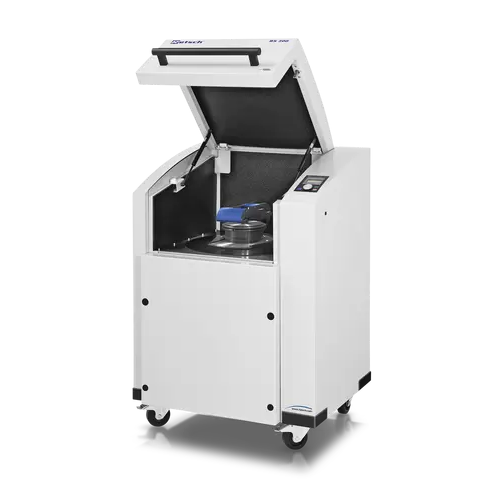

Vibratory disc mill for sample homogenization to analytical fineness

Achieve exceptional precision in sample preparation with a mill that rapidly pulverizes even the toughest materials to analytical fineness, ensuring consistency and reproducibility for demanding laboratory and industrial applications.

Pulverizes and Homogenizes Sample Materials Efficiently

The Vibratory Disc Mill RS 200 from Retsch is a robust solution for laboratories needing precise sample processing. It employs circular horizontal vibrations driven by a powerful 1.5 kW motor, generating intense pressure and friction to achieve analytical fineness within minutes. Specifically designed for industries such as construction materials, geology, and ceramics, it ensures reproducible results essential for quality control. The RS 200 processes a diverse range of materials including cement, minerals, and metal oxides, making it indispensable for producing refined powders. With a capacity to handle 15-250 ml batches, it offers speed variability from 700 to 1500 rpm and automatic speed adjustments for tungsten carbide or agate sets, enhancing material preservation and energy efficiency. Safety features include a noise-insulated chamber and sensor-controlled operations. Supported by a user-friendly interface with digital settings, it allows storing multiple operating protocols and facilitates seamless integration into automated laboratory environments. The grinding sets, available in various materials like zirconium oxide and hardened steel, assure durability and resistance to mechanical stress, while allowing easy cleaning and maintenance.

Benefits

- Achieves consistent analytical fineness, enhancing the accuracy of quality control and research outcomes.

- Reduces sample preparation time with rapid processing speeds, increasing laboratory efficiency.

- Minimizes material waste through precise speed adjustments, ensuring sample integrity.

- Enhances operator safety with ergonomic design and sensor-controlled operations.

- Supports diverse material processing for versatile application across multiple industries.

- Applications

- Minerals, Slag, Cement, Coke, Corundum, Glass, Coal, Glass/ceramics, Geology/metallurgy, Soil, Iridium, Ceramics, Construction materials, Electronic scrap, Dolomite, Metal powders, Ores, Environment/recycling, Silicate, Metal oxides, Concrete

- End products

- Coke breeze, Metal oxide capsules, Shredded circuit boards, Dolomite ceramics, Agricultural soil amendments, Recycled glass cullet, Glass fiber battings, Cement dust samples, Pottery clay powders, Metallurgical powder samples, Silicate flame retardants, Ore concentrate powders, Ceramic glaze powders, Blast furnace slag cement, Iridium alloy powders, Refined metal alloys, Refractory corundum, Coal dust samples, Geological mineral samples, Industrial concrete aggregates, Electronics recovery slag

- Steps before

- Sample collection, Size reduction of larger pieces, Drying

- Steps after

- Spectral analysis, XRF analysis, Pellet pressing

- Input ingredients

- cement, cement clinker, ceramics, coal, coke, concrete, corundum, glass, metal oxides, minerals, ores, silicate, slag, soil, electronic scrap, iridium, dolomite

- Output ingredients

- analytical fineness, particle size distribution, reduced sample size, uniform particle distribution

- Market info

- Retsch is renowned for manufacturing high-quality laboratory equipment, specializing in milling, sieving, and assisting technologies for sample preparation and characterization, known for precision, reliability, and innovation in the scientific and industrial laboratory markets.

- Speed

- 700 - 1, 500 rpm

- Size reduction principle

- Pressure, friction

- Material feed size

- , lt

- 15 mm

- Final fineness

- , lt

- 20 µm

- Batch size / Feed quantity

- 15-250 ml depending on size of grinding set

- Drive

- 3-phase asynchronous motor with frequency converter

- Drive power

- 1.5 kW

- Net weight

- ~ 225 kg (without grinding set)

- Protection code

- IP 20

- Grinding jar sizes

- 50 ml / 100 ml / 250 ml

- Setting of grinding time

- Digital, 00

- Batch vs. continuous operation

- Batch

- Automation level

- Manual / PLC

- Changeover time

- Quick-action clamping system enables safe tightening

- Cleaning method

- Manual

- Energy efficiency

- Low kWh/kg

- Grinding mechanism

- Pressure and friction with Stabilized-Plane-Drive

- Sample size range

- 15-250 ml depending on grinding set size

- Material detection

- Automated sensor for grinding material recognition

- Sample homogenization time

- 60 to 180 seconds

- Safety features

- Sensor checks correct positioning and safety interlock

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- CE marking

- Yes

- Standards compliance

- EN 61010

- Machine footprint (W x H x D)

- 836 x 1220 x 780 mm

- Net weight

- ~ 225 kg (without grinding set)

- Grinding jar sizes

- 50 ml / 100 ml / 250 ml

- Control panel type

- Digital with graphic display

- Variable speed

- 700 to 1500 rpm

- Grinding jar material

- Hardened steel, tungsten carbide, agate, zirconium oxide

- Grinding jar sizes

- 50 ml / 100 ml / 250 ml

- Quick-action clamping system

- Yes

- Automatic speed reduction

- For agate and tungsten carbide sets

- Storable SOPs

- 10

- Language options for menu guidance

- 13 languages