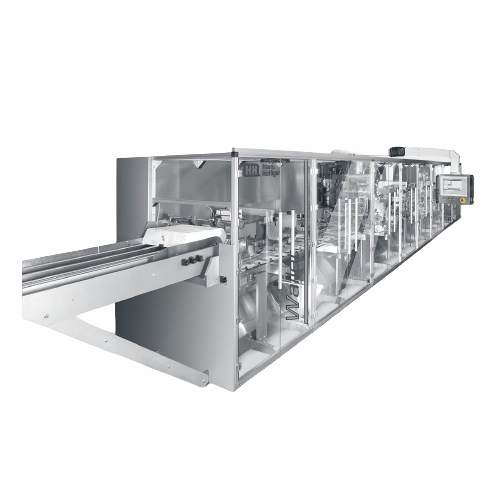

Tablet blister wallet packaging line

Enhance packaging efficiency with a high-speed line that integrates blister packaging into secure, multi-panel wallet packs, ensuring precision and tamper-proof assurance for pharmaceutical products.

Packages Tablet Blisters into Wallets

The Wallet Line from Harro Höfliger is designed to seamlessly integrate into your production line, efficiently packaging tablet blisters into wallets. This modular system tackles the challenges of precise folding, closing, and labeling with its continuous high-speed operation. Ideal for pharmaceutical manufacturers, the Wallet Line accommodates various packaging formats, including physician samples and combination dose packs, ensuring that detailed administering directions are securely enclosed.

The machine features a servo-controlled toothed belt drive, providing smooth operation and quick format changes. Its modular design allows for customization, with options for tamper-proof and child-proof packaging. With a throughput of up to 330 packagings per minute, it ensures optimal productivity. The Wallet Line supports integration with existing blister, cartoning, and inspection systems, and its touch-panel interfaces enable straightforward operation and monitoring, enhancing packaging accuracy and efficiency.

Made with durable materials, the Wallet Line’s construction supports rigorous production demands while maintaining compliance with pharmaceutical packaging standards. Maintenance and cleaning are simplified through easily accessible components, and the system offers engineering support for customized configurations suited to your specific operational requirements.

Benefits

- Enhances productivity with high-speed operation, packaging up to 330 wallets per minute.

- Streamlines changeovers with fast, reproducible format adjustments.

- Ensures compliance and safety with tamper-proof and child-proof packaging options.

- Facilitates seamless integration with existing production lines via modular design.

- Improves operational efficiency through consistent control with intuitive touch-panel interfaces.

- Applications

- Supplements, Products with detailed administering directions, Pharmaceutical tablets, Physician samples, Multiple dosing products

- End products

- Physician sample blister packs, Blister-packed aspirin tablets, Blister packs with detailed dosage instructions, Multivitamin supplements in blister packaging, Combination dose packs with multiple tablets

- Steps before

- Blister production, Blister machine operation, Product feeding

- Steps after

- Inspection, Labeling, Shipping box packaging

- Input ingredients

- tablet blisters, booklets, carton blanks, wallet blanks, seal components

- Output ingredients

- wallet packages, blister card, wallets with several pages, closed box wallets, packages with labels

- Market info

- Harro Hoefliger is known for its expertise in manufacturing custom, engineered-to-order packaging and production equipment, particularly for the pharmaceutical, healthcare, consumer goods, and chemical industries, with a reputation for precision, innovation, and quality engineering solutions.

- Output

- Up to 330 wallets/min

- Modular design

- Expandable

- Child-proof and tamper-proof packaging

- Yes

- Automation

- Servo-controlled

- Format change

- Fast with reproducible settings

- Folding panels

- Up to five perpendicular, two in direction of movement

- Connection technologies

- Various options

- Vacuum take-up

- Rotating suction bar

- Feeding modules

- For wallets, booklets, blisters

- Digital displays

- Ensure short transition times

- Product feeding

- Individually configured systems

- Labeling

- Applied from a roll, position inspected

- Smooth running

- High degree, continuous flow

- Product handling systems

- Large repertoire available

- Folding station

- Gently folds packages

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Fast

- Cleaning method

- Manual

- Energy efficiency

- Optimized for high-speed operation

- Machine footprint

- Compact

- Modular design

- Yes

- Control panel type

- Touch panel

- Machine structure

- Modern balcony structure

- Discharge method

- Rotating suction bar

- Product feeding system

- Customized

- Modular design

- Expandable in any manner

- Operating concept

- Touch panels

- Closing variants

- Tamper-proof / Glue point / Resealable label