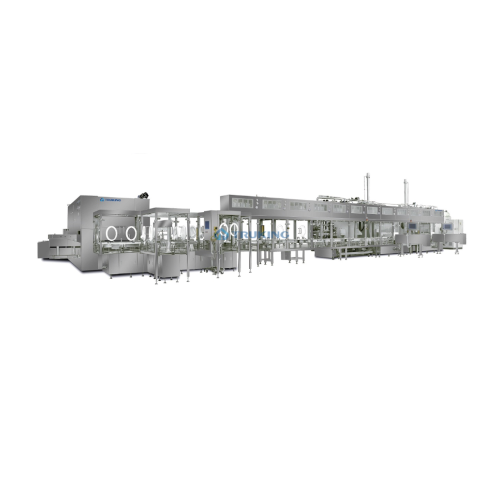

Auto loading & unloading system for freeze dryers

Efficiently manage vial handling in freeze-drying processes with automated loading and unloading, ensuring sterile transfer and compliance with regulatory requirements, optimized for temperature-sensitive products.

Automates Loading and Unloading of Vials

The Integrated Auto Loading and Unloading System Lalutk Series from TRUKING is tailored for seamless vial transfer in freeze-drying operations. Specially engineered for biopharmaceutical and pharmaceutical applications, this system ensures sterile handling and meets stringent cGMP and FDA standards.

Featuring a Siemens multi-servo synchronous technology, it efficiently conveys, buffers, and rejects vials while maintaining high-speed capacity. The system’s automatic bellows integrity testing and pizza sliding door mechanism guarantee contamination-free operations. It supports dynamic speed control and includes features for precise vial orientation and feeding.

Ideal for producing vaccines, antibodies, and lyophilized pharmaceuticals, the Lalutk Series is equipped with options for ORABS, CRABS, and isolators, ensuring containment up to OEL5. The robust industrial PC control, complying with 21 CFR Part 11, offers audit trails, data integrity, and remote access.

This solution is designed to integrate seamlessly with existing production lines, enhancing throughput and operational reliability while minimizing manual intervention and safeguarding temperature-sensitive products.

Benefits

- Enhances precision and efficiency in freeze-drying operations, minimizing product loss.

- Ensures compliance with industry standards, fostering trust and safety in production.

- Streamlines processes, reducing labor costs and manual handling.

- Protects temperature-sensitive pharmaceuticals with tailored loading solutions.

- Seamlessly integrates with existing systems for uninterrupted production flow.

- Applications

- Injectable, Pharmaceutical tablets, Oral liquid, Softbag production, Lyophilization production, Biopharmaceuticals, Diagnostic reagent, Pre-filled syringe production, Ampoule production, Chinese traditional medicine

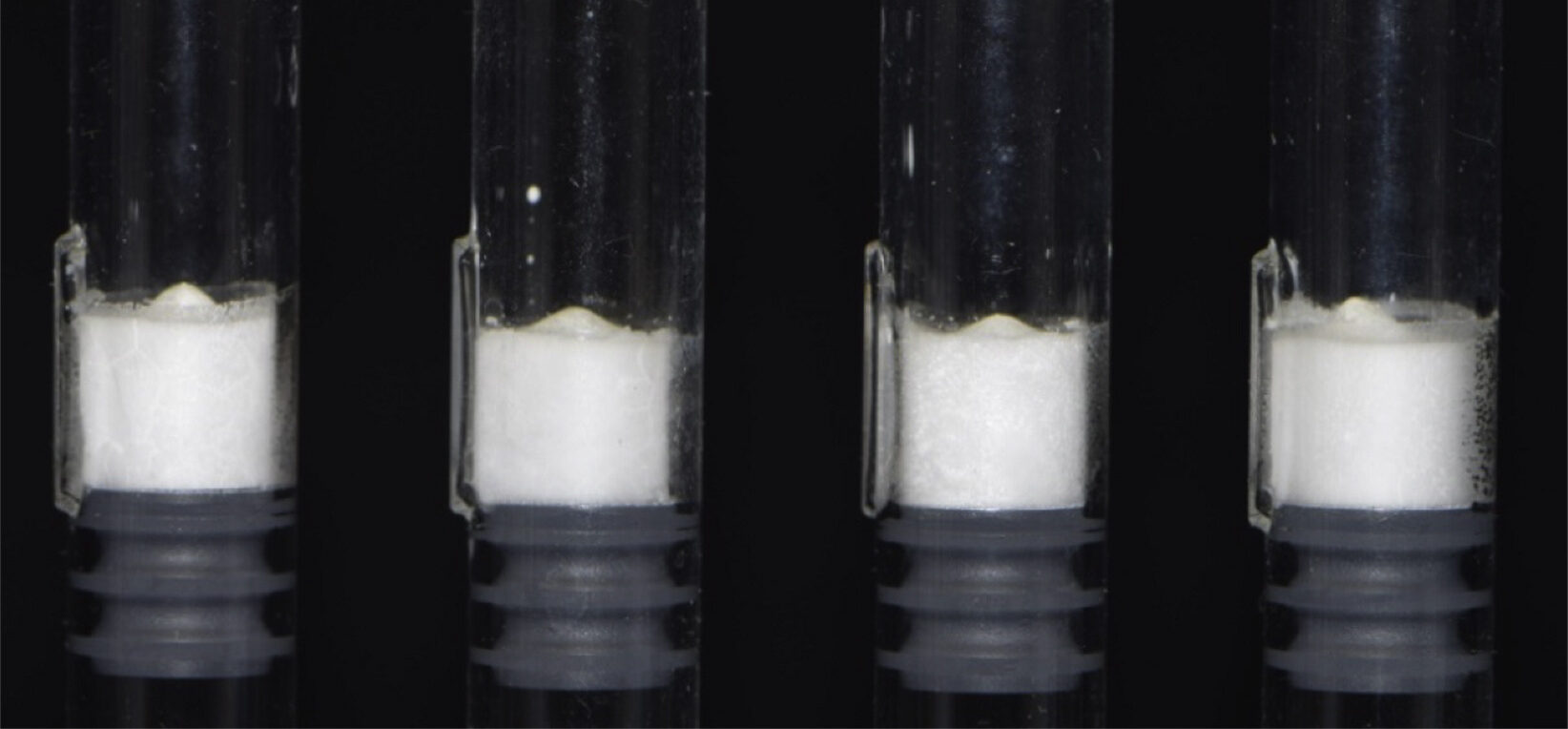

- End products

- Vitamins, Traditional chinese medicine powder, Lyophilized vaccines, Diagnostic reagents for blood glucose testing, Traditional chinese herbal extracts, Antibiotics, Elixirs, Linctuses, Lyophilized enzymes, Insulin, Ampoules containing liquid medicines, Cough syrups, Vaccines, Pre-filled insulin syringes, Ophthalmic solutions, Parenteral nutrition solutions, Soft iv bags for saline solutions, Diagnostic test kits, Antibody therapeutics, Enzyme supplements, Freeze-dried plasma, Pre-filled heparin syringes

- Steps before

- Purification, Preparation, Loading, Vial Orientation, Bottle Feeding

- Steps after

- Unloading, Sterilization, Inspection, Packing, Labeling

- Input ingredients

- vials, bottles, temperature sensitive products

- Output ingredients

- freeze-dried vials, rejected bottles, processed sterile vials

- Market info

- Truking is known for manufacturing engineered-to-order pharmaceutical equipment, specializing in liquid and solid preparation systems. They have a strong reputation for innovation and quality in the pharmaceutical machinery sector.

- Vials conveying

- Automatic

- Vials buffering

- Yes

- Fallen bottle rejection

- Automatic

- Freeze-drying machine layer connecting

- Automatic

- Bottle feeding and outfeed conveying

- Integrated

- Automatic vials transfer

- Yes

- Vial orientation,rejection

- Automatic

- Infeed and outfeed integration

- Dynamic speed control

- In feed adoption

- Siemens multi-servo synchronous technology

- Automatic Bellows integrity testing

- Online

- Pizza sliding door

- Incorporated with auto loading system

- Containment level

- OEL 5

- Temperature-sensitive product loading

- Low temperature

- Control system

- Industrial PC

- Audit trail

- 21 CFR Part 11 compliance

- Data integrity

- Yes

- Graphical debugging

- Available

- Remote access

- Available

- Vials conveying

- Automatic

- Vial orientation,rejection

- Automatic

- Infeed and outfeed integration

- Dynamic speed control

- Auto stacking,loading and unloading system

- Front and back pusher

- Containment level

- OEL 5

- Sterile transfer

- Till OEL5

- Automatic bellows integrity testing

- Online

- Temperature sensitive loading

- Low temperature

- Control system

- Industrial PC

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Vial capacity

- Various, depending on system configuration

- Loading/Unloading system

- Front and back pusher

- Containment level

- OEL5

- Door type

- Pizza sliding door

- Automation level

- Fully automatic, semi-automatic

- Control panel type

- Industrial PC, Siemens multi-servo synchronous technology

- Integration possibilities

- Complies with GAMP, cGMP, FDA

- Containment level

- OEL 5, ORABS/CRABS/Isolators

- Remote access

- Enabled, complying with 21 CFR Part 11

- Temperature control

- Low temperature loading for temperature sensitive products