High-speed blister packaging with integrated cartoning

Achieve unmatched efficiency in blister packaging with seamless integration of cartoning for high-volume pharmaceutical production, ensuring reliability and precision in every batch.

Blisters and Cartons Solid Dose Tablets

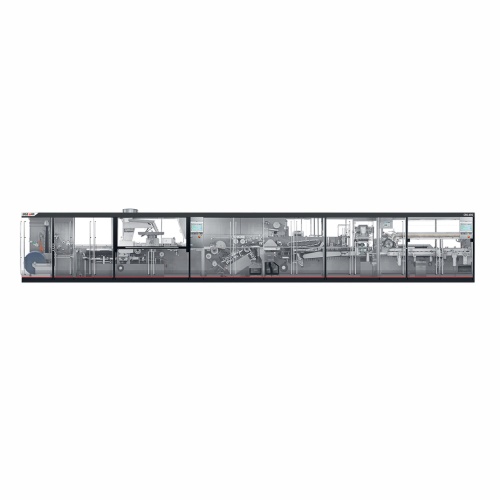

The C96-A96 from IMA Safe is a super high-speed blister packaging and cartoning line designed for pharmaceutical manufacturers producing large volumes of solid dose tablets. This compact system efficiently blisters and cartons products like aspirin and multivitamins, achieving an impressive output of up to 1,300 blisters and 500 cartons per minute. The continuous running process ensures smooth product feeding, positive blister transport, and seamless integration with upstream and downstream operations. Featuring energy-efficient design and compatibility with recyclable materials, the C96-A96 minimizes operational costs. Its user-friendly interface, quick changeover capabilities, and light format parts enhance accessibility and maintenance ease. Fully automated with a Track & Trace module for serialization, it complies with pharmaceutical industry standards, ensuring product safety and traceability.

Benefits

- Maximizes production capacity with up to 1,300 blister packs per minute.

- Enhances product safety and compliance with integrated Track & Trace serialization.

- Lowers operational costs through energy-efficient design and recyclable material compatibility.

- Reduces changeover time and maintenance effort with ergonomic, easy-access design.

- Ensures smooth integration into existing lines with continuous, positive product transport.

- Applications

- Solid dose solutions, Pharma products, Pharmaceutical tablets

- End products

- Blister-packed antacid tablets, Blister-packed aspirin tablets, Blister-packed ibuprofen tablets, Blister-packed paracetamol tablets, Blister-packed multivitamin tablets

- Steps before

- Forming

- Steps after

- Cartoning, Serialization

- Input ingredients

- blister packaging materials, carton packaging materials, recyclable materials, compostable materials

- Output ingredients

- blisters, cartons

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Speed

- 1, 300 blisters/minute

- Speed

- 500 cartons/minute

- Compact footprint

- Yes

- Automation

- Continuous running

- Blister dimensions

- Width

- Blister dimensions

- Length

- Blister dimensions

- Depth/Height

- Carton dimensions

- Width

- Carton dimensions

- Length

- Carton dimensions

- Depth/Height

- Sustainability

- Energy consumption reduced

- Material compatibility

- Recyclable / Compostable

- Changeover

- Fast and computer-guided

- Transport

- Positive blister transport

- Working mechanism

- Continuous running

- Batch vs. continuous operation

- Continuous Inline

- Automation level

- High-level automation

- Changeover time

- Fast and computer-guided

- Product feeding efficiency

- High efficiency due to continuous running

- Positive blister transport

- Essential for high-speed operation

- Accessibility

- Complete accessibility and ergonomic design

- Energy efficiency

- Reduced energy consumption

- Recyclable material compatibility

- Yes

- Compostable material usage

- Yes

- Compact footprint

- Yes

- Machine footprint

- Small

- Control panel type

- Computer-guided

- Integration possibilities

- Track, Trace, camera and ink-jet system integration

- Compact footprint

- Small