Making Effervescent Tablets

Find innovative production technology for making effervescent tablets and connect directly with world-leading specialists

The fizz of effervescent tablets is commonly associated with a vitamin C boost. But the soluble pill is an excellent drug delivery method for pediatric and geriatric patients. Sometimes referred to as carbon tablets, manufacturing effervescent tablets binds biocarbonate and citric acid that produce the smooth hiss as they dissolve in liquid.

Select your effervescent tablets process

Tell us about your production challenge

Manufacturing effervescent tablets with a mix of lubricants reduces scumming

Water-soluble lubricants such as sodium benzoate have an added benefit in acting as glidants when manufacturing effervescent tablets. The anti-adherent properties of the organic salt add plasticity to the final product.

However, the inclusion of other lubricants like magnesium stearate and polyethylene glycol in negligible amounts reduces scumming in the final solution.

Limit humidity to 1.0% weight during wet granulation

Moisture levels are restrained to between 18°C and 23°C, with 10% relative humidity during the manufacturing process.

This presents an added challenge when wet granulation is performed. During this stage, water is kept to a maximum of 1.0% weight by weight of the mixture. Granules are then immediately conveyed to an oven dryer.

Apply drying agents in tube packaging

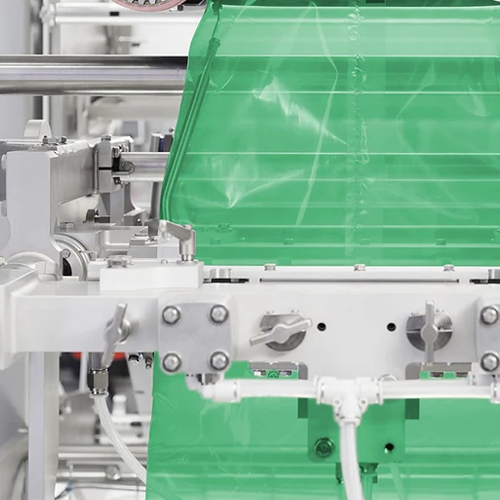

Avoid polymer blister materials or tubes for packaging that let in moisture and air. The compaction of effervescent tablets traps air bubbles. But if the tablets are exposed to water or oxygen, these will trigger the effervescent reaction ahead of use.

Blister packaging and aluminum foil protect the tablets from the surrounding environment following manufacturing. In the case of tubes, drying agents or silica gel prevents the penetration of humidity and air.

Processing steps involved in effervescent tablets making

Which effervescent tablets technology do you need?

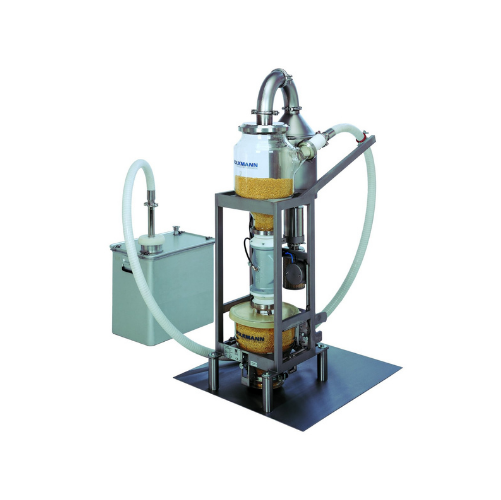

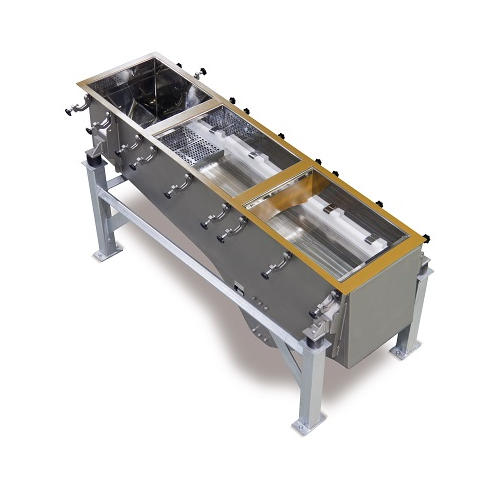

Powder sampler systems for food and dairy plants

Ensure precise quality control by implementing advanced sampling techniqu...

In-situ fiber optic Uv-vis spectrometer for dissolution studies

Optimize drug formulation by obtaining real-time, in-sit...

In-vitro dissolution-absorption assessment

Optimize drug formulation tests by combining dissolution and absorption measure...

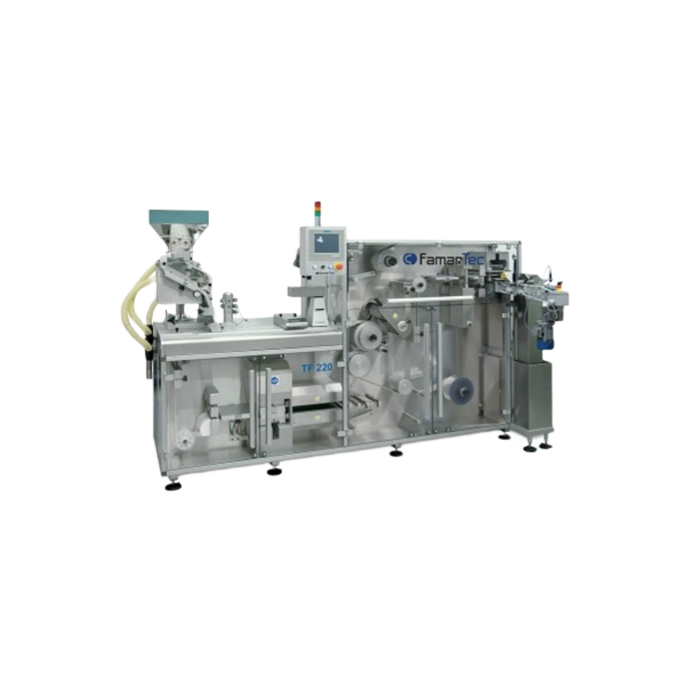

Blister thermoforming for Pvc/alu

Effortlessly mold and seal blister packs for a range of solid products, optimizing packag...

Stickpack filling and closing system

Optimize your stickpack production with precise dosing, uniform sealing, and seamless ...

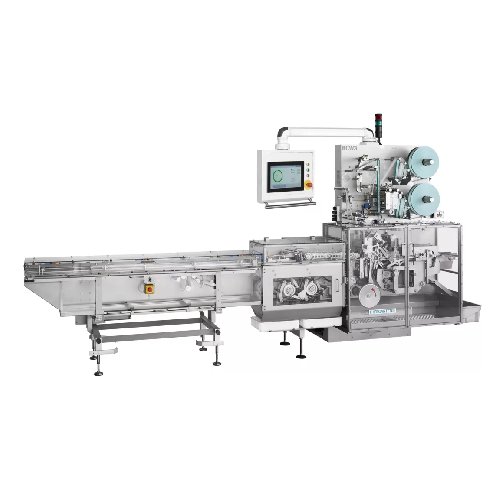

Compact strip packaging for solid products

Efficiently package a variety of solid pharmaceutical products with precision a...

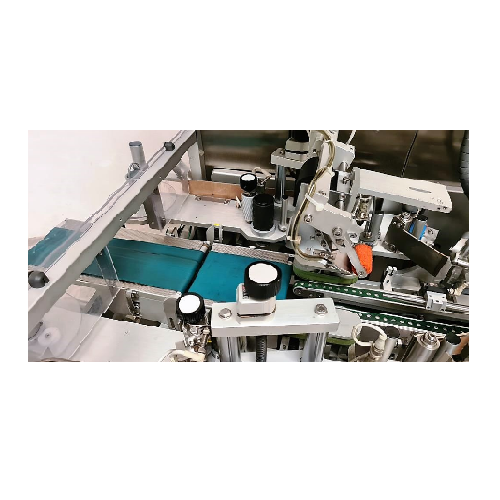

Counting and capping solution for tablets and capsules

Streamline your tablet and capsule production with a high-speed so...

Mixing granulator for pharmaceutical and cosmetic industries

Achieve precise granulation and uniform mixing for high-qua...

Film coater for Otc and food supplements

Achieve optimal film coating for tablets and capsules with precision-engineered so...

Carbon dioxide headspace analyzer for parenteral containers

Ensure accurate headspace gas analysis to maintain container...

Water activity headspace analyzer for drug product samples

Ensure precise control of moisture levels across the entire p...

High-containment diverter for continuous tablet and capsule filling

Enhance your production line with a versatile solut...

Dust-tight dispenser for metal detector test tablets

Ensure seamless integration of test tablets in high-containment envi...

Tablet deduster with upward conveying

Ensure consistent dedusting and deburring of tablets and capsules while maintaining h...

High performance tablet deduster with metal detection

Achieve precision dedusting and metal detection in tablet processin...

High-containment tablet deduster

Ensure optimal purity and safety in pharmaceutical production with high-containment dedusti...

Capsule polisher for pharmaceutical production

Enhance capsule quality and safety by effectively polishing, dedusting, and...

Capsule polisher for pharmaceutical capsules

Ensure your capsules are free from dust and perfectly polished with a solutio...

Tablet and capsule diverter

Streamline your tablet and capsule production with precise container filling and flexible config...

Powder induction system for high solid concentrations

Optimize your production line with this advanced system designed to...

Ultrasonic liquid processor for feasibility testing and procedure optimization

Optimize your liquid formulations by en...

Industrial silos for powdered and granulated products

Optimize your storage and material flow for powdered and granulated...

Single-pot granulation processor for pharmaceutical applications

For manufacturers needing precise granulation and dryin...

Horizontal intermittent motion sachet packaging solution

Optimize your packaging operations with a versatile sachet solut...

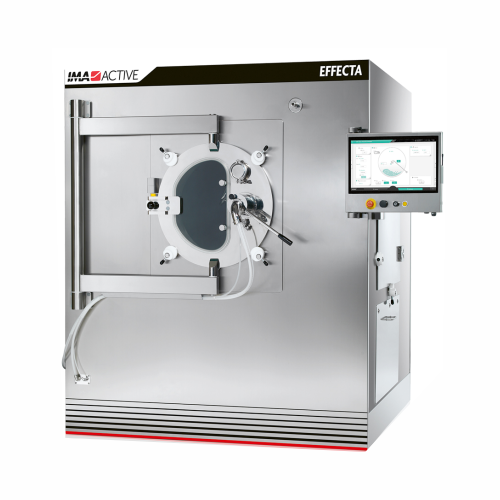

Continuous coater for tablet coating

Achieve seamless tablet coating with continuous processing, enhancing efficiency and r...

Tablet coating pan for pharmaceutical and nutraceutical industries

Enhance coating efficiency with a versatile solution...

Tablet pressing system for solid chemicals and cosmetic products

Optimize your tableting process for diverse solid produ...

Pure steam generation and distribution system

Ensure reliable sterilization with pure steam that’s free from contami...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Conical paddle mixer for accurate powder blending

Achieve precise blending of fragile powders and liquids with a versatil...

Continuous powder agglomeration system

Enhance product solubility and flowability while minimizing energy consumption with ...

Sugar grinding and recrystallization system

Optimize your sugar production with a system that integrates grinding and recr...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Discharge systems for difficult bulk materials

Achieve seamless bulk material discharge with our advanced systems that eff...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

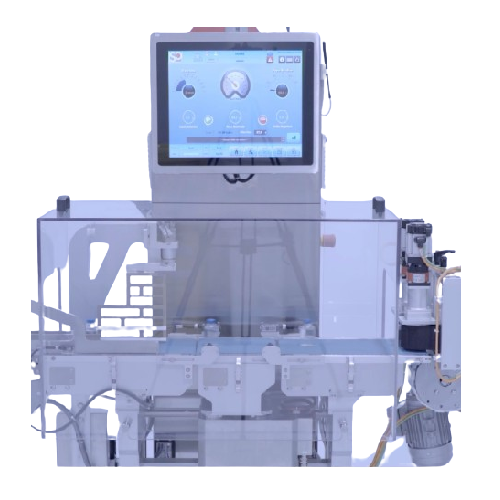

Fill level and closure inspection system

Ensure precise fill levels and secure closures in high-speed liquid packaging envi...

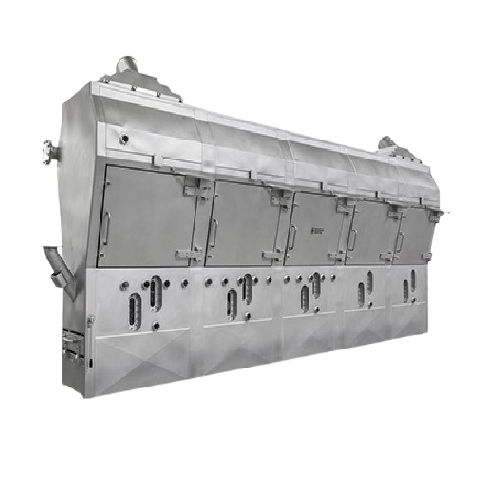

Continuous drying system for viscous substances

When handling viscous substances, ensure precise moisture control with con...

In-process weighing system for capsules and tablets

Ensure precise dosing and consistent quality with a format-free syste...

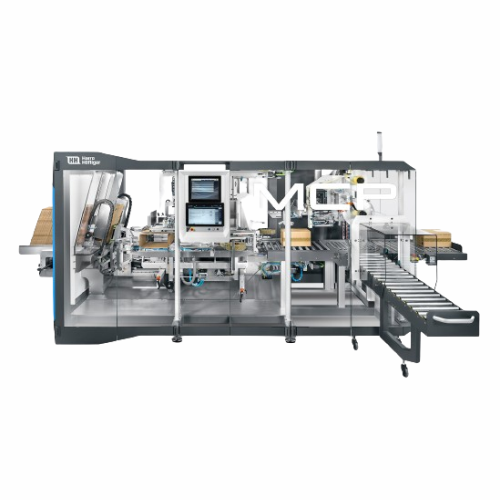

End-of-line casepacker for shipping boxes

Streamline your packaging line efficiency with this versatile casepacker, design...

High-containment capsule dosing and filling system

Achieve precise dosing and optimal containment for pharmaceutical prod...

Capsule filling system for powder, pellets, and tablets

Optimize capsule production with rapid dosing changes, minimizing...

Powder flow control system for gravity transfer

Ensure precise dosing and prevent spillage during powder transfers in your...

Tablet storage and transport containers

Ensure the safe and gentle handling of tablets during storage and transport, minimi...

Industrial bin blenders for uniform batch production

Optimize your blending process by achieving uniform mixtures with in...

Conical mills for size reduction in pharmaceutical production

Achieve precise particle size control with an innovative m...

Capsule conveyors for gentle capsule transfer

Streamline your capsule production line with a system designed for high-spee...

High shear granulation mixing system

Optimize your powder granulation process with a system designed for precise control ov...

Pilot High shear granulator for wet granulation

Achieve consistent particle sizing and superior homogeneity in your powder...

Mini High shear granulator for wet granulation

Optimize your powder granulation with precision and flexibility, ensuring c...

High shear wet granulation line

Achieve consistent and uniform granules with energy-efficient wet granulation designed to op...

Laboratory fluid bed system for solvent processing

Optimize your laboratory scale operations with a versatile fluid bed s...

Benchtop roller compacting system

Achieve precise powder densification and uniform dry granulation with this compact system...

Laboratory fluid bed granulator and coater

For researchers and manufacturers requiring precise control in drying, granulat...

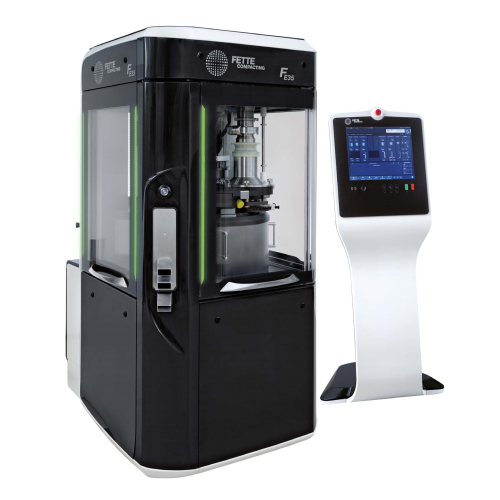

High-capacity tablet press for pharmaceutical production

Achieve precise compression and consistent tablet density with a...

High performance tablet press for large batches

For manufacturers aiming to boost tablet production without sacrificing pr...

Fluid bed processor for granulation and coating

Fluid bed processors offer efficient granulation and coating, streamlining...

Particle sizer for precise sifting

Optimize your production line with high-speed particle sizing, ensuring precise control ...

Laboratory high speed mixer for powders and granules

Achieve homogenous blending of powders and granules efficiently with...

Advanced friability and abrasion testing solution

Ensure precise compliance in pharmaceutical tablet testing with this in...

All-purpose mixer and processor for laboratory and small scale production

Optimize your small-scale production with a ...

Wet granulator for pharmaceutical applications

Achieve precise granule consistency with advanced oscillating rotor technol...

Conical mill for particle size reduction and homogenization

Achieve precise particle size reduction and homogenization w...

Dissolution testing system with Hplc analysis

Streamline your dissolution testing with integrated HPLC analysis, offering ...

Dissolution testing software for compliance and efficiency

Ensure data integrity and streamline compliance with a robust...

Dissolution online system for automated Uv-vis analysis

Ensure precise dissolution testing and seamless UV/VIS analysis w...

Intermittent stick pack packaging system for pharma products

Achieve precise dosage and packaging of pharmaceutical and ...

Intermittent stick pack system for pharmaceuticals

Effortlessly streamline your packaging process with a high-speed, mult...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

Pilot single-pot processor for granulation and drying

For efficient pilot production, streamline your mixing, granulating...

Fluid bed processor for granulating, drying, and coating in pilot scale

When scaling from laboratory to production, rel...

Planetary stirrer for creamy and foamy masses

Achieve consistent texture and optimal air incorporation in your products wi...

Laboratory coater and fluid bed processor

Optimize your research and development with a versatile benchtop unit that integ...

Laboratory cone mill for even grinding

Achieve consistent particle size for laboratory powders with precision calibration a...

Laboratory fluid bed dryer for pharmaceutical granulation

Optimize your lab-scale drying and granulation processes with ...

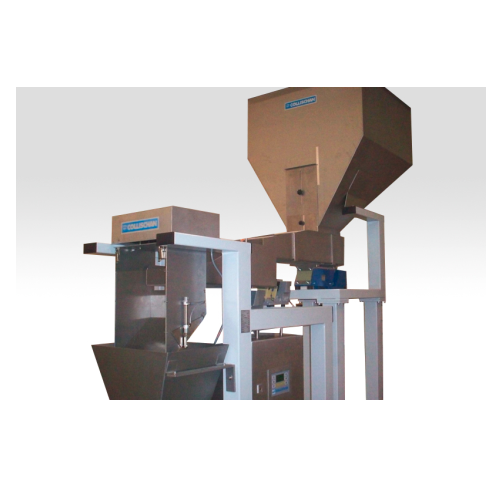

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

Basic checkweigher for weight control in low to medium performance

Ensure accurate weight control with a versatile chec...

Tablet counting solution for pharmaceutical industry

Maximize dosing precision and reduce miscounts in high-speed pharmac...

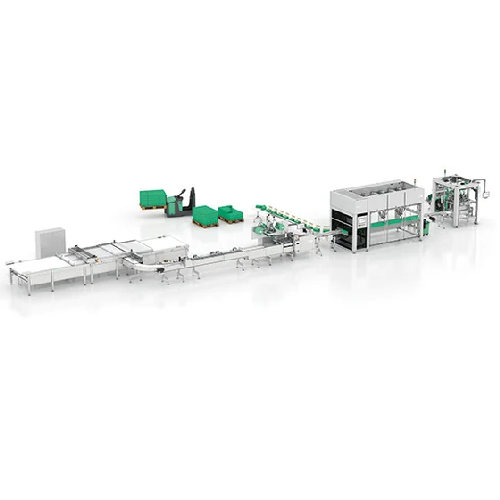

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

Microdosing system for granules and powder

Achieve precise dosing with minimal variance across all fills, ensuring consist...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

Mobile lifter solutions for pharmaceutical handling

Streamline your handling of sensitive materials with versatile mobile...

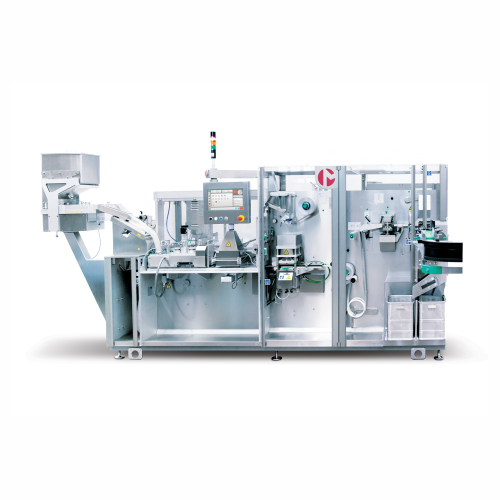

High speed blister packaging for pharmaceuticals

Need efficient packaging with quick format changeovers for various capsul...

Analyze wet granulation properties for pharmaceutical formulation

Optimize your pharmaceutical and chemical formulation...

Lab scale mixer, extruder & spheronizer for r&d formulation

Optimize and streamline your research and development proces...

Variable density pellets extruder and spheronizer

Develop diverse pellet densities for enhanced drug formulation with pre...

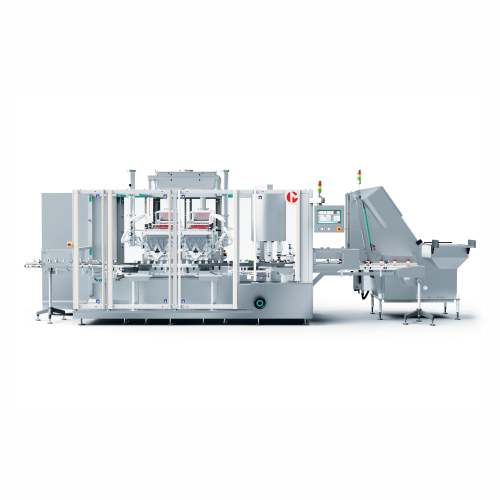

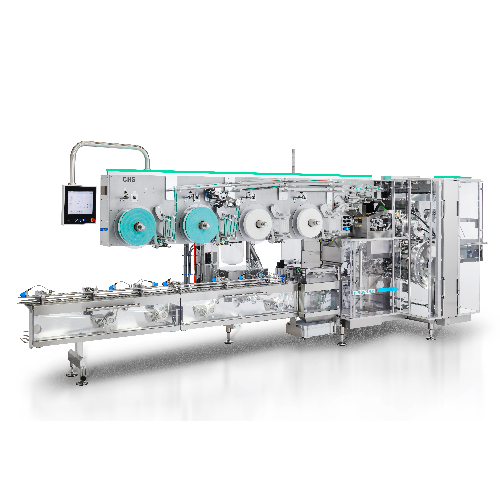

High-speed strip packaging for tablets and capsules

Optimize your high-speed pouching operations with precise four-side s...

High speed strip packaging for tablets and capsules

Ensure precise packaging of pharmaceutical tablets and capsules with ...

Bench-top mixer and spheronizer for formulation development

Accelerate R&D success by seamlessly integrating mixing...

Protein and nitrogen analysis system for laboratories

Streamline your nitrogen and protein analysis with precision titrat...

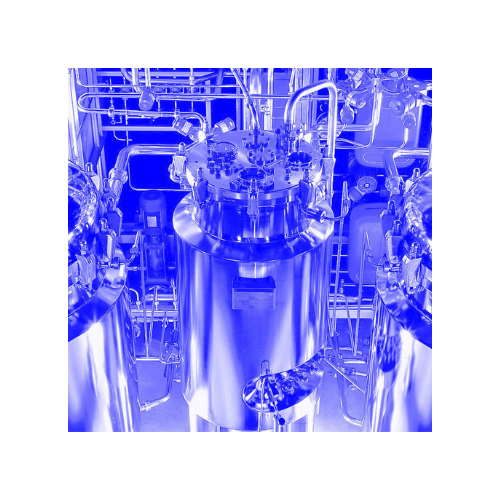

Media and buffer preparation solution for bioprocessing

Achieve seamless media and buffer preparation with precise dosing...

Dry cleaning container & hopper station

Effectively manage cleaning of rotation-symmetrical containers with minimal downtim...

Precise weighing solutions for small batch production

Streamline handling of diverse ingredient blends with precise dosin...

Gmp washer for pharmaceutical contamination control

Ensure verifiable cleaning and drying of critical components in bioph...

Wet granulating equipment for pharmaceutical industry

Enhance production efficiency and safety in high-potency pharmaceut...

Continuous wet granulation equipment

Optimize your production line with continuous wet granulation, seamlessly transforming...

Pharmaceutical roller compactor for dry granulation

When precision and uniformity in tablet production are crucial, optim...

Pharmaceutical roller compactor

Achieve consistent granulate quality with optimized compacting processes, ideal for transfor...

Lifting column for plastic boxes in pharmaceutical processing

Optimize your tablet and powder processing by seamlessly l...

Tablet coating system for high-capacity operations

Streamline your tablet production with a coater that maximizes through...

Advanced fluid bed for pharmaceutical granulation

Achieve precise granulation and drying for pharmaceutical powders with ...

Fluid bed granulator for pharmaceutical applications

Optimize your granulation and drying processes with advanced fluid-b...

Integrated granulation train for pharmaceutical processes

Achieve precise granulation, uniform mixing, and efficient dry...

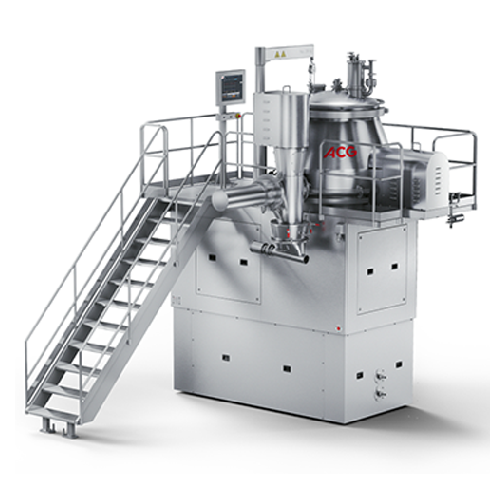

High-shear mixer for large-scale pharmaceutical production

Optimize your granulation process with an advanced high-shear...

High-shear mixer for small batch granulation

Enhance your production efficiency with a high-shear mixer designed for preci...

Fluid bed combo for granulation and coating

Streamline your manufacturing with a versatile fluid bed combo, integrating gr...

Continuous direct compression line for pharmaceuticals

Optimize tablet production with a seamless system combining contin...

Double-sized bi-layer tablet press

Achieve high-volume production with precision using a double-sized bi-layer tablet press...

Circular distribution feeder for fragile product handling

Achieve precise dosing and reduced product damage with a versa...

Pharmaceutical intermediate bulk containers (ibc)

Streamline pharmaceutical production with precise containment and trans...

Continuous granulation and drying system for pharma production

Achieve precise control over granule quality with a conti...

High shear granulator for pharmaceutical applications

Efficiently transform powders into uniform granules for consistent ...

Pharmaceutical bottom-drive high shear granulator

Achieve optimal granule uniformity and precise control over moisture le...

Integrated granulation and drying system for pharmaceuticals

Achieve seamless granulation and drying with our fully inte...

Single pot processor for granulation and drying

Streamline your pharmaceutical production with an integrated solution that...

Fluid bed processing of pharmaceuticals

Enhance your pharmaceutical production with versatile fluid bed processors, enablin...

Pharmaceutical fluid bed r&d processing

Ensure precise formulation and consistency in pharmaceutical and nutraceutical tabl...

Large production autoclaves for laboratory and pharmaceutical use

Enhance your production line with our large autoclave...

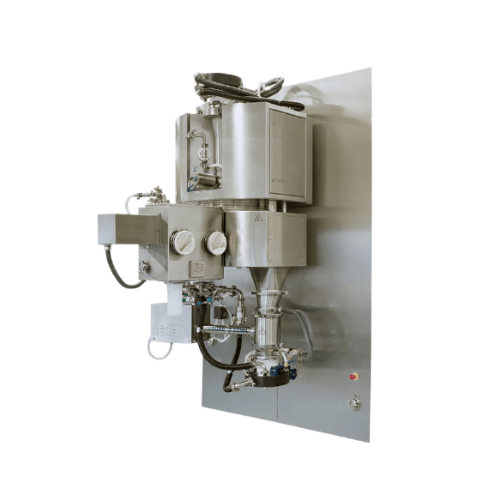

Pharmaceutical vacuum conveyors for hygienic transport

Ensure contamination-free transport of sensitive pharmaceuticals a...

Vacuum conveyor for tablets and capsules

Ensure the integrity of your tablets and capsules with gentle vacuum conveying des...

Drum discharge system for bulk material handling

Achieve precise, gentle transfer of sensitive pharmaceuticals and granula...

Ibc docking and discharge stations

Ensure seamless material transfer with dust-free docking and effective discharge, mainta...

Stick pack packaging for pharmaceutical products

Enhance your production efficiency with compact stick pack solutions, off...

Stick pack packaging line for pharmaceuticals

Optimize your pharmaceutical production with stick pack packaging lines that...

Pharmaceutical autoclave for terminal sterilization

Optimize your sterile production with high-precision terminal sterili...

Ultrasonic pre-washing system for large infusion glass bottles

Optimize your cleaning process with an ultrasonic pre-was...

Mini extruder for early development phase testing

In early development, tackling limited material availability is crucial...

Stuffing feeding device for extruders

Efficiently feed cohesive or lightweight powders into extruders to enhance product qu...

Cooling conveyor belt for extrudates and granules

Efficiently cool and convey extrudates and granules with precise temper...

Metal detector for packaging lines

Ensure product purity and safety with precision metal detection, seamlessly eliminating ...

Overflow conveyor for efficient product handling

Streamline your production with overflow conveyors that manage excess pro...

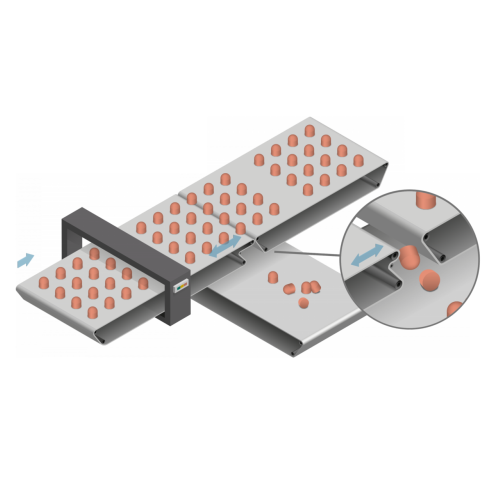

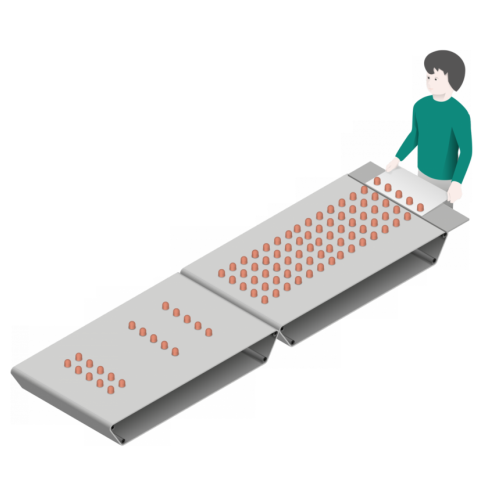

Row aligner for product packaging

Optimize your packaging line with precise alignment and high-speed product handling, ensu...

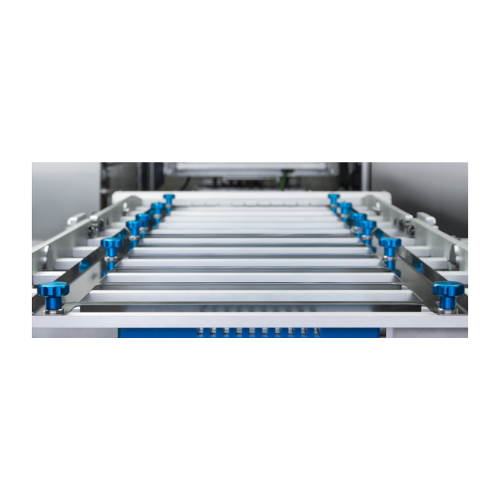

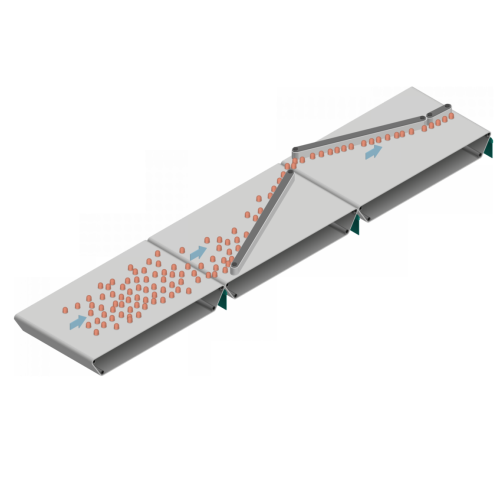

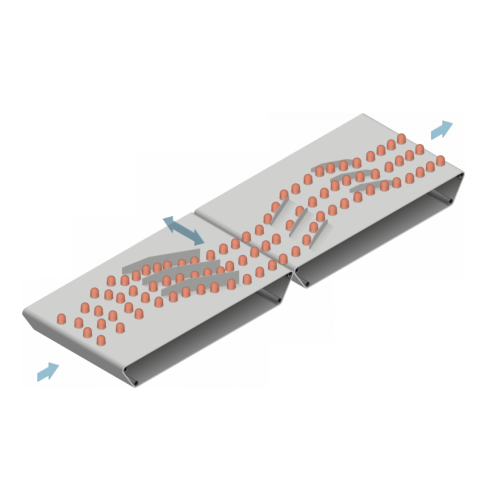

Separating and aligning conveyor for packaging systems

Efficiently manage the flow of diverse solid products like confect...

Vision-based robotic feeding system

Enhance your production line with precise robotic feeding, optimizing product placement...

High-speed double twist packaging system for soft caramels

Streamline your confectionery packaging process with a high-s...

High-speed forming, cutting, and wrapping for side and bottom folds

Streamline your confectionery production with a mac...

High speed packaging system for fold wrap and stick packs

Streamline your confectionery production with a versatile syst...

Accumulation conveyor for controlled feeding in packaging lines

Ensure seamless product flow and enhance efficiency in y...

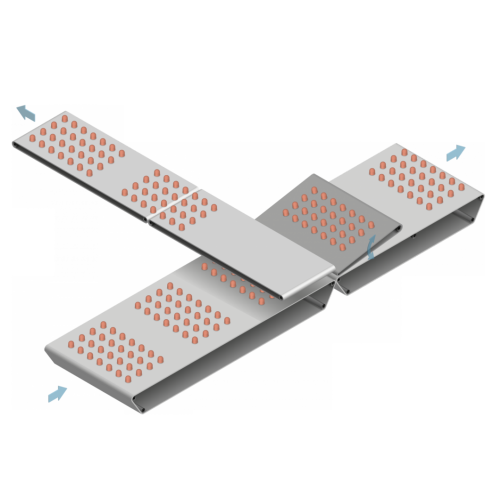

Cross transfer station for mould configuration products

Streamline the transfer of mould-configured products across your ...

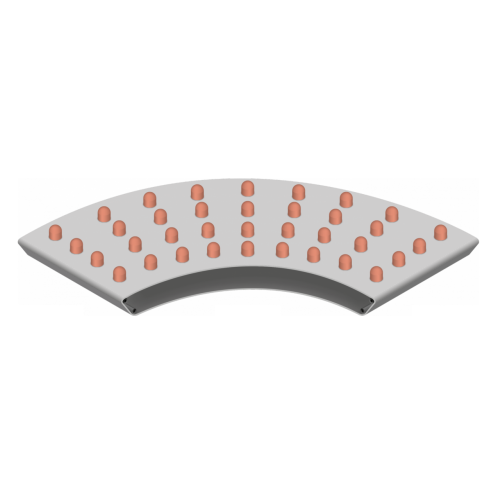

Curved conveyor for product transport

Streamline your product flow with a versatile curved conveyor, perfect for maintainin...

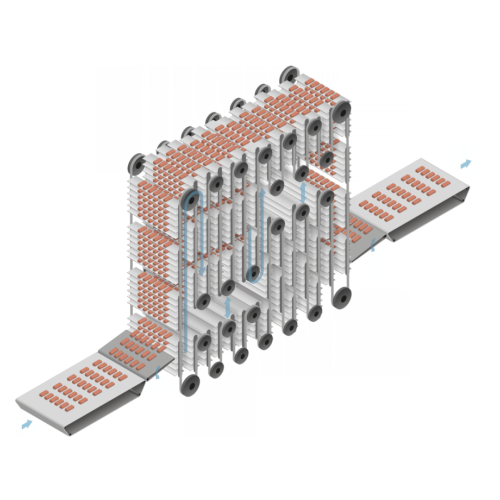

Gondola storage system for efficient product handling

Manage production line inconsistencies with precision by employing ...

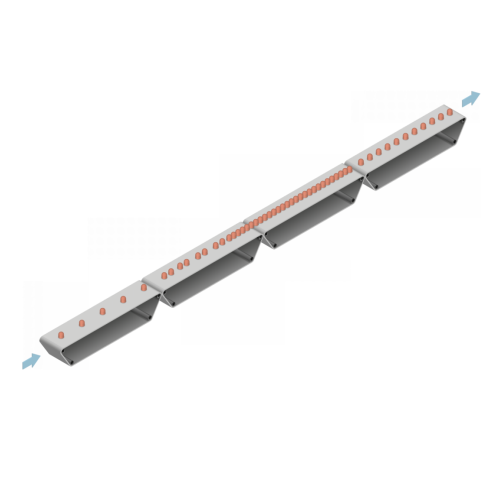

Lane arrangement for efficient product transfer

Optimize your production line’s efficiency with seamless integration...

High speed wrapping solution for pre-formed products

Achieve seamless integration of primary and secondary packaging with...

Flexible high-speed wrapping machine for chocolate products

Optimize your confectionery production line with a flexible ...

Flexible high-speed wrapper for confectionery products

Streamline your packaging process with a versatile machine designe...

High-speed forming and cutting for soft caramels and chewy sweets

Efficiently streamline your confectionery production ...

High speed forming, cutting and wrapping machine for soft caramels

Enhance your confectionery line with a versatile sol...

Twin-lane high-speed forming, cutting, and wrapping system

Achieve unparalleled packaging efficiency with a high-speed t...

High speed fold wrap and stick packs packaging system

Enhance your confectionery production line with a packaging system ...

High speed forming, cutting, and wrapping for side fold packaging with comic strip

Maximize your output with high-spe...

High speed packaging system for soft caramels

Optimize your confectionery line with a high-speed solution designed to seam...

High-speed wrapping machine for chocolate or compressed powder products

For confectionery and pharmaceutical operations...

Forming, cutting, and wrapping system for soft caramels

Optimize your confectionery production line with a solution desig...

Forming, cutting, and wrapping products in multiple styles

Achieve versatile and efficient packaging for confections and...

Forming and wrapping system for soft caramels with comic strip

Elevate your confectionery packaging with a high-speed fo...

Modular high-speed wrapper for chocolate flow packs

Efficiently wrap a wide range of products, from chocolate bars to dis...

High-speed wrapping solution for compressed powder products

Efficiently wrap high-volume compressed powder products with...

Modular high-speed forming, cutting, and wrapping for soft caramels

Streamline your confectionery production with a hig...

High speed wrapping solution for hard candies and toffees

Enhance your production with a high-speed solution designed fo...

High-speed packaging machine for bouillon cubes

Streamline your production process with a machine designed to handle up to...

Bouillon cube wrapping system

Streamline your packaging line with a high-speed system tailored for compact, compressed produ...

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

Pilot to full-scale roller compactor for dry granulation

Easily transition from pilot to full-scale production with this ...

Roller compaction for dry granulation in pharmaceuticals

Ensure consistent granule size and density in your product line ...

Roller compactors for dry granulation

Optimize your powder processing with advanced roller compaction, ensuring consistent ...

Modular high-speed flow pack wrapper for preformed products

Eliminate packaging line bottlenecks with a versatile high-s...

High-shear mixer granulator for pharmaceutical production

Achieve optimal granulation with enhanced mixing efficiency, r...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Automated visual inspection for pharmaceutical products

Ensure the integrity and safety of your parenteral products with ...

Lab Pharmaceutical aseptic separator

Achieve high-yield recovery and safe handling of potent pharmaceuticals with this asep...

Pilot pharmaceutical aseptic separator and dryer

Achieve high-yield recovery of potent compounds with a separator that com...

Vacuum rated vibro sifter for pharmaceutical materials

Ensure precise separation of impurities and achieve consistent par...

Fluid bed dryer for wet granulation in pharmaceutical industry

Streamline your production with fast, uniform drying and ...

High shear granulator for uniform wet granules

Achieve uniform and homogeneous wet granules with high-speed mixing and aut...

Steam/electrical kettle for wet granulation processes

Achieve precise moisture content and uniformity in your granulation...

Material lifting system for dust-free transfer in pharma plants

Achieve seamless material transfer with reduced manual h...

Bin washing station for pharmaceutical applications

Achieve reliable sanitation and enhanced efficiency with this tailore...

Wet granulation cleaning system

Ensure optimal cleaning and purification within your production line with a system designed ...

Pharmaceutical sieving equipment for high hygiene standards

Ensure the purity of pharmaceutical powders and granulates w...

Automated sample preparation workstation for content uniformity testing

Streamline your laboratory workflows with autom...

Automatic carton labelling and weighing system

Boost your carton packaging precision with a solution that seamlessly integ...

High precision pharmaceutical checkweigher

Ensure precise weight compliance in high-speed production lines with this advan...

Flow-wrapping machine with quick format changeovers

Optimize your packaging flexibility with a flow-wrapping machine desi...

Continuous roller compactor for dry granulation of pharmaceuticals

When making tablets, pharmaceutical manufacturers ne...

High Speed Double-Sided Tablet Press

To achieve as much as double the output of single-sided tablet press, the upper and lo...

High Speed Tablet Press

High speed pharmaceutical tablet presses convert powder to tablets. The operations should be quick an...

Dust-tight metal detector for tablets

For FDA-compliant production of tablets, the elimination of airborne dust containing ...

Small feeder with flexible wall hopper

In many laboratory applications and production processes, smaller quantities of powd...

Automatic tablet coater for lab scale

The ability to coat tablets in an even and controlled way is an important stage in th...

Single and double layer tablet press

High performance tablet presses that are capable of producing both single and double-l...

Granulation line of mixer and fluid bed dryer

A complete granulation line allows for the mixing and granulation of pharmac...

Single layer tablet press

High performance tablet presses for the modern production environment need to be fast, accurate an...

Rotary tablet press

For pharmaceutical tablet producers looking to reduce waste, costs and increase production volume, a hig...

High-shear mixer

For the efficient mixing of larger batches of pharmaceutical compounds and high-shear mixer provides the opti...

Entry-level high-shear mixer for drug formulation

For pilot and lab-scale pharmaceutical formulations, a high-shear granu...

R&D electronic counter for capsules and tablets

This machine has been designed to offer an ever-precise and reliable count...

Premium vacuum conveyor

When you have a need to tailor make your conveyor and still have the high requirement on hygiene, e.g...

Sorption dehumidifier with air-chilled condenser

It is not always possible to duct out the wet air from a dehumidifier ser...

Small portable dehumidifier

Water damaged areas require dehumidification to limit the damage and prepare the area for restor...

Sorption dehumidifier for large temperature differences

Small, humid areas can be difficult to dehumidify in humid ambien...

Sorption dehumidifier for deep drying

Humid ambient conditions such as those in tropical climates make dehumidification mor...

Dehumidifier for difficult wet airflows

Sealed rooms can be challenging to dehumidify with ordinary dehumidifiers. The wet ...

Sorption dehumidifier for overpressured rooms

Small humid spaces, used for processing or storage, often need a simple dehu...

Heat recycling sorption dehumidifier

Facilities that handle large amounts of water can become very humid. High humidity may...

Industrial desiccant dehumidifier

Dehumidification of medium sized manufacturing and processing facilities can be a dauntin...

Large scale desiccant dehumidifier

Moisture sensitive processing and storage facilities need low humidity environments to s...

Customizable dehumidifier

Dehumidification needs can vary significantly from one project to another. Dehumidifiers with a fi...

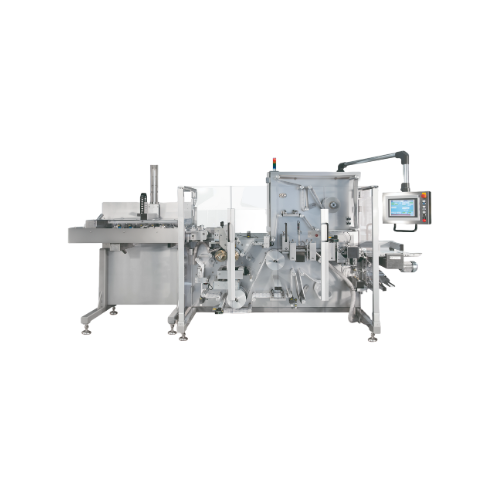

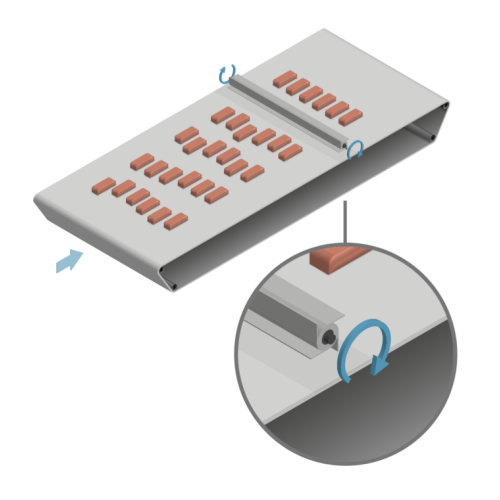

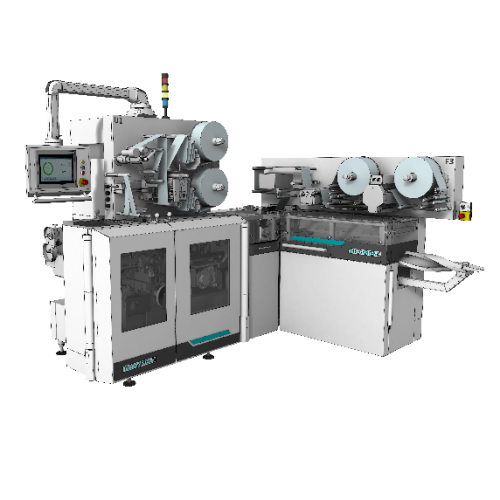

Strip packaging machine for effervescent tablets

Pack your effervescent tablets with extreme precision and care at a speed...

High-sensitivity metal detection system

Highly efficient metal detector with enhanced quality control and reporting capabil...

Entry-level X-ray inspection system

Without compromising on performance, if you need an entry level x-ray inspection system...