Microspheres process equipment for classification, washing, drying

Achieve high yield production of polymeric microspheres by seamlessly integrating classification, washing, and drying into a single automated process, ensuring consistent operational efficiency and product quality.

Processes and Refines Polymeric Microspheres

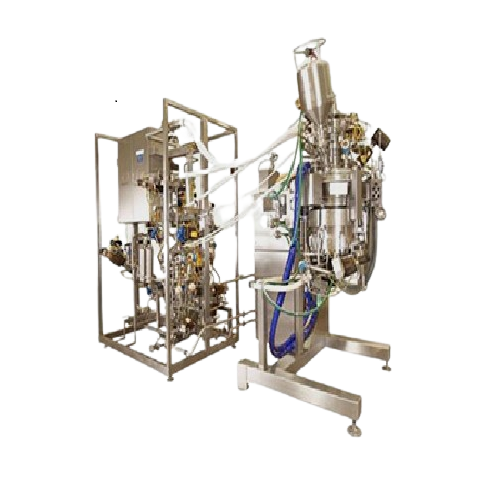

The Microsphere Refiner (MSR) from AUSTAR is an automated, all-in-one solution for polymeric microsphere processing, incorporating classification, filtration, washing, and drying stages within a single unit. Specially designed for pharmaceutical and biopharmaceutical applications, it effectively aids in the production of polymeric microspheres, sustained-release tablets, and drug delivery carriers. The MSR handles both laboratory (gram scale) and commercial production (up to 25 kg), ensuring high yield operations. Featuring horizontal and vertical filtration, jacketed heating and cooling for efficient drying, and tilt discharging for optimized output, it seamlessly integrates into existing process skids. The equipment’s automated control and remote monitoring capabilities bolster operational efficiency, while its robust design ensures compatibility with industry standards for chemical resistance and cleanliness. Customizable configurations are available, reducing costs by offering production without the need for sterile isolation or freeze-drying systems.

Benefits

- Enhances production efficiency with integrated classification, washing, and drying in one unit.

- Reduces operational costs by eliminating the need for sterile isolation or freeze-drying systems.

- Cuts labor expenses with fully automated process controls and remote monitoring.

- Offers flexibility in production scale, supporting both laboratory and commercial operations.

- Ensures high product yield, optimizing resource utilization and maximizing return on investment.

- Applications

- Biopharmaceuticals, Pharmaceutical powders, Fine chemicals, Pharmaceutical tablets

- End products

- Powdered fine chemicals, Sustained-release tablets, Active pharmaceutical ingredients (apis), Polymeric microspheres, Pharmaceutical excipients, Drug delivery carriers

- Steps before

- Solvent Extraction, Polymeric Microsphere Formation

- Steps after

- Sterilization, Packing

- Input ingredients

- polymeric microspheres, solvent

- Output ingredients

- classified microspheres, filtered microspheres, washed microspheres, dried microspheres

- Market info

- Austar is known for specializing in the design and manufacture of engineered-to-order industrial equipment, particularly in the pharmaceutical and biotechnology sectors, offering solutions that focus on quality, innovation, and meeting specific customer requirements.

- Yield

- Up to 90%

- Automation

- Automated process control

- Drying method

- Freeze-drying

- Classification method

- Horizontal and vertical filtration

- Discharge method

- Tilt discharging

- Production scale

- Gram scale to 25 kg

- Heating and Cooling

- Jacket heating, cooling

- Working mechanism

- Horizontal and vertical filtration

- Integrated steps

- Classification, Washing, Drying, Sampling and Discharge

- Automation level

- Automated process control

- Batch vs. continuous operation

- Batch

- Discharge method

- Tilt discharging

- Energy efficiency

- Efficient drying with jacket heating, cooling

- Production scale flexibility

- From laboratory (gram scale) to commercial production (maximum 25kg)

- Sterilization assurance

- Brilliant sterilization assurance

- Sterilization assurance

- Optimized process routing and equipment

- Equipment size

- Laboratory scale (gram) to commercial production (maximum 25kg)

- Discharge method

- Tilt discharging

- Filtration configuration

- Horizontal and vertical filtration

- Integration capabilities

- Could integrate with Process Skid

- Control panel type

- Integrated with automation system

- Production Configuration

- Without sterile isolation or freeze-drying system