Single track pallet conveyors for electronics production

Efficiently manage single-piece flow with precise routing, balancing, and tracking, ensuring seamless integration into complex production environments while maintaining flexibility.

Handles and Routes Pallets for Single-Piece Flow

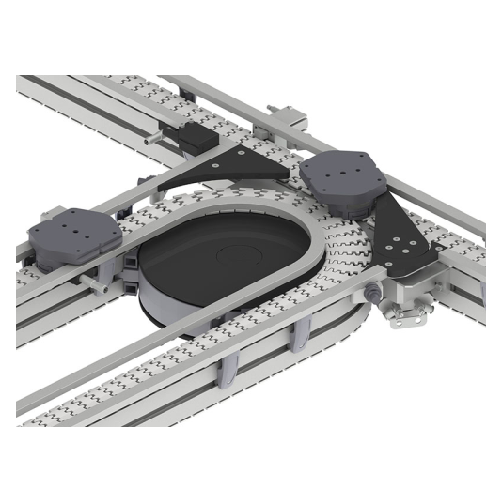

The X65P Single Track Pallet Conveyors from FlexLink utilize standardized components to create customized solutions for diverse industrial applications, from electronics to automotive parts manufacturing. This system excels in handling and routing individual product carriers on 65 mm pallets, supporting weights from a few grams up to 3 kg. Its use of RFID technology for track-and-trace capabilities ensures impeccable logistic control within your production line. Configurable modules facilitate efficient layout creation for processes like routing, balancing, buffering, and positioning. Featuring a maximum speed of 30 m/min and operational within a -20°C to +60°C temperature range, this conveyor seamlessly integrates into high-speed, continuous environments. Constructed from durable materials suitable for dry settings, it upholds ease of maintenance and is adaptable to specific production requirements. FlexLink’s engineering support and advanced design tools further enhance customization and system integration, ensuring your operations run smoothly and efficiently.

Benefits

- Enhances production efficiency through customizable layout configurations.

- Improves logistic control with RFID-enabled track-and-trace capabilities.

- Increases operational speed up to 30 m/min with minimal energy usage.

- Supports versatile product handling, accommodating weights up to 3 kg.

- Integrates seamlessly in dry, continuous production environments, reducing downtime.

- Applications

- Personal care, Food, Home care, Automotive, Tobacco, Beverage, Healthcare, Industrial goods, Tissue and hygiene, Pet care, Electronics, Pharmaceuticals

- End products

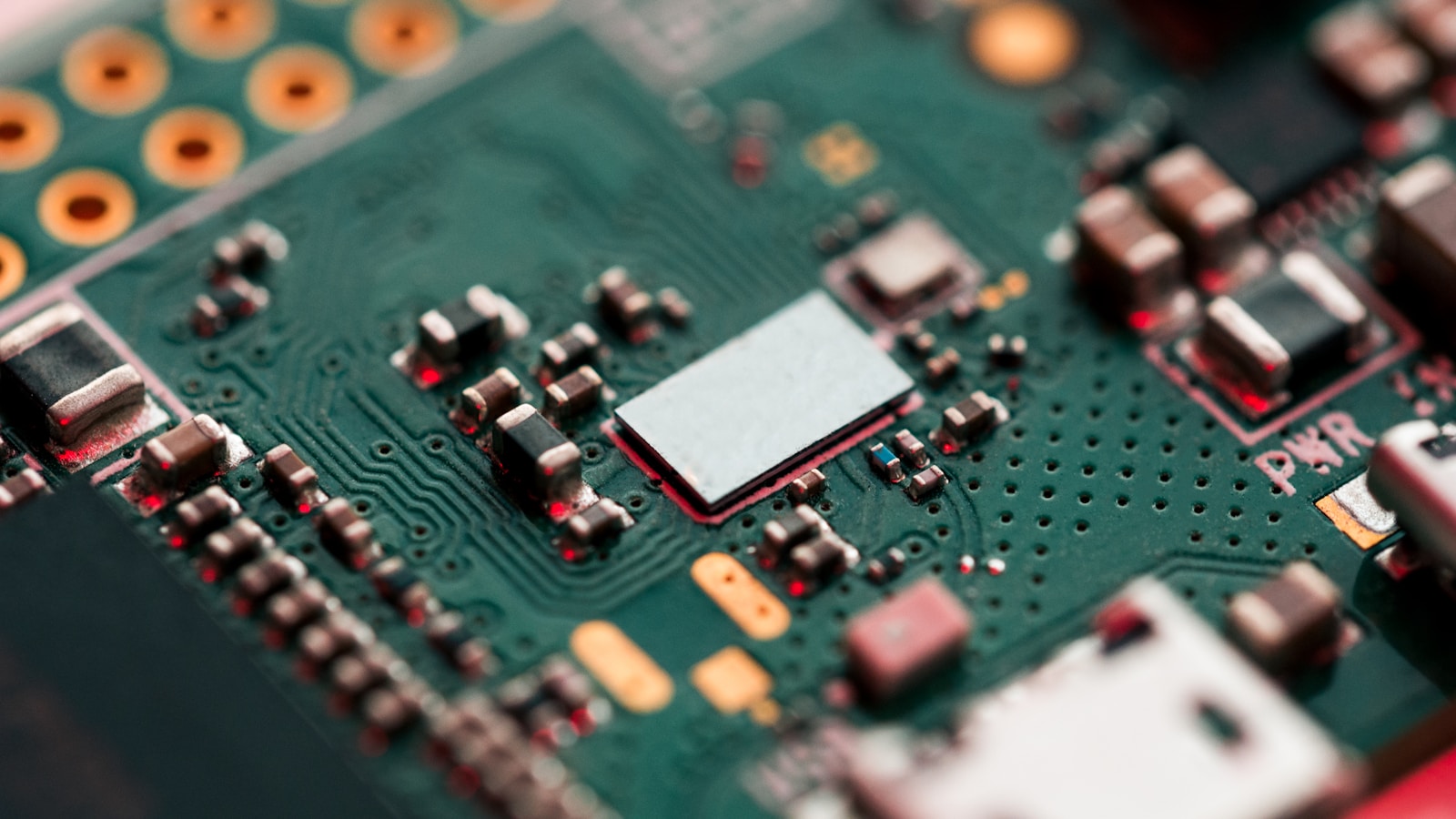

- Circuit boards, Medical devices, Pharmaceutical tablets, Pet food pouches, Beverage cans, Tissue paper, Microchips, Cereal boxes, Cigarette packs, Shampoo bottles, Detergent bottles, Automotive parts

- Steps before

- Routing, Balancing, Buffering

- Steps after

- Positioning, Track-and-Trace, Logistic Control

- Input ingredients

- individual products, product carriers, pallets, clean products, dry products

- Output ingredients

- individual products, packaged products, tracked products

- Market info

- FlexLink (Coesia Group) is renowned for its innovative conveyor and automation systems, optimizing production efficiency for various industries such as food, automotive, and electronics, with a strong emphasis on modular and customizable solutions.

- Pallet Width

- 65 mm

- Product Weight Range

- A few grams up to 3 kg

- Max Speed

- 30 m/min

- Operating Temperature

- -20 to +60°C

- Chain Type

- Plain chain

- Max Product Length

- 41 mm

- Max Product Width

- 100 mm

- Automation level

- Integrated RFID for logistic control

- Changeover time

- Quick and easy with configurable standard modules

- Batch vs. continuous operation

- Single Piece Flow

- Cleaning method

- Manual

- Energy efficiency

- N/A

- Abrasion resistance

- Suitable for high wear applications

- Cleanability

- Easy to clean surfaces

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Biological compatibility

- Food grade materials available

- Density/particle size

- Accommodates diverse product sizes

- Product Shape

- Asymmetric, Rectangular, Round, Symmetric

- Standard pallet width

- 65 mm

- Pallet width customization

- 65 mm standard

- Module customization

- Configurable standard modules

- Layout customization

- Advanced and straightforward layouts