Chewable Tablets Equipment

Find innovative production technology for making chewable tablets and connect directly with world-leading specialists

Chewable tablets are suitable for patients who have difficulty swallowing. Chewable tablet formulation masks the natural flavors of pharma drugs and alters their aftertaste. But besides the taste, chewable tablets favor the bioavailability of pharmaceutical ingredients.

Technology picks for chewable tablet production

Automated disintegration tester for tablets

Efficiently determine tablet disintegration times with advanced waterbath tech...

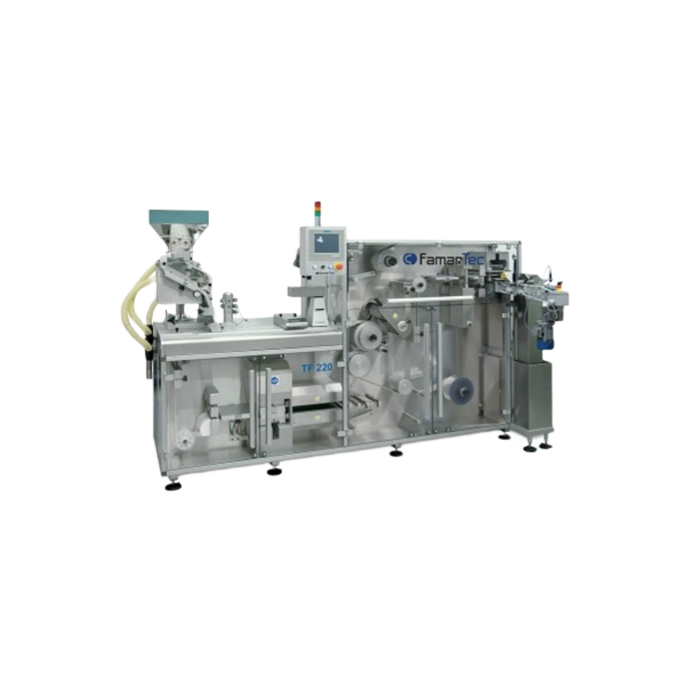

Blister packaging for solid dosage forms

Optimize your packaging line with high-speed, continuous blister packaging that en...

Benchtop tablet press

For lab work or small-scale production, a purpose-designed tablet press that meets your exact requireme...

Automatic tablet coater for lab scale

The ability to coat tablets in an even and controlled way is an important stage in th...

Stories about chewable tablets

Aim your safety standards high, while granulating dry

Coat-astrophe averted: a sprightly spin on tablet efficiency

Lean into efficiency with inclined tablet discharging

#Changemaker: Ready to protect your pharmaceutical products from moisture?

Chewable or regular aspirin: what is the difference?

Making chewable multivitamin tablets for kids

#Changemaker: Keep track of your medicine every day with FabriSol sticker

Tell us about your production challenge

Apply chewable tablets to antacid drugs

Antacids release cations that neutralize excess stomach acids and are made with a range of magnesium ingredients such as magnesium carbonate, magnesium trisilicate, and magnesium hydroxide.

Formulating antacid remedies into chewable tablets speeds up the dissolution rate. Sweeteners such as sucrose is a necessary expedient, adding sweetness and acting as a plasticizer to make the tables chewable.

Keep the hardness value to within 12 kilogram-force

The US Food and Drugs Administration recommends a low hardness threshold in the formulation of the final product. A kilogram-force value above 12 is admitted only with explicit authorization.

The chewing difficulty index is measured by force required to crush the tablet. The hardness value of chewable tablets is determined by loading the product until the breaking point. Measure the diametrical tensile strength for round tablets and flexural tensile strength for elongated ones.

Add alternative diluents to offset dryness effect of mannitol

Odorless and white, mannitol is a suitable diluent in chewable tablet blends with most ingredients. While it adds mouthfeel, mannitol also causes dryness in the mouth.

Diluent concentrations can be balanced with polyols like sorbitol that let off a cooling sensation besides a sweet taste. Mannitol registers 50% lower than sucrose on the sweetness index.

Processing steps involved in chewable tablets making

Which chewable tablets technology do you need?

In vitro dissolution and flux measurement platform

Optimize drug formulation by accurately assessing dissolution, solubil...

In-situ fiber optic Uv-vis spectrometer for dissolution studies

Optimize drug formulation by obtaining real-time, in-sit...

In-vitro dissolution-absorption assessment

Optimize drug formulation tests by combining dissolution and absorption measure...

Water activity headspace analyzer for drug product samples

Ensure precise control of moisture levels across the entire p...

In-process weighing system for capsules and tablets

Ensure precise dosing and consistent quality with a format-free syste...

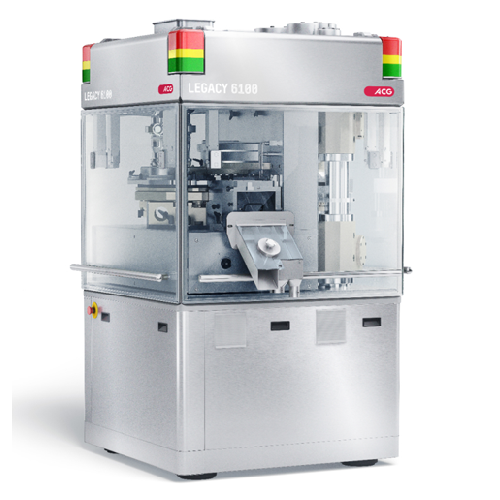

High performance tablet press for large batches

For manufacturers aiming to boost tablet production without sacrificing pr...

Tablet coating solution

Achieve precise tablet coating with uniformity and efficiency, tailored for diverse tablet types, ens...

Tablet hardness tester

Ensure consistent tablet quality by precisely measuring hardness, thickness, diameter, and weight with...

Advanced friability and abrasion testing solution

Ensure precise compliance in pharmaceutical tablet testing with this in...

High-speed strip packaging for tablets and capsules

Optimize your high-speed pouching operations with precise four-side s...

Tablet coating system for high-capacity operations

Streamline your tablet production with a coater that maximizes through...

Tablet coater for batch sizes up to 250 liters

Enhance your tablet production process with high-speed coating solutions de...

Single rotary tablet press

Streamline your tablet production with enhanced efficiency and precision, ensuring consistent tab...

Flat-forming blister packager for small production batches

Ideal for pharmaceutical and nutraceutical firms seeking effi...

High-output blister packaging system

Maximize blister packaging efficiency with continuous-motion capabilities, ensuring su...

Atex horizontal bead mill

Ensure precision and safety in explosive environments with a robust solution that finely grinds an...

Automated sample preparation workstation for content uniformity testing

Streamline your laboratory workflows with autom...

Continuous wet granulator and dryer for R&D

Pharmaceutical laboratories need compact equipment to handle and produce small...

Dry granulator for pharmaceutical powders

In pharmaceutical industries, where large-volume production is the norm, compact...

Energy-efficient film coating machine for pharmaceutical tablets

Tablet coating involves applying a thin layer of coatin...

Pharmaceutical tablet coating machine

Tablet coating requires spraying, mixing, and drying procedures that must be carried ...

High Speed Visual Inspection System for Tablets

In order to ensure quality and standard specifications of tablets, capsule...

Contained Visual Inspection System

In the medicine industry, it is important to ensure there are no defects in tablets or c...

Side-load case packer

As the final stage in the packaging process, an automated case-packing solution can ensure that your co...

Small feeder with flexible wall hopper

In many laboratory applications and production processes, smaller quantities of powd...

Automatic tablet coater for lab scale

The ability to coat tablets in an even and controlled way is an important stage in th...

Single and double layer tablet press

High performance tablet presses that are capable of producing both single and double-l...

Lab scale single layer tablet press

Automated pressing of tablets saves time and improves quality. In R&D or laboratory...

Granulation line of mixer and fluid bed dryer

A complete granulation line allows for the mixing and granulation of pharmac...

Single layer tablet press

High performance tablet presses for the modern production environment need to be fast, accurate an...

Rotary tablet press

For pharmaceutical tablet producers looking to reduce waste, costs and increase production volume, a hig...

Entry-level high-shear mixer for drug formulation

For pilot and lab-scale pharmaceutical formulations, a high-shear granu...

Premium vacuum conveyor

When you have a need to tailor make your conveyor and still have the high requirement on hygiene, e.g...

Sorption dehumidifier with air-chilled condenser

It is not always possible to duct out the wet air from a dehumidifier ser...

Small portable dehumidifier

Water damaged areas require dehumidification to limit the damage and prepare the area for restor...

Sorption dehumidifier for large temperature differences

Small, humid areas can be difficult to dehumidify in humid ambien...

Sorption dehumidifier for deep drying

Humid ambient conditions such as those in tropical climates make dehumidification mor...

Dehumidifier for difficult wet airflows

Sealed rooms can be challenging to dehumidify with ordinary dehumidifiers. The wet ...

Sorption dehumidifier for overpressured rooms

Small humid spaces, used for processing or storage, often need a simple dehu...

Heat recycling sorption dehumidifier

Facilities that handle large amounts of water can become very humid. High humidity may...

Industrial desiccant dehumidifier

Dehumidification of medium sized manufacturing and processing facilities can be a dauntin...

Large scale desiccant dehumidifier

Moisture sensitive processing and storage facilities need low humidity environments to s...

Customizable dehumidifier

Dehumidification needs can vary significantly from one project to another. Dehumidifiers with a fi...