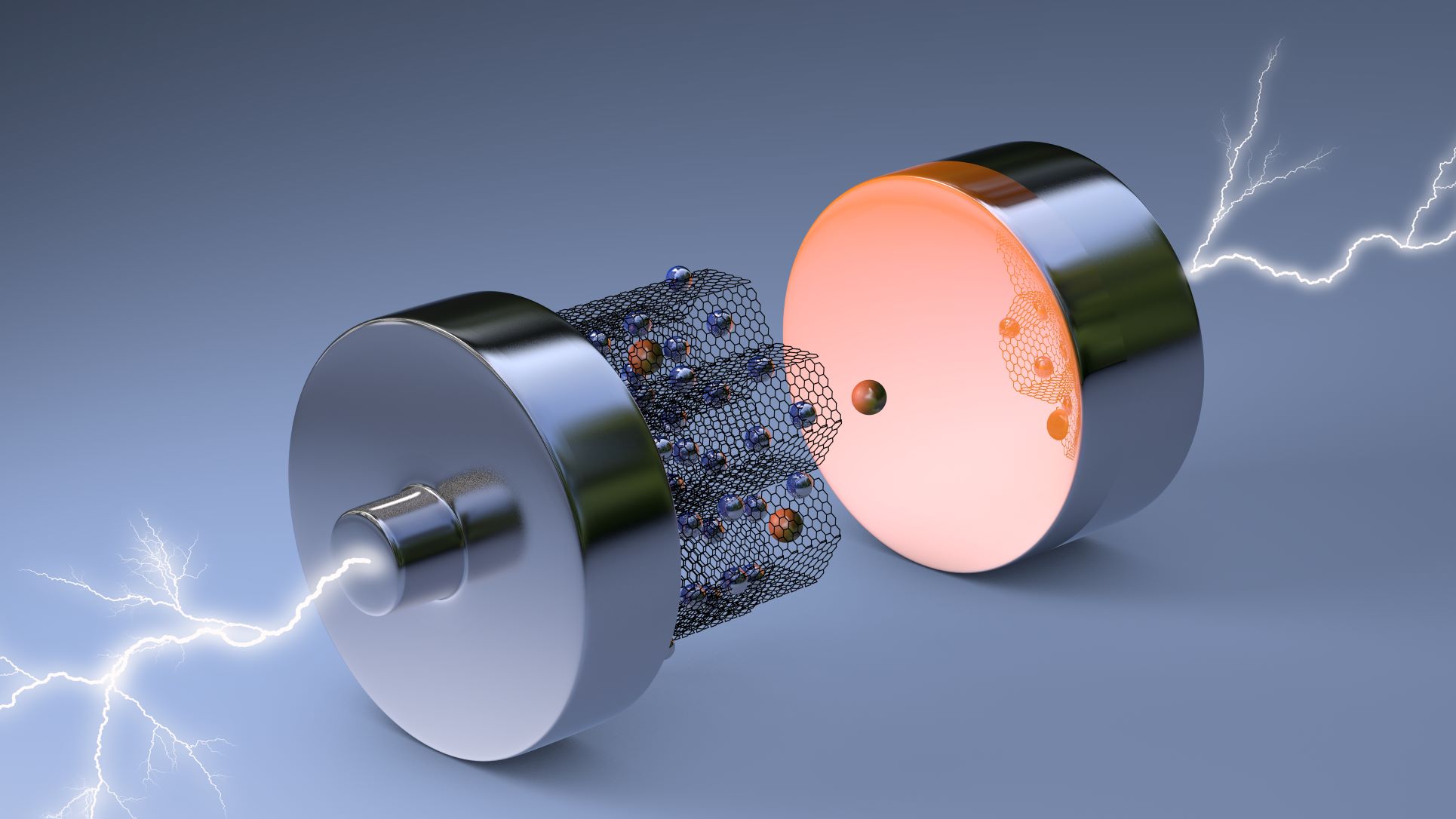

Lithium-ion battery powder processing solution

Optimize your lithium-ion battery manufacturing with advanced powder treatment solutions, ensuring precise drying and calcination for high-performance cathode and anode materials.

Calcines and Dries Battery Powders

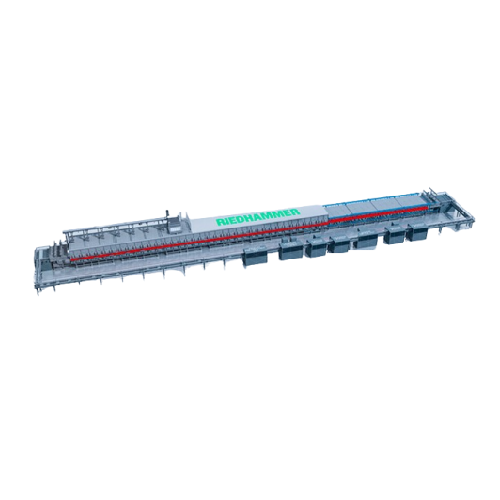

The Gastight Roller Hearth Furnace from SACMI is engineered for precision in battery powder processing. This furnace features a robust roller hearth design, allowing for controlled atmosphere adjustments essential for calcining lithium-ion battery materials, including cathode active materials (CAM) and LFP powders. Tailored for continuous and automated operations, it seamlessly integrates into production lines, ensuring consistent material quality and reducing contamination risks. With the capability to manage various temperature profiles and gas compositions, this furnace optimizes energy use while achieving uniform powder characteristics. Ideal for battery manufacturers and advanced material processors, it supports up to 300 operational units, demonstrating reliability and industry acceptance. Stainless steel construction ensures chemical resistance, and the design supports easy integration with upstream and downstream equipment, enhancing overall production efficiency.

Benefits

- Enhances material quality with precise atmosphere and temperature control.

- Minimizes operational costs through automated, continuous processing.

- Reduces energy consumption by optimizing heating efficiency.

- supports diverse battery powder formulations, ensuring production flexibility.

- Integrates effortlessly into existing production lines, maximizing efficiency.

- Applications

- Batteries, Lfp powders, Cam, Lithium-ion batteries, Battery powders, Cathode active materials, Aam

- End products

- Aam powder, Lfp cathode powders, Cam powder, Lithium-ion battery precursors, Battery electrode materials

- Steps before

- Intralogistics automation, Material preparation

- Steps after

- Packing, Battery recycling

- Input ingredients

- AAM, CAM, precursors, LiB materials, battery powders, LFP cathode powders

- Output ingredients

- processed battery materials, finished Li-ion battery components, calcined powders

- Market info

- Sacmi is renowned for manufacturing advanced industrial equipment, primarily focusing on ceramics, packaging, and food processing. With a commitment to innovation and quality, Sacmi is a market leader in providing engineered-to-order solutions across various sectors.

- Process Type

- Spray drying, calcination

- Automation Level

- Intralogistics automation

- Atmosphere Control

- Precise atmosphere adjustment

- Drying Method

- Spray drying

- Temperature Profiles

- Multiple profiles

- Heating Method

- Indirect heating

- Plant Type

- Battery recycling plant

- Production Capacity

- >300 roller hearth kilns, >60 rotary kilns

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- PLC / SCADA

- Powder treatment integration

- Intralogistics, automation, packaging

- Atmosphere control

- Multi-atmosphere

- Temperature profile flexibility

- Custom profiles

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Customized

- Feed/Discharge Method

- Automated

- Structure Type

- Roller Hearth Furnace / Rotary Kiln / Spray Dryer

- Temperature Control

- Wide Range / Precise

- Heating Method

- Indirect / Direct

- Atmosphere Adjustment

- Multiple Atmospheres

- Control panel type

- Touchscreen / PLC

- Integration possibilities

- SCADA / ERP

- Temperature control

- Precise / Adjustable

- Atmosphere adjustment

- Multiple atmospheres

- Device type

- Roller hearth kiln / Rotary kiln / Spray dryer