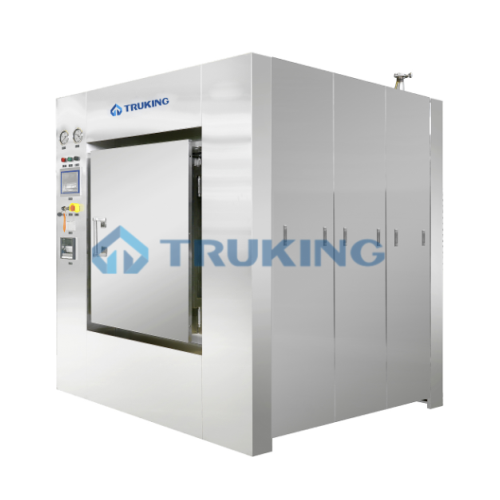

Pharmaceutical autoclave for terminal sterilization

Optimize your sterile production with high-precision terminal sterilization, ensuring the integrity of liquid and solid pharmaceutical products.

Sterilizes and Seals Pharmaceutical Products

The TRUKING Autoclave from TRUKING TECHNOLOGY LIMITED stands out for its precision in sterilizing pharmaceutical products. It features a real-time F0 value processing system, allowing for accurate sterilization against pressure and temperature parameters. This system is ideal for applications in biopharmaceuticals, such as vaccines and injectable formulations, ensuring a high standard of safety and compliance with GMP and FDA requirements.

Designed for continuous and high-speed operation, the TRUKING Autoclave can handle large-scale production, integrating seamlessly with upstream and downstream processes thanks to its industrial PC control with remote access and audit trail capabilities. The innovative jacketed chamber supports faster cooling cycles while maintaining energy efficiency.

Constructed with advanced TIG welding technology and a mirror-finished chamber at Ra 0.5um, the autoclave minimizes contamination risks. It includes a liquid ring pump for low-noise operation and a unique chamber door sealing device to maintain sealing pressure during power outages. Maintenance is simplified with an easy-access modular design and online sterilization and integrity testing features.

Benefits

- Ensures product safety with precise and reliable sterilization.

- Enhances production efficiency through continuous high-speed operation.

- Reduces energy usage with efficient cooling systems.

- Simplifies maintenance with easy-access modular design.

- Complies with GMP and FDA standards for pharmaceutical applications.

- Applications

- Lyophilization productions, Liquid formulations, Pharmaceutical tablets, Oral preparations, Injectable formulations, Biopharmaceuticals, Traditional chinese medicine, Pharmaceutical powders

- End products

- Herbal capsules, Vaccines, Lyophilized vaccines, Liquid parenterals, Insulin, Cough syrups, Fill-finish vials, Pre-filled syringes, Herbal extracts, Effervescent tablets, Antibiotic powders

- Steps before

- Purification, Preparation System, Oral Preparation, Drying, Extraction, Concentration

- Steps after

- Packing, Inspection, Leakage Testing, Secondary Packaging

- Input ingredients

- containers for terminal sterilization, BFS (Blow-Fill-Seal) containers, PFS (Pre-Filled Syringe), LVP (Large Volume Parenterals), SVP (Small Volume Parenterals)

- Output ingredients

- sterilized BFS containers, sterilized PFS, sterilized LVP, sterilized SVP

- Market info

- Truking is known for manufacturing engineered-to-order pharmaceutical equipment, specializing in liquid and solid preparation systems. They have a strong reputation for innovation and quality in the pharmaceutical machinery sector.

- Real time F0 value processing

- Yes

- Pressure,temperature accuracy

- Accurate curve graph

- Contamination prevention

- Air partition with steam pressure relief outlet

- Process control monitoring

- Online and real time feedback

- Jacketed chamber design

- Faster cooling through PID program

- Utility consumption efficiency

- Modular design

- Welding technology

- Advanced TIG welding

- Chamber finish

- Mirror finish at Ra 0.5um

- Door sealing device

- Ensures sealing pressure in case of power failure

- Sterile filter testing

- Online sterilization and integrity testing

- Control system

- Industrial PC control

- Audit trail compliance

- 21 CFR Part 11 compliance

- Real-time monitoring

- Yes

- Cycle monitoring

- Online, real-time feedback

- Process control

- State of the art

- Automation level

- Industrial PC control / PLC

- Batch vs. continuous operation

- Batch

- Sterilization method

- Steam air mixture / Super-heated water

- Separation design

- Superior design separators

- Cooling process

- Innovative jacketed chamber design

- Sterile filter testing

- Online sterilization and integrity testing

- Data integrity

- 21 CFR Part 11 compliance

- Machine Footprint

- Compact

- Chamber Shape

- Jacketed

- Chamber Finish

- Mirror Finish at Ra 0.5um

- Feed/Discharge Method

- Terminal Sterilization

- Cooling System

- Faster Cooling through PID Program

- Noise Level

- Minimum Noise with Liquid Ring Pump

- Door Sealing Device

- Unique Sealing Pressure Device

- Jacketed Chamber Design

- Yes

- Chamber Door Sealing Device

- Yes