Making Granola

Find innovative production technology for making granola and connect directly with world-leading specialists

Granola is one of the most beloved breakfast menus for its versatility and convenience - you can put it in milk, use it as a topping for yogurt, or even make healthy cookies out of it. Setting up a granola production equipment line is quite similar to muesli. The only difference would be that the sheet of hard grains, nuts, and dried fruits goes through the baking process.

Stories about granola

Select your granola process

Tell us about your production challenge

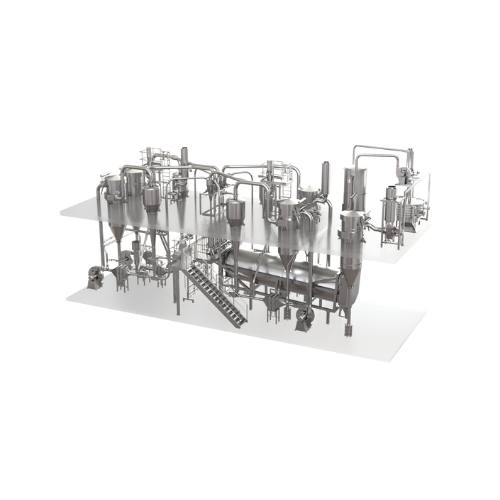

Setting up your granola production equipment line

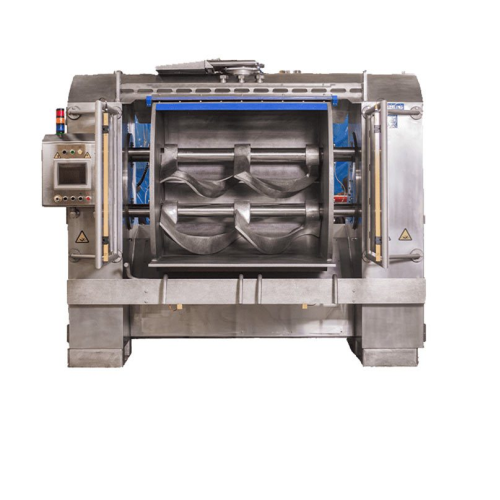

To make crunchy granolas, first, you need to create loosely combined sheets of grains, nuts, and dried fruits. You will bake these sheets and break them into small clusters as the final product. As the very first step of creating these sheets, the dry ingredients, sugar, and oil are blended in a mixer.

This mixed batch is evenly spread, and they go into a compression roll for gauging for the baking process, looking at the shape and level of the sheet. If there is no issue found, you can move these sheets forward to the convection oven, which allows sugar to melt and grains to be cooked. Then, the cooling tunnel will lower the temperature of these sheets, binding all the ingredients even more. Finally, the kibbling machine breaks down these sheets into small clusters.

Crunchy granola vs. granola bars

Are the process of making crunchy granola cereals and granola bars the same? Mostly yes. The very last parts of manufacturing these two products are varied. As it is mentioned above, making both crunchy granola and granola bars start from manufacturing these loosely combined sheets of ingredients. You bake and cool these sheets, and when it comes to forming the shape of these products, two different processes are taken. For granola bars, the sheets go through a slitter which is the process of a guillotine cutting the sheets into the shape of bars. For crunchy granola, the sheets are broken into small clusters with a kibbling machine.

Baking time and temperature of granola

One of the most important factors that can change the taste of granola is the temperature and time of baking. If the sheets of ingredients are cooked for too short, the ingredients cannot mature, and if they are baked for too long, the taste of the granola can be influenced. Also, if they are cooked at too high or low temperature, the color and the texture of the final product will not be ideal. Depending on the specification of the manufacturing machine, the time and temperature of the baking process will be different. Hence, to achieve the specific taste, level of crunchiness, and the color you are looking for, it is important to adjust the time and temperature of the oven.

Processing steps involved in granola making

Which granola technology do you need?

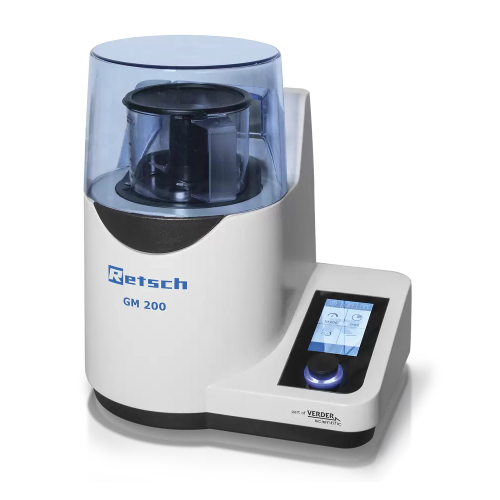

Cyclone mill for Nir analysis sample preparation

Ensure accurate NIR analysis by optimally preparing samples with efficien...

Ultra centrifugal mill for size reduction of soft and medium-hard materials

Achieve precise particle size reduction an...

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Vertical spindle mixer for dough processing

Optimize your dough consistency and quality with this vertical spindle mixer, ...

Continuous mixer for cookie and snack dough

Achieve uniform and consistent mixing of cookie and snack dough with seamless ...

Precise dough sheet cutting station for bakeries

Efficiently shape and cut dough sheets for diverse snack and bakery produ...

Industrial tumble dryer for moisture control in snack production

Ensure precise moisture reduction and optimal air circu...

Instant dough hydration system

Efficiently hydrate dry ingredients instantly with minimal heat increase, streamlining your m...

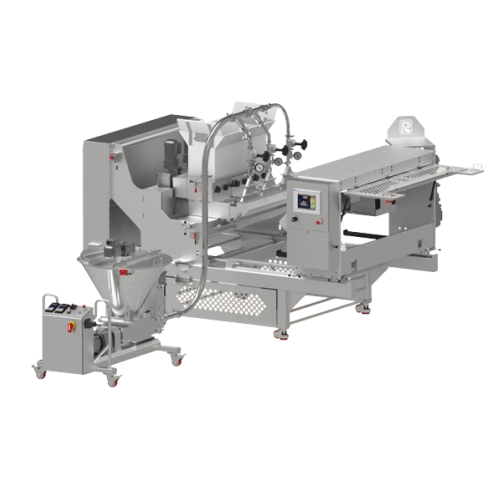

Servo in-line dough laminator for industrial bakeries

Optimize your snack production with precise dough sheet cutting, st...

Continuous mixer for cookie dough

Achieve consistent dough quality and streamline your production with a continuous mixing ...

Low pressure extruder for pretzel and snack production

Achieve versatile snack production with a low pressure extruder th...

Industrial multi-pass dryer for bakery products

Ensure consistent moisture reduction and quality enhancement in your baker...

Filled stick extruder for bakery products

Streamline your snack production line with a versatile extruder capable of creat...

Fried snack extruder for potato rings

Efficiently produce a variety of fried snacks, from potato rings to ethnic noodles, w...

High pressure extruder for expanded snacks

Enhance your snack production with precise control over texture and shape throu...

Smart bakery oven zone for flexible heating

Optimize your production with flexible heat transfer options that enhance cont...

Electric oven zones for snack and cookie baking

Optimize your baking line with electric oven zones designed to eliminate e...

Emithermic zone for baking biscuits and cookies

Enhance your baking efficiency and precision with a flexible heat transfer...

Emithermic Xe zone for baking biscuits and crackers

Achieve precise baking and drying for your bakery products with a sys...

Continuous mixer for wheat-based products

Achieve consistent dough quality with minimal variation using a continuous mixer...

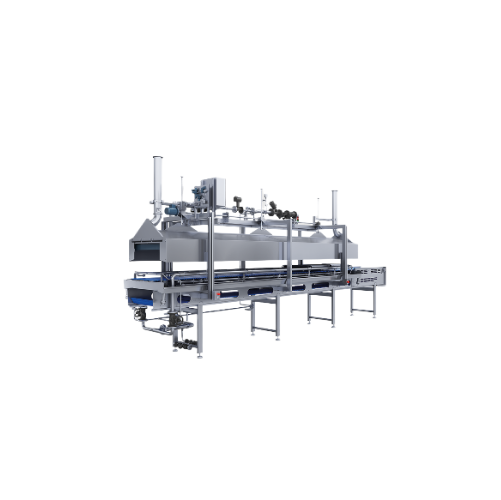

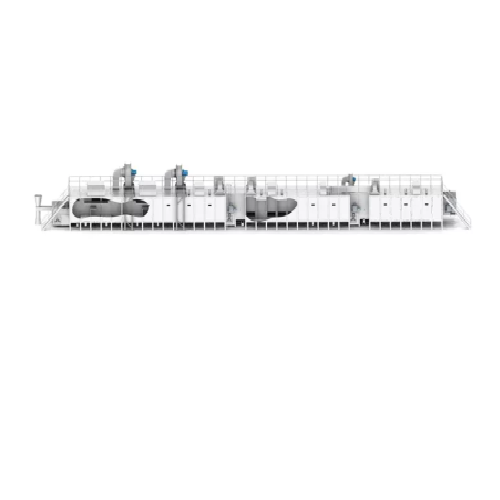

Convection oven with integrated dryer for large scale baking

Optimize your baking process with a convection oven that ef...

Industrial direct drive mixer for dough preparation

Optimize your production line with a robust mixer designed for seamle...

Automated dough handling system for pretzel production

Streamline your dough processing with a system that precisely port...

Efficient dough dump station for bakery systems

Streamline your dough handling process with this advanced dumping station,...

Vertically feeding system for cookie dough

Optimize your dough handling with a system that ensures seamless and efficient ...

Industrial continuous heat treatment for dry ingredients

Optimize your production line with a continuous system that ensu...

3-roll sheeter for dough forming

Achieve smooth and consistent dough sheeting crucial for high-quality biscuits, cookies, an...

Ambient air cooler for bakery products

Efficiently cool fragile baked goods without causing distortion, using ambient air t...

Medium duty mixer for breads and pastries

Achieve consistent dough development and uniform mixing for a wide variety of ba...

Medium duty mixer for dough preparation

Achieve perfect dough consistency across various products with a versatile medium d...

Traditional enclosed frame mixer for dough and batter preparation

Optimize your production with high-capacity mixing, e...

Industrial enclosed frame mixer for high-capacity dough mixing

Optimize your bakery’s output with a mixer designed...

Grain flow regulator for roller mills

Achieve consistent grain distribution and safeguard your roller mills from wear and c...

Single shaft paddle mixers for dry powders and granulates

Achieve uniform and precise mixing for your batch processing n...

High accuracy micro dosing system

When handling diverse ingredients, precise dosing is crucial to ensuring consistent produ...

Chain conveyors for long-distance bulk material transport

Efficiently transport challenging bulk materials across long d...

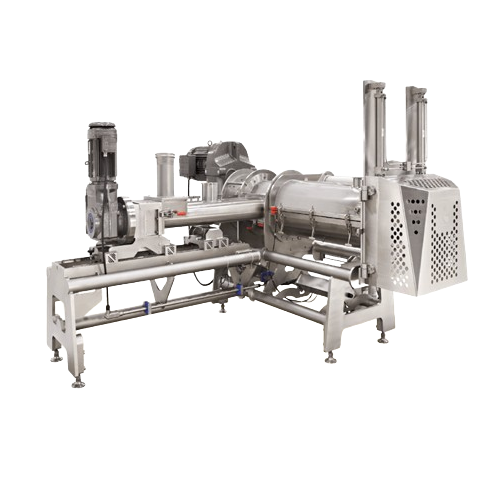

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

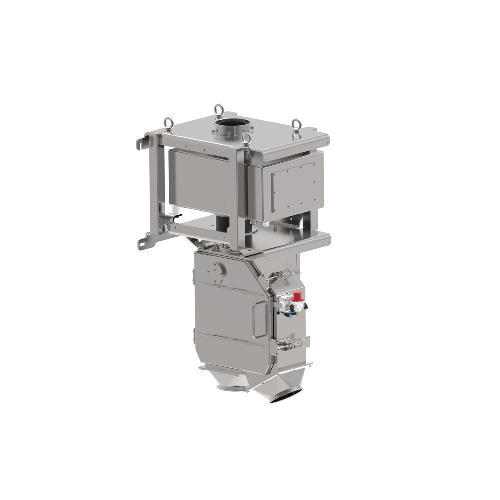

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

Laboratory ploughshare mixer for small-scale production

Achieve precise mixing and granulation for R&D and small-bat...

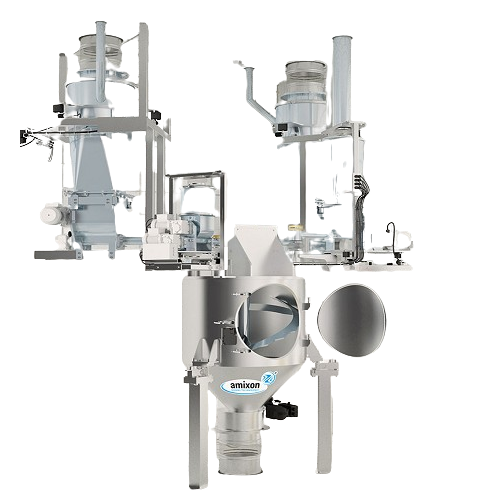

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this...

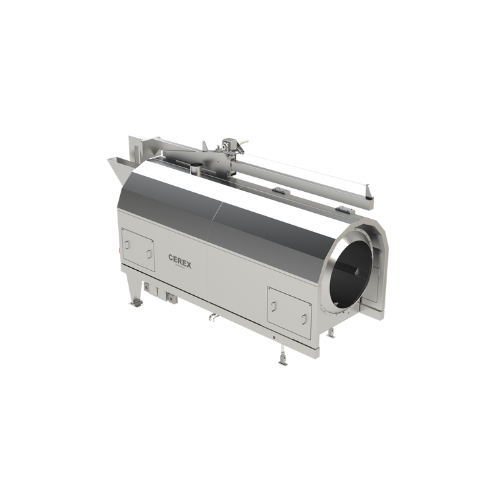

Cereal moulding solution for bars, bites, and clusters

Efficiently shape and form a variety of granola and cereal-based p...

Flexible packaging solution for large food volumes

For high-volume food packaging, achieving consistent bag sizes and red...

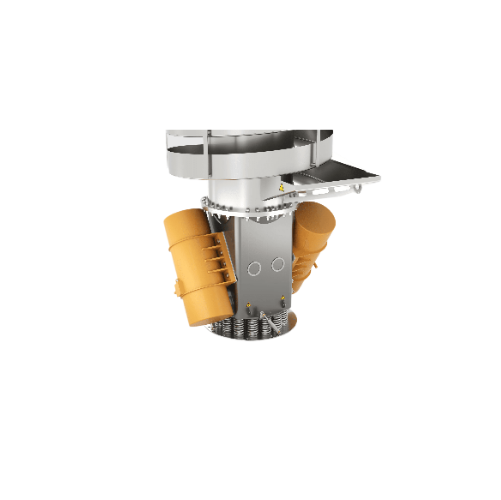

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

Homogenous blending solution for powders and granules

Achieve precise, homogenous blending of challenging materials like ...

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Vacuum dryer for powders and granules

Achieve precise moisture control for sensitive materials with a versatile vacuum dryi...

Roller press for fine-grained material compaction

Achieve optimal density and stability in your solid press agglomerates ...

High-speed hammer mill for continuous operation

Achieve precise particle size reduction with high-speed hammer milling, id...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Flake crusher for hygroscopic substances and lumped salts

Efficiently turn fragile, aggregated materials into manageable...

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

Automatic bulk material filling system

Ensure precise, contamination-free filling of various bulk materials with an advance...

Powder flowability and compressibility analysis

Ensure accurate powder flowability and compressibility data with this adva...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

Wafer distribution device for chocolate coating plants

Enhance your chocolate coating operations with precision wafer dis...

Cream preparation plant for homogeneous mixing

Optimize your snack production with precise mixing technology, ensuring con...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

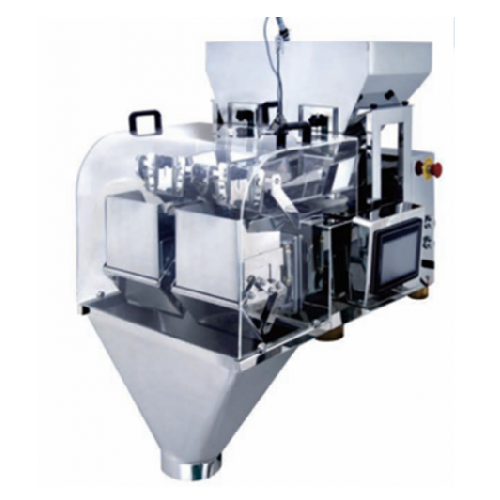

Linear weigher for dry or frozen free-flowing products

Optimize precision in high-speed weighing tasks with a compact sol...

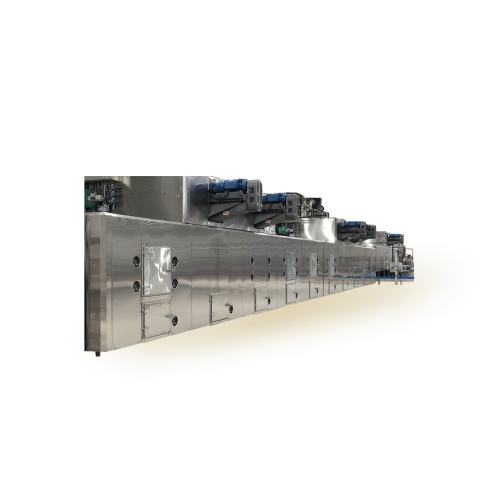

Continuous tunnel dryer for food products

Achieve precise moisture removal with adaptable drying technology, ensuring your...

Spouted bed processing for food, feed, and fine chemicals

Tackle the challenge of processing temperature-sensitive and s...

Sampling valve for secure sample extraction

Ensure product quality by safely extracting representative samples without hal...

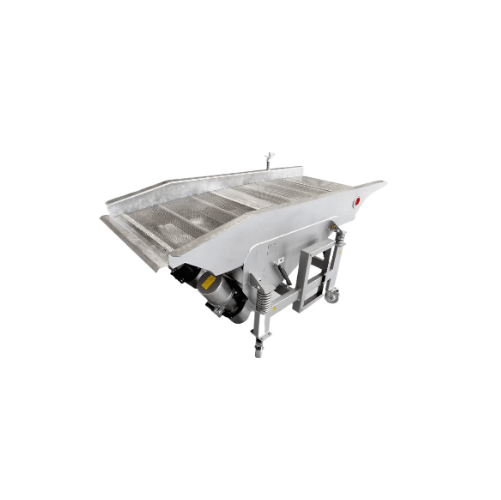

Vibration transport system for hygienic conveying of bulk goods

Optimize your production line with efficient and hygieni...

Batch mixer for powder and grain processing

Achieve ultra-fast, homogenous mixing in just 20 to 50 seconds with this versa...

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

Rotary drum sifter for pellets and chunks

Achieve precise particle separation and minimize product loss with a rotary drum...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Industrial food mixer for high-volume processing

Achieve consistent mixing and precise blending of diverse food ingredient...

Industrial moisture and temperature control conditioner

Optimizing moisture absorption and temperature management, this c...

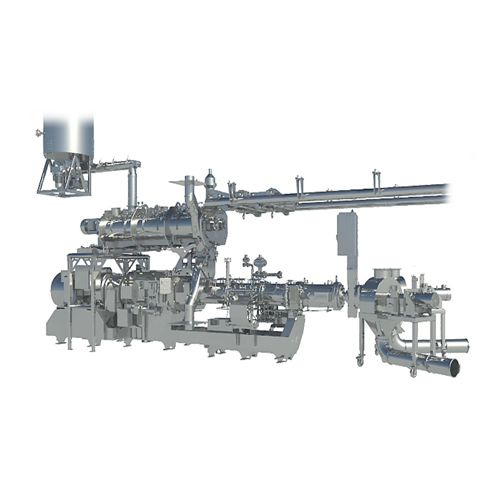

High throughput twin screw extruder for low bulk density products

When handling low bulk density materials, achieving m...

Food extruders for pet food production

Achieve precise control in food production with advanced twin screw extruders, desig...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

High-performance twin-screw extruder for food production

Enhance your production line efficiency and product quality with...

Industrial 2-zone toaster for optimal cereal processing

Achieve precise toasting of cereals and seeds with the 2-zone toa...

Single-zone toasters for raw grain processing

Optimize your cereal and snack food production by achieving consistent toast...

Industrial coating drum for breakfast cereals

Optimize your cereal production with a coating drum designed to enhance prod...

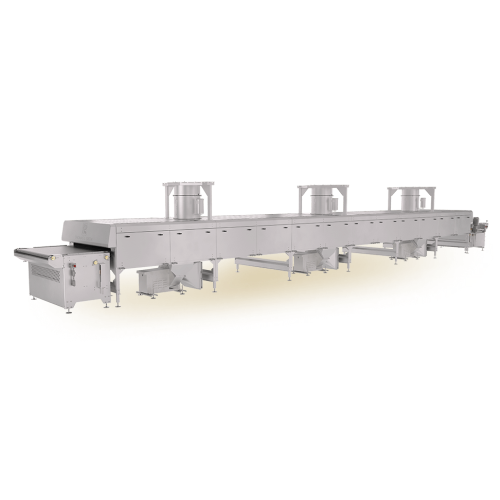

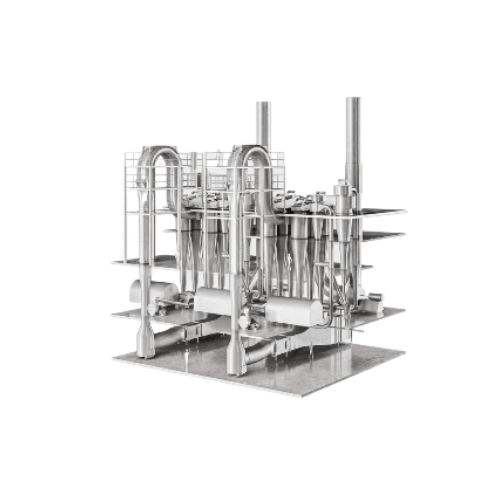

Coating dryers for breakfast cereal production

Achieve precise moisture control in coated cereal production with these mod...

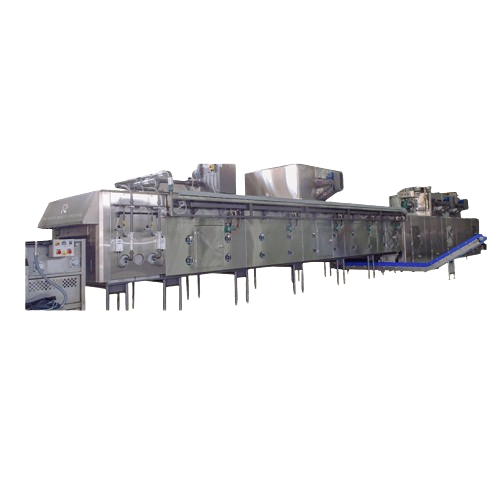

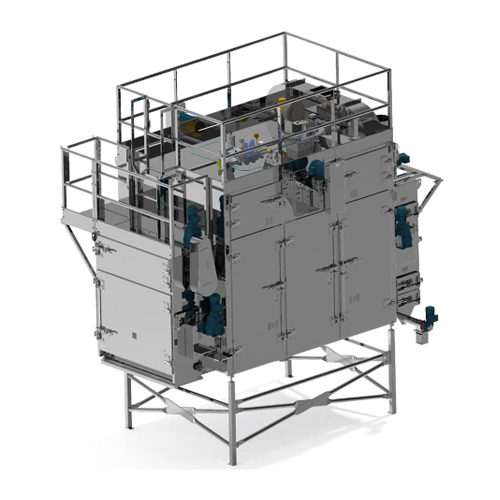

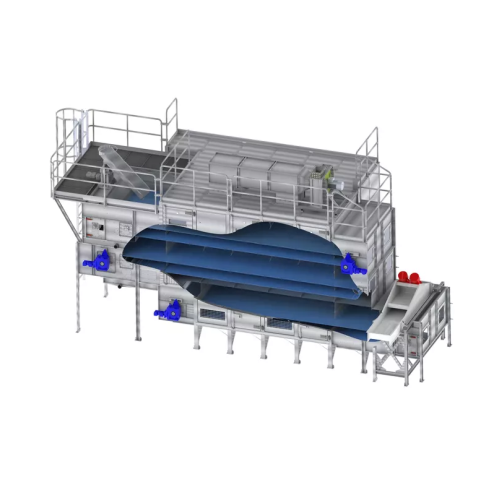

Granola drying solution

Optimize your granola production with modular drying technology that ensures precise moisture control...

Multi-tier dryers for modern breakfast cereals

Optimize dry and cool cereal, nuts, and seed production with a compact modu...

Nut and seed roaster for snack production

Ensure precise roasting and cooling of nuts and seeds while maintaining hygiene ...

Grain puffing system for breakfast cereals

Achieve precise and efficient grain expansion in breakfast cereals with this ad...

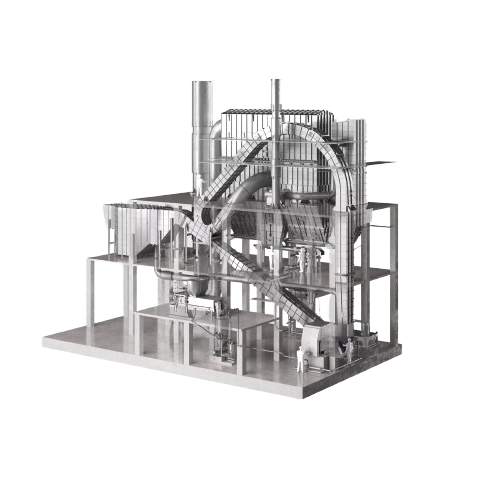

Rotary cooker for uniform steam heating in cereals production

Achieve consistent product quality in high-volume cereal p...

Industrial screeners for grain product processing

Optimize your cereal production line with specialized industrial screen...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Air cleaners for grain dust removal

Enhance safety and operational efficiency by effectively removing dust and light partic...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

Versatile steam distillation unit for laboratory applications

Achieve reliable analysis of complex samples with this ste...

Industrial fat extraction system for food and feed analysis

Optimize your laboratory workflow with a versatile fat extra...

Lab-scale twin screw extruder

Optimize your material testing and production efficiency with our versatile twin screw extrude...

Small twin screw extruder

Optimize your lab and pilot production with a versatile twin screw extruder, designed for precise ...

Gluten quality testing solution

Ensure optimal flour quality by rapidly assessing gluten properties, allowing you to refine ...

Vertical case packer for reusable and Rsc cases

Streamline your packaging line with versatile, high-speed case packing tha...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Double shaft paddle mixer for solids and powders

Achieve unparalleled mixing precision for fragile and diverse materials w...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Continuous granulator for powdery goods

Achieve uniform particle size and structure with a continuous granulation process t...

Continuous powder mixer for dry, moist and suspended goods

Achieve precise homogenization and deagglomeration with a con...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Small scale chip depositor for confectionery production

Efficiently deposit a variety of confectionery and snack products...

Aeration and aroma mixing system for chocolate production

Optimize your chocolate and confectionery production with prec...

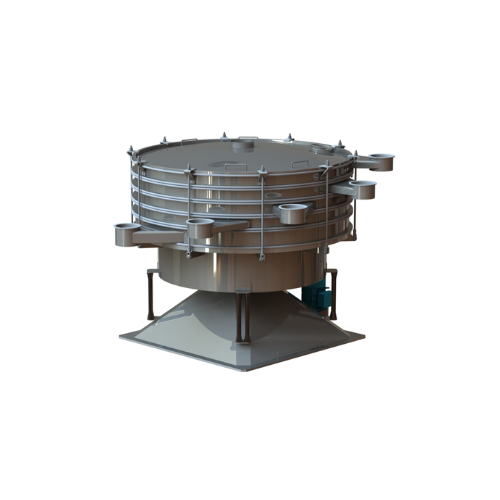

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle han...

Industrial powder sifter with sanitary compliance

Optimize your powder processing with this versatile sifter, ensuring pr...

Rotary cleaner for raw material sieving

Ensure precise raw material quality with a rotary cleaner that efficiently sieves a...

Vibratory spiral elevator for vertical transport

Achieve efficient vertical transport with precise temperature control, su...

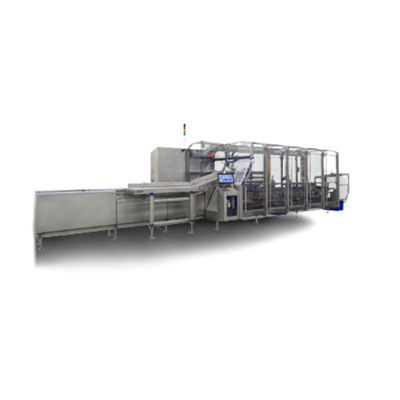

Continuous motion packaging for short-cut pasta

Optimize your packing line with a high-speed solution designed for efficie...

Vertical packaging system for short-cut pasta and dry granular food

Streamline your packaging operations with a high-sp...

Intermittent motion bulk packaging for pasta and granular products

Optimize your production line with precision packagi...

Packaging system for short-cut pasta and dry granular food

Streamline your packaging process with a versatile system des...

Eco-friendly vertical packaging for pasta

Reduce plastic waste and enhance sustainability in pasta packaging with high-spe...

Vertical packaging system for fragile food products

Handle delicate food items like pasta nests and bakery products with ...

Intermittent motion packaging system for dry granular food

Achieve precision packaging for dry foods with an advanced sy...

Industrial cooling system for packaging temperature control

Achieve precise temperature control and maximize energy effi...

Industrial pasteurizer for efficient bacterial reduction

Ensure your food products are safe with an industrial pasteurize...

Extruder for short-cut pasta and lasagna production

Achieve seamless pasta and snack production with an extruder designed...

Batch standing mixer for dough preparation

Enhance your mixing precision with a batch standing mixer that optimizes paddle...

Industrial water cooker for pasta processing

Enhance your pasta production with precise water cooking, ensuring consistent...

Round die washer for pasta and snack production

Ensure impeccable hygiene with a specialized washer that streamlines die m...

Rotating cutter for short pasta production

Optimize your short pasta production line with a versatile rotating cutter desi...

Semi-automatic powder filling system for food products

Achieve precise and flexible filling for food powders and granules...

Industrial ring dryer for efficient particle processing

Control particle size and drying efficiency with precise recircul...

Flash dryer for industrial moisture removal

Optimize your production with rapid moisture removal, efficiently transforming...

Screw belt mixer for dry materials

Achieve uniform mixing of bulk dry materials with variable speed control, ensuring preci...

Coating pans for precision culinary coatings

Achieve consistent, high-quality coatings on a diverse range of products, fro...

Light duty oven for snacks and light density foods

Maximize efficiency with precision-controlled drying and heating of sn...

Extruder for aquatic feed production

Efficiently produce a wide range of aquatic and pet feed with precise control over pel...

Forming extruders for flaked cereals

Optimize your production line with versatile forming extruders designed for precision ...

High-sme extruder for structured meat analogs

Enhance production versatility with precise extrusion control, accommodating...

Coating and enrobing system for pet foods and treats

Achieve precise coating and flavoring of various food and feed produ...

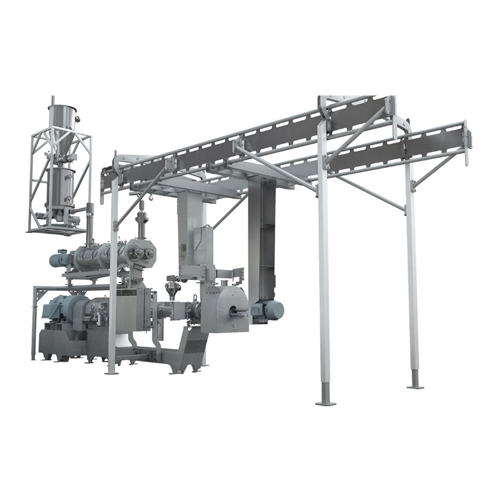

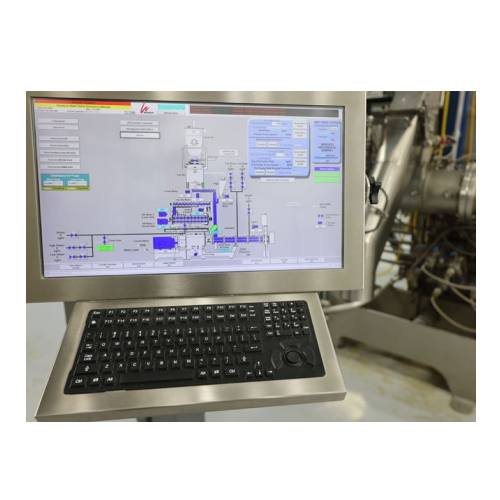

Automated process management system for industrial extrusion

Optimize your production line with precise control and moni...

High intensity preconditioner for textured vegetable proteins

Optimizing your production with precise moisture control a...

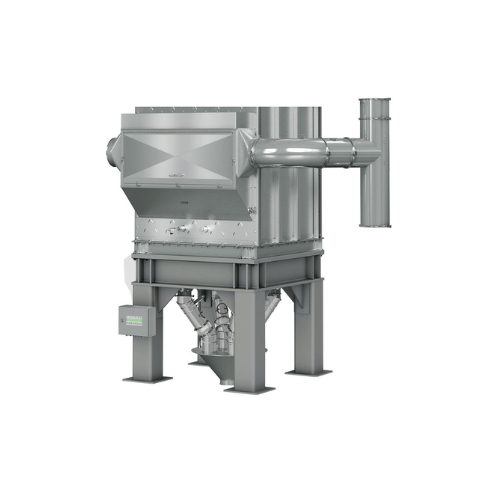

Atex certified flanged round dust collectors

Designed for potentially explosive environments, these flanged round dust col...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

High capacity vertical conveying for grains and cereals

Ensure efficient vertical transport of bulk materials like cereal...

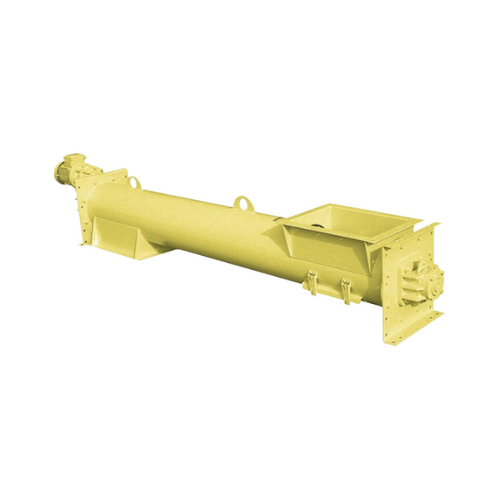

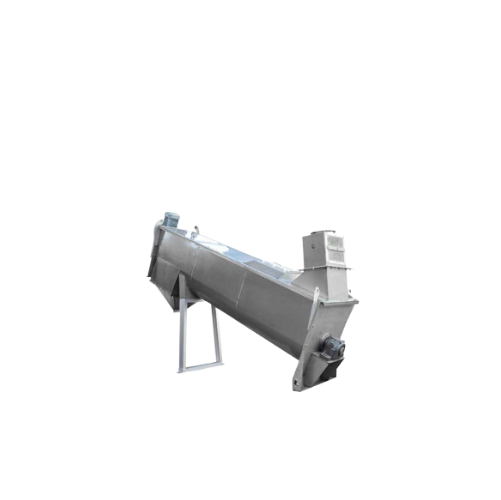

Tubular trough screw conveyors for gentle powder and granular material handling

Achieve precise powder and granular ma...

Automatic rotary filler and sealer for premade pouches

Enhance your production line efficiency with a dual-lane system th...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Industrial food processor for diverse applications

Optimize your production line with a versatile processor capable of ch...

Industrial extraction scale for accurate material weighing

Ensure precise ingredient proportions in your milling operati...

Bucket elevator for grain and powder products

Efficiently transport bulk materials like grain and powder vertically with p...

Industrial impact detacher for semolina processing

Optimize your grain processing line with a solution designed to enhanc...

Inclined intensive dampener for grain processing

Ensure consistent moisture levels for optimal grain processing and enhanc...

High-precision sorter for nuts, coffee, seeds, and grains

Achieve unrivaled accuracy in sorting nuts, seeds, and grains ...

Cooling conveyor belt for extrudates and granules

Efficiently cool and convey extrudates and granules with precise temper...

Overflow conveyor for efficient product handling

Streamline your production with overflow conveyors that manage excess pro...

Flexible high-speed wrapper for confectionery products

Streamline your packaging process with a versatile machine designe...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

Modular linear packing system for granular products

Streamline your packing operations with a versatile system that integ...

Linear weigher for accurate food portioning

Ensure precise weight control for snacks and confectioneries with our advanced...

Linear weigher for dry free flowing powder

Optimize your packaging line with precise weighing for free-flowing granular pr...

Cooking extruders for continuous food processing

Optimize your extrusion processes with cooking extruders designed for con...

Cold forming extruder for food manufacturing

Achieve precise shape and density control in cereal and snack production by i...

Sanitary separator for food processing applications

Ensure efficient separation and prevent contamination in food product...

Thermal conditioning for improved meal flow and starch digestibility

Ensure optimal meal flow and starch digestibility ...

Small batch mixing rotosphere blender for food industry

Achieve precise mixing of small batch powders and granules with a...

Industrial hammermill for fine grinding applications

Elevate your milling efficiency with hammermills designed for precis...

High-capacity sleeve filters for silo dedusting

Optimize your production with filtration systems that ensure efficient dus...

Agricultural cleaner-separator for grain processing

Optimize your grain processing with a versatile cleaner-separator eng...

Mobile circulating dryer for agricultural products

Optimize your drying processes with a mobile circulating dryer, design...

Stationary grain dryer with exhaust air system

Optimize your drying process with a system designed to handle diverse mater...

Grain dryer with air circulation system

Enhance efficiency and product quality with our versatile grain dryer, designed to ...

Low-emission belt drying systems for timber industry

Optimize moisture control and energy efficiency in drying processes ...

Belt dryer for timber industry

Optimize moisture removal and ensure consistent drying in your production line with advanced ...

Layer dryer for food and pet food applications

Optimize drying efficiency with multi-layer technology that minimizes space...

Belt dryer for food and pet food products

Optimize drying processes with customizable belt dryers, engineered to handle ro...

Belt dryer for sawdust

Optimize your drying process with advanced technology engineered for precise moisture reduction in div...

Hybrid dryer for agriculture and industrial applications

Achieve efficient moisture reduction in varied materials, from f...

High-force texture analyser for precise measurement

Achieve unparalleled precision in texture analysis for high-force app...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Precise metering system for dry confectionery ingredients

Achieve precise dosing of granular and dry ingredients like nu...

Z-conveyor for confectionery production

Ensure the gentle transport of delicate dry and granulated ingredients with a versa...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

Refrigeration jacket for triple roller bar mixers

Enhance dough mixing performance by efficiently managing temperature co...

Dough chunkers for bakery production

Optimize dough processing by efficiently feeding and dividing dough portions, ensuring...

Metal detection system for powders & granules

Ensure product integrity and protect your machinery from metallic contaminan...

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

Single shaft horizontal batch mixer

Achieve consistent, high-quality blends with precise homogenization using a single shaf...

Twin shaft horizontal batch mixers for homogenous material mixing

Achieve consistent and rapid mixing of diverse materi...

Modular packaging systems for diverse industries

Effortlessly adapt to market demands with versatile packaging systems, de...

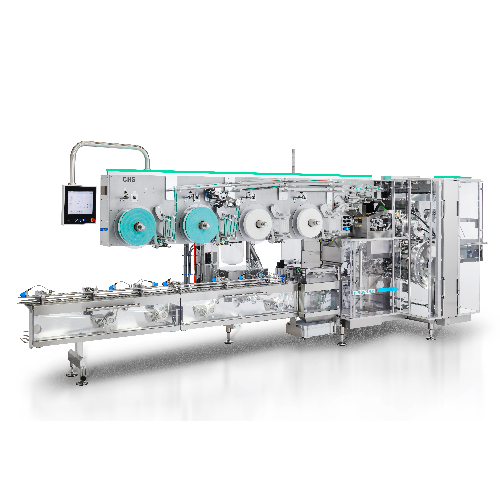

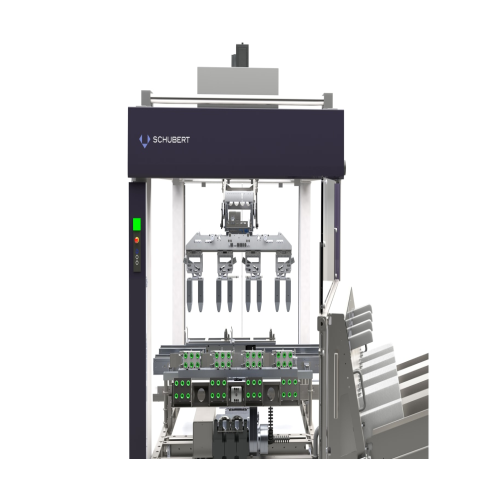

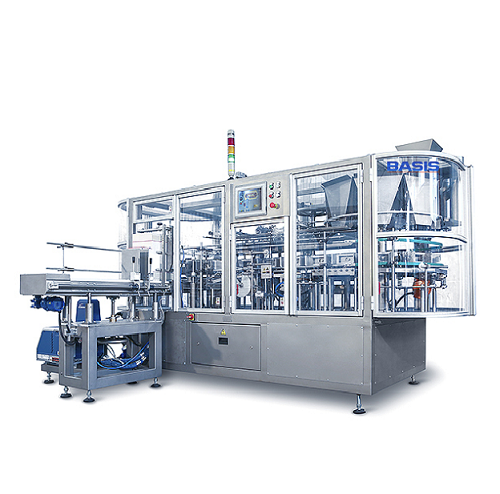

Intelligent Continuous Food Cartoner

Fully automated robotic packing solutions enable larger-scale food producers to pack a...

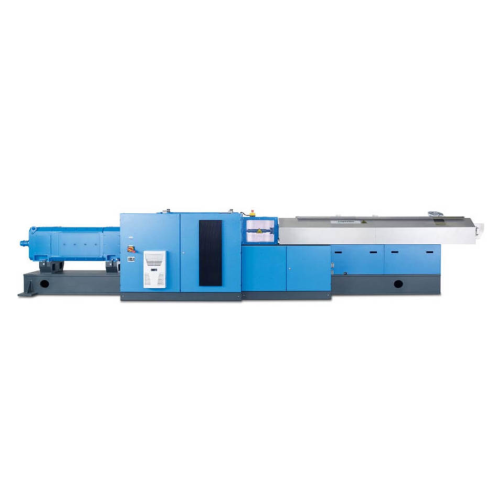

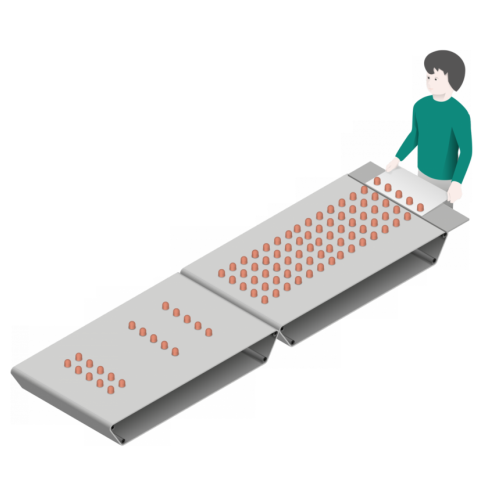

Entry-level cereal bar making machine

Cereal and grain bars are increasingly popular, both as snack foods and as functional...

Small cooling belt for tempering/enrobing

For larger productions of chocolate after coating, enrobing or tempering in a co...

Case packer machine for pouches

Automated case packer machines are a good solution to achieve reliability and to increase th...

Mixer and kneader for sugar based recipes

For the production of chocolate paste based on refined or icing sugar, the decis...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Hygienic vertical bagging machine

Hygienic bagging with a compact packing machine that can withstand the harshest wash down...

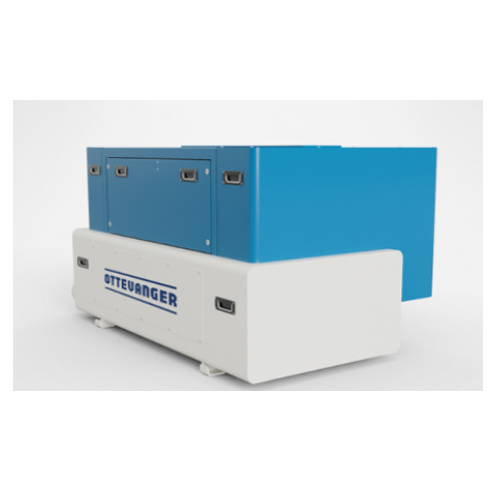

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Entry-level automatic cereal bar machine

Start up your manufacturing of cereal bars or produce smaller batches to test and ...

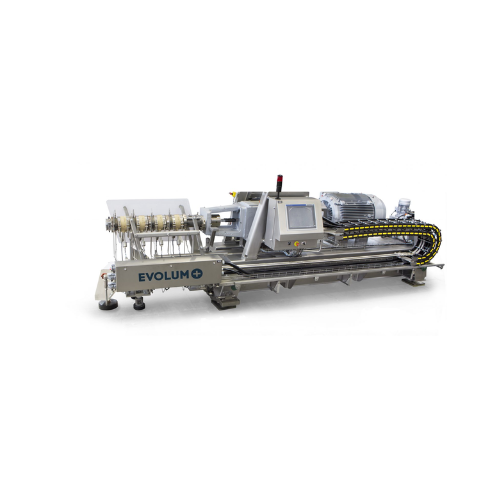

Strand forming machine

Form ingredient mixes into strands and slabs for further processing into bars, and other final product...

Continuous vertical cartoner

When producing cereals, it is paramount to stay on top of market trends. New packaging forms ca...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

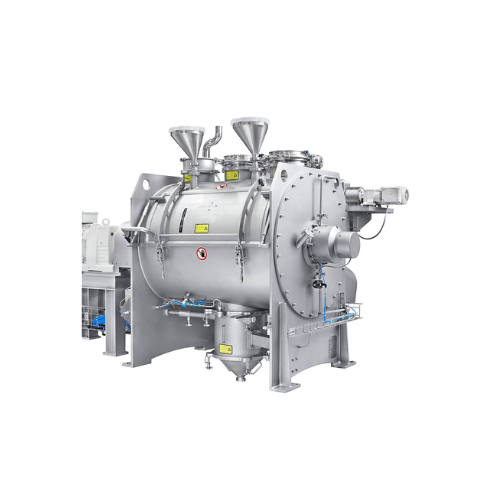

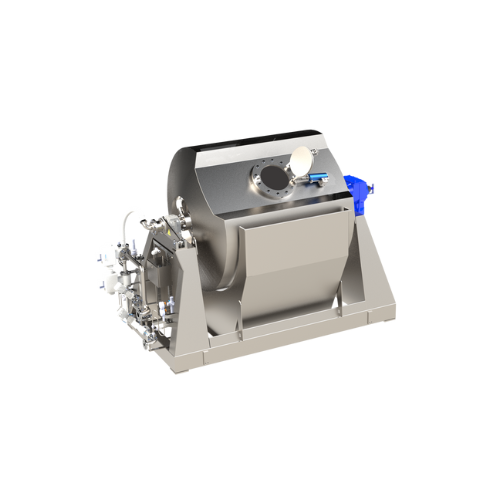

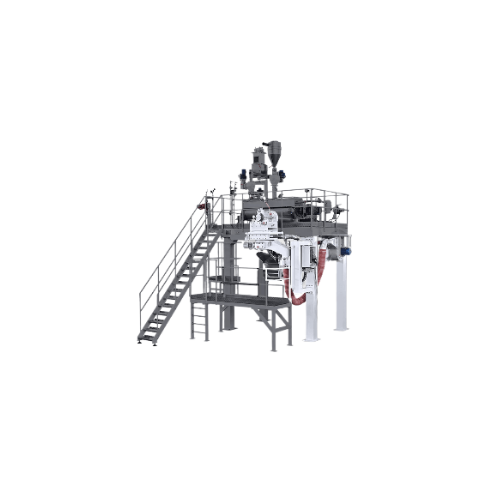

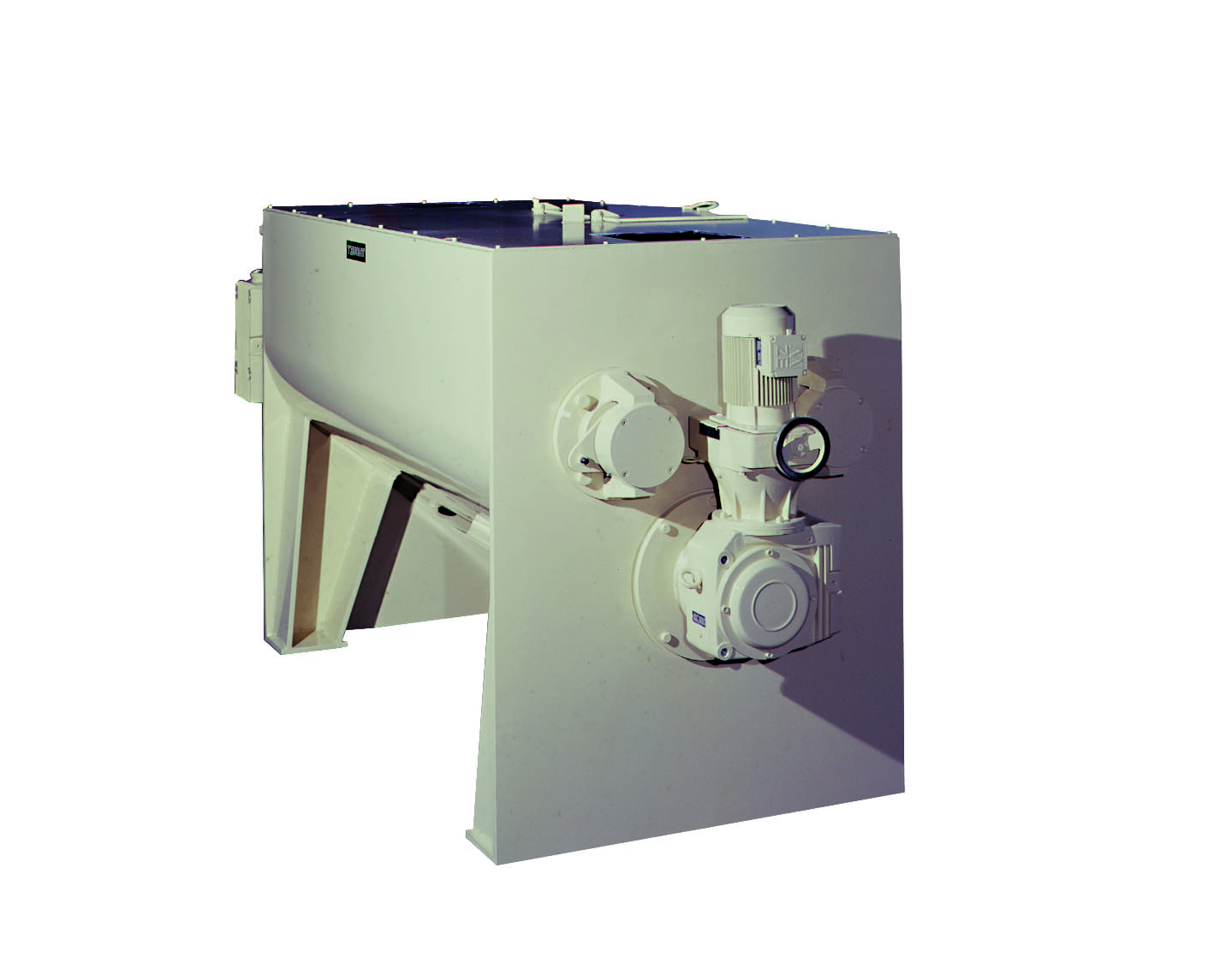

Granola batch mixer

The production of granola-based recipes requires careful ingredients handling to ensure optimum quality. ...

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...