Sterile lyophilised filling solution

Achieve precise filling and control of moisture-sensitive pharmaceuticals while ensuring sterility and contamination-free processing throughout your production line.

Fills Lyophilized Pharmaceuticals with Precision

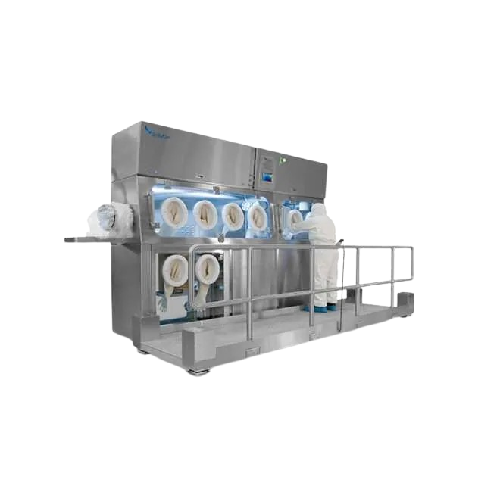

The Sterile Lyophilised Filling Line from Telstar is designed specifically for pharmaceutical and biotech manufacturers, ensuring sterile and precise filling of lyophilized pharmaceuticals such as monoclonal antibodies and injectable drugs. This engineered-to-order system features a multi-chamber design that facilitates seamless integration into existing production lines, addressing stringent regulatory requirements with GMP compliance. The line’s high-accuracy weighing and filling capabilities ensure consistent dosing, minimizing product wastage and contamination risks. With automated PLC controls, it allows for remote monitoring and integration with upstream and downstream processes. Constructed from high-grade stainless steel, it offers excellent corrosion resistance and is equipped with a CIP system for efficient cleaning, reducing downtime and ensuring continuity in production. Customizable elements, such as chamber sizes and throughput rates, ensure that the system can be tailored to your specific production needs, accommodating various pharmaceutical powders, lyophilized vaccines, and controlled-release formulations.

Benefits

- Ensures precise dosing, minimizing waste and enhancing product consistency.

- Reduces contamination risks through sterile, closed-system design.

- Integrates seamlessly into existing lines, improving overall production efficiency.

- Minimizes downtime with CIP-enabled quick and thorough cleaning.

- Tailors to specific needs with customizable chamber sizes and throughput capabilities.

- Applications

- Apis (active pharmaceutical ingredients), Pharmaceuticals, Biopharmaceuticals, Hygroscopic products, Pharmaceutical powders, Ophthalmic products

- End products

- Inhalable pharmaceutical powders, Lyophilized vaccines, Lyophilized pharmaceuticals, Active pharmaceutical ingredient powders, Monoclonal antibodies, Oral solid dosage forms, Moisture-sensitive biopharmaceuticals, Ophthalmic solutions, Oncology drugs, Injectable drugs, Controlled-release formulations

- Steps before

- Sample removal, Weighing

- Steps after

- Testing, Unloading, Charging

- Input ingredients

- API containers, drums, bags

- Output ingredients

- weighed samples, tested samples

- Market info

- Telstar is known for specializing in the design, engineering, and manufacturing of advanced vacuum and aerospace solutions, gaining a strong reputation for their innovative and customized equipment in pharmaceutical, medical, and scientific research sectors.

- OEL (Occupational Exposure Limit)

- <0.1μg/m³ over an 8hr TWA

- Chamber Type

- Multi-chamber system

- Glove Chamber Configuration

- 2 glove pass-in chamber, 4 glove main chamber, 2 glove sampling chamber

- Integrated Weigh Platform

- High accuracy

- Drum Docking System

- Contained connection

- Working mechanism

- Multi-chamber system with glove boxes

- Integrated steps

- Sample removal, weighing, testing

- Automation level

- High

- PLC controlled

- CIP/SIP

- Available

- Batch vs. continuous operation

- Batch

- Changeover time

- Optimized for efficiency

- Cleaning method

- CIP / Manual

- OEL (Operator Exposure Limit)

- <0.1μg/m³ over an 8hr TWA

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Compact design

- Chamber Configuration

- Multi-chamber with glove ports

- Glove Ports

- 2-code pass-in chamber, 4-glove main chamber, 2-glove sampling chamber

- Docking System

- Drum docking system

- Pass-in Chamber

- Single glove for drums/bags

- Integrated Features

- Integrated weigh platform

- Glove chamber configuration

- 2 glove, 4 glove

- Weigh platform integration

- High accuracy

- Sampling chamber configuration

- Single glove

- Drum docking system

- Contained connection