Rotary tablet press for large volume industrial tablets

Optimize your high-volume tablet production with a fully automatic rotary press that excels in compressing both abrasive and corrosive powders, ensuring consistent shape and density for applications ranging from detergents to automotive components.

Compresses and Shapes Industrial Tablets

The R253 Rotary Tablet Press from GEA is a fully automatic, high-speed industrial solution designed for demanding tablet production needs. It excels in precision and durability, utilizing a dual-layer compression system capable of producing single-layer or dual-layer tablets with robust compression forces of up to 200 kN. This machine addresses the challenges of producing diverse tablets—from detergents to automotive catalysts—by ensuring uniformity and consistency, supported by features like advanced powder confinement and tablet weight control through force measurement. The R253 seamlessly integrates into high-capacity production lines, enhancing efficiency with its Siemens PLC control and industrial PC database monitoring. Its construction caters to harsh environments, boasting a stainless-steel housing and nickel-coated turret for corrosion resistance. Maintenance demands are minimized with automatic punch lubrication and a pre-compression cam for extended die dwell times, ensuring long-term reliability and reduced operational costs.

Benefits

- Ensures consistent tablet quality with integrated weight control, minimizing rejects and enhancing productivity.

- Durable design with corrosion-resistant materials extends machine lifespan in harsh industrial settings.

- High-speed operation maximizes output, achieving up to 126,000 tablets per hour.

- Reduces maintenance needs with automated punch lubrication and robust construction.

- Enhances safety and cleanliness with isolated and sealed compression zones.

- Applications

- Detergent tablets, Coffee pods, Batteries, Confectionery, Industrial tablets, Abrasive powders, Corrosive powders, Hard metals, Nuclear fuel pellets, Catalysts, Salt tablets, Automotive parts

- End products

- Steps before

- Powdering, Granulation, Mixing, Blending

- Steps after

- Tablet Inspection, Packing, Quality Control, Coating

- Input ingredients

- detergent powder, catalysts, automotive materials, battery components, abrasive powders, corrosive powders

- Output ingredients

- detergent tablets, catalyst tablets, automotive part tablets, battery tablets, tablets with vertical holes, single-layer tablets, double-layer tablets, solid tablets, ring-shaped tablets, tablets with multiple vertical holes

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Compression force

- Up to 200 kN

- Pre-compression force

- Up to 10 kN

- Maximum fill depth

- 60 mm

- Maximum output capacity at compression force 150 kN

- 96, 000-126, 000 tab/h

- Maximum output capacity at max. compression force

- 69, 000-102, 000 tab/h

- Number of stations

- 27 or 39

- Punch-holder body diameter

- 48 or 40 mm

- Outside die diameter

- 70 or 48 mm

- Max. top punch penetration

- 16 or 25 mm (bi-layer)

- Press height

- 2, 810 mm

- Floor space

- 1, 500 x 1, 400 mm

- Weight

- +/- 9, 000 kg

- Automation

- PLC-controlled

- Control System

- Siemens PLC with industrial PC and MultiControl5 system

- Touchscreen Display

- 21.5-inch HD

- Working Mechanism

- Rotary High-speed Press

- Automation Level

- Fully Automatic

- Batch vs. Continuous Operation

- Continuous Operation

- Tablet Production Capability

- Single-layer/Double-output or Double-layer/Single-output

- 24/7 Operation

- Yes

- Pre-compression System

- Pre-compression Cam

- Tablet Weight Control

- Force Measurement

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Easy cleaning due to smooth surfaces

- Density/particle size

- Compatible with various densities and particle sizes due to multiple-fill configurations

- Machine footprint

- 1, 500 x 1, 400 mm

- Weight

- +/- 9, 000 kg

- Press height

- 2, 810 mm

- Construction material

- Cast iron frame

- Housing material

- Stainless steel

- Control panel type

- 21.5-inch HD touchscreen

- Turret material

- Nickel-coated steel

- Number of stations

- 27 or 39

- Compression zone

- Isolated and sealed

- Control system

- Siemens PLC with industrial PC and MultiControl5 system

- Touchscreen interface

- User-friendly 21.5-inch HD touchscreen

- Material options for punch tips

- Steel or tungsten carbide

- Multi-tip design

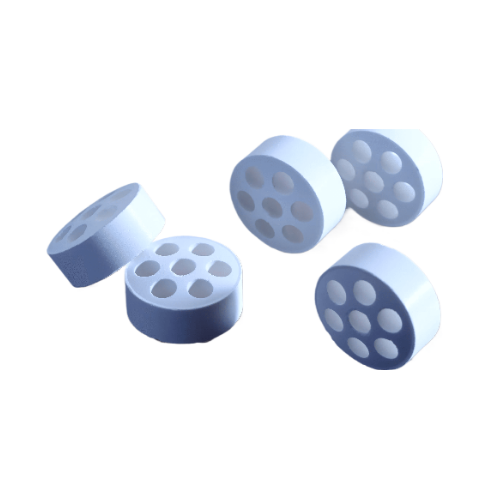

- Available for solid and ring-shaped tablets