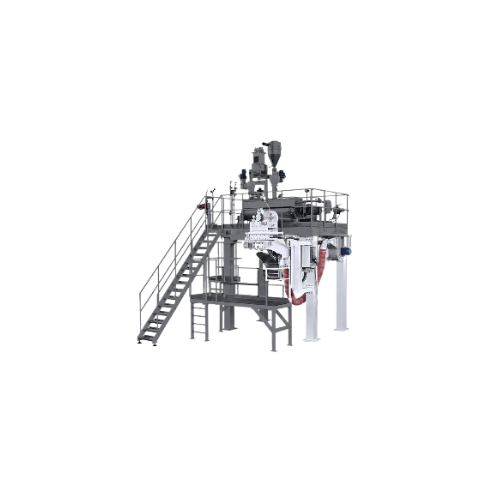

Rotating cutter for short pasta production

Optimize your short pasta production line with a versatile rotating cutter designed to enhance precision in cutting and manage process airflow efficiently, ensuring high-speed and continuous operation for a variety of pasta shapes.

Cuts and Vents Short Pasta with Precision

The Roto-Pennaut from GEA is a versatile universal rotating pasta cutter designed for precise cutting of short pasta varieties, such as penne, rigatoni, and macaroni. This equipment integrates seamlessly into both modern and existing production lines, with an electronically controlled mechanical arm that optimizes the cutting process and air flow management systems that prevent product pileups. Its innovative design includes options for directing air flow toward the die or slide, enhancing flexibility in pasta production. The Roto-Pennaut is available in universal and Pavan-specific models, allowing for easy adaptation to various press configurations. Built for continuous, automated, high-speed operations, it supports efficient production within food processing plants, particularly in the pasta, snack, and breakfast cereal industries.

Benefits

- Enhances production efficiency by maintaining consistent cutting precision.

- Prevents product pileup, minimizing waste and ensuring smooth operations.

- Adapts to existing lines, reducing the need for major infrastructure changes.

- Provides flexibility with dual airflow management options to optimize product texture.

- Supports high-speed continuous processing, increasing overall output.

- Applications

- Pasta production, Snacks, Macaroni, Short pasta, Penne, Breakfast cereals

- End products

- Ditalini, Granola clusters, Shells, Rigatoni, Penne rigate, Ziti, Farfalle, Pasta chips, Elbow macaroni, Cavatappi, Fusilli

- Steps before

- Mixing, Extrusion, Dough Preparation

- Steps after

- Packaging, Quality Control, Storage

- Input ingredients

- short pasta, penne, macaroni

- Output ingredients

- cut pasta, penne, macaroni

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Automation

- Electronically controlled

- Airflow control

- Directed toward die or slide

- Working mechanism

- Rotating cutter

- Integration flexibility

- Adapts to old and new production lines

- Automation level

- Electronically controlled mechanical arm

- Product pileup prevention

- Integrated system

- Airflow management

- Directable airflow system with optional heating

- Adaption capability

- Universal and Pavan model compatibility

- Abrasion resistance

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Compatible with various densities

- Discharge method

- Mechanical arm with electronically controlled rise and fall

- Model variations

- Universal / Pavan

- Integration possibilities

- Compatible with new/old production lines