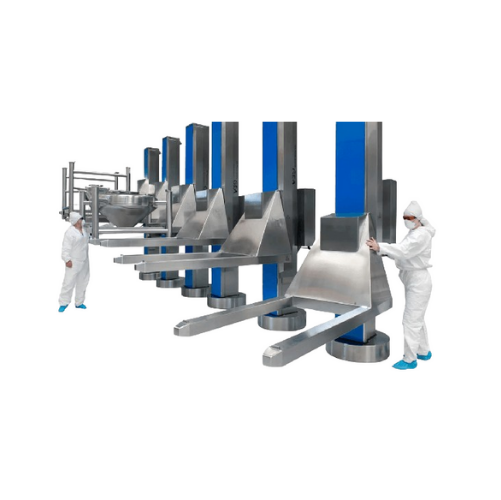

Ibc post hoists for pharmaceutical manufacturing

Ensure precise material handling with advanced lifting solutions designed for seamless integration into pharmaceutical production lines, enhancing operational control and safety.

Lifts, Docks, and Blends Pharmaceutical Materials

The GEA Post Hoist offers a comprehensive solution for pharmaceutical manufacturers handling sensitive materials. This versatile lifting system employs a robust rack and pinion mechanism, designed to carry up to four times its working load, ensuring reliable and safe operation. Specializing in the lifting, docking, and blending of powders and granules, it facilitates processes such as IBC inverting and weighing.

Typically utilized in the production of antibiotic granules, pain relief, and oncology tablets, as well as vaccine powdered ingredients, the IBC Post Hoist excels in challenging environments. With options for manual or electrically driven slewing, it provides flexible integration into continuous or batch processing lines. Engineered with a user-friendly control interface, including Siemens or Allen Bradley PLC/HMI systems, it supports sophisticated control needs and variable speed operation.

The IBC Post Hoist’s all-electric, braked motor eliminates hydraulic issues, aligning with GMP requirements and simplifying maintenance. It supports static and dynamic operations, suitable for environments demanding high safety standards, and meets compliance regulations. Equipped with a fully enclosed column and remote control system, this hoist ensures seamless integration with upstream and downstream processes, enhancing efficiency and productivity in pharmaceutical, food, and fine chemical industries.

Benefits

- Enhances operational safety with a robust lifting mechanism rated for high load limits.

- Facilitates precise material handling, improving process efficiency and reducing errors.

- Integrates seamlessly into production lines, supporting both batch and continuous operations.

- Supports GMP compliance, streamlining validation and regulatory approval.

- Simplifies maintenance with accessible design eliminating hydraulic components.

- Applications

- Biopharmaceuticals, Pharmaceutical powder, Fine chemicals, Pharmaceutical tablets

- End products

- Vaccine powdered ingredients, Antibiotic granules, Fine chemical powders, Active pharmaceutical ingredients (apis), Oncology tablets, Pain relief tablets

- Steps before

- Granulation, Dispensary Operations

- Steps after

- Milling, Sifting, Tablet Pressing, Blending, Filling

- Input ingredients

- IBC, granules, powders, dispensary materials, granulation equipment

- Output ingredients

- blended material, filled IBC, discharged IBC

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Safe Working Load

- 400 kg / 900 kg / 1600 kg

- Lift Speed

- 4 m/min for last lifting/lowering, 1 m/min for controlled docking

- Standard Column Height

- 3.8 m

- Reach

- 1450 mm from the centre of column to the centre of the IBC

- Lift Motor Power

- 1.5 kW / 2.2 kW / 3.0 kW

- Slew Motor Power

- 0.12 kW

- Pneumatics Supply Pressure

- 6 Barg

- Pneumatics for Slewing Position Lock

- 3 L/sec

- Pneumatics for Vibration

- 10 L/sec

- Pneumatics for Butterfly Valve Actuation

- 3 L/sec

- Power Lift

- Available for PL400, PL900, PL1600

- Automation

- Siemens or Allen Bradley PLC/HMI control system

- IBC Size

- Size 2/3/4 / Size 4 / Size 4/5

- Electrical Power

- 220-240V 3 Ph 60 Hz or 380-415V 3 Ph 50 Hz

- Safety Mechanism

- Robust rack and pinion rated at four times working load

- Drive Mechanism

- Electric braked motor

- Automation Level

- PLC/HMI controlled

- User Interface

- Hold-to-run principle

- Modular Design

- Versatile lifting and handling

- Gravity Discharge

- Eliminates vacuum conveying

- Variable Speed Drive

- Inverter option for variable speed

- Cleaning Method

- No hydraulic lifts (GMP compliant)

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Column mounted with push buttons

- Column Height

- Standard 3.8 m

- Reach

- 1450 mm from the centre of column to the centre of the IBC

- Fixing

- Floor, ceiling

- Column Design

- Fully enclosed motor and drive

- Control panel type

- Simple push buttons / PLC/HMI (Siemens or Allen Bradley)