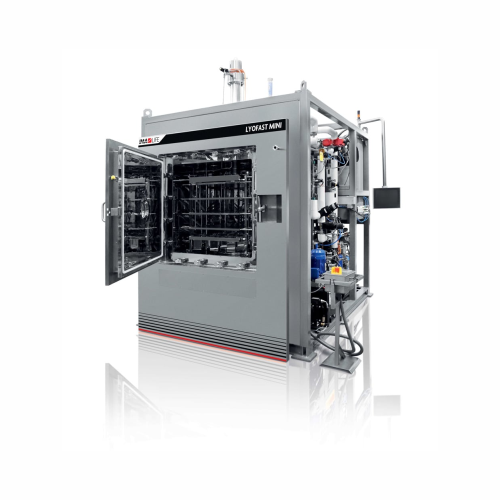

Pilot freeze dryer for pharmaceutical applications

Optimally bridge laboratory development and full-scale production with this compact freeze dryer, designed to enhance process reliability and efficiency in pharmaceutical and biotech applications, ensuring precise control over moisture removal for high-quality end products like vaccines and monoclonal antibodies.

Optimizes Freeze Drying for Biopharmaceuticals

The LYOFAST MINI from IMA Life is a compact pilot freeze dryer designed to bridge laboratory development and full-scale production. This equipment excels in optimizing freeze drying for critical applications such as vaccines, monoclonal antibodies, and lyophilized powders. It features four configurations, offering shelf areas from 1 to 2.8 m² with automatic stoppering pressure control. Integration is seamless with UAF, RABS, and isolators, supported by a compact SCADA system for comprehensive monitoring. The patented FUSION™ technology enhances heat transfer efficiency, allowing precise temperature control and energy usage reduction. Clean-in-place (CIP) and steam-in-place (SIP) systems ensure compliance with GMP standards, while flexible shelf spacing accommodates varied product types. Ideal for pharmaceutical, biotech, and food industries, the LYOFAST MINI supports R&D departments in scaling up freeze drying processes efficiently and reliably.

Benefits

- Enhances process reliability with FUSION™ technology for superior heat transfer.

- Seamlessly integrates with isolators and RABS, ensuring contamination control.

- Minimizes energy costs through optimized motor control.

- Scales efficiently from R&D to pilot production, reducing development time.

- Maintains compliance with GMP standards for pharmaceutical applications.

- Applications

- Pilot production products, Freeze drying products, Biotech products, Biopharmaceuticals, Pharmaceutical products, Laboratory development products

- End products

- Active pharmaceutical ingredients (apis), Vaccines, Monoclonal antibodies, Lyophilized powders, Diagnostic reagents, Stabilized biological samples, Injectable drugs, Clinical trial drugs, Recombinant proteins, Laboratory-scale samples

- Steps before

- Product development, Laboratory development, Process cycle optimization, Scale-up batches preparation

- Steps after

- Industrial production, Small-scale production, Integration with RABS/isolators, Loading and unloading systems

- Input ingredients

- product batches, unstable product at ambient temperatures, 2R vials

- Output ingredients

- freeze-dried product, stabilized product, reduced energy requirement

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Shelf Area Range

- 1 - 2.8 m²

- Shelf Spacing

- 110 - 130 mm

- Number of Shelves

- 4 / 5

- Maximum Vials Loading Capacity (2R vial)

- 4, 536 - 11, 520

- Condenser Capacity

- 28 - 58 kg @ 12.7 mm ice

- CIP/SIP

- Included

- Slot Door

- Suitable for RABS/isolator integration

- Variable Shelf Interdistance

- Provided

- Automatic Stoppering Pressure Control

- Available

- Redundant Shelf Inlet Temperature Probes

- Available

- SCADA System

- Lyomaster compact

- Integration Compatibility

- UAF, RABS, Isolators, Automatic and Semi-automatic Loading and Unloading Systems

- Shelf Technology

- FUSION™ - FUSION PLUS™

- Batch vs. continuous operation

- Batch

- CIP/SIP

- Included

- Automation level

- SCADA

- Integration capability

- RABS/Isolator

- Stoppering control

- Automatic pressure control

- Shelf variability

- Variable shelf interdistance

- Process cycle optimization

- Included

- Process scale-up potential

- Laboratory to industrial

- Loading/Unloading options

- Automatic/semi-automatic

- Corrosive resistance (e.g. acids)

- Stainless Steel / Corrosion Resistant Coatings

- Machine footprint

- Not specified

- Shelf Area Range

- 1 to 2.8 m²

- Shelf Size (w x d)

- 643 x 615 mm / 643 x 916 mm

- Number of Shelves

- Variable based on configuration

- Slot door integration

- Compatible with RABS/isolator

- Shelf Interdistance

- Variable

- Control panel type

- Lyomaster compact SCADA

- Compact footprint

- Yes

- Control panel type

- Lyomaster compact SCADA

- Integration possibilities

- UAF, RABS, isolators, automatic and semi-automatic loading/unloading systems

- Shelf configurations

- 1 to 2.8 m²

- Shelf interdistance

- Variable

- Automatic stoppering pressure control

- Included

- Shelf technology

- IMA Life’s FUSION™ technology