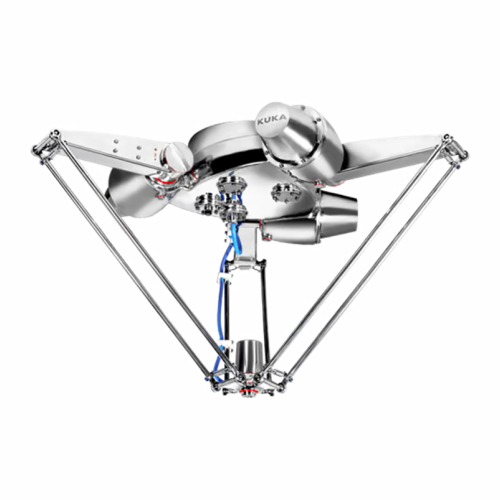

Hygienic design robot for food industry

Optimize your production line with a high-speed, hygienic design robot engineered for precision handling and packaging, ensuring superior contamination control and streamlined operations.

Handles and Sorts Products in Hygienic Conditions

The KR DELTA HM from KUKA AG is a hygienic high-speed pick-and-place robot, designed for industries such as food, pharmaceuticals, and electronics. Leveraging three-armed parallel kinematics, it operates with a precision vital for sensitive applications, including packaging and assembly of products like medicinal tablets and microchips. This robot excels in environments requiring stringent hygiene, featuring a stainless steel design compliant with LFGB and FDA standards, and offering both IP 67 and IP 69K protection classes for reliable performance in high-pressure cleanings.

Its operation is seamlessly controlled by the KR C5 micro controller, reducing energy consumption by nearly 35% compared to older models while maintaining operational safety and connectivity. The KR DELTA HM manages tasks within a compact and efficient 1,200 mm reach, supporting payloads up to 6 kg, making it ideal for high-throughput environments. Additionally, it integrates with various KUKA software packages, such as KUKA.PickControl and KUKA.VisionTech, allowing automated synchronization across multiple units.

This robot is engineered for ease of maintenance with self-lubricating materials and encapsulated gears, ensuring low upkeep demands and sustained productivity. Customizable to specific production needs, the KR DELTA HM represents a robust solution for manufacturers aiming to automate with cleanliness and efficiency at the forefront.

Benefits

- Enhances efficiency with 0.5-second cycle times, increasing production output.

- Maintains high hygiene standards, ensuring product safety in sensitive industries.

- Reduces energy costs by nearly 35% with the KR C5 micro controller.

- Facilitates seamless automation across production lines with integrated KUKA software.

- Minimizes maintenance needs due to self-lubricating and corrosion-resistant components.

- Applications

- Food, E-commerce, Assembly, Consumer goods, Palletizing, Sorting, Packaging, Food processing, Metal industry, Retail logistics, Electronics, Pharmaceuticals

- End products

- Circuit boards, Bottled beverages, Bulk packaging of snacks, Confectionery, Packaged ready meals, E-commerce goods packaging, Retail product stacks, Medicinal tablets, Microchips, Consumer electronics, Pharmaceuticals packaging, Small metal components, Pallets of electronic goods, Canned goods

- Steps before

- Material Sorting, Conveyor Setup

- Steps after

- Packaging, Palletizing, Quality Inspection

- Input ingredients

- small parts, food, medicines, electronic components

- Output ingredients

- assembled parts, packaged food, packaged medicines, sorted electronic components

- Market info

- KUKA is renowned for its expertise in industrial robotics and automation solutions, specializing in providing advanced robotic systems for manufacturing, automotive, electronics, and logistics industries, with a reputation for innovation and quality in engineered-to-order equipment.

- Load capacity

- 3 kg

- Reach

- 1200 mm

- Cycle time

- 0.5 seconds

- Protection class

- IP 67 for entire robot, IP 69K for axe 4

- Construction type

- Standard

- Automation

- Controlled by KR C5 micro robot controller

- Material

- Stainless Steel

- Corrosion resistance

- Yes

- Cleaning method

- High pressure and with alkaline or acidic cleaning agents

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Rapid

- CIP/SIP

- CIP Compatible

- Energy efficiency

- High

- Cleaning method

- Easy to Clean / Hygienic Design

- Cleaning capability

- High pressure, alkaline or acidic cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Diameter 350 mm (installation area)

- Mounting position

- Ceiling

- Control panel type

- Touchscreen / Button panel

- Integration with software

- KUKA.PickControl, KUKA.VisionTech

- Mounting position

- Ceiling

- Modular design

- Yes

- Tool flange flexibility

- High variety of tools