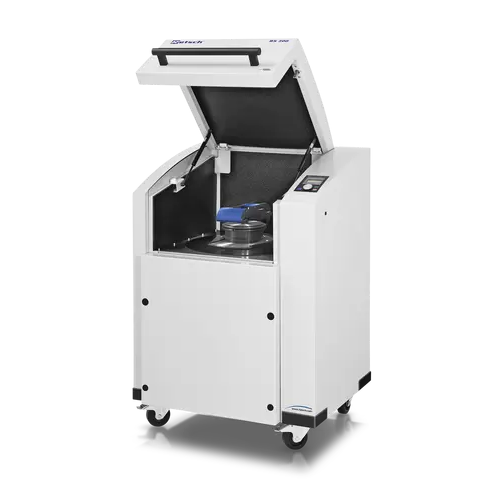

Vibratory disc mill for sample homogenization to analytical fineness

Achieve exceptional precision in sample preparatio...

Ultrafine grinding solution for nanoparticles

Achieve ultrafine particle sizes with high-speed precision, ideal for labora...

Rotating sample divider for large bulk materials

Achieve precise, dust-free division and volume reduction of bulk material...

Fluid bed dryer for bulk material laboratory drying

Efficiently dry and mix organic and inorganic materials with precise ...

Sample dividing solutions for laboratory applications

Streamline your lab’s precision in sample preparation with so...

Industrial powder security screening and de-agglomeration

Ensure product purity by efficiently screening and de-agglomer...

Conical milling for high-efficiency particle sizing

Maximize efficiency in your production line with conical milling tech...

Production-scale milling and screening system

Achieve precise particle size distribution and high throughput rates with a ...

Cone mill for size reduction

Achieve precise particle size reduction and deagglomeration with minimal heat generation, ensur...

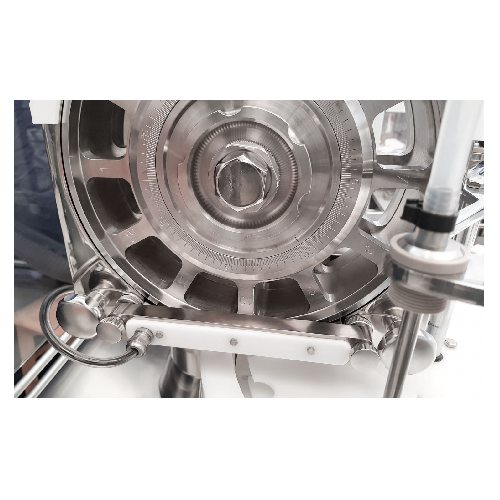

Microsphere refiner for aseptic drug manufacturing

Achieve precise control over microsphere drug formulations with this m...

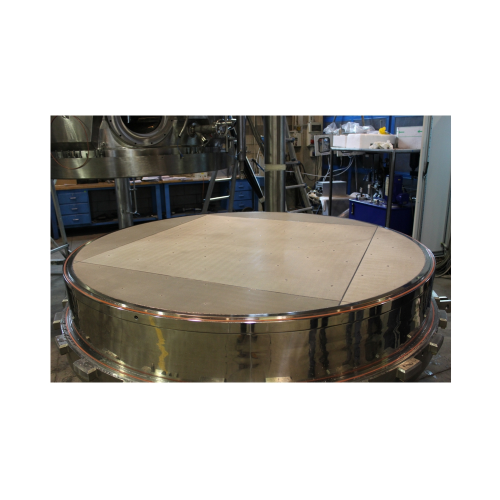

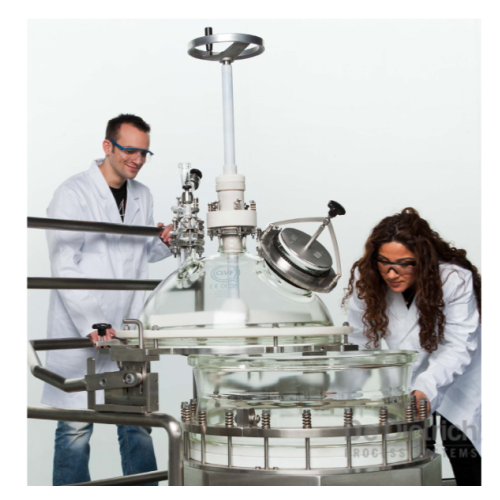

Agitated nutsche filter dryers for chemical synthesis

Enhance your production efficiency by integrating a system that com...

Vacuum tray dryer for pharmaceutical applications

Optimize drying of heat-sensitive compounds while maintaining product i...

Laboratory nutsche filter dryer for solid-liquid separation

Optimize your lab processes with a versatile benchtop filter...

Pilot scale nutsche filter dryer for solid-liquid separation

Achieve maximum product recovery and consistent quality wit...

Nutsche filter dryer system for small scale batches

Efficiently tackle filtration and drying challenges with a compact, m...

Vacuum cold trap for efficient purging and drying

Optimize your laboratory’s efficiency by integrating high-perform...

Diaphragm vacuum pumps for laboratory applications

Optimize your lab processes with oil-free diaphragm vacuum pumps, ensu...

Compact laboratory chiller for recirculating temperature-controlled fluid

Ensure consistent cooling and significant wa...

Immersion chiller for laboratory applications

Achieve precise temperature control in extraction labs and research environm...

Deep water bucket bath for lab heating applications

Achieve precise temperature control and uniform heating for delicate ...

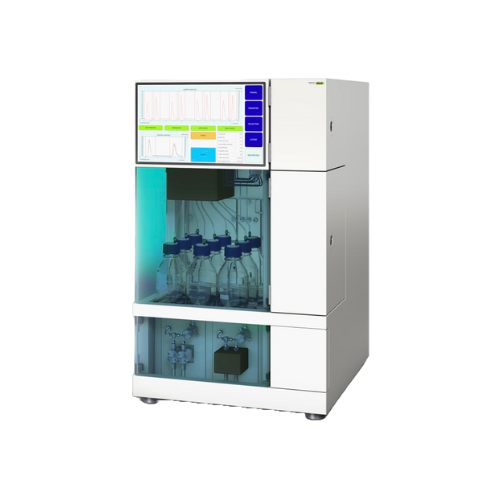

Dissolution profiling system for biorelevant media volumes

Optimize your lab’s efficiency by integrating this dissolutio...

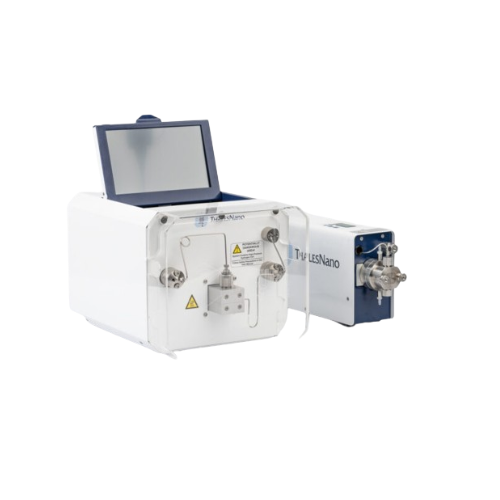

In vitro dissolution and flux measurement platform

Optimize drug formulation by accurately assessing dissolution, solubil...

In-situ fiber optic Uv-vis spectrometer for dissolution studies

Optimize drug formulation by obtaining real-time, in-sit...

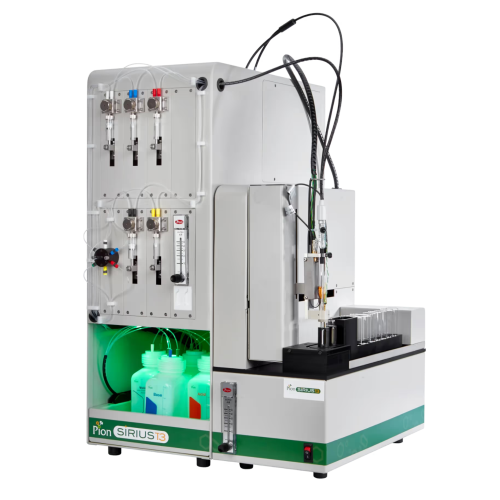

Automated platform for determination of physicochemical properties

Optimize your compound screening process with a full...

Dissolution-absorption study system for drug formulations

Optimize drug formulations with precise in-situ dissolved subs...

In-vitro dissolution-absorption assessment

Optimize drug formulation tests by combining dissolution and absorption measure...

Uv monitoring system for small volume dissolution studies

Efficiently monitor small-volume dissolution processes in real...

Low-volume dissolution-absorption testing system

Optimize your development of oral formulations with a device that enables...

15l vertical-wheel bioreactor for cell therapy scale-up

Accelerate your cell therapy scale-up with a bioreactor that offe...

Large-scale bioreactor for cell therapy manufacturing

Tackle the challenge of scaling therapeutic cell production with a ...

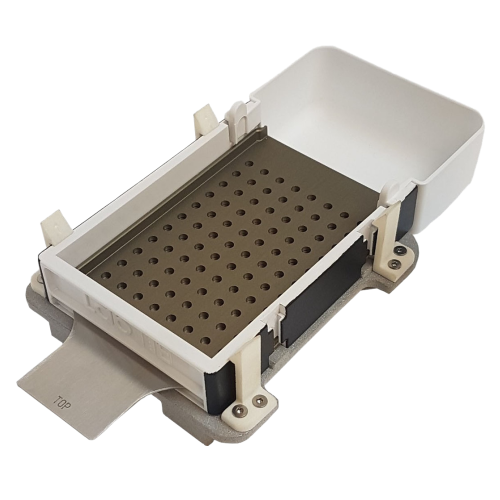

High-speed capsule filling system

Maximize production efficiency with high-speed capsule filling designed for precise dosin...

Aseptic bag-in-box filler for laboratory use

Achieve aseptic filling precision on a lab-scale with a compact solution that...

Micro-dosing system for pharmaceutical powders in vials

Ensure accurate aseptic dosing of sensitive pharmaceutical powder...

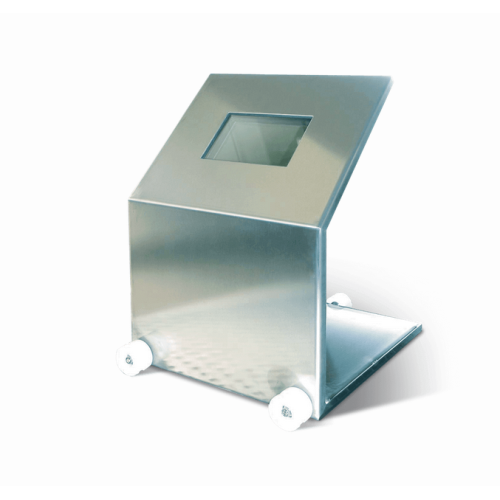

Lab powder dispenser for precision measurements

Effortlessly streamline your lab’s powder dispensing tasks with a ve...

Laser diffraction particle size analyzer

Achieve precise particle size analysis with laser diffraction technology, ensuring...

Nanoparticle size analyzer

Master precise nanoparticle and zeta potential analysis with dynamic light scattering technology,...

Dished end for optimized mixing in small-volume vessels

When space constraints challenge vessel design, this solution eli...

High power mixing solution for powder applications

Achieve rapid, uniform mixing of challenging powders and non-shear sen...

Flexible powder recipe formulation system

Streamline your batch production with efficient, dust-tight formulation and blen...

Ibc blender for industrial powder mixing

Streamline your powder mixing with rapid batch changeovers and reduced cleaning do...

Wet mixer for viscous and paste-like products

Achieve high-quality mixing of medium to highly viscous products with precis...

Vacuum paddle dryer for laboratory use

Achieve precise temperature and moisture control in your batches with this vacuum sh...

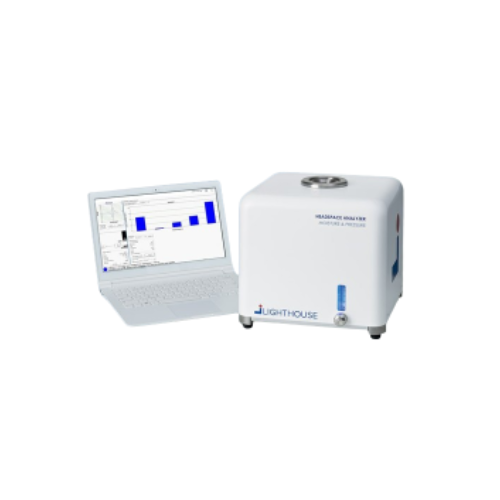

Water activity headspace analyzer for drug product samples

Ensure precise control of moisture levels across the entire p...

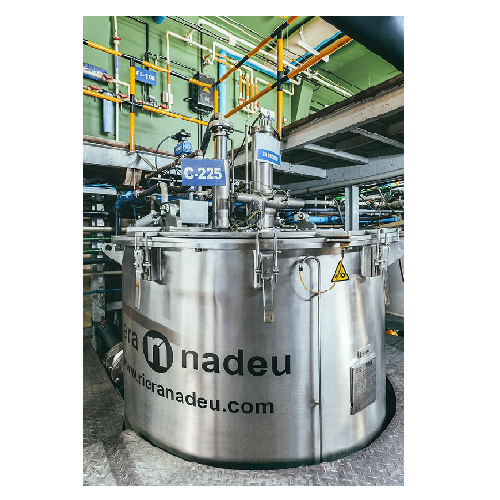

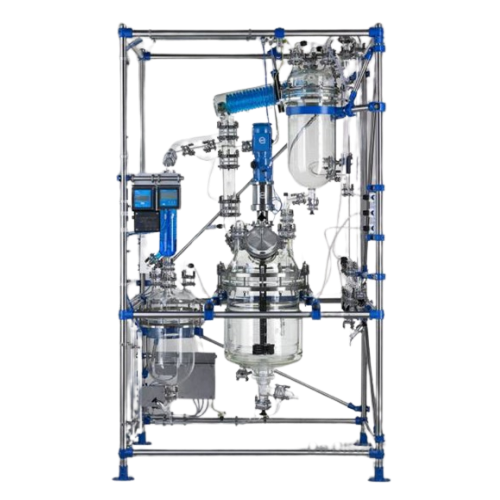

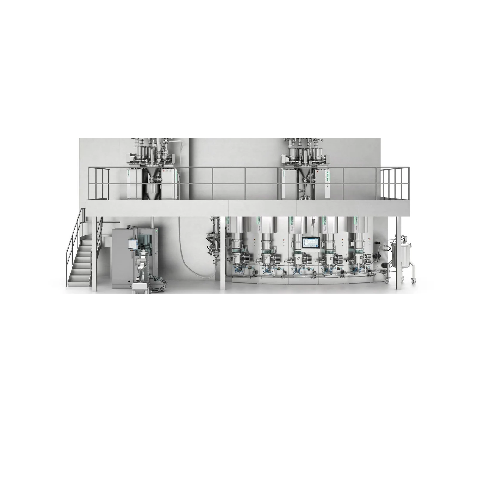

Highly scalable reactors for chemical synthesis

Optimize your production line with versatile reactors designed for seamles...

Laboratory mill for dry sample preparation

Achieve precise particle size reduction for pharmaceuticals and fine chemicals ...

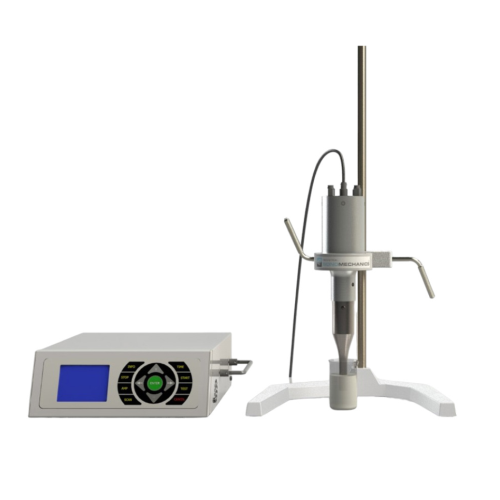

Laboratory dispersion reactor for 2l mixing and reaction processes

Streamline your laboratory processes with a versatil...

Super high shear inline disperser for nanoparticle production

Achieve unmatched particle size reduction with cutting-edg...

Powder induction system for high solid concentrations

Optimize your production line with this advanced system designed to...

Laboratory dispersion reactor for 10l batch processes

Enhance precision and efficiency in lab-scale liquid formulations w...

Ultrasonic liquid processor for feasibility testing and procedure optimization

Optimize your liquid formulations by en...

Vibrating control screeners for high volume screening and sifting

Ensure precise material separation with a solution de...

Heavy duty lump breaker for coarse and pre-grinding

Achieve consistent particle size reduction with this heavy-duty solut...

Universal mill for fine grinding in food and pharma industries

Achieve unparalleled particle size reduction with high-pe...

Air classifier mill for ultra-fine powder grinding

Optimize your milling operations with precision particle size control ...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

Stand dispersing unit for pilot plant applications

Achieve precise particle size reduction and efficient mixing with this...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

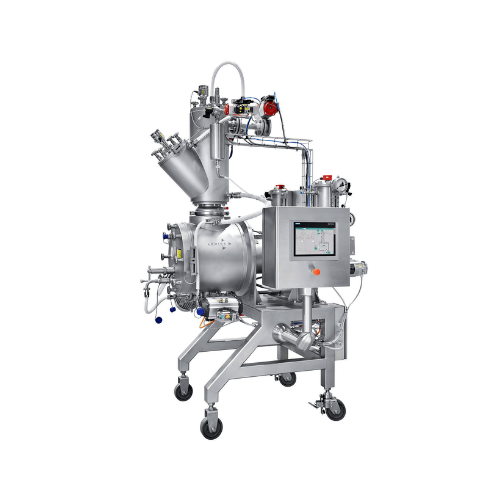

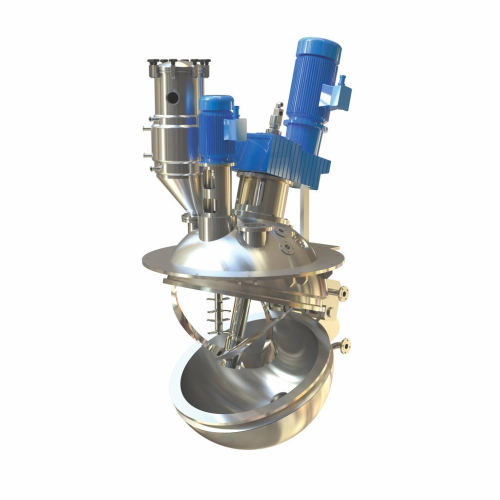

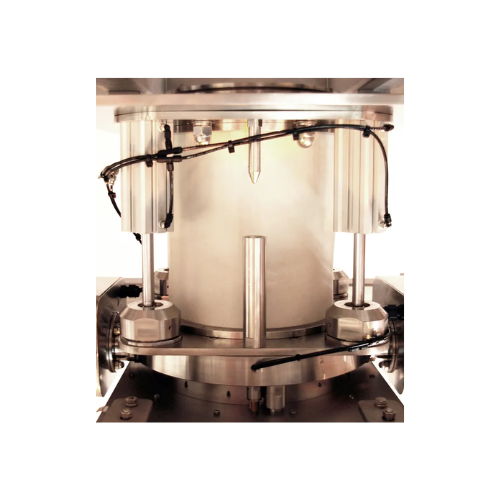

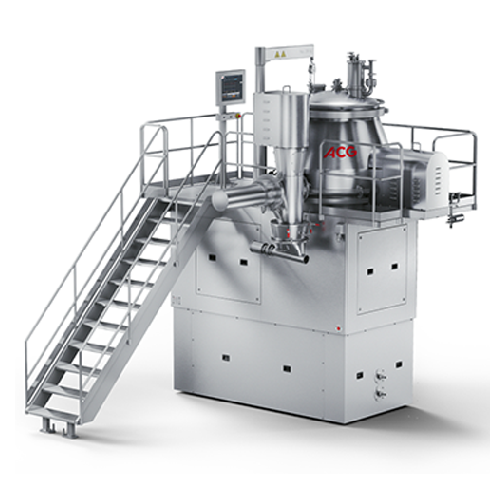

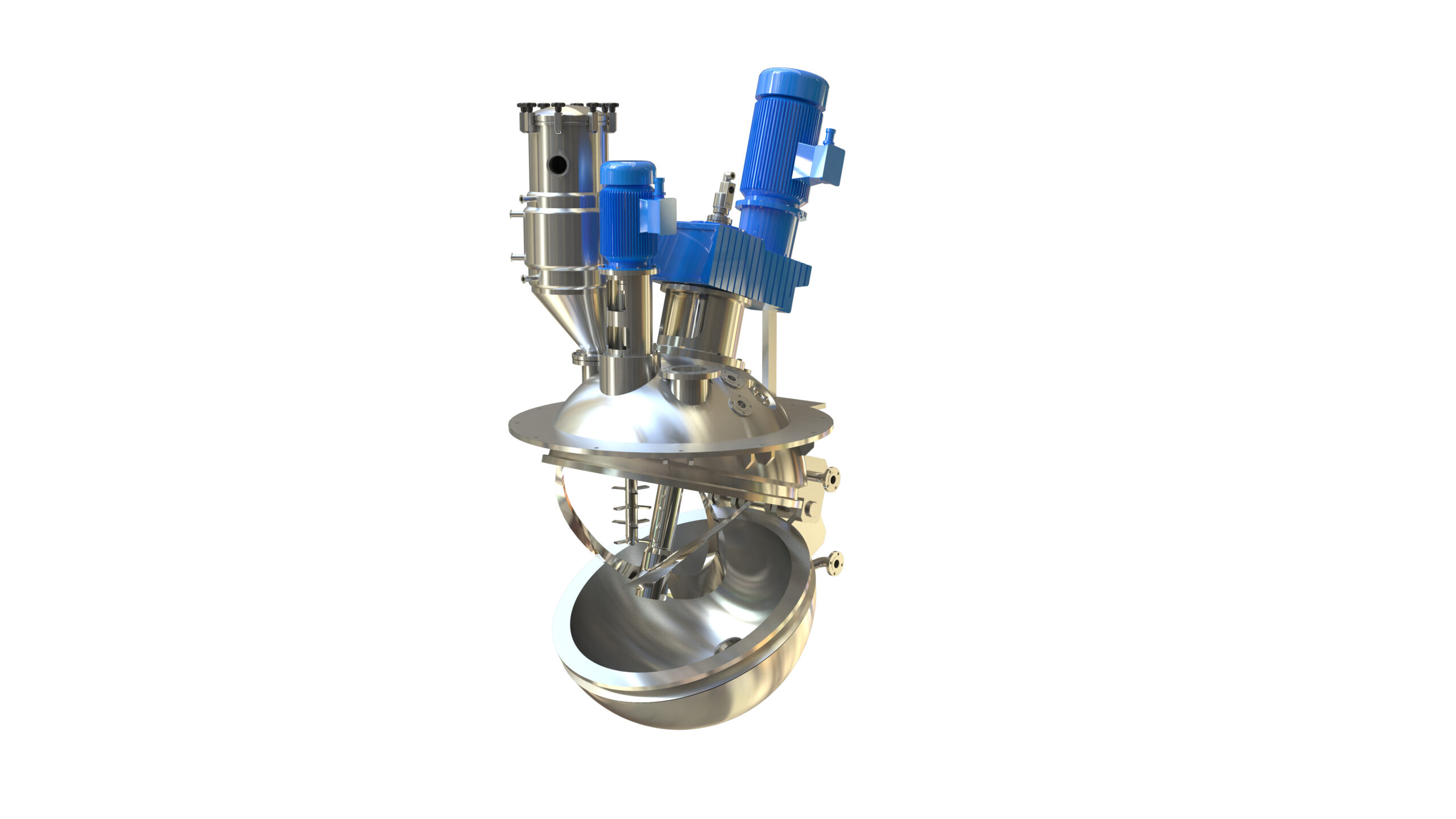

Single-pot granulation processor for pharmaceutical applications

For manufacturers needing precise granulation and dryin...

Powder filling and stoppering for antibiotic production

Tackle antibiotic resistance with precision powder filling and st...

Industrial tablet coating solution

Achieve precise film and sugar coatings on a versatile range of tablet and pellet forms,...

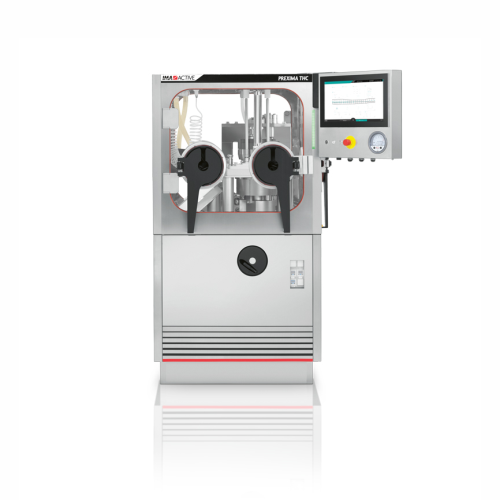

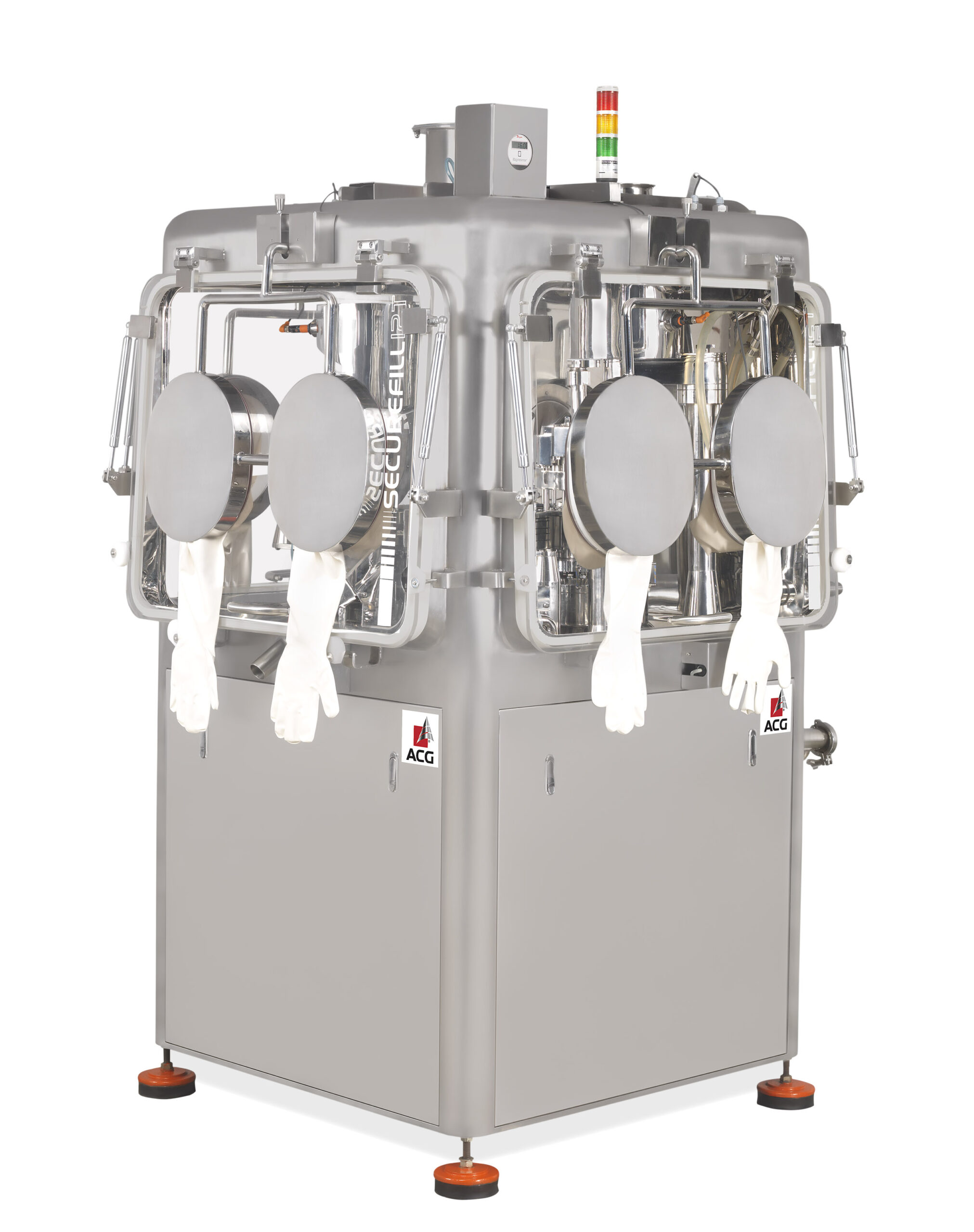

Tablet press for high containment environments

For handling potent compounds without compromising safety, a high-containme...

Pilot freeze dryer for pharmaceutical applications

Optimally bridge laboratory development and full-scale production with...

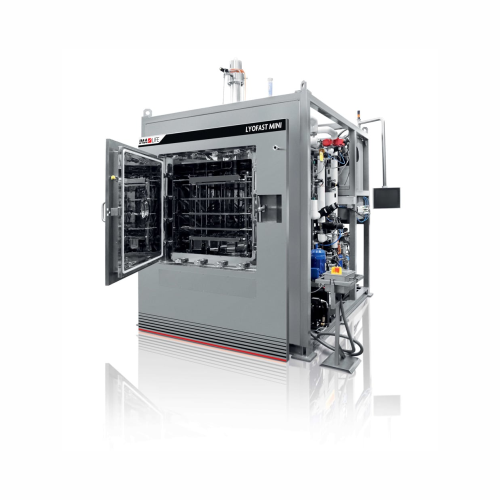

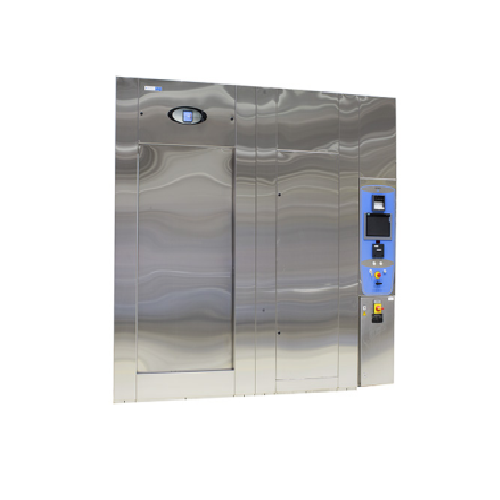

Industrial GMP freeze dryer

Optimize the lyophilization of sensitive pharmaceutical compounds with a machine designed for pr...

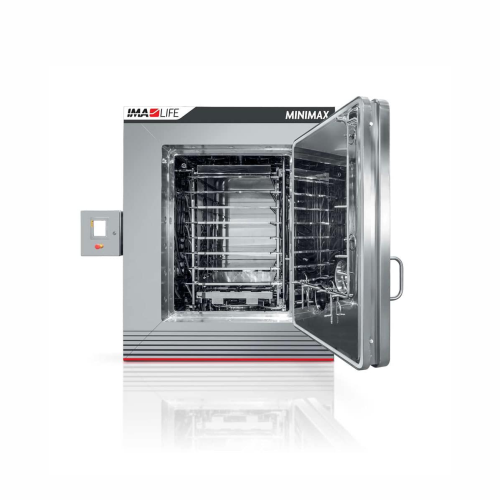

Small-scale freeze dryer for pharmaceutical applications

Optimize small-batch and pilot-scale lyophilization with advance...

Continuous aseptic spray-freeze-drying system

Achieve higher sterility and improved product uniformity with a continuous a...

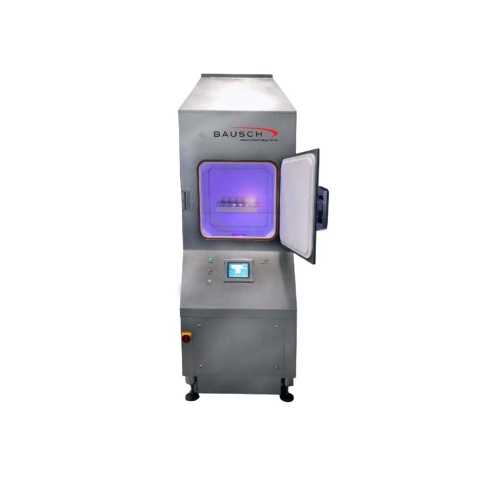

Pharmaceutical components washing station

Ensure optimal cleanliness with high-efficiency washing and drying of pharmaceut...

Customised tank systems for liquid and bulk material storage

Ensure safe and compliant storage of liquids and bulk mater...

Continuous mixing for fine and cohesive powders

Achieve unparalleled mixing precision for cohesive powders while reducing ...

Batch mixer for segregative, free-flowing powders and pastes

Achieve precise and gentle batch mixing for delicate produc...

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Choppers and disintegrators for industrial size reduction

Enhance your production efficiency by mastering size reduction...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Lab-scale powder processing system

Achieve precise control in ultra-small batch processing with a versatile modular system,...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

Laboratory vacuum dryer for heat-sensitive materials

Optimize moisture control in heat-sensitive materials with precise a...

Containment solutions for hazardous material processing

Ensure safe and efficient processing of hazardous materials with ...

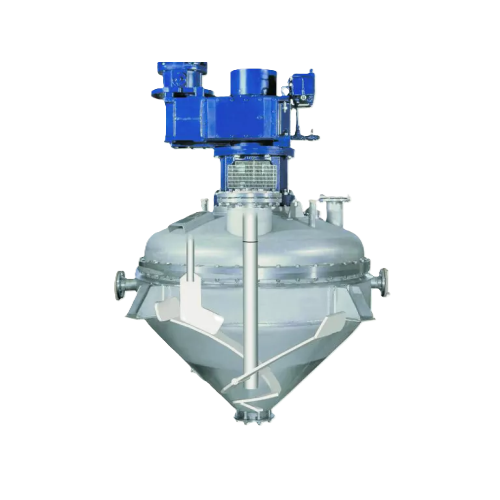

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Pharmaceutical freeze dryer

Achieve contamination-free, high-quality pharmaceutical powders through an innovative freeze-dry...

Conical paddle vacuum dryer for powders and granules

Achieve efficient drying of sensitive materials with this versatile ...

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Ultra-fine powder grinding with jet mills

Achieve unparalleled fineness and purity in powder production with cutting-edge ...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

Ultrafine air classifier for powder separation

Achieve precise particle separation with technology designed to enhance you...

Laboratory vacuum milling for fine particle size reduction

Streamline your lab and pilot processes with high-speed vacuu...

Vacuum recirculation mill for particle size reduction

Achieve precise particle size reduction and eliminate air entrapmen...

Immersion mill for pail and drum-sized batches

Streamline your production with a versatile solution that efficiently handl...

Compact full product inspection system for pharmaceuticals

Easily detect fill level inaccuracies, closure misalignments,...

Vial inspection system for pharmaceutical products

Ensure the integrity and safety of parenteral drugs with advanced imag...

Syringe and cannula inspection system

Ensure flawless quality in injectable products with advanced inspection technology th...

Vacuum pan dryer for heat-sensitive pasty products

When dealing with highly viscous, heat-sensitive products, efficient m...

Vertical vacuum dryer for heat sensitive products

Achieve optimal drying and mixing for your heat-sensitive and shear-sen...

Containment system for filter dryers

Ensure safe handling and containment of hazardous materials during sampling and discha...

Chemical filter dryer for fine chemical production

When processing chemical intermediates, precise filtration and drying ...

Filter dryer with containment system for hazardous materials

Ensure operator safety and product integrity during hazardo...

Pharmaceutical filter dryer

Achieve precise moisture control and efficient drying of sensitive materials with this advanced ...

Multilayer filter plates for pharmaceutical and chemical applications

Achieve efficient filtration and separation in yo...

Horizontal vacuum paddle dryer for bulk production facilities

Achieve precise moisture control in powders with a versati...

Horizontal vacuum paddle dryer for sensitive pharmaceutical ingredients

Achieve precise drying and mixing of sensitive ...

Pilot plant filter dryer for small scale production

Optimize filtration and drying processes in your pilot plant with a v...

Pilot unit filter dryer for laboratory applications

Efficiently manage filtration and drying processes with precise tempe...

Sterilizable filter dryer for pharmaceutical applications

Ensure full sterility and efficient moisture removal in critic...

Vertical peeler centrifuge for pharmaceutical industry

Ensure thorough separation and purification of products with this ...

Vertical pilot plant centrifuge for chemical industry

Optimize your lab and pilot plant operations with this mobile centr...

Vertical pilot plant centrifuge for pharmaceutical applications

Ensure precise separation and optimal scaling in your la...

Conical screw cooker for food production

Optimize batch and continuous operations in your production line with efficient mi...

Conical screw vacuum dryer for hazardous and temperature-sensitive products

When you need precise moisture control for...

Vacuum drying solution for filter cake or viscous materials

When faced with the challenge of drying filter cake or trans...

Cylindro conical mixer for batch mixing

Maximize mixing efficiency in compact spaces with this versatile solution, ideal fo...

Laboratory system for drying and mixing processes

Enhance your R&D capabilities with precise drying and mixing contr...

Pilot plant conical screw dryer

Optimize drying efficiency with this versatile pilot plant solution, ideal for simulating an...

Horizontal pilot plant centrifuge for chemical processing

Enhance your R&D and pilot-scale processes with a centrif...

Horizontal pilot centrifuge for pharmaceutical applications

Achieve precise separation of solid and liquid phases with c...

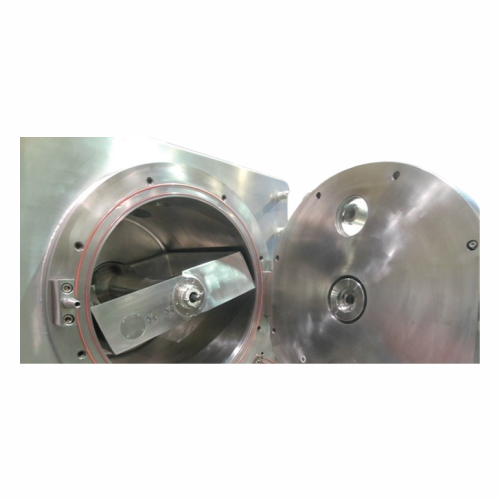

Inverting filter centrifuge for difficult-to-filter products

Designed for challenging filtration tasks, this centrifuge ...

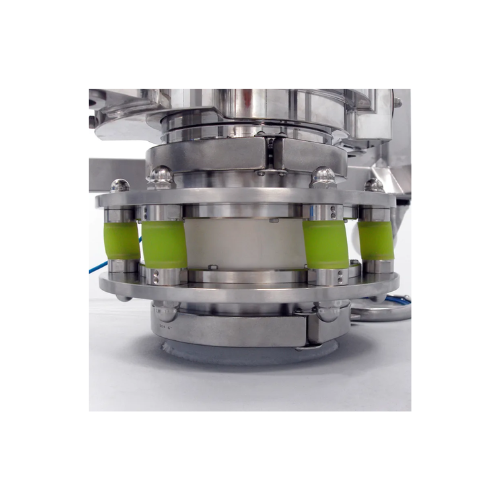

Inverting filter centrifuge for high-potent Api products

Achieve optimal separation and reduce residual moisture with pre...

Separation of cutting fluids from metal chips

Enhance your production line efficiency by effectively separating cutting fl...

Top discharge centrifuge for chemical manufacturing

Achieve precise filtration and separation with top discharge centrifu...

Top discharge centrifuge for pharmaceutical production

Optimize your product yield and quality with precise filtration an...

Classifying centrifuge for wet classification of fine particles

Ensure precise particle classification in continuous pro...

Horizontal peeler centrifuge for chemical applications

Achieve high-throughput product separation and purification with p...

Pharmaceutical horizontal peeler centrifuge

Optimize product consistency and purity with precise separation and filtration...

Lab machine for producing portion packs

Efficiently form, fill, seal, and punch portion packs in laboratory settings with c...

Powder dosing for lab and galenics

Ideal for precise dosing needs, this compact lab device streamlines powder filling proce...

Powder flow control system for gravity transfer

Ensure precise dosing and prevent spillage during powder transfers in your...

Laboratory and pilot scale blending module

Efficiently integrate multiple blending functions on a single drive for streaml...

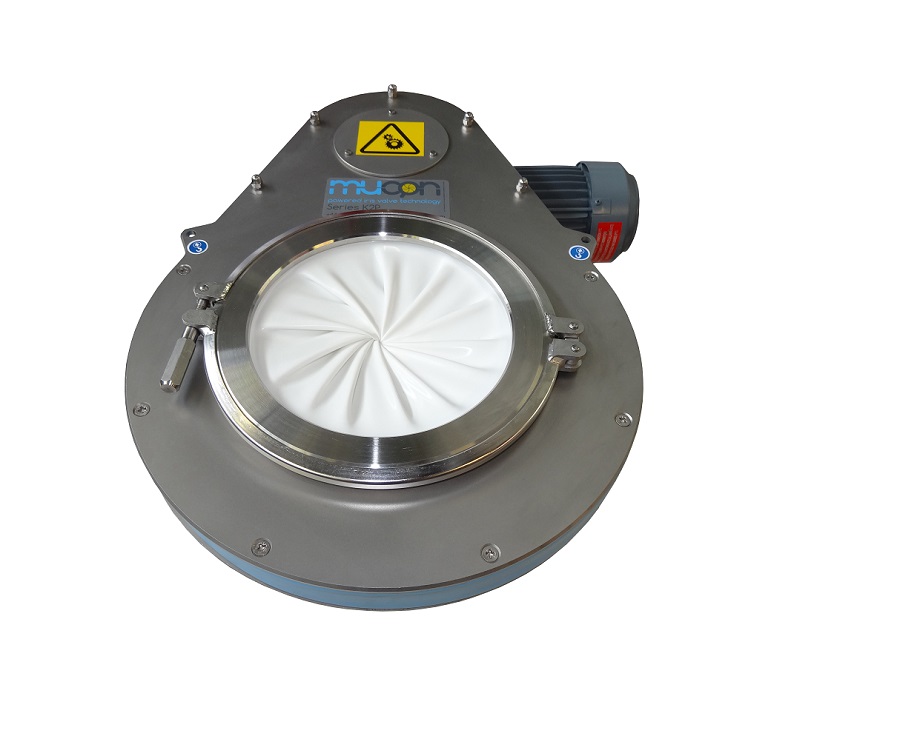

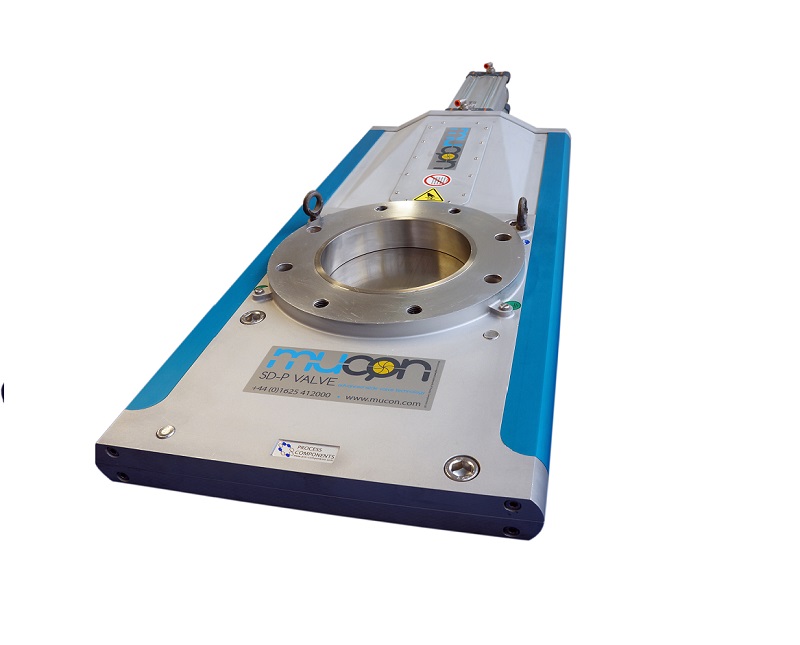

Split butterfly valve for sterile powder transfer

Ensure safe and sterile transfer of powders with unparalleled containme...

Industrial bin blenders for uniform batch production

Optimize your blending process by achieving uniform mixtures with in...

Ibc tumbler for uniform batch mixing

Achieve consistent and homogenous mixing of powders, granules, and solid products with...

Vial filling for pharmaceuticals

Streamline your aseptic processing with vial filling machines that ensure sterile, precise,...

Laboratory filter-reactor for chemical synthesis and extraction

Optimize your chemical processes with a versatile filter...

Lab nutsche filter for small scale filtration

Efficiently manage filtration and drying needs in fine chemical and pharmace...

Centrifugal disc filter for solid-liquid separation

Optimize solid-liquid separation in your processing line with an adva...

Nutsche filter dryer for pharmaceutical and chemical industries

Achieve precise filtration and efficient drying in one s...

Chemical and pharmaceutical solid-liquid separation pilot plant

Optimize your pilot-scale production of pharmaceuticals ...

Rotary vacuum paddle dryer for pharmaceutical ingredients

Ensure precise moisture control and efficient drying for sensi...

Vacuum paddle dryer for active pharmaceutical ingredients

For precise moisture control and contamination-free conditions...

Spherical vacuum dryer for Apis and fine chemicals

Achieve precise moisture control and efficient drying for APIs and fin...

Vertical conical dryer for pharmaceutical ingredients

Optimize drying and mixing processes for high-value substances with...

Glass lined columns for chemical plants

Optimize your chemical processing with glass-lined columns, designed to ensure maxi...

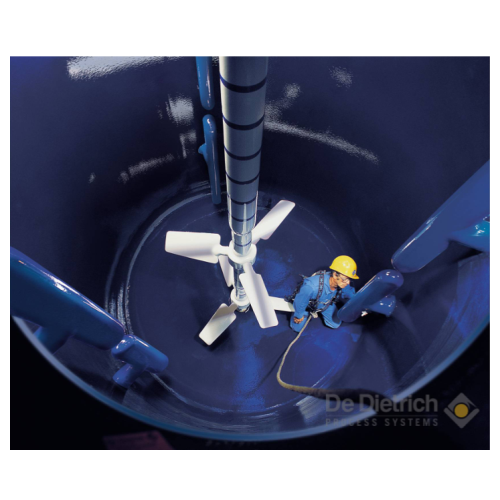

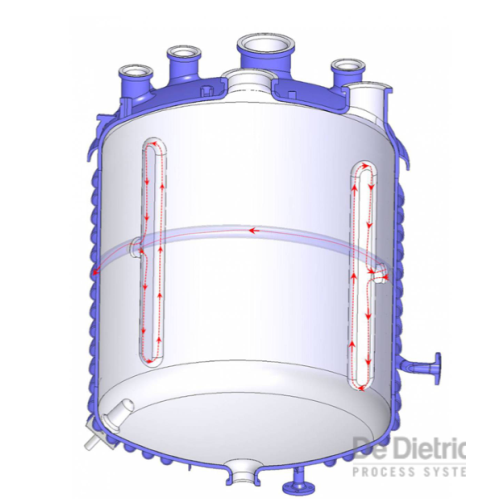

Glass-lined mixing systems for pharmaceutical industry

Achieve consistent mixing and thorough agitation for complex formu...

Fluid bed granulation system for food and chemical industries

Achieve efficient granulation and drying of liquids with c...

Asme glass-lined reactors for chemical processing

Optimize your chemical processes with high-pressure, corrosion-resistan...

Sterility testing isolator for pharmaceutical labs

Ensure reliable sterility testing in a controlled sterile environment ...

Cost-effective rigid-wall isolator for aseptic applications

Ensure sterility and safety with a versatile isolation and d...

Reusable containers for sterile and toxic material transfer

Ensure safe and contamination-free transfer of sterile and t...

Bioprocess sensor for accurate measurement

Optimize your bioprocessing with advanced sensors designed to deliver precise m...

Gravimetric feeders for pharmaceutical applications

Ensure precise ingredient metering in continuous pharmaceutical proce...

Planetary mill for nano grinding

Achieve precise nano-scale particle production and uniformity for demanding research enviro...

Commercial scale spray dryer for pharmaceutical materials

Optimize the drying of pharmaceutical and industrial materials...

High shear GMP wet granulator

Achieve precise and homogenous wet granulation of powders with adaptable settings for improved...

Mini High shear granulator for wet granulation

Optimize your powder granulation with precision and flexibility, ensuring c...

High shear wet granulation line

Achieve consistent and uniform granules with energy-efficient wet granulation designed to op...

Benchtop spray dryer for drug discovery

Optimize your formulation development with a compact spray dryer that streamlines t...

Filter washing cabinet for industrial cartridge filters

Achieve hygienic standards with precision washing and drying of i...

Roller compaction system for dry granulation

Achieve precise densification and consistent powder granulation with a system...

Laboratory fluid bed granulator and coater

For researchers and manufacturers requiring precise control in drying, granulat...

Development fluid bed system for feasibility studies

Explore precise granulation and coating capabilities for small batch...

Advanced sludge dewatering for sewage treatment plants

Optimize sludge dewatering with a centrifuge that enhances separat...

Cleanroom air filtration unit for pharmaceutical production

Ensure sterile integrity in your manufacturing process with ...

Pharmaceutical isolator for contamination control

Ensure sterility and safety in pharmaceutical manufacturing with advanc...

Modular cleanroom panel systems

Transform your cleanroom projects with modular panel systems that streamline installation an...

Conical mill for particle size reduction and homogenization

Achieve precise particle size reduction and homogenization w...

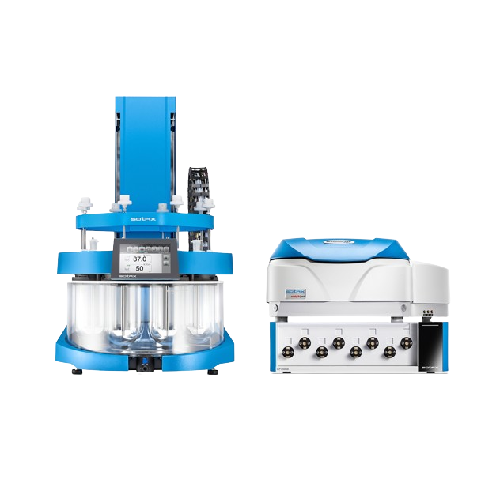

Dissolution testing system with Hplc analysis

Streamline your dissolution testing with integrated HPLC analysis, offering ...

Automatic dissolution testing for sustained release dosage forms

Effortlessly simulate pH changes for accurate dissoluti...

Dissolution online system for automated Uv-vis analysis

Ensure precise dissolution testing and seamless UV/VIS analysis w...

High volume dissolution tester for pharmaceutical research

Achieve precise dissolution testing of tablets across two bat...

Intermittent stick pack machine for pharma and healthcare

Looking to streamline your packaging operations with high-spee...

Central water purification system for laboratories

Ensure consistent supply of ultrapure water essential for critical lab...

Industrial hydrogenation plant for pharmaceutical raw materials

Optimize your hydrogenation processes with a modular pla...

Laboratory mixer and dryer for solids

Enhance your laboratory capabilities with precision mixing and drying for small batch...

Pilot plant for highly viscous applications

Perfect for R&D, this pilot plant efficiently handles complex mixing and ...

Vacuum dryer for free-flowing and pasty solids

Achieve precise drying and mixing with this vacuum dryer, optimizing heat t...

In situ dry-ice snow generator for food and pharma applications

Achieve precise cooling and deburring with this versatil...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

High-care big bag filling system for hygienic environments

Ensure precise hygienic filling of Big Bags in high-care envi...

Extraction plant for natural essences and active ingredients

Optimize your extraction processes with a versatile system ...

Crossflow filter for clarified and unclarified wines

Optimize your filtration process with ceramic membrane technology th...

Powder blender for efficient mixing and discharge

Achieve precise mixing and efficient discharge with advanced powder ble...

Glass-lined reactor for enhanced mixing performance

Optimize your chemical processes with a reactor that enhances mixing ...

Pharmaceutical reactor for efficient cleanability

Optimize your production with this reactor, designed for efficient mixi...

Industrial universal reactor for large-scale chemical synthesis

For chemical producers scaling past laboratory setups, t...

Vacuum drying for heat-sensitive products

Ensure moisture-sensitive formulations are dried efficiently without compromisin...

Industrial pan dryer for pharmaceuticals

For heat-sensitive powders and pastes requiring precise moisture levels, this pan ...

High performance heat transfer system

Enhance your production efficiency with a system that shortens cycle times by increas...

Heat exchanger for corrosive substance handling

Optimize your process of handling corrosive substances with a heat exchang...

Corrosion-resistant shell and tube heat exchangers for pharmaceuticals

Ensure efficient thermal management in high-puri...

Agitated nutsche filter and filter-dryer for pharmaceuticals

Ensure precise filtration, washing, and drying of sensitive...

Glass nutsche filter for fine chemical and pharmaceutical filtration

For precise separation and filtration in R&D ...

Pilot scale filter-dryer for pharmaceutical and chemical batches

Streamline small-batch production with a mobile filter-...

Microwave-enhanced filter dryer for chemical and pharmaceutical applications

Achieve rapid drying and efficient separa...

Static nutsche filters for liquid-solid separation

Achieve efficient separation of solids from liquids with precise contr...

Big bag emptying station for powder handling

Ensure safe and efficient powder discharge with precision containment, adapta...

Mobile powder transfer system for pharmaceuticals and chemicals

Efficiently transfer and charge powders into various ves...

Rotary evaporator for solvent evaporation

Achieve precise solvent recovery and concentration control with this rotary evap...

Thin film evaporator for temperature sensitive products

Need to purify temperature-sensitive compounds efficiently? Achie...

Liquid/liquid extraction mixer-settler plant

Optimize your extraction processes with a highly efficient mixer-settler syst...

12l solid/liquid extractor for pilot plant solutions

Optimize your extraction processes with a versatile extractor that a...

Solid/liquid extraction system for industrial applications

Optimize your solid-liquid extraction needs with a compact mu...

Condensation and separation unit for solvent handling

Enhance solvent management and VOC recovery with this compact conde...

Industrial filter dryer for high potent Api production

Optimize your process of producing high-potency pharmaceuticals by...

Solid/liquid extraction unit for process development

Optimize your extraction processes with flexible operation modes for...

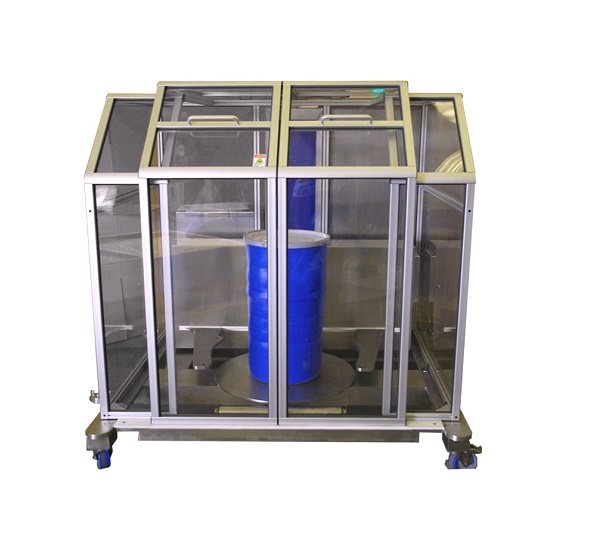

Powder handling drum dock station

Ensure safe and efficient powder transfers with high containment levels, minimizing opera...

Powder conditioning station for high containment applications

Ensure safe and precise handling of hazardous powders with...

Distillation equipment for large reactors

Efficiently achieve high-purity separations and syntheses with distillation equi...

Falling film evaporator for thermal separation

Optimize energy efficiency in separation processes by utilizing gravity-dri...

Force circulation evaporator for high viscous products

Optimize energy efficiency and manage challenging liquid compositi...

Horizontal thin film evaporator for continuous distillation

Experience precise control over evaporation and distillation...

Rectification column for close boiling point separation

Achieve high-purity separation and distillation for compounds wit...

Percolation extractor for high-volume vegetable protein extraction

Optimize extraction efficiency across diverse materi...

General purpose freeze dryer for small commercial batches

Maximize your production line’s flexibility with this ve...

High-volume oilseed extraction system

Achieve optimal extraction efficiencies with a versatile system that handles various ...

Laboratory fluid bed dryer for pharmaceutical granulation

Optimize your lab-scale drying and granulation processes with ...

Wheeled laboratory mixer for powder and granule mixing

Achieve uniform mixing of small powder and granule batches with pr...

Pharmaceutical design feeders for precise ingredient handling

Achieve precise ingredient handling and seamless integrati...

Pharmaceutical twin screw extruders

Optimize the mixing and extrusion of active pharmaceutical ingredients with unmatched p...

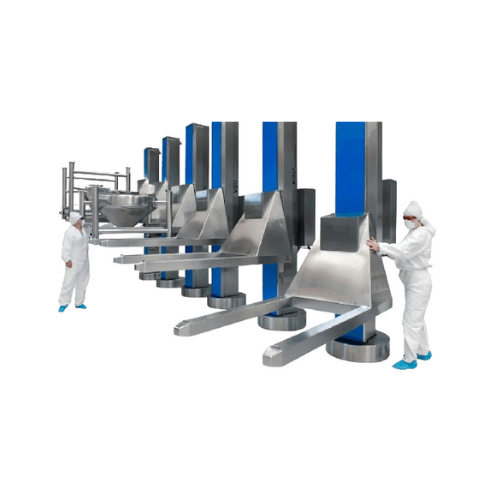

Tipping and filling line for bulk Api powder production

Ensure precise and aseptic handling of pharmaceutical powders wit...

Hot cell system for solid target manipulation in radiopharma

Optimize radiopharmaceutical synthesis with precise manipul...

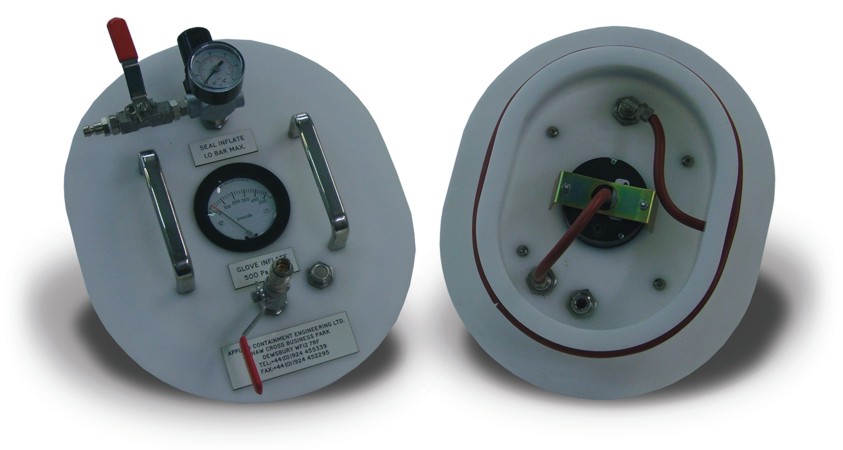

Automatic portable glove tester

Ensure glove integrity in critical environments with rapid, precise leak testing, safeguardi...

Shielded radiochemistry fume hood

Enhance your lab’s safety and efficiency with a fume hood designed for precise hand...

Preparation tank isolator for reactor charging

Ensure aseptic conditions for sterility testing and safe handling of sensit...

Modular dispensing and weighing isolator for pharmaceuticals

Achieve precise dispensing and weighing of high-potency pha...

Mini plant isolator for laboratory protection

Ensure maximum operator safety and product integrity with a versatile isolat...

Shielded cell for radiopharmaceutical synthesis

Ensure operator safety and seamless radiopharmaceutical synthesis with adv...

Mo-99 dispensing and packaging hot cell

Safely manage high-activity radiopharmaceuticals with this advanced hot cell, desig...

Shielded isolator for gallium-68 synthesis and dispensing

Optimize your radiopharmaceutical production by ensuring preci...

Isolators for safe Hapi transfer and dispensing

Ensure the safe, precise transfer and dispensing of highly active pharmace...

High containment isolator for wet analysis in pharma

Achieve high containment and precise wet analysis with this isolator...

Laminar flow hood for aseptic preparation

Ensure aseptic conditions for sterile injectable drug preparation with this adva...

Sliding radiation shield for benches

Enhance safety in laboratory and production environments with a robust bench-top slidi...

Isolator for weighing and dispensing of micronized substances

Ensure safe and precise handling of highly potent substanc...

Atex compliant isolator for dispensing powder procedures

Ensure safe weighing and transfer of explosive and pharmaceutica...

Automated ioflupane i-123 injection dispensing solution

Ensure precision and efficiency in radiopharmaceutical production...

Vibratory collar for powder flow assistance

Struggling with sticky or poorly flowing powders during discharge? This vibrat...

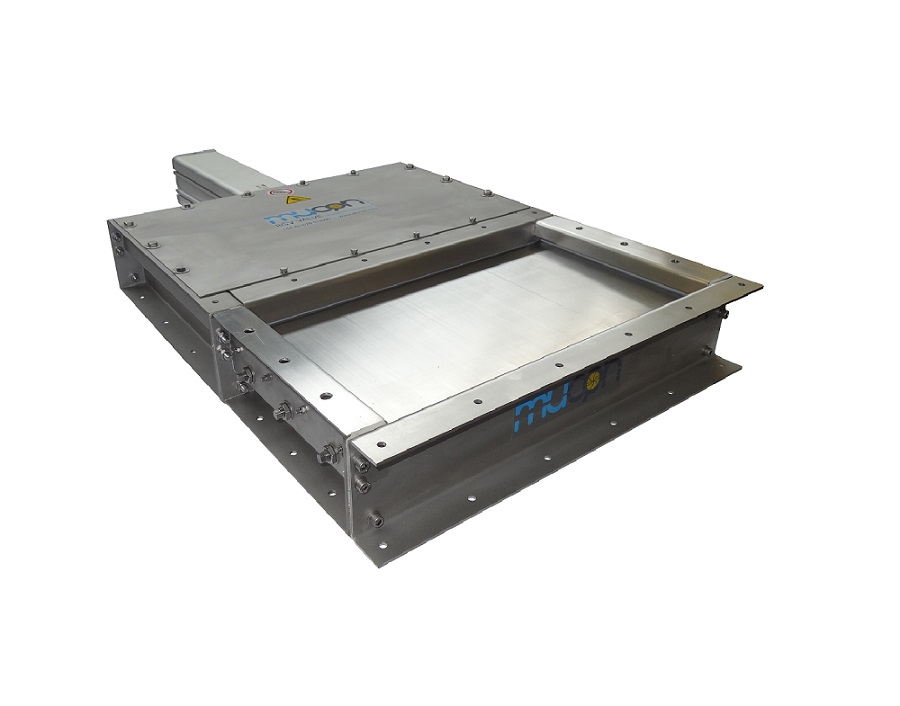

High containment powder transfer valve

Ensure high containment for potent powders in your production line, reducing contami...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

Dust particulate extraction system

Ensure safe containment and minimize airborne particulates in your production line with ...

Mobile lifter solutions for pharmaceutical handling

Streamline your handling of sensitive materials with versatile mobile...

Plastic containers for bulk powder transfer

Maximize your facility space with innovative plastic containers designed for e...

Automatic docking system for bulk powder handling

Optimize docking precision and ensure seamless alignment in bulk powder...

Single use valves for powder transfer

Efficiently transfer powder ingredients with a single-use containment solution, ensur...

Transfer valve cleaning for sterility assurance

Ensure seamless cleaning and sterility while maintaining containment integ...

Aseptic transfer valve for sterility assurance

Ensure sterility and safety in your critical production processes with adva...

Autoclave passive opener for sterilisation of passive valves

When sterilising passive valves, ensuring maximum exposure ...

Bottle cleaning station for controlled environments

Ensure high-level decontamination of passive units and containers wit...

Stainless steel container for powder transfer

Ensure seamless and sterile movement of high-value powders with this contain...

Bulk powder transfer safety device

Ensure stable and secure docking by minimizing equipment damage during powder transfer p...

Industrial filter centrifuges for high solids content processing

Optimize processing of high-solid slurries with efficie...

Laboratory oven for accurate thermal processing

Achieve precise thermal control for sensitive formulations, ensuring consi...

High temperature laboratory oven for precise heating

Achieve precise temperature control and uniformity essential for hea...

Split tube furnace for high-temperature applications

Enhance your thermal processing operations with a split tube furnace...

Controlled atmosphere oven for high-temperature applications

Achieve precise atmosphere control and uniform heating for ...

Rotary evaporator for large-scale industrial distillation

Achieve precise separation and concentration with a rotary eva...

Rotary evaporation for laboratory applications

Achieve precise evaporation and concentration with modular, high-speed rota...

Supercritical fluid chromatography system for preparative separations

For complex substance formulations requiring rapi...

Parallel evaporation system for laboratory sample preparation

Achieve precise sample concentration and drying with autom...

Protein and nitrogen analysis system for laboratories

Streamline your nitrogen and protein analysis with precision titrat...

Nano spray drying system for pharmaceuticals and nanotechnology

Transform minuscule samples into submicron particles eff...

Compact flash and prep Hplc chromatography system

Streamline your purification processes with a versatile system that int...

Flash chromatography system for basic applications

Streamline your purification process with a modular system designed fo...

Industrial recirculating chiller for laboratory applications

For consistent distillation results, maintain accurate temp...

Industrial rotary evaporator for large-scale distillation

Ideal for scaling up laboratory processes, this robust rotary ...

Encapsulation equipment for microbeads and microcapsules

Achieve precise encapsulation of active ingredients and material...

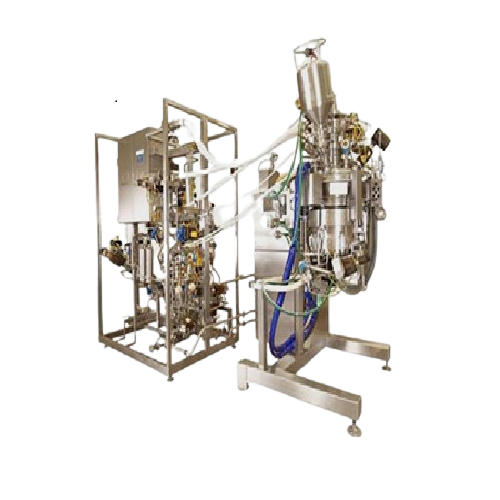

Pilot fermentors for biotech processes

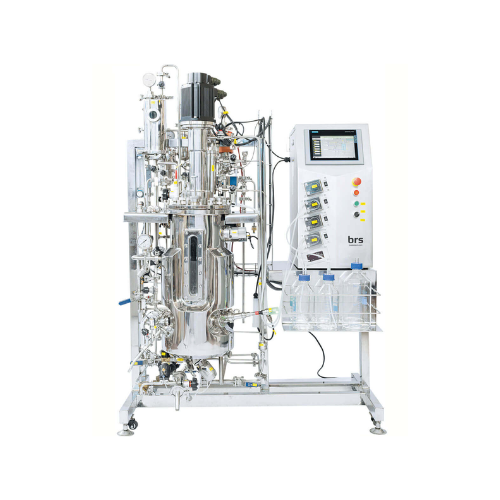

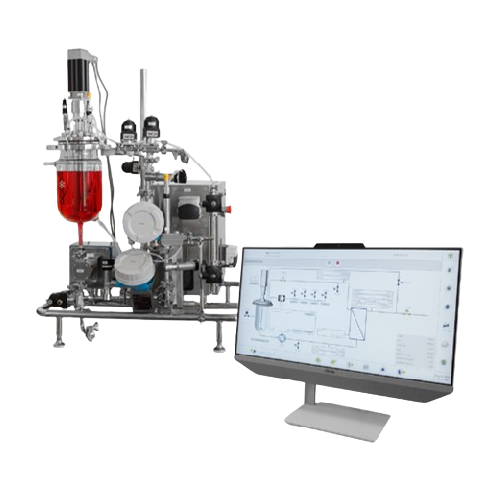

Optimize your pilot-scale production with versatile fermentors and bioreactors desig...

Raw material handling systems for plastic and pharmaceutical industries

Effortlessly manage and optimize the handling a...

Organic solvent nanofiltration for liquid separation

Optimize your process streams with solvent recovery that minimizes e...

Pervaporation membrane for solvent dehydration

Efficiently separate and dehydrate solvents at molecular levels, ensuring p...

Laboratory crossflow filtration test system

Efficiently test and determine optimal filtration parameters with this portabl...

Compact filtration device for laboratory and field use

Achieve precise filtration with minimal sample sizes for rapid ana...

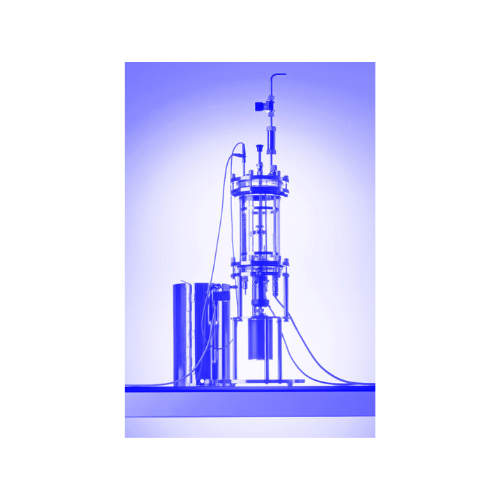

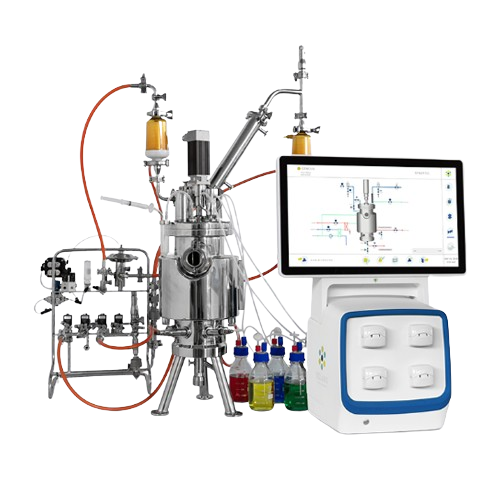

Lab-scale in-situ sterilizable bioreactor

Ensure precision in your laboratory and pilot projects with this bioreactor, des...

Lab-scale fermenters for research and development

Optimize your small-scale production with compact bioreactors designed ...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Sterile transfer chamber for pharmaceutical components

Ensure the sterility of your components rapidly with an enclosed c...

Vertical ribbon vacuum dryer for thermosensitive products

Achieve optimal drying of thermo-sensitive materials like powd...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Agitated nutsche filter for solid-liquid separation

Ensure high-purity solid-liquid separation with minimized contaminati...

Agitated nutsche filter dryer for solid-liquid separation

Achieve high-purity solid-liquid separation with optimized thr...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

Horizontal vacuum paddle dryer for thermosensitive products

For high-viscosity products like active pharmaceuticals or p...

Horizontal vacuum paddle dryer for thermosensitive products

Achieve precise drying and mixing of high-viscosity, thermos...

Industrial vacuum mixer and reactor for liquids

For manufacturers needing precise blending and stability, this advanced va...

Vacuum mixer reactor for liquids and semi-solids

Achieve precise mixing and emulsification of complex liquid formulations ...

Conical screw mixer for solids and powders

Achieve precise homogenization of your solid and powder mixtures with minimal e...

Double cone vacuum dryer for thermosensitive products

For precise drying of heat-sensitive powders, this double cone vacu...

Automatic minor components weighing system

Streamline precision in your production by automating the weighing of minor and...

Nutsche filter-dryer for solid-liquid separation

Ensure precise moisture control and efficient solid-liquid separation for...

In-line external homogenizer for industrial fluid processing

Maximize fluid consistency and ensure efficient material di...

Flexible isolator for aseptic containment

Ensure sterility and safety with a flexible isolator designed for efficient cont...

Automatic powder vacuum conveying system for infusion production

Enhance your production line with our vacuum conveying ...

Fine chemical powder system

Optimize your powder processing with a solution tailored to handle complex feeding, conveying, a...

Commercial freeze dryer for pharmaceutical Api production

Ensure the stability and potency of your biopharmaceutical pro...

Microspheres process equipment for classification, washing, drying

Achieve high yield production of polymeric microsphe...

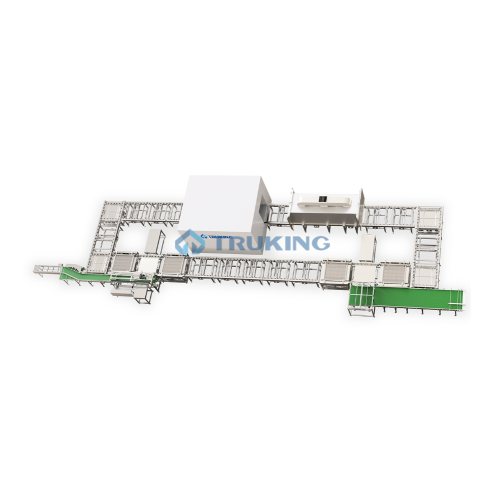

Sterile Api production line for powder treatment

Achieve seamless sterile API production by integrating precise weighing, ...

Non-sterile Api production line for powder and solid formulations

Ensure a dust-free, automated process for pharmaceuti...

High containment isolator for toxic and active drug handling

Ensure safe handling and environmental protection while pro...

Jet mill for micronizing pharmaceutical powders

Achieve precise particle size reduction with a jet mill that leverages hig...

Bead mill for nano-preparation grinding

Achieve precise nano-processing and efficient wet grinding for pharmaceuticals and ...

Particle size control equipment for pharmaceutical applications

Achieve precise particle size control for diverse materi...

Wet granulating equipment for pharmaceutical industry

Enhance production efficiency and safety in high-potency pharmaceut...

Continuous wet granulation equipment

Optimize your production line with continuous wet granulation, seamlessly transforming...

Ultrafiltration and depth filtration system for biopharmaceuticals

Achieve precise separation and purification of bioph...

Pilot-production freeze dryers for diagnostic kits and tissue banking

Optimize your freeze-drying process with compact,...

Customizable production freeze dryer for pharmaceuticals

Ensure precise moisture control and preservation with a versatil...

Aseptic filling line for biopharmaceuticals

Streamline your aseptic filling process with precision dosing and minimal spac...

Pharma peeler centrifuge for high purity separations

Achieve unparalleled product purity and yield in demanding pharmaceu...

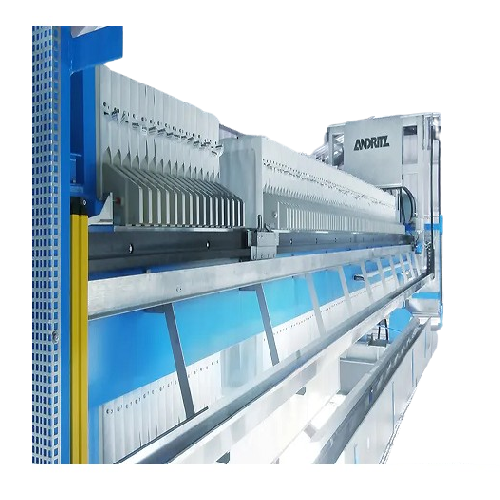

Industrial filter press for dewatering and filtration

Optimize your dewatering and filtration needs with a highly adaptab...

Vertical vacuum dryer and mixing reactor

Achieve precise control over drying and mixing processes with a versatile unit des...

Compact cross-flow membrane filtration system for lab use

Optimize your lab’s filtration process with this compact...

Yeast centrifuge separator for pharmaceutical applications

Optimize microorganism recovery with high purity and efficien...

Mixproof valve for cleaning-in-place control

Streamline your cleaning processes and ensure product safety with a versatile...

Compact industrial boiler for steam and hot water applications

Experience reliable steam and hot water generation with t...

Pharmaceutical roller compactor for precise granulation

Achieve consistent and high-quality granulation with a solution t...

Pharmaceutical roller compactor for dry granulation

When precision and uniformity in tablet production are crucial, optim...

Industrial grater and shredder for pharmaceutical and chemical applications

Optimize your production line with a versa...

Bin blender for pharmaceutical powder mixing

Achieve uniform mixing and homogenization of dry powders directly in storage ...

Lifting column for drums and bins

Optimize your powder handling operations with a versatile lifting solution designed for p...

Mobile bin blender for mixing and homogenizing dry powders

Ensure thorough powder uniformity and eliminate cross-contami...

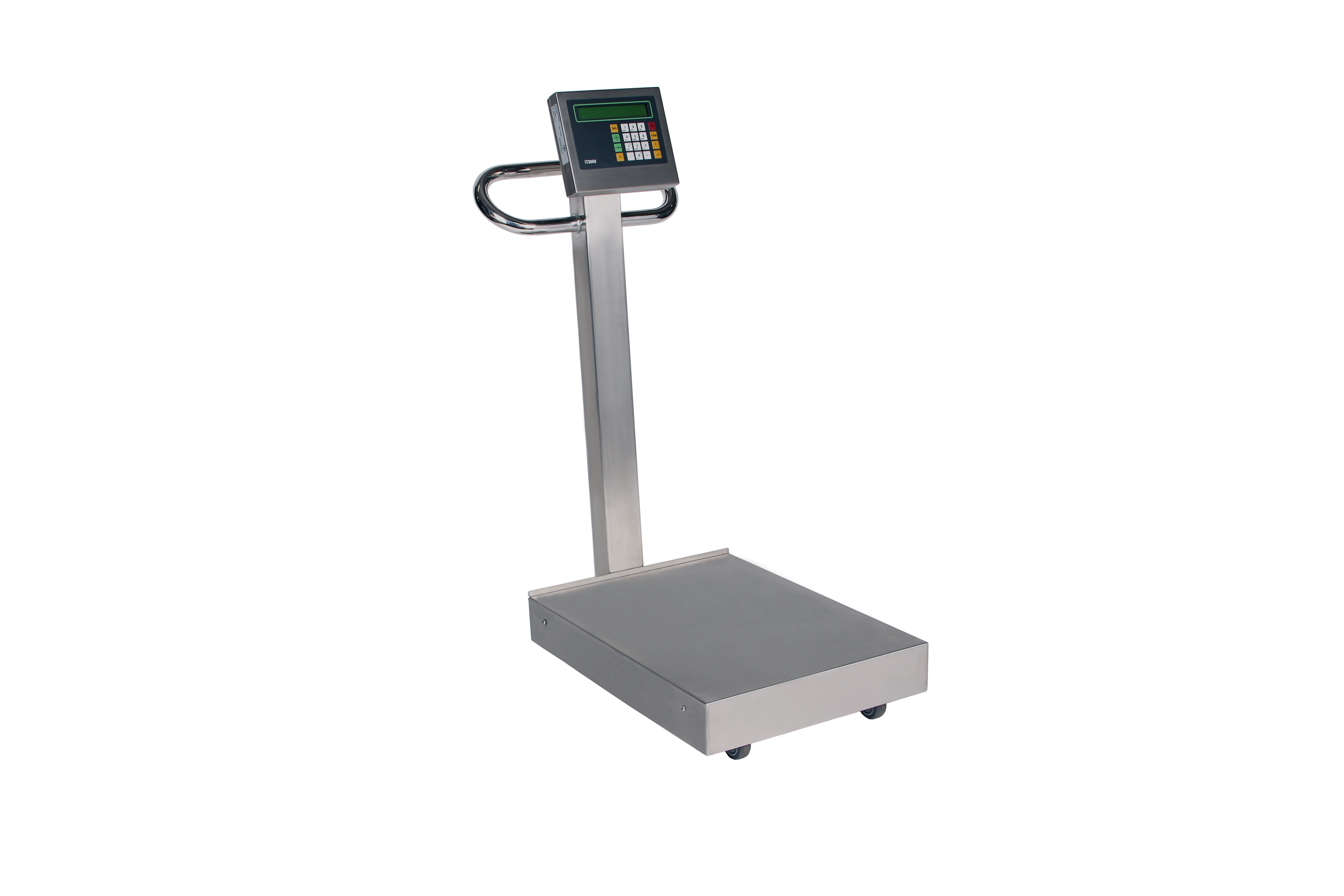

Powder dosing and weighing system

Optimize precision in pharmaceutical processing with a system designed to ensure accurate...

Mobile lifting column for drum handling

Streamline your powder and drum handling operations with this versatile mobile lift...

Ped-compliant vacuum conveyor for powder transfer

Achieve safe and efficient powder transfer in pressure environments wit...

Vacuum transfer system with integrated cleaning

Ensure sterile powder handling and contamination-free production with vacu...

Hygroscopic material lump breaker

Ensure seamless processing by breaking down compacted or hygroscopic powders efficiently,...

300l stainless steel dual-jacketed reactor for winterization

Enhance your extract processing with precision temperature ...

Pharmaceutical large freeze dryer with vacuum pump

Preserve the integrity and potency of sensitive compounds with precisi...

Pharmaceutical freeze dryer for medium scale production

Ensure optimal preservation of active ingredients through precise...

Nsf certified class Ii a2 biosafety cabinet

Ensure laboratory safety and specimen integrity with a biosafety cabinet desig...

Analytical balance for precise laboratory measurements

Achieve unparalleled precision and reliability in your lab’s...

Ultra-microbalance for precise weight measurement

Achieve unparalleled precision in weight measurement with an ultra-micr...

High precision analytical balance for laboratory use

Ensure precision and reliability in your laboratory measurements wit...

Moisture analyzer for laboratory samples

Accurate moisture analysis is crucial for ensuring product quality in pharmaceutic...

High-precision analytical balance for laboratory use

Achieve precise measurements and ensure reliability in your laborato...

Cold trap for laboratory applications

Achieve efficient condensation and separation in laboratory processes with this versa...

Bridgman crystal growth furnace for advanced crystallization processes

Achieve high precision in crystal growth with th...

20l glass reactor for crystallization and isolation processes

Optimize your lab’s crystallization and isolation pr...

Stainless steel crystallization reactor 100l

Optimize your crystallization and formulation processes with precision-contro...

Decarboxylation package for botanical extraction

Optimize decarboxylation and reaction processes with precise temperature ...

Decarboxylation package for botanical extraction

Ensure precise temperature control and efficient reaction conditions in y...

Dual asymmetric centrifugal processing system for epoxies and slurries

Streamline complex formulations with a system th...

50l jacketed glass reactor with explosion-proof motor

Enhance your reaction processes with precise temperature and pressu...

Laboratory -40°c upright freezer

Ensure optimal preservation of sensitive biological samples with a freezer engineered for u...

Dual-jacketed reactor for decarboxylation processes

Streamline your decarboxylation process with a dual-jacketed reactor ...

Dual-jacketed reactor for botanical extraction winterization

Optimize your production with precise temperature control a...

100l laboratory jacketed glass reactor

Optimize your batch processing with this 100L jacketed glass reactor, designed for p...

10l glass reactor system for synthetic reactions

Achieve consistent reaction control with efficient temperature and vacuum...

20l jacketed glass reactor for controlled chemical reactions

Optimize your chemical synthesis with precise temperature c...

20l jacketed glass reactor system for laboratory synthesis

Achieve precise chemical synthesis and enhanced material reco...

20l jacketed glass reactor

Optimize your chemical reactions with precise temperature control and adaptive stirring capabilit...

Large capacity jacketed glass reactor

Achieve precise control over temperature and vacuum conditions with this versatile re...

1200°c Pe/cvd furnace for high-temperature material synthesis

Enhance your material processing capabilities with precise...

High-temperature tube furnace for laboratory applications

Achieve precise thermal treatment with this high-temperature t...

24-ton laboratory pellet press

Achieve precise pellet formation with reliable 24-ton pressing power, ideal for compaction of...

Controlled atmosphere top-open tube furnace

Achieve precise thermal processing and sintering with this versatile tube furn...

High-shear mixer granulator for pharma and nutraceuticals

Optimize your batch and high-speed production with a powerful ...

High-shear mixer granulator for small batches

Achieving consistent particle size and mix uniformity in pharmaceutical and ...

High-shear granulator for wet granulation

Achieve precise content uniformity with advanced high-shear granulation, designe...

Containment tablet coater for high-potency drugs

Ensure operator safety while achieving precise tablet coating on high-pot...

Tablet coater for batch sizes up to 250 liters

Enhance your tablet production process with high-speed coating solutions de...

Containment tablet coater for high-potency pharmaceuticals

Ensure operator safety and maintain stringent OEB 4 complianc...

Tabletop granulation system for small batches

Enhance R&D capabilities with this innovative solution designed for gra...

Versatile fluid bed combo for granulation and coating

Optimize lab-scale R&D with an adaptable fluid bed system, sea...

Intermediate-scale fluid bed system for drying and granulation

Achieve precise drying and granulation with this versatil...

Advanced fluid bed for pharmaceutical granulation

Achieve precise granulation and drying for pharmaceutical powders with ...

Fluid-bed granulator for top-spray applications

Need precise granulation and drying for sensitive materials? This fluid-be...

Fluid-bed drying and granulation system

Optimize your production line with high-speed batch processing for efficiently dryi...

Integrated granulation train for pharmaceutical processes

Achieve precise granulation, uniform mixing, and efficient dry...

High-shear mixer for large-scale pharmaceutical production

Optimize your granulation process with an advanced high-shear...

High-shear mixer for small batch granulation

Enhance your production efficiency with a high-shear mixer designed for preci...

Containment capsule filler for highly potent drugs

Achieve complete operator safety while encapsulating potent pharmaceut...

Containment capsule filling system for highly potent drugs

Ensure operator safety while filling capsules with high-poten...

Fluid bed dryer with granulation and coating

Enhance your processing efficiency with a versatile system capable of combini...

Fluid bed combo for granulation and coating

Achieve seamless granulation and coating with batch and high-speed operations,...

Fluid bed combo for granulation and coating

Streamline your manufacturing with a versatile fluid bed combo, integrating gr...

Containment blister packaging for highly potent Apis

Ensure operator safety during the blister packaging of highly potent...

Clean-in-place system for diverse processing needs

Ensure the precision and consistency of your cleaning cycles with a ro...

Tablet compression module for high containment applications

Quickly switch between tablet batches without compromising s...

Pharmaceutical direct compression with linear blending

Streamline your pharmaceutical production with a continuous direct...

Containment valves for pharmaceutical powder transfer

Ensure safe transfer of highly potent pharmaceuticals with this mod...

Disposable containment system for solid dosage material

Ensure safe and dust-free transfer of hazardous materials with ou...

Ibc post hoists for pharmaceutical manufacturing

Ensure precise material handling with advanced lifting solutions designed...

Contained powder sampling system

Ensure contamination-free sampling of active powders with fully contained system integratio...

Pharmaceutical intermediate bulk containers (ibc)

Streamline pharmaceutical production with precise containment and trans...

Continuous granulation and drying system for r&d

Develop precise pharmaceutical granules with this compact system, tailore...

Pharmaceutical r&d granulation system

Optimize your pharmaceutical research with a versatile small-scale granulation system...

Pharmaceutical homogenization skid system

Achieve precise particle size reduction and efficient cell rupture with an auton...

High shear granulator for pharmaceutical applications

Efficiently transform powders into uniform granules for consistent ...

Pharmaceutical bottom-drive high shear granulator

Achieve optimal granule uniformity and precise control over moisture le...

Integrated small-scale granulation and drying system

Ensure precise granule size and moisture control for enhanced tablet...

Integrated granulation and drying system for pharmaceuticals

Achieve seamless granulation and drying with our fully inte...

Bubble column reactors for chemical reactions

Enhance gas-liquid interactions with bubble column reactors designed for eff...

Compact plate evaporator for temperature-sensitive products

Ensure optimal heat transfer and minimal space usage with th...

Pharmaceutical spray dryer

Unlock the potential of spray drying to enhance bioavailability, achieve controlled release, and ...

Spray dryers for ceramics and pharma products

Achieve consistent powder quality for heat-sensitive and sticky products wit...

Fluid bed pellet coating solution

Achieve precise and uniform pellet coating with fluid bed technology for enhanced product...

Pharmaceutical fluid bed processor for r&d

Optimize your pharmaceutical R&D with a versatile fluid bed processor desi...

Flexstream fluid bed processor for pharmaceutical applications

Addressing the limitations of traditional fluid bed proce...

Batch distillation plants for diverse compound mixtures

Optimize your separation processes with flexible batch distillati...

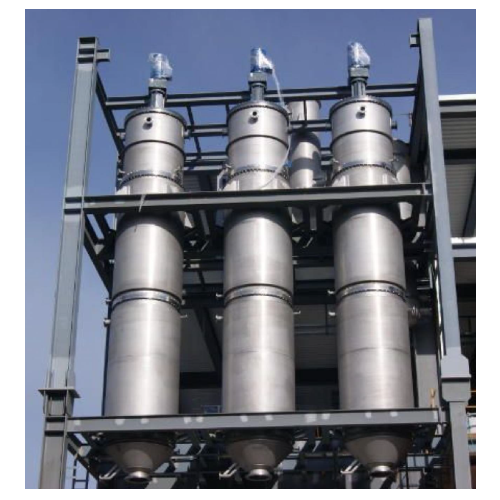

Multiple-effect distillation plants for industrial applications

Optimize your energy use with multiple-effect distillati...

Mvr and Tvr heated distillation system

Achieve superior energy efficiency and reduced steam consumption in your distillatio...

Industrial tray and packing column solutions

For efficient separation and product purification, tray and packing columns o...

Spray dryer for food and dairy products

Achieve consistent drying for diverse powders and granulates with precision technol...

Centrifugal separator for pharmaceutical extraction

Optimize your extraction process with precision centrifuging that enh...

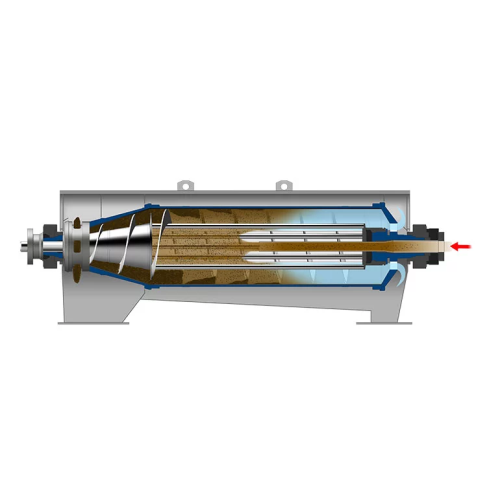

Chemical and mineral processing decanter centrifuge

Achieve efficient clarification and dewatering of complex mixtures in...

Clarifying decanter for chemical processing

Optimize your clarification and dewatering processes with a versatile decanter...

Laboratory vacuum drying system

Achieve precise moisture removal and maintain product integrity with advanced vacuum drying,...

Autoclaves for laboratory and production with square chamber

Optimize your laboratory space with compact autoclaves that...

Combined Avi and Cci tester for vials

Ensure comprehensive quality control of parenteral products with an integrated soluti...

Vacuum conveyors for explosive and inert gas environments

Optimize the safe transfer of hybrid mixtures and fine powders...

Powder locks for safe bulk material handling

Ensure containment and prevent contamination while processing sensitive bulk ...

Pharmaceutical vacuum conveyors for hygienic transport

Ensure contamination-free transport of sensitive pharmaceuticals a...

Vacuum conveyor for tablets and capsules

Ensure the integrity of your tablets and capsules with gentle vacuum conveying des...

Big-bag unloading station for bulk materials

Facilitate seamless integration into your production line with efficient bulk...

Drum discharge system for bulk material handling

Achieve precise, gentle transfer of sensitive pharmaceuticals and granula...

Explosion-proof production disperser for paint manufacturing

Ensure safe and efficient dispersion in volatile environmen...

Explosion-proof bead mill for industrial grinding applications

For manufacturers seeking precise particle size control, ...

Explosion-proof horizontal bead mill

For manufacturers seeking precise particle sizing, this explosion-proof bead mill ensu...

Horizontal bead mill for ultrafine particle grinding

Achieve precision in ultrafine grinding with a system that allows fo...

High-capacity dissolvers for industrial mixing

Enhance your production line with precision mixing, achieving consistent di...

High shear batch process homogenizer for production

Achieve efficient emulsifying, homogenizing, and dispersing with prec...

Dissolving system for high-viscosity products

Optimize the dispersion of high-viscosity liquids and pastes with this versa...

Explosion-proof dissolver for high-viscosity products

Optimized for safely processing high-viscosity products, this explo...

Explosion-proof vacuum dissolver for high-viscosity products

Optimize your production by eliminating air inclusions and ...

Basket mill with integrated dissolver for high viscosity products

Optimize your production efficiency by combining disp...

Explosion-proof horizontal bead mill for fine grinding

Ensure precise, explosion-proof grinding in hazardous environments...

Atex horizontal bead mill

Ensure precision and safety in explosive environments with a robust solution that finely grinds an...

Explosion-proof dissolver for hazardous area mixing

When operating in hazardous environments, maintaining consistent and ...

Lab stirrer for high-viscosity substances

Need precise, high-torque stirring for your complex formulations? This lab stirr...

Laboratory and pilot plant horizontal bead mill

Achieve precision milling with minimal product waste, ensuring consistent ...

Rotary homogenizer for laboratory and pilot plant

For achieving optimal dispersion in complex formulations, this solution...

Dissolver for mixing and processing in lab and pilot plant

Optimize your material dispersion and homogenization processe...

Pressure monitoring solution for dosing processes

Optimize your production line by ensuring precise pressure monitoring, ...

Side-mount agitator for large tank mixing

Achieve efficient mixing in large tanks with reduced energy consumption by lever...

Industrial stativ mixer with adjustable height

Achieve precise mixing and stirring across diverse batches with a mobile, a...

Tank agitator for low-level installation

Efficiently optimize your mixing processes with a bottom-entry tank agitator, desi...

Laboratory dedusting systems

Designed for high-containment lab environments, this solution efficiently captures and manages ...

Containment single-use filter module

Ensure safe handling of high-potency substances and streamline filtration processes wi...

Compact dust extractors for cleanroom applications

Ensure safe and efficient dust extraction in cleanroom environments wi...

Industrial particle size reduction processor

Optimize your production line with high-capacity, continuous particle size re...

Handheld particle counters for cleanroom environment monitoring

Ensure precision in contamination monitoring and quality...

Gentle rocker for dissolving active drug in Ngi tray

Experience consistent and reproducible sample preparation with a roc...

Robotic sterilization logistics system

Ensure seamless aseptic transfers across production stages with this robotic logisti...

Pharmaceutical autoclave for terminal sterilization

Optimize your sterile production with high-precision terminal sterili...

Pharmaceutical isolator system for aseptic production

Ensure aseptic conditions and operator safety with a robust isolati...

Feeding isolator for liquid preparation in pharmaceuticals

Ensure precise and contamination-free preparation of liquid p...

Active pharmaceutical ingredient isolation system

Ensure the aseptic production of pharmaceuticals while protecting perso...

Sterility testing isolator for aseptic environment

Ensure precise sterility testing and prevent contamination with an iso...

Automatic chromatography column for biopharmaceutical separation

Ensure high-purity monoclonal antibodies and herbal ext...

Complex preparation system for industrial microsphere production

Achieve precise particle size and uniform drug encapsul...

Industrial freeze dryer for pharma

Optimize moisture removal in lyophilized products with precise thermal conduction and ef...

Twin-screw extruder for high containment applications

Achieve precise mixing of sensitive compounds with a twin-screw ext...

Mini extruder for early development phase testing

In early development, tackling limited material availability is crucial...

Flat-bottom twin-screw feeder for precise powder feeding

Achieve precise control in powder dispensing with this flat-bott...

Precise volumetric or gravimetric powder feeder

For precise feeding of challenging powders prone to clumping and bridging,...

Isolator high containment for granule production

Ensure high-purity production in pharmaceuticals with controlled granulat...

Benchtop x-ray diffractometer for routine analysis

Achieve high-precision phase analysis and crystalline characterization...

Twin-screw extruder for pharmaceutical formulations

Streamline your pharmaceutical production with a dual-purpose extrude...

Micronization for pharmaceuticals

Achieve ultra-fine particle size reduction for complex materials, essential when precisio...

Jet milling system for super fine particle size reduction

Achieve ultra-fine particle sizes with precision milling techn...

Atex approved hammer mills for high-capacity particle size reduction

Ensure precise and reliable particle size reductio...

High accuracy hammer milling for precise particle size reduction

Achieve precise particle size control to enhance produc...

Lab scale hammer mills for fine particle size reduction

Optimize your R&D scaling efforts with versatile lab equipme...

Vacuum extruder for high-viscosity materials

Optimize material processing with precision de-airing and temperature control...

High-pressure hydrogen generator for laboratory use

Replace cumbersome hydrogen cylinders with an on-demand generation so...

High-temperature and high-pressure flow reactor

Achieve unparalleled precision in high-temperature and high-pressure chemi...

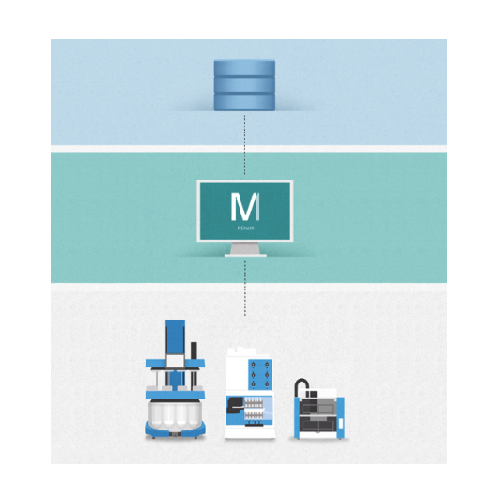

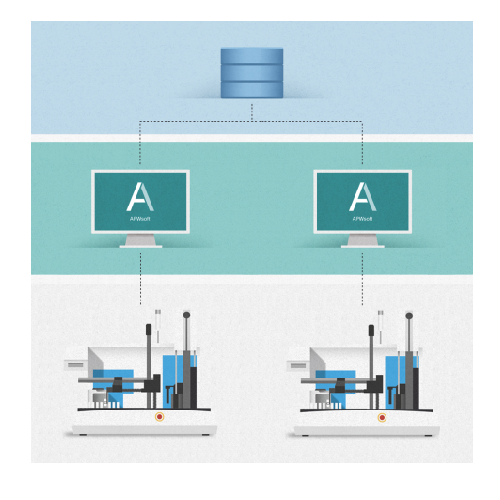

Remote control software for laboratory flow reactors

Streamline your laboratory experiments with a system that provides s...

Automated liquid handler for hydrogenation reactions

Enhance reaction efficiency and precision in laboratory settings wit...

Continuous flow hydrogenation reactor for corrosive reagents

Transform your hydrogenation processes with a reactor engin...

Catalyst cartridge switching system for flow chemistry

Effortlessly switch between multiple catalysts in a single run, op...

Catalyst cartridge packing system

Efficiently pack and seal catalysts into cartridges with precision, ensuring reliable and...

Reusable catalyst cartridges for safe hydrogenation

Simplify catalyst handling and enhance reaction control with reusable...

Hydrogenation reactors for safe and efficient syntheses

Experience safe, on-demand hydrogen generation for precise flow h...

Advanced hydrogenation in continuous flow

Achieve precise, on-demand hydrogenation with advanced safety features, eliminat...

Automatic mono-dose strip filling system

Optimize your liquid product packaging with a multi-functional system designed for...

Saturated steam sterilizer for pharmaceutical production

Ensure sterility for a diverse range of pharmaceutical products ...

pharmaceutical lyophilised filling line

For high-precision production of moisture-sensitive drugs, this aseptic system ensu...

Sublimation front monitoring system for freeze drying

Ensure precise control over your freeze-drying process with real-ti...

Sterile lyophilised filler

Achieve precise weighing and contamination-free lyophilisation with our cutting-edge sterile fill...

Sterile lyophilized filling line

Ensure sterility and precision in filling pharmaceuticals with advanced isolator lines desi...

Sterile lyophilised filling solution

Achieve precise filling and control of moisture-sensitive pharmaceuticals while ensuri...

Two lyophiliser unloading isolators for hygroscopic products

Ensure precise moisture control and sterility for hygroscop...

Chest ultra low temperature freezer for biological sample storage

Efficiently preserve high-value biological and medica...

Containment isolators for pharmaceutical and biotech applications

Ensure operator safety and product integrity during t...

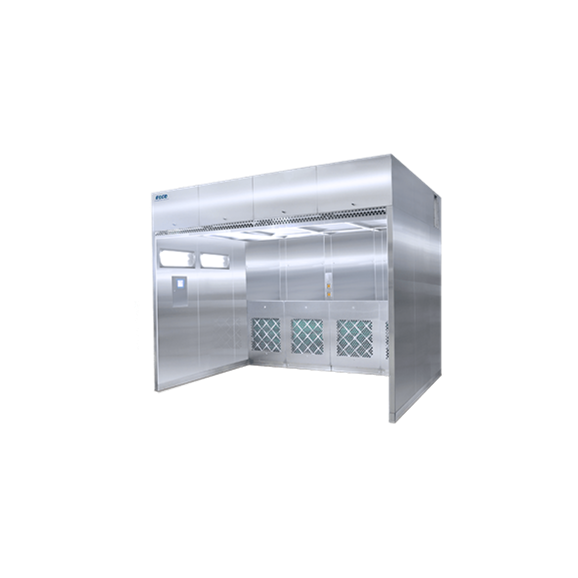

Downflow booths for hazardous material processing

Ensure product integrity and operator safety during hazardous material ...

Sterility test isolator for pharmaceutical processes

Ensure precise sterility testing with an isolator that maintains an ...

Basic research freeze dryer for biomedical applications

For laboratories seeking precise sample preservation, this bencht...

Continuous manufacturing for pharmaceuticals

Achieve precision in oral solid dosage production with seamless continuous pr...

Pharmaceutical aseptic separator filter dryer

Achieve seamless filtration, washing, and vacuum drying in a single aseptic ...

Lab Pharmaceutical aseptic separator

Achieve high-yield recovery and safe handling of potent pharmaceuticals with this asep...

Pilot pharmaceutical aseptic separator and dryer

Achieve high-yield recovery of potent compounds with a separator that com...

Pharmaceutical aseptic separation system

Achieve precise separation and efficient drying of pharmaceutical powders with an ...

Pharmaceutical aseptic separator tumble dryer

Streamline moisture reduction with precision: this solution accelerates dryi...

3d metal printer powder screening system

Enhance your 3D metal printing workflow by efficiently reclaiming and rebottling u...

Sterilization system for biosafety applications

Ensure sterility and compliance in critical manufacturing processes with a...

Mobile biodecontamination unit for small to mid-size rooms

Efficiently achieve 6-log bioburden reduction in controlled e...

Pharmaceutical grade washer for large components

Ensure compliance and maximize productivity with a high-performance solut...

Vacuum rated vibro sifter for pharmaceutical materials

Ensure precise separation of impurities and achieve consistent par...

Medium torque top entering mixer for high fluid forces

Equip your production line with a robust mixer that transforms cha...

Tall form dryer for producing large non-agglomerated particles

Achieve precise particle size control and optimal moistur...

Pharmaceutical sieving equipment for high hygiene standards

Ensure the purity of pharmaceutical powders and granulates w...

Pilot-production freeze dryer for diagnostic kits and Api

Optimize your lyophilization process with this versatile freez...

Production freeze dryer for pharmaceutical manufacturing

Achieve precise lyophilization for sensitive products with custo...

Refrigerated vacuum cold trap for laboratory vapors

Protect your vacuum pumps by efficiently trapping harmful condensable...

Semi-automatic tablet hardness tester

Optimize your tablet production with precise and reliable testing of hardness, dimens...

Tapped density tester for pharmaceutical powders

Ensure precise quality control in pharmaceuticals by accurately measuring...

Automated weighing system for tablets

Ensure precision in pharmaceutical manufacturing by seamlessly integrating advanced w...

Automated sample preparation workstation for lab efficiency

Streamline laboratory operations by automating sample prepar...

Automated sample preparation workstation for content uniformity testing

Streamline your laboratory workflows with autom...

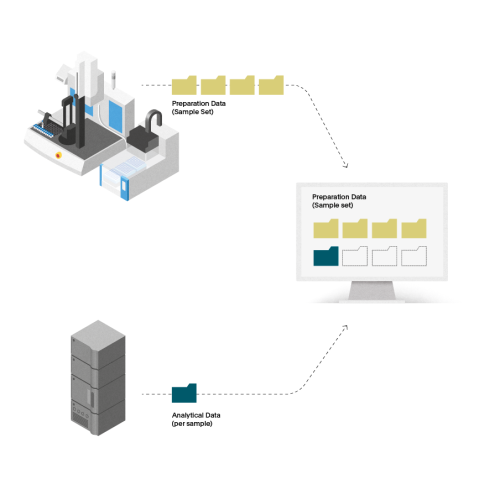

Automated sample preparation software for pharmaceutical testing

Streamline your laboratory’s sample preparation w...

Dissolution medium preparation system

Streamline your laboratory workflows with a system that prepares and manages dissolut...

Automated flow-through cell dissolution testing system

Enhance precision in dissolution testing with real-time UV-Vis ana...

Flow-through cell dissolution testing with Uv analysis

Effortlessly monitor real-time dissolution with flow-through cell ...

Manual tablet disintegration tester

Ensure precise and reliable disintegration testing of pharmaceutical tablets, capsules,...

Tablet friability tester

Ensure your tablets meet rigorous quality standards by accurately measuring friability and abrasion,...

Multi-parameter tablet hardness tester for laboratories

Optimize your tablet production line with a versatile tester that...

Advanced dissolution tester for pharmaceutical laboratories

Achieve consistent and reproducible dissolution results with...

Manual dissolution tester for pharmaceutical applications

Achieve precise and repeatable sampling in pharmaceutical test...

Automated dissolution testing with direct Hplc injection

Streamline your lab operations with precise and efficient direct...

Integrated Uv-vis spectrophotometer for dissolution testing

Streamline your dissolution testing with real-time UV-Vis an...

Real-time Uv-vis analysis for dissolution testing

Efficiently perform dual dissolution tests simultaneously, seamlessly i...

Automated dissolution testing system for 16 vessels

Maximize your laboratory throughput by conducting parallel dissolutio...

Dissolution testing software for automated analysis

Streamline your laboratory testing with seamless data capture and in-...

Dissolution testing software for pharmaceutical industry

Optimize dissolution testing with advanced software that manages...

Automated sample preparation software

Enhance your laboratory’s efficiency with a software solution that automates sa...

Self-cleaning dissolution tester for automated series testing

Achieve unparalleled precision in dissolution testing with...

Ventilated autoclave for sterilization processes

Optimize sterile production with advanced ventilated autoclaves, ensuring...

Benchtop Sip fermenter for bioprocessing applications

Optimize your bioprocesses with precise control over fermentation a...

Benchtop tangential flow filtration system

Ensure high-purity yields and streamline your filtration processes with this be...

Customizable pilot-industrial fermenters bioreactors

Designed for precision fermentation, these fermenters and bioreactor...

Medical lab sterilization autoclave

Ensure product sterility with high-performance ventilated autoclaves designed to optimi...

High shear lab mixer for laboratory work and r&d

Achieve unparalleled precision and consistency in laboratory and pilot-sc...

High shear batch mixer for industrial mixing

Optimize your production cycle with this high shear batch mixer, designed to ...

Laboratory freeze dryer for research and process amplification

Optimize freeze-drying processes with precision control, ...

Industrial grinding solution for hard and abrasive materials

Efficiently grind and mill a spectrum of materials from coa...

Loss-in-weight feeder for battery cell production

In battery cell production, achieving precise dosing and safe handling ...

Frozen storage and shipping for biopharmaceuticals

Ensure the integrity of critical biopharmaceuticals with a robust solu...

High-accuracy moisture analyzer for lab weighing

Achieve precise and reproducible moisture content determination for diver...

Explosion proof weighing cells for hazardous environments

Designed for hazardous environments, these weighing cells ensu...

Lithium-ion battery powder processing solution

Optimize your lithium-ion battery manufacturing with advanced powder treatm...

Pharmaceutical horizontal batch centrifuge

Ensure unparalleled product purity and operational efficiency with a centrifuge...

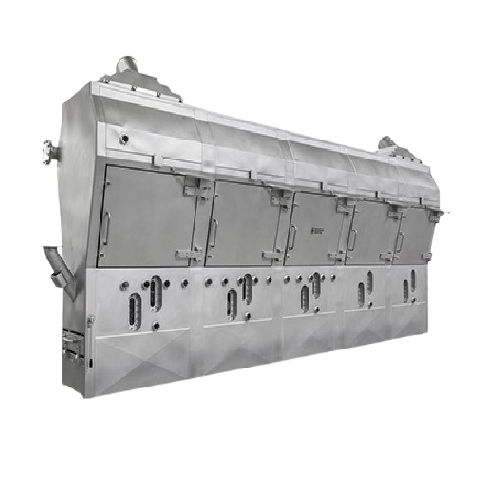

Continuous hot air conveying dryer for chemical and pharmaceutical industries

Ensure rapid moisture removal with high-...

Semi-continuous freeze dryer with easy-loading

Freeze-drying is both a time- and energy-consuming process. In addition to ...

3D powder mixer for active pharmaceutical ingredients