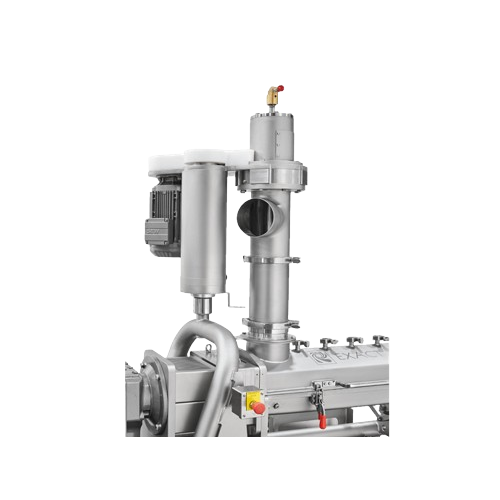

Instant dough hydration system

Efficiently hydrate dry ingredients instantly with minimal heat increase, streamlining your mixing process and reducing equipment footprint and energy costs.

Rapidly Hydrates and Mixes Ingredients

Hydrobond Technology by Reading Bakery Systems offers an innovative solution for industrial bakeries and snack manufacturers focusing on dough processing efficiency. This system specializes in the rapid hydration of dry ingredients, integrating seamlessly with your existing continuous mixing line. It utilizes a pre-mixing hydration step that reduces the size of the required downstream mixer, which in turn lowers both the energy consumption and equipment footprint. Capable of processing a wide variety of products, including pretzel sticks, cheese crackers, and kibble for pets, it is ideal for high-throughput operations in the food, snack production, and pet food industries.

Automation is streamlined with an in-house designed PLC control system, allowing for precise operation and integration within your production facility. The Hydrobond Technology system is noted for its robust construction, designed to handle the rigors of continuous and batch operations while minimizing heat generated during mixing, thus maintaining ingredient quality. Cleaning is simplified through easily accessible components, ensuring quick maintenance turnaround and adherence to sanitation standards. This equipment can be customized to meet specific production needs, supported by Reading Bakery Systems’ engineering expertise.

Benefits

- Minimizes equipment footprint to save valuable production space.

- Cuts energy costs by reducing mixer size and optimizing hydration efficiency.

- Enhances product quality by preventing heat buildup during mixing.

- Streamlines cleaning processes to ensure high sanitation standards.

- Customizability supports a wide range of bakery and snack production needs.

- Applications

- Cookies, Biscuits, Stackable chips, Snacks, Popped snacks, Expanded snacks, Crackers, Baked pet food, Baked granola, Pretzels, Fried potato rings

- End products

- Pretzel sticks, Stacked potato chips, Chocolate chip cookies, Kibble for cats, Cheese puffs, Onion rings, Cheese crackers, Popcorn chips, Nutri-grain bars

- Steps before

- Pre-hydration, Ingredient Weighing, Screening

- Steps after

- Proofing, Baking, Cooling, Packaging

- Input ingredients

- dry materials, flour, liquids, minors, water

- Output ingredients

- hydrated dough, mixed dough

- Market info

- Reading Bakery Systems is renowned for its expertise in designing and manufacturing innovative industrial bakery equipment, particularly for snack food production, combining advanced technology and industry knowledge to enhance productivity and quality.

- Hydration Efficiency

- Superior hydration without excess heat

- Mixer Footprint

- Smaller footprint

- Energy Cost

- Lower energy costs

- Mixing Time Reduction

- Reduced total mixing time

- Temperature Gain

- Little temperature gain

- Mixing Capacity

- Mix more dough with same size mixer

- Cleaning Process

- Cleans quickly and easily

- Compatibility

- Can be used with continuous mixer or pre-hydration system

- Working mechanism

- Continuous mixing

- Integrated steps

- Pre-hydration system

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- Automated/PLC

- CIP/SIP

- Designed with easy cleaning

- Changeover time

- Quick and efficient

- Energy efficiency

- Lower energy costs

- Cleaning method

- Quick and easy cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Requires no additional floor space

- Control panel type

- Custom-designed control systems

- Discharge method

- Efficient blend of dry and wet ingredients before main mixing chamber

- Footprint

- Compact

- Control panel type

- Custom Designed