Making Enteric Coated Tablets

Find innovative production technology for making enteric coated tablets and connect directly with world-leading specialists

When taking a tablet, it is usually the job of our stomach to break down the medication to make it ready to be absorbed into the bloodstream. However, some drugs are not meant to be dissolved in the stomach because the acidic pH of the stomach can disintegrate the drug, making it no longer effective. Using tablet coating equipment that applies a polymer barrier to the tablet makes it possible to protect it from stomach acidity.

Stories about enteric coated tablets

Scientifically tested continuous drying for your tablets

Aim your safety standards high, while granulating dry

Discover the best mix for your blending application

Coat-astrophe averted: a sprightly spin on tablet efficiency

Lean into efficiency with inclined tablet discharging

Wet milling: The revolution in the API production

The sweet world of pharmaceutical tablets - The trifecta for achieving coating uniformity

#Changemaker: Ready to protect your pharmaceutical products from moisture?

#Changemaker: Keep track of your medicine every day with FabriSol sticker

Select your enteric coated tablets process

Tell us about your production challenge

Why is an enteric-coated tablet needed?

So if it can’t be the stomach’s job to dissolve the tablets, whose job will that be? Enteric comes from the Greek word énteron, meaning intestine. As we mentioned earlier, some drugs like Rabeprazole or Pantoprazole are destroyed by the acidic pH of the stomach acids.

The funny thing is that these drugs are meant to reduce the acids in the stomach, but they are destroyed by the acids themselves without having a chance to provide their effectiveness. So they need to bypass the stomach and be released in the small intestine.

The enteric coating ensures that the tablet remains unaltered and stable in the stomach’s acidic pH (pH ~3) but breaks down and dissolves at higher pH (alkaline, pH 7–9) of the intestine. On the other hand, some drugs like aspirin and NSAIDs (Nonsteroidal anti-inflammatory drugs) can also cause side effects such as gastric irritation or nausea. The enteric coating protects the gastric mucosa from the drug itself. Another reason for enterically coated tablets is to provide a delayed release of the medication.

Polymers used for enteric coating

The enteric coating is nothing more than applying a polymer film on a tablet. Obviously, the polymers used for this coating must be resistant to gastric fluids. Polymers for enteric coating remain unionized at low pH, but when they reach the small intestine, they become soluble and swell, and begin to dissolve at a pH of 5.0-5.5. In addition to this, they should be compatible with the drug substrate and the coating solution and should be non-toxic in nature.

Examples of enteric film-coating polymers are cellulose acetate phthalate (CAP), which is the oldest and the most used for enteric coating, Cellulose acetate trimellitate (CAT), Hydroxypropyl methylcellulose phthalate (HPMCP) and Shellac.

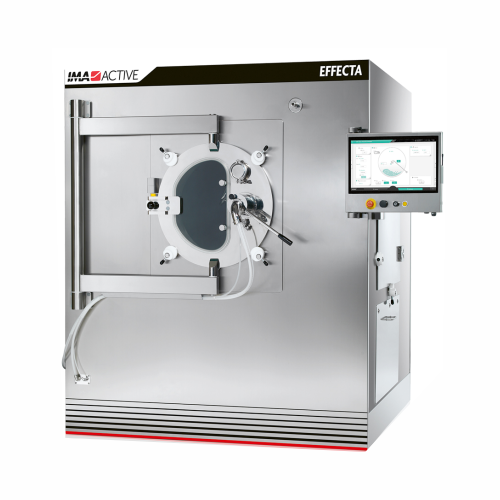

Applying a polymer film using tablet coating equipment

When preparing an enteric coating formulation, you need to pay attention to the mixing part. The mixture should be uniform and fine enough to pass through the coating system. The most common tablet coating equipment used for enteric coating is a pan coating system. This involves spraying the film-forming material onto the tablet surface as the tablets rotate in the pan.

Hot air is applied which helps the organic solvent evaporate and form the coat over the tablets. You need to repeat the process according to the desired thickness of the tablet’s film.

Enteric-coated tablets are pills that have a special coating designed to protect the active ingredients from stomach acid. While protecting, these tablets are still able to release the important API in the intestine. This feature is particularly important for drugs like naproxen and ibuprofen. Which have been known to cause irritation of the stomach lining. And thus, can cause ulcers. Enteric coated tablets are commonly used in the treatment of arthritis and inflammation and can be found at most local pharmacies.

Processing steps involved in enteric Coated Tablets making

Which enteric coated tablets technology do you need?

In vitro dissolution and flux measurement platform

Optimize drug formulation by accurately assessing dissolution, solubil...

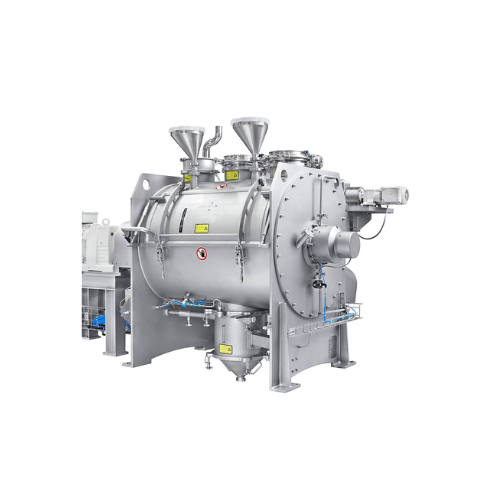

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this...

Laboratory tablet coater for pharmaceuticals

Achieve consistent and efficient coating of tablets with this innovative coat...

Tablet coating pan for pharmaceutical and nutraceutical industries

Enhance coating efficiency with a versatile solution...

Automated coating pan for pharmaceutical tablets

Enhance your tablet production with a fully automated system that ensures...

In-process weighing system for capsules and tablets

Ensure precise dosing and consistent quality with a format-free syste...

Laboratory film coating system for development and clinical batches

Achieve precision in tablet coating with a versatil...

Laboratory fluid bed system for solvent processing

Optimize your laboratory scale operations with a versatile fluid bed s...

Laboratory fluid bed granulator and coater

For researchers and manufacturers requiring precise control in drying, granulat...

Development fluid bed system for feasibility studies

Explore precise granulation and coating capabilities for small batch...

Tablet coating solution

Achieve precise tablet coating with uniformity and efficiency, tailored for diverse tablet types, ens...

Automated disintegration tester for tablets

Efficiently determine tablet disintegration times with advanced waterbath tech...

Dissolution online system for automated Uv-vis analysis

Ensure precise dissolution testing and seamless UV/VIS analysis w...

Laboratory granulator and coating system

Optimize your research with a versatile benchtop unit that combines fluid-bed proc...

Bench-top mixer and spheronizer for formulation development

Accelerate R&D success by seamlessly integrating mixing...

Tablet coating for r&d and small-scale production

Achieve precise, efficient tablet coating with a compact, versatile mac...

Tablet coater for batch sizes up to 250 liters

Enhance your tablet production process with high-speed coating solutions de...

Fluid bed combo for top-spray granulation and wurster coating

Optimize your batch processing with a versatile system cap...

Intermittent motion cartoning machine for blister packs

Optimize your packaging line with a space-efficient cartoning mac...

Fluid bed pellet coating solution

Achieve precise and uniform pellet coating with fluid bed technology for enhanced product...

Drum discharge system for bulk material handling

Achieve precise, gentle transfer of sensitive pharmaceuticals and granula...

Belt dryers for gelatin processing

Efficiently transform liquid gelatin into high-quality solids with precise moisture cont...

Tablet coating system

Achieve precise and uniform coating on pharmaceutical tablets with this scalable system, designed for o...

Agitator bead mill for API

To achieve precisely defined API properties and safe and reproducible production, rigorous implem...

Continuous wet granulator and dryer for R&D

Pharmaceutical laboratories need compact equipment to handle and produce small...

Dry granulator for pharmaceutical powders

In pharmaceutical industries, where large-volume production is the norm, compact...

Energy-efficient film coating machine for pharmaceutical tablets

Tablet coating involves applying a thin layer of coatin...

Industrial sieving machine for pharmaceuticals

One of the physical attributes that granular pharmaceutical products must h...

Fluidized bed system for the granulation and drying of pharmaceuticals

Pharmaceutical industries employ several process...

Pharmaceutical tablet coating machine

Tablet coating requires spraying, mixing, and drying procedures that must be carried ...

Single-use containment valves

From GMP and HSE perspective material transfer is critical for chemical and pharmaceutical for...

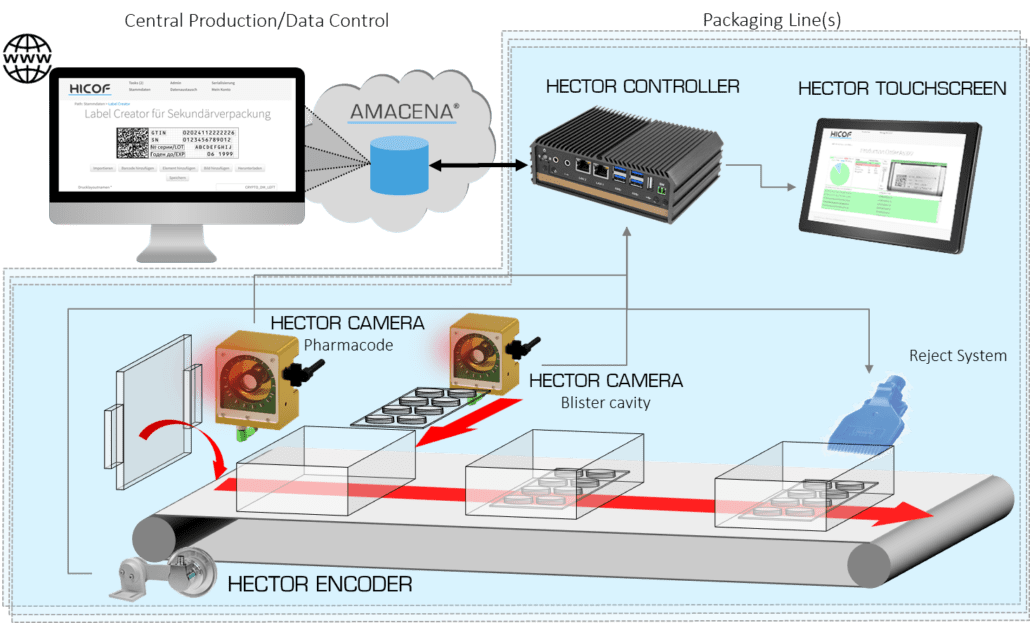

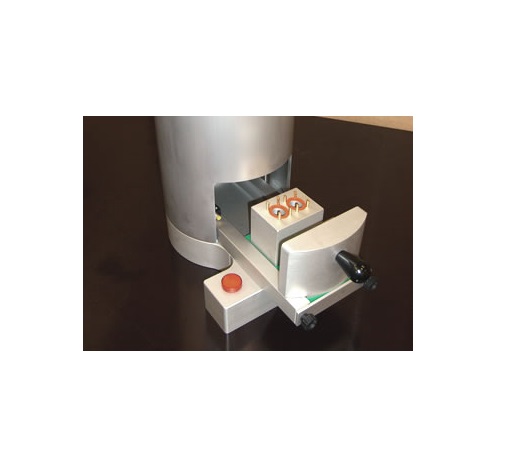

Individual item serialization equipment

Traceability is critical to quality assurance in the pharmaceutical sector. But ser...

Serialization and aggregation inspection system

Including serialization and aggregation inspection systems to packaging li...

Pharmaceutical data management software

A typical pharmaceutical production handles numerous work flow activities like mana...

Vision inspection system for tablets and capsules

Pharmaceuticals and healthcare product manufacturers dealing with oral ...

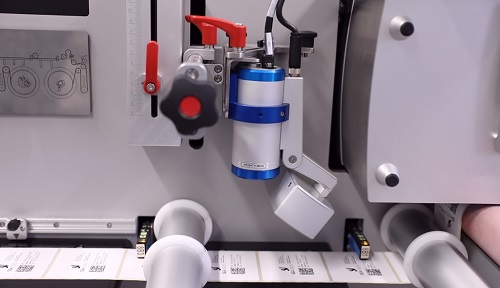

Serialized labels inspection and printing station

Labels are a key component in pharmaceutical packaging lines as they in...

Clinical trial lab sealer for a laminar airflow bench

When running small production for clinical trials, stability studie...

High speed bottle filler with inspection

Medicines in tablet, capsule, or soft gel forms undergo various processes before r...

Lifter and De-duster for Tablets

The use of several different tools for lifting, de-dusting, and polishing in the pharmaceut...

High Speed Visual Inspection System for Tablets

In order to ensure quality and standard specifications of tablets, capsule...

Contained Visual Inspection System

In the medicine industry, it is important to ensure there are no defects in tablets or c...

Tablet coater for laboratory scale

Tablet coating can be applied for adding colours or glosses, or based around sugar in or...

Tablet counting machine

Production of pharmaceutical solid dosage forms usually require complete accuracy, flexibility, and c...

Pharmaceutical bottle unscrambler

Pharmaceutical packaging industry requires the ability to quickly manage the process yet ...

Dessicant inserting machine

Desiccant canisters play an important role in the pharmaceutical and nutraceutical industries. T...

Metal detector for bottles

For metal contamination detection in finished products that are bottled, traditional solutions re...

Metal detector for tablets and capsules

Identification of metallic contaminants is a vital part of pharmaceutical quality c...

Dust-tight metal detector for tablets

For FDA-compliant production of tablets, the elimination of airborne dust containing ...

Wash-in-Place metal detector for tablets

Where hygiene and decontamination are vital, traditional pharmaceutical metal dete...

Side-load case packer

As the final stage in the packaging process, an automated case-packing solution can ensure that your co...

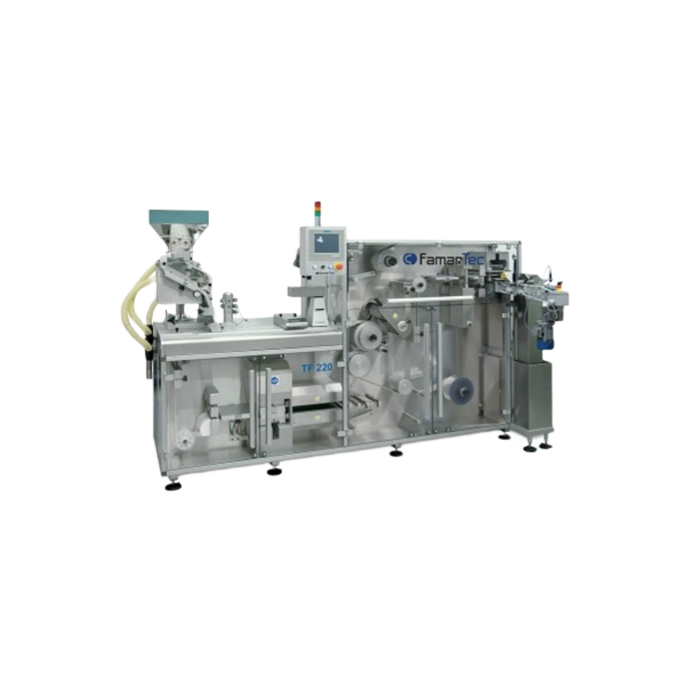

Entry-level blister packaging machine

Blister packaging is a popular packing method in the pharmaceutical industry thanks t...

Industrial blister packaging machine

High-volume, fully-automated blister packaging is the perfect choice for large scale p...

Plate sealing blister machine

Blister packaging is the preferred choice for most large-scale pharmaceutical lines, and a pla...

Continuous pack cartoner

High volume automatic cartoning is vital for large scale production of cosmetic or pharmaceutical pr...

Automatic blister packaging machine

Automated blister packaging is a popular choice for pharmaceutical production thanks to...

Semi-automatic case packer

Pharmaceutical products require complete traceability throughout the production cycle. For smalle...

Stand-alone aggregation station

The aggregation of pharmaceutical products for tracking purposes is already compulsory in ma...

Serialization coding and labeling equipment

In the pharmaceutical industry, product serialization is the cornerstone of al...

Small feeder with flexible wall hopper

In many laboratory applications and production processes, smaller quantities of powd...

Conical mill for drug formulation

The efficient size reduction of granular powders is a key step in many pharmaceutical pro...

Automatic tablet coater for lab scale

The ability to coat tablets in an even and controlled way is an important stage in th...

Tablet auto coater for lab scale

Many pharmaceutical doses in tablet form require a coating before they are ready for use. T...

Single and double layer tablet press

High performance tablet presses that are capable of producing both single and double-l...

Lab scale single layer tablet press

Automated pressing of tablets saves time and improves quality. In R&D or laboratory...

Granulation line of mixer and fluid bed dryer

A complete granulation line allows for the mixing and granulation of pharmac...

Rotary tablet press

For pharmaceutical tablet producers looking to reduce waste, costs and increase production volume, a hig...

Fluid bed dryer for production scale

Fluidized bed drying (FBD) is a common process in the pharmaceutical industry for dryi...

High-shear mixer

For the efficient mixing of larger batches of pharmaceutical compounds and high-shear mixer provides the opti...

Entry-level high-shear mixer for drug formulation

For pilot and lab-scale pharmaceutical formulations, a high-shear granu...

High capacity weight sorter for tablets & capsules

By employing a weight sorter that is fully flexible and able to ha...

R&D electronic counter for capsules and tablets

This machine has been designed to offer an ever-precise and reliable count...

Premium vacuum conveyor

When you have a need to tailor make your conveyor and still have the high requirement on hygiene, e.g...

High containment split butterfly valve

Powder containment is the cornerstone of chemical and pharmaceutical manufacturing. ...

Sorption dehumidifier with air-chilled condenser

It is not always possible to duct out the wet air from a dehumidifier ser...

Small portable dehumidifier

Water damaged areas require dehumidification to limit the damage and prepare the area for restor...

Sorption dehumidifier for large temperature differences

Small, humid areas can be difficult to dehumidify in humid ambien...

Sorption dehumidifier for deep drying

Humid ambient conditions such as those in tropical climates make dehumidification mor...

Dehumidifier for difficult wet airflows

Sealed rooms can be challenging to dehumidify with ordinary dehumidifiers. The wet ...

Sorption dehumidifier for overpressured rooms

Small humid spaces, used for processing or storage, often need a simple dehu...

Heat recycling sorption dehumidifier

Facilities that handle large amounts of water can become very humid. High humidity may...

Industrial desiccant dehumidifier

Dehumidification of medium sized manufacturing and processing facilities can be a dauntin...

Large scale desiccant dehumidifier

Moisture sensitive processing and storage facilities need low humidity environments to s...

Customizable dehumidifier

Dehumidification needs can vary significantly from one project to another. Dehumidifiers with a fi...

Compact blister machine

A compact blister machine ideal for packing tablets, capsules, ampoules and syringes and other applic...

Small bottle checkweigher

Any small-diameter bottle, containing prescription medication or cosmetic applications, can be pro...

Checkweigher

A check weigher that is equipped with high speed/high accuracy force balance load cell. It meets stringent accura...

Entry-level X-ray inspection system

Without compromising on performance, if you need an entry level x-ray inspection system...