Making Granola Bars

Find innovative production technology for making granola bars and connect directly with world-leading specialists

You make granola bars from caramelized nuts, grains, and cereals, baking and shaping them into crunchy snacks. Granola bar production involves mixing, forming, baking, and cutting into bars. The quality of granola bars is affected by baking. How the sugar caramelizes and blends with the other ingredients determines the final taste and texture of your granola bar.

Stories about granola bars

Select your granola bars process

Tell us about your production challenge

Binders keepers: getting that granola bar together

To maintain the shape of granola bars, you may use binders. Fortunately, various healthy ingredients act as binders to better enhance your granola bar’s quality.

Good binders also reduce the water activity of your granola bars and contribute to shelf-life extension and quality improvement. Ingredients rich in fiber act as great binders. This lets them adsorb and bind all the other ingredients together with the sugar. Examples of these are oats and chia seeds.

You can also substitute sugars, an example of which is honey. Its sticky nature allows it to act as a binder for your granola bar. Using honey also reduces the glycemic index of your granola bars, providing sweetness but providing lesser calories.

Cereal, granola, or muesli, which is which?

Identifying whether the bar is cereal, granola, and muesli can be confusing. Among the three, cereal bars and granola bars share the same process, the only difference being in the grains you use. Cereal bars generally use refined grains while granola bars use whole grains. Cereal bar production is like that of granola bar production and basically follows the same sequence stated above.

Muesli bars are different because of their method of production. Although similar, the process involves soaking the ingredients overnight in milk or juice usually from some sort of fruit.

Keeping that bar crunch during granola bar production

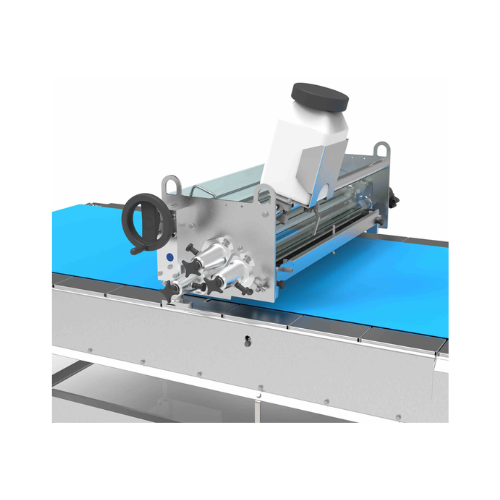

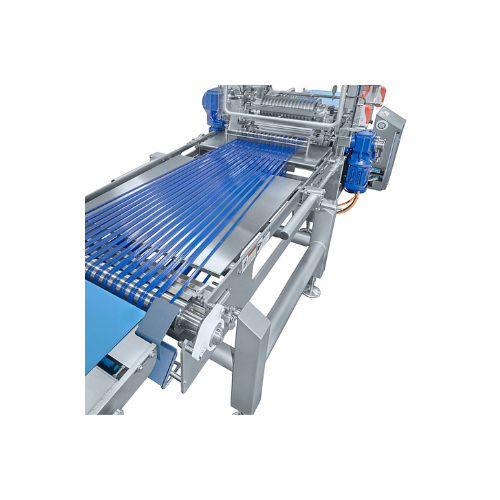

Developing the granola bar’s crunch depends on its and baking process. How you design your sheeting process determines the appropriate thickness of your granola bars. Setting the distance between your sheeter rollers and controlling the speed of sheeting develops the texture of your bars.

Baking parameters you use during your granola bar production facilitates the melting of sugars and helps achieve that perfect bar crunch. You can bake granola bars at 325 to 350 °F (162 to 176 °C) for 10 to 25 minutes.

Processing steps involved in granola bars making

Which granola bars technology do you need?

Cookie dough wirecut machine

Achieve precise control and flexibility in shaping a wide variety of cookies and bars with this...

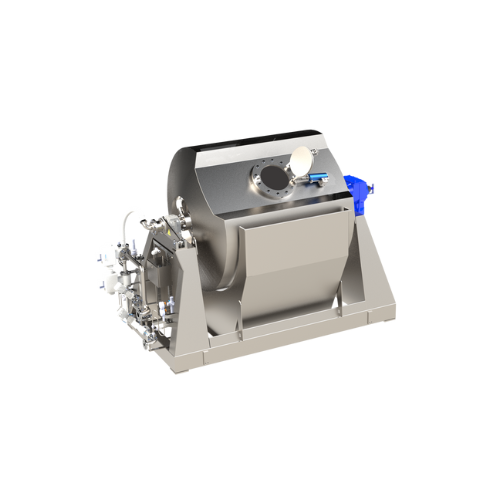

Continuous mixer for cookie and snack dough

Achieve uniform and consistent mixing of cookie and snack dough with seamless ...

Rotary moulder for high-definition cookie dough shapes

Efficiently shape intricate dough designs with precision, ensuring...

Precise dough sheet cutting station for bakeries

Efficiently shape and cut dough sheets for diverse snack and bakery produ...

Servo in-line dough laminator for industrial bakeries

Optimize your snack production with precise dough sheet cutting, st...

Filled stick extruder for bakery products

Streamline your snack production line with a versatile extruder capable of creat...

Automated frozen dough production solution

Maximize your frozen dough production with precision control and streamlined ma...

Convection oven with integrated dryer for large scale baking

Optimize your baking process with a convection oven that ef...

Automated dough handling system for pretzel production

Streamline your dough processing with a system that precisely port...

Efficient dough dump station for bakery systems

Streamline your dough handling process with this advanced dumping station,...

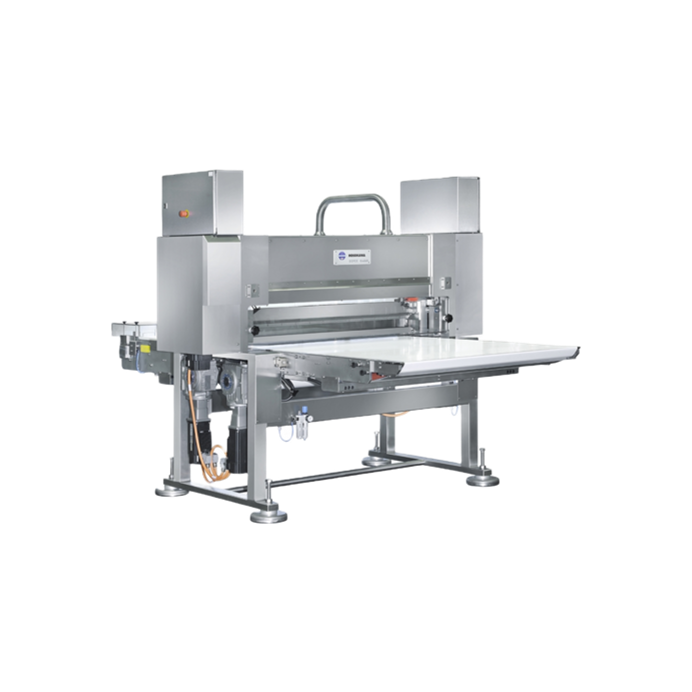

3-roll sheeter for dough forming

Achieve smooth and consistent dough sheeting crucial for high-quality biscuits, cookies, an...

Ambient air cooler for bakery products

Efficiently cool fragile baked goods without causing distortion, using ambient air t...

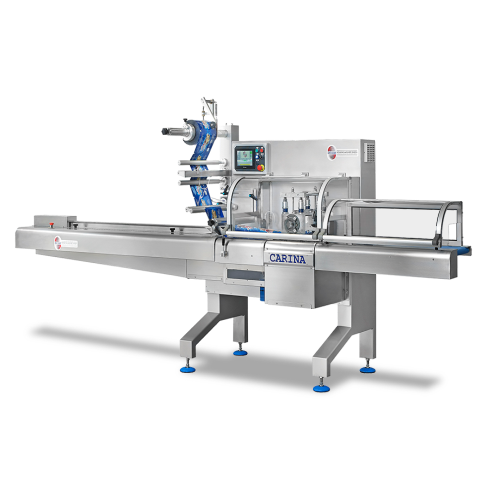

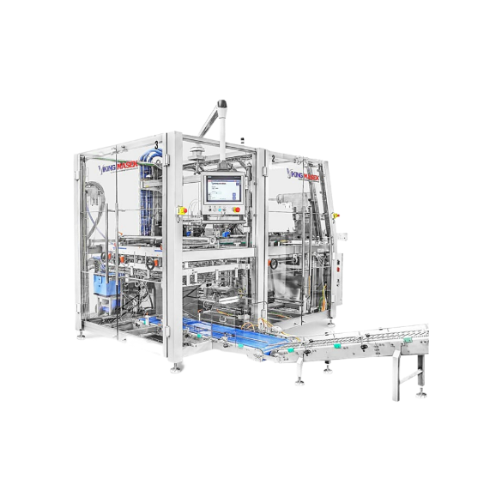

Medium-speed end load cartoner for food and beverage packaging

Streamline your packaging line with versatile cartoning c...

Intermittent end load cartoner for baked goods and snacks

Optimize your packaging line with an efficient, space-saving c...

Conical milling for high-efficiency particle sizing

Maximize efficiency in your production line with conical milling tech...

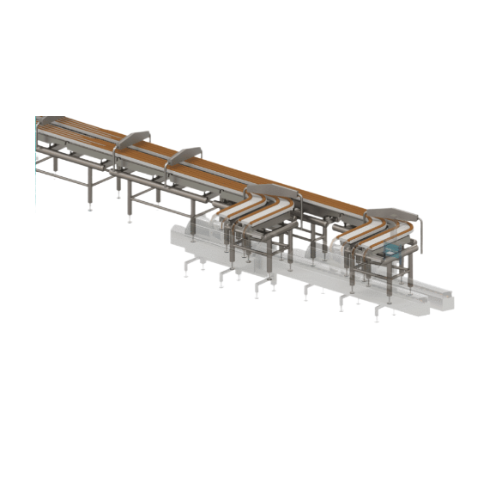

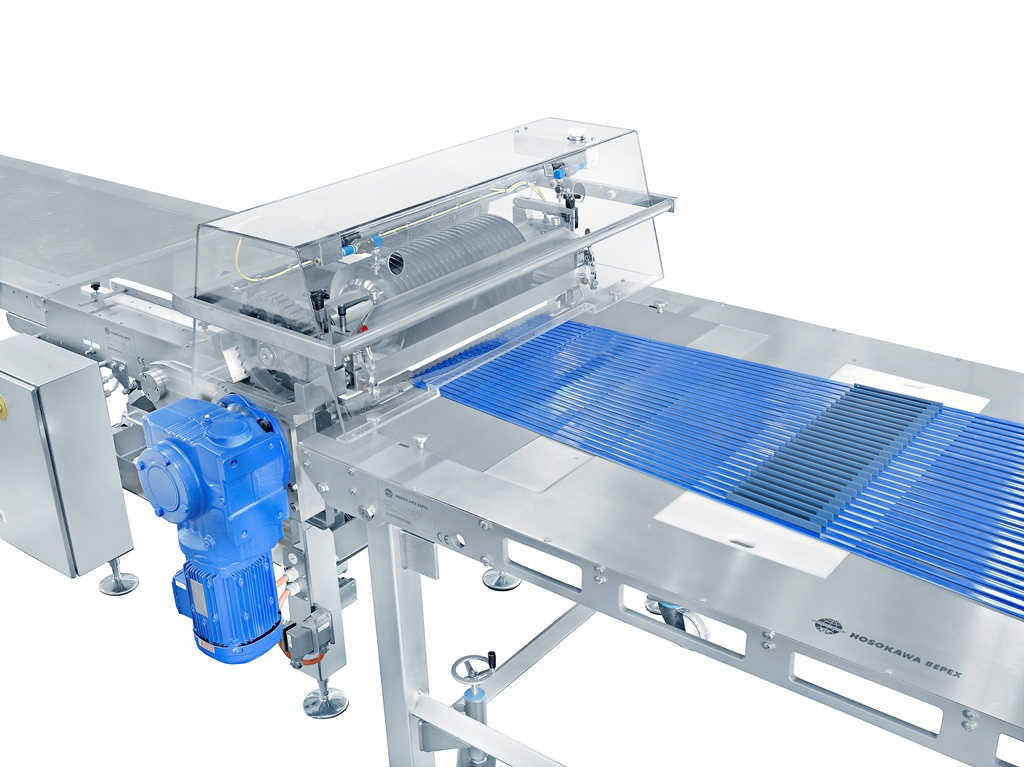

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

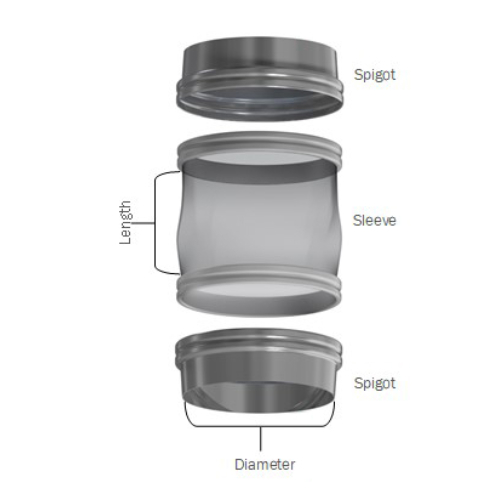

Flexible connector for bulk powder manufacturing

Eliminate leakage and enhance hygiene in your powder processing with a sn...

Open frame mixer for bread and pastry dough

Enhance your dough consistency and reduce production downtime with a robust, h...

Slurry mixer for cake batters and premix ingredients

Efficiently mix cake batters and premix ingredients with precision, ...

Industrial bag tie-wrapping solution

Ensure your bulk packaging is reliably sealed with a tamper-evident tie-wrap, allowing...

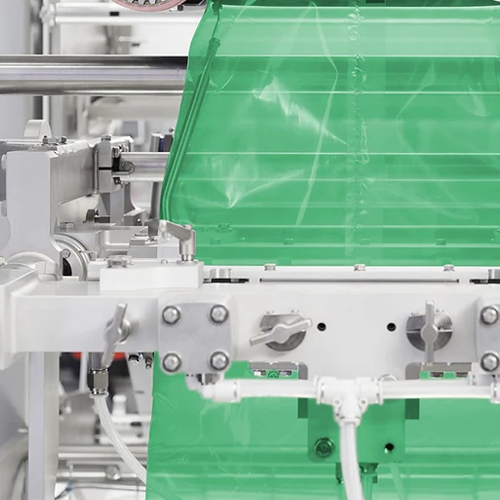

Capsule packaging system for individual gusseted bags

Streamline your coffee capsule production with high-speed, precisio...

High-speed shrink wrapping for beverage packaging

Optimize end-line packaging with a high-speed solution designed to hand...

High-precision batch counting solution

Achieve precise product alignment and counting with advanced vibration and photocell...

Horizontal cartoner for diverse industries

Streamline your packaging process with precise cartoning capabilities, effectiv...

Horizontal continuous motion cartoner

Streamline your packaging process with a high-speed cartoning solution that ensures p...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Chocolate raw material pre-mixer

Streamline your chocolate production by efficiently combining raw ingredients in a single p...

Nougat and cereal bar forming drum

Streamline your snack production with precision forming of nougat and cereal bars, ensur...

Valves for bulk powder flow control

Ensure efficient and controlled discharge of diverse powder forms while minimizing flow...

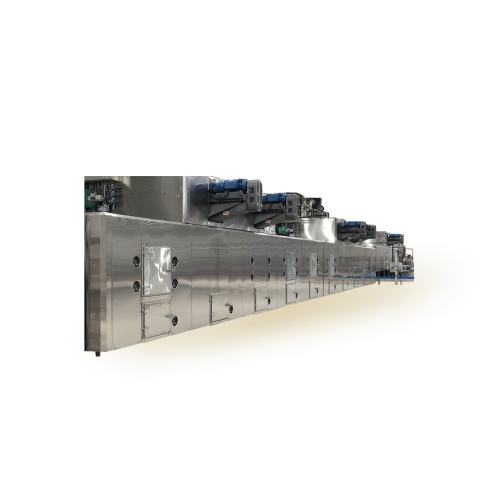

Cooling system for heat-treated products

Efficiently reduce temperatures of high-heat products to protect quality and textu...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

Curtainless x-ray inspection for small lightweight packaged food products

Eliminate product damage and false rejects w...

Top-loading cartoner for bar and confectionery packaging

Optimize your high-speed packaging operations with a flexible ca...

Fold wrapping solution for chewing gum tabs

Streamline your high-speed packaging line with a solution that expertly wraps ...

Twin station fold wrapping machine for chocolate bars

Efficiently transform diverse chocolate and confectionery items int...

Horizontal flow wrap solution for chocolate bars

Achieve high-speed precision in packaging with a machine designed to hand...

Fold wrapping solution for round pharma tablets

Ensure precise and gentle packaging of round tablets with our innovative f...

Entry-level moulding machine for small to medium production

Ideal for scaling new product lines, this versatile moulding...

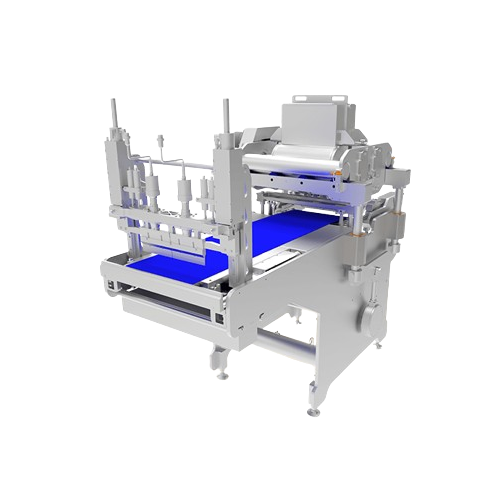

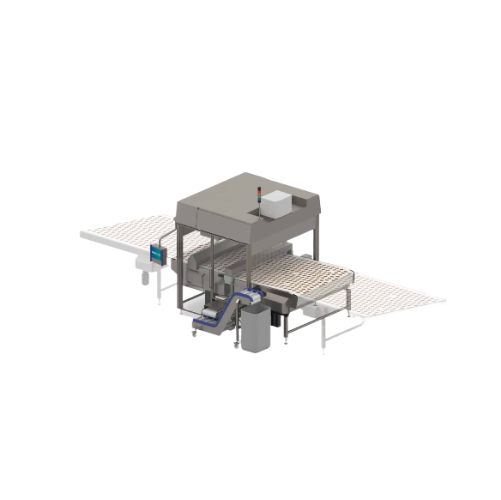

Cereal moulding solution for bars, bites, and clusters

Efficiently shape and form a variety of granola and cereal-based p...

High speed rolling line for confectionery production

Enhance your confectionery production with a versatile rolling line ...

Food dosing systems for industrial applications

Optimize your food production efficiency by minimizing waste with precisio...

Entry-level flow wrapping machine for small and medium products

Optimize your packaging line with a high-speed flow wrap...

Horizontal flow wrapper for medium performance level

Offering high-speed, continuous flow wrapping, this versatile machin...

Flow wrapping solution for fresh produce and food products

Optimize packaging efficiency for irregular products with a v...

Stand-up pouch making system

Efficiently transform pre-printed reels into customizable stand-up pouches with precise unwindi...

Feeding system for single wrapping lines

Optimize your high-speed wrapping operations by ensuring precise product alignment...

Flow wrapper for high-speed confectionery packaging

Achieve gentle, high-speed packaging for delicate confectionery items...

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

High-speed multi-head weigher for confectionery products

Achieve precise measurements and minimize waste in high-speed fo...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

Ultra-fine grinding jet mill for coarse and fibrous materials

Effortlessly achieve ultra-fine particle sizes in coarse a...

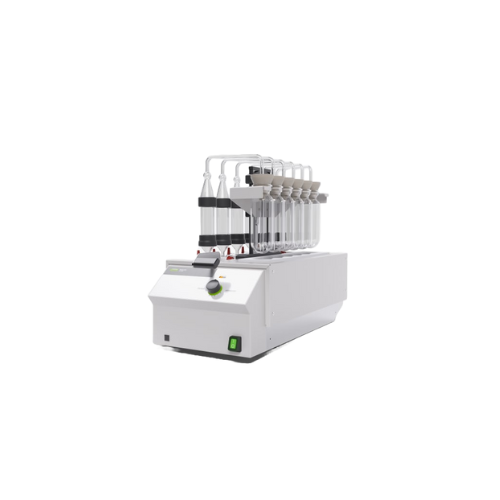

Powder flowability and compressibility analysis

Ensure accurate powder flowability and compressibility data with this adva...

Foreign object detection for packaged and unpackaged food

Ensure the integrity of packaged and unpackaged foods by detec...

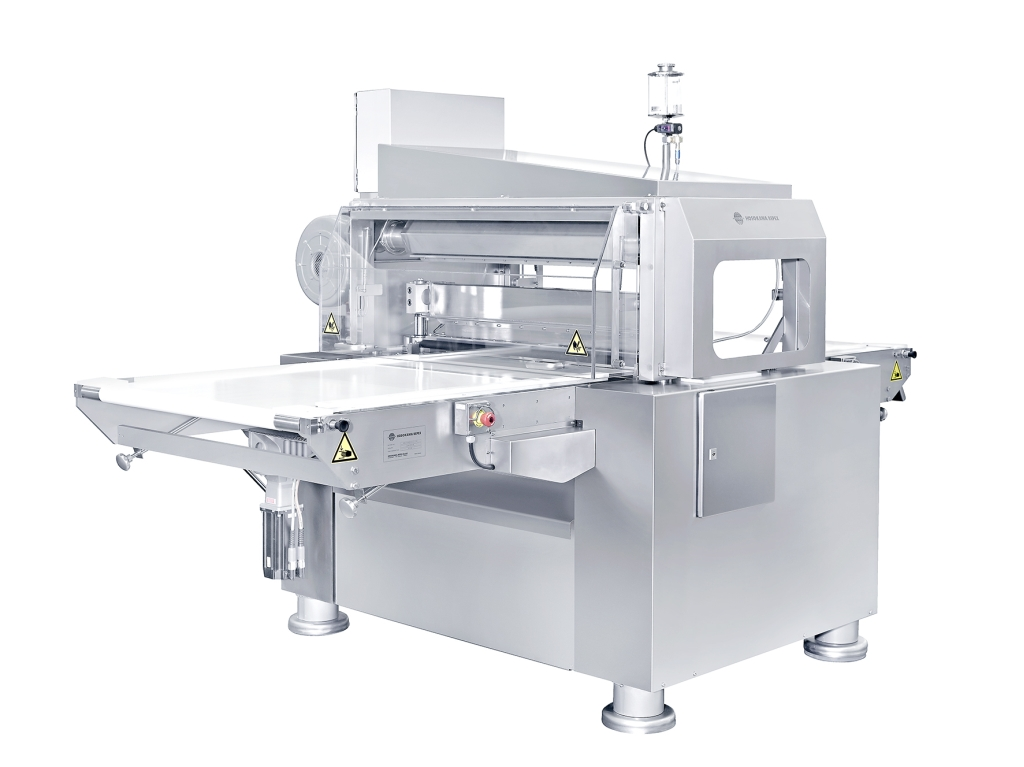

Wafer cutting system for cream-filled wafers

Achieve precise cuts on filled and coated wafer products with high-speed effi...

Industrial raw material mixer for complex recipes

Struggling with complex raw material mixtures? This advanced mixing sol...

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Metal detection and weight verification system

Optimize space and boost inspection accuracy by combining metal detection a...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

Multi-lane checkweigher for mixed-application production lines

Achieve precise weight verification across multiple lanes...

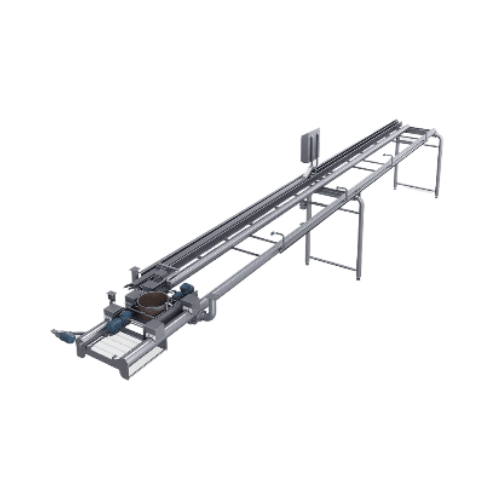

Accumulation conveyor for snacking industry

Optimize your production line with a space-saving accumulation conveyor that r...

Product transfer shuttle for filling applications

Efficiently manage product flow with precise, customizable filling solu...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Versatile dual axis funnel filling system

Eliminate messy spills and maximize efficiency by synchronizing conveyor and tra...

Multihead weigher for food processing

Enhance production efficiency and accuracy with multihead weighing technology, offeri...

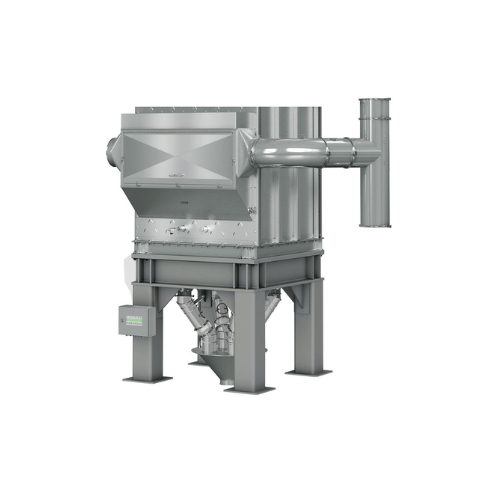

Batch drying system for food, pet feed, pharmaceuticals, and more

Optimize your drying needs with precision control for...

Adjustable weighing system for raw materials

Optimize your confectionery and nutraceutical production with precise weighin...

Continuous multi-lane wrapping solution

Achieve precision and speed in packaging with an advanced solution designed for con...

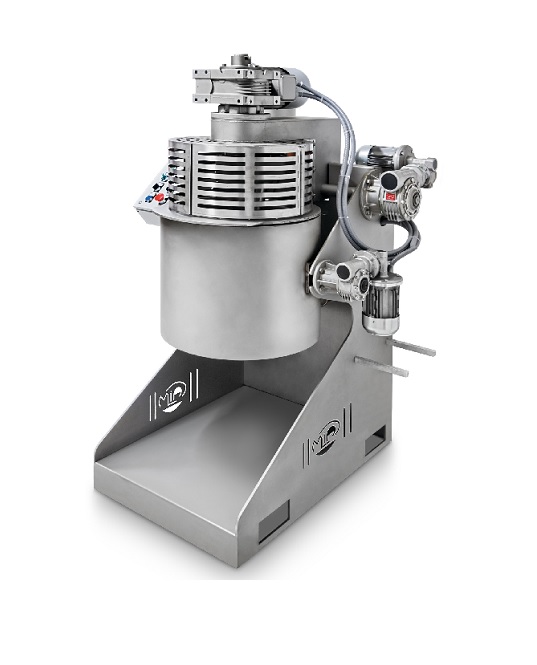

High-speed mixer for granulating and mixing powders

Achieve consistent granulation and mixing with precise temperature co...

Double shaft powder batch mixer

Achieve high homogeneity and gentle handling with a double shaft mixer designed for efficien...

Continuous flow-wrapping system for high productivity

Optimize your packing line with a high-speed flow-wrapping system d...

Waxing station for confectionery products

Optimize your product’s final presentation and quality by applying a preci...

Carbon/nitrogen analyzer for organic samples

Optimize your lab’s efficiency with fast, reliable nitrogen and carbon ...

Product handling system for big bags and containers

Optimize your production line with a comprehensive system for transpo...

Horizontal flow pack packaging solution

Achieve seamless packaging with versatile flow pack machines, designed to efficient...

Flow pack packaging for flexible wrapping material

Achieve precise and secure packaging with three-sided sealed packages ...

Three-side sealing flow pack machine

Optimize packaging efficiency with a high-speed flow pack machine that ensures precise...

Three-side sealing packaging machine

Achieve precise, three-side sealed packaging for both food and non-food products, enha...

Precision feeders and mixers for plastics processing

Achieve precise blending and feeding for plastics processing with mo...

Rotary cooker for uniform steam heating in cereals production

Achieve consistent product quality in high-volume cereal p...

High-speed packaging system for flow-wrapping

Streamline your packaging operations with a high-speed flow-wrapping solutio...

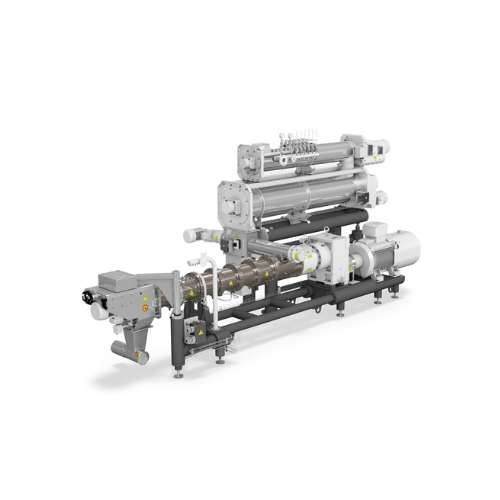

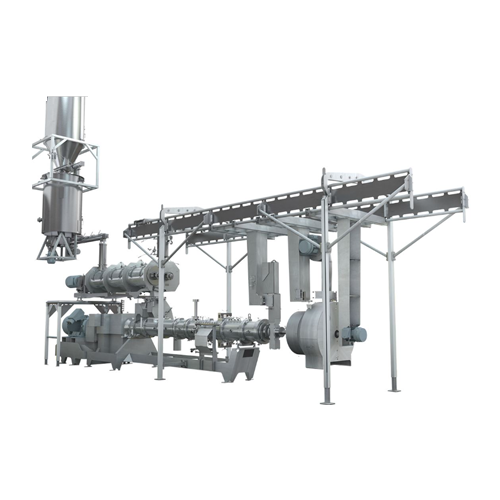

Food and confectionery twin-screw extruder

Enhance your confectionery production with a versatile twin-screw extruder desi...

Wafer block cooling tower

Optimize your confectionery production with seamless wafer cooling, ensuring precise temperature c...

Wafer block spiral cooler

Enhance your confectionery production with a modular spiral cooler that ensures gentle handling an...

Washover unit for baked goods

Maximize production efficiency with quick-changeover washover units designed for seamless liqu...

Transversal cutting for confectionery production

Achieve precise and customizable cuts in high-speed confectionery and bak...

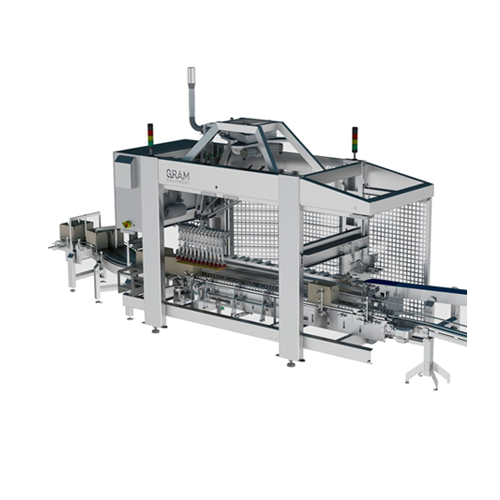

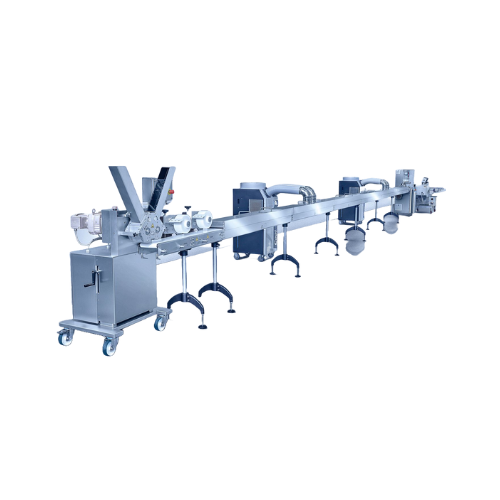

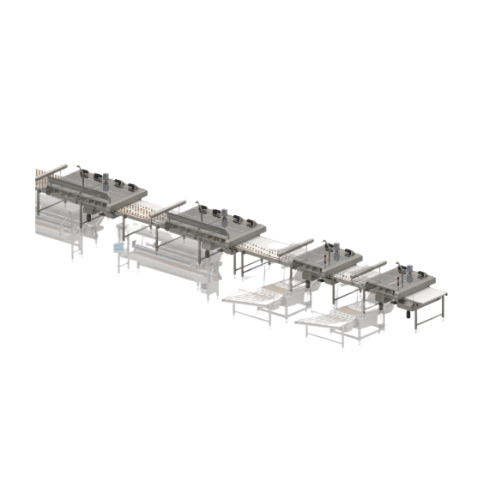

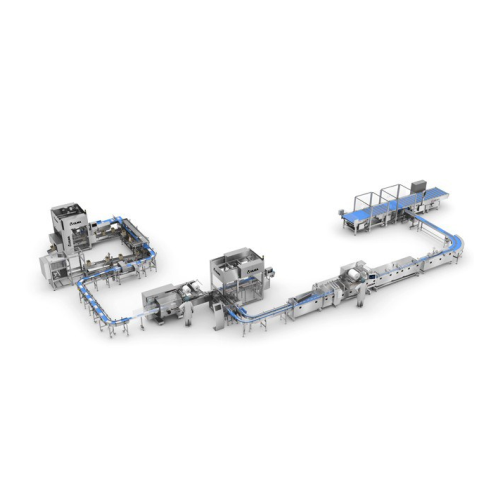

Small-scale cereal bar production system

For nimble snack producers, this system offers versatility by seamlessly integrati...

Single-screw extruder for pet food and aqua feed

For producers aiming to diversify their offerings, this single-screw extr...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

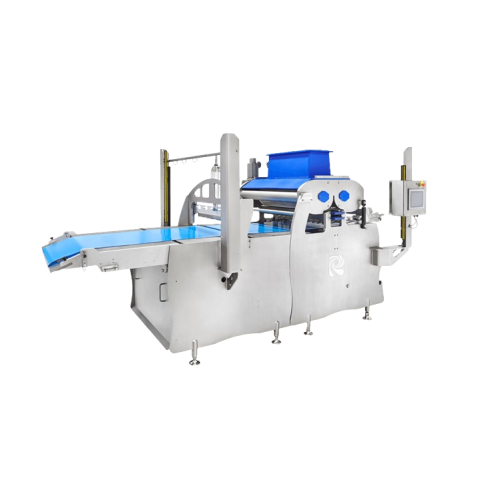

Dough sheeter for rotary-cut biscuits

Achieve consistently smooth dough bands essential for high-quality biscuits and confe...

Hybrid tunnel oven for biscuits and cakes

Enhance production efficiency and product consistency with a versatile oven syst...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Industrial fanning belt for strand separation

Enhance your production line efficiency with precise strand separation, ensu...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Acid hydrolysis system for total fat determination

Streamline your laboratory workflow with a powerful hydrolysis system ...

Lab-scale extruders for material development

Optimize your lab and pilot-scale extrusion processes with advanced material ...

Vision guided robotics case packer

Maximize efficiency with vision-guided robotics for versatile case and tray loading, red...

Vision-guided variety pack solution for confectioneries

Achieve seamless variety pack assembly by dynamically loading var...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

X-ray and checkweigher combination for medium horizontal products

Streamline your packaging line with integrated checkw...

Combi x-ray inspection and checkweighing for small products

Optimize your production line’s quality control with a...

X-ray inspection for contaminants in horizontal products

Ensure your packaged and unpackaged products are contaminant-fre...

Bar forming line for protein bars

Efficiently form and process a wide range of snack and confectionery bars with our versat...

Pillow bag horizontal form-fill-seal solution

Optimize production efficiency with seamless integration of continuous, high...

Turnkey filling lines for packaging solutions

Optimize your production line with our turnkey filling solutions, designed t...

Low-shear portable mixer

For processes demanding strict hygiene, this mixer eliminates rust and chipped coatings by offering ...

High speed horizontal flow wrapper for food products

Achieve precise, high-speed packaging for snacks with this versatile...

Batch roaster for nut processing

Achieve precise roasting and flavor development with batch roasters that offer customizable...

Granulator for nut processing

Efficiently transform various nut varieties into uniform, sharp-edged granules while minimizin...

Accurate chocolate tempering measurement tool

Ensure precise chocolate tempering with real-time accuracy, enhancing qualit...

Breading applicator for poultry, meat & seafood

Ideal for optimizing your coating line, this applicator efficiently handle...

Circular distribution feeder for fragile product handling

Achieve precise dosing and reduced product damage with a versa...

Industrial predryer for humidity reduction in food processing

Ensure optimal shelf life and prevent product sticking wit...

Industrial spiral cooler for thermal treatment

Improve your final conditioning and packaging process with a spiral cooler ...

High-accuracy package weigher for pasta and granular products

Optimize your packaging line with precision weighing and i...

Surface drying system for pasta production

Ensure optimal surface drying of pasta and snacks post-pasteurization, preventi...

Dough distribution system for multiple mixing points

Ensure precise dough allocation across multiple production stages wi...

Water cooker for fresh pasta processing

Enhance cooking precision and product quality with this water cooker, designed to c...

Industrial water cooling system for food products

Efficiently cool and convey food products with a system designed for un...

Automatic continuous mixer for dough preparation

Streamline your production line with a mixer that ensures precise dosing ...

Multiple feed lane converger system for thermoforming packaging

Efficiently manage high-speed packaging lines by seamles...

Vertical form fill sealer for high-speed packaging

Achieve consistent, high-speed packaging with flexible bag styles, per...

Product distribution system for large capacity wrappers

Optimize your high-speed production lines by efficiently distribu...

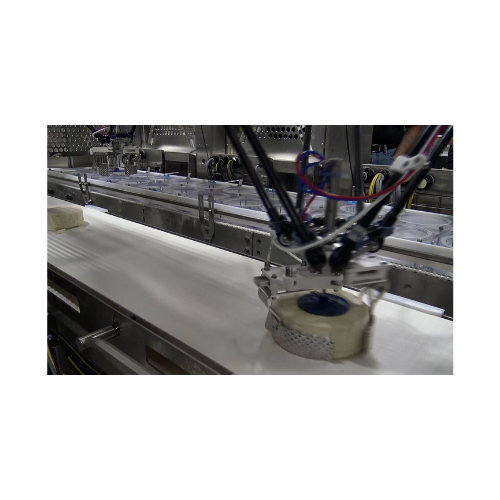

Vision guided robotic pick and place system for bakery settings

For manufacturers tackling high-volume, diverse-sized ba...

Robotic pick and place system for cookies

Streamline your bakery production with a flexible robotic system that seamlessly...

Cooling system for post-baking stabilization

Optimize your production line by integrating a cooling system that ensures po...

Vision-based product inspection system for rejecting defective items

Enhance your production line efficiency by ensurin...

Vibratory buffer system for line efficiency

Enhance your production line by efficiently managing downstream stoppages and ...

High-volume product distribution system

Efficiently manage high-volume snack and confectionery production flows with a syst...

Laned product distribution for high-capacity wrappers

Efficiently distribute high-capacity product flow across multiple w...

High-speed checkweigher for dynamic weighing

Achieve precision and consistency in high-speed production environments with ...

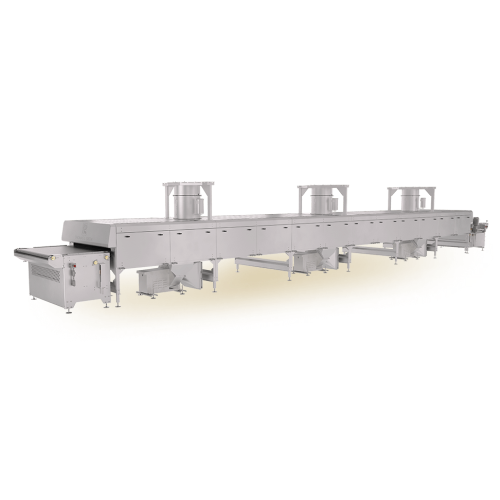

High capacity horizontal dryers and coolers for industrial applications

Achieve consistent moisture levels and uniformi...

Sanitary dryers for textured vegetable proteins

Optimize drying and sanitation for textured vegetable proteins and pet foo...

Single screw extruder for pet food and aquatic feed

Maximize production capacity and optimize product quality with advanc...

Twin screw extruder for pet and aquatic feed

Achieve exceptional cooking precision with our twin screw extruder, designed ...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Stand-up pouch filling and sealing system

For packaging lines that demand quick, efficient, and flexible pouching, this hi...

Stand-up pouch packaging for various products

For manufacturers seeking versatile packaging solutions, this machine delive...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

Continuous motion vertical form fill seal packaging system

Achieve high-speed, consistent packaging for diverse products...

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Endload automatic cartoning solution

Streamline your packaging line with this versatile cartoning solution, perfect for eff...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Premade pouch fill and seal solution

Effortlessly fill and seal various pouch sizes for streamlined packaging in diverse fo...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that ...

Conveyor belts for hot and cold product handling

Efficiently transport hot and cold goods with versatile conveyor solution...

Multi piston depositors for high-volume baking production

Optimize your high-speed production line with precision deposi...

Industrial food portioning depositor

Optimize portioning precision and streamline your production with this advanced deposi...

Hygienic thermoformer for flexible film packaging

Streamline your packaging process with a hygienic thermoformer, offerin...

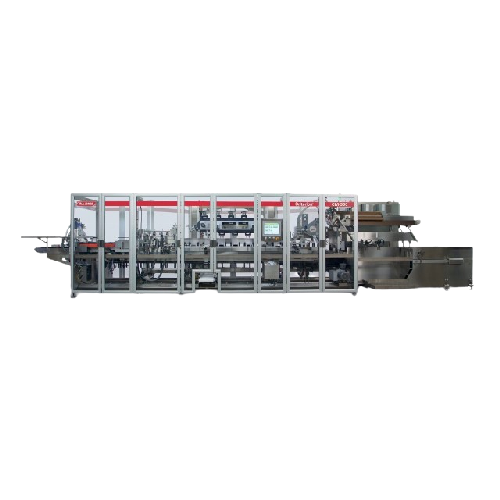

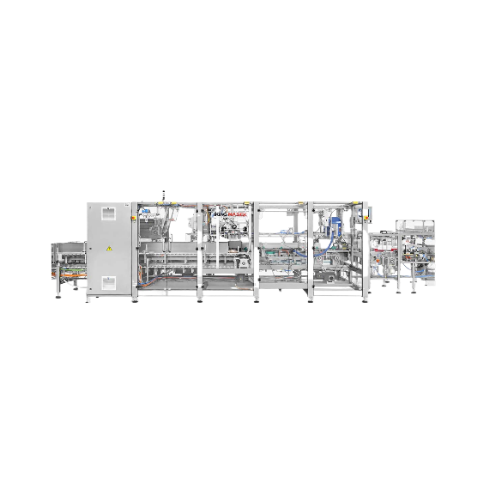

Complete primary and multipack packaging solution for bars

Enhance your bar production efficiency by seamlessly integrat...

Automated packaging and case packing for snack bars

Optimize your snack bar production line with this high-speed solution...

Ultrasonic food cutting

Optimize your production line with precision ultrasonic cutting technology, designed to enhance consi...

Compact food dehydrator with Bpa-free trays

Achieve precise dehydration with compact, kitchen-friendly equipment, perfect ...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

Conveyor belt laboratory for cooling extrudates

Achieve precise temperature control for high-temperature extrudates with a...

High sensitivity metal detectors for food products

Ensure food safety and product quality by effectively detecting and re...

Metal detector for packaging lines

Ensure product purity and safety with precision metal detection, seamlessly eliminating ...

Vision-based robotic feeding system

Enhance your production line with precise robotic feeding, optimizing product placement...

High speed packaging system for fold wrap and stick packs

Streamline your confectionery production with a versatile syst...

Lane arrangement for efficient product transfer

Optimize your production line’s efficiency with seamless integration...

High-speed forming and cutting for soft caramels and chewy sweets

Efficiently streamline your confectionery production ...

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

Modular packing system for multihead weighing

Streamline your production with a versatile multihead system designed for pr...

Commercial food mixers for versatile culinary applications

Streamline your food production with mixers and kneaders desi...

Commercial bakery equipment for improved baking efficiency

Streamline your baking processes with commercial bakery equip...

Industrial checkweigher for food production

Ensure consistently accurate package weights with minimal downtime using a hig...

Pilot to full-scale roller compactor for dry granulation

Easily transition from pilot to full-scale production with this ...

Automated cleaning in place system for bakery production lines

Ensure unmatched hygiene and operational efficiency in fo...

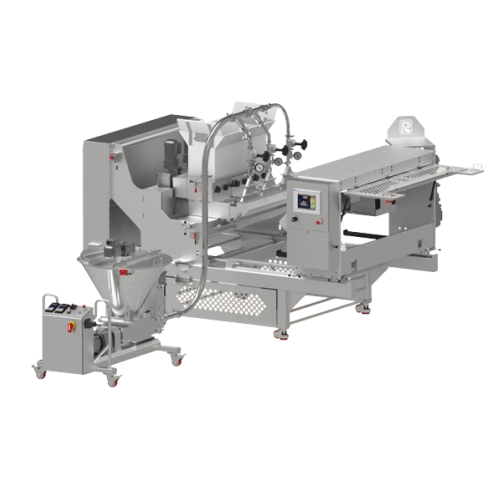

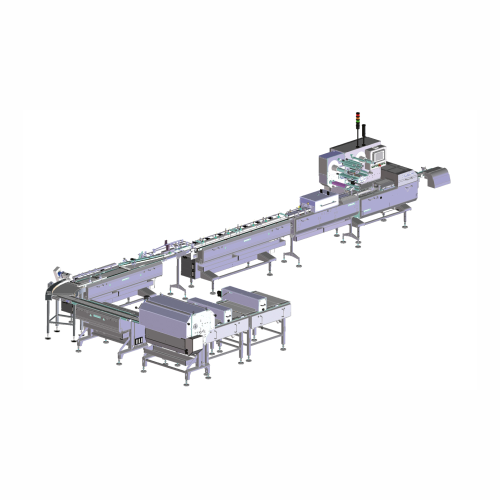

Automatic cereal bar production line

Efficiently transform diverse ingredients into consistent, high-quality cereal bars wi...

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Industrial air heater for agriculture and industry

Optimize energy efficiency and maintain high air quality in your produ...

Texture analyzer for high force applications

Achieve precise texture measurement across a vast array of products with a so...

Electrostatic drum flavouring for uniform coating

Achieve precise and uniform flavor distribution on snack products with ...

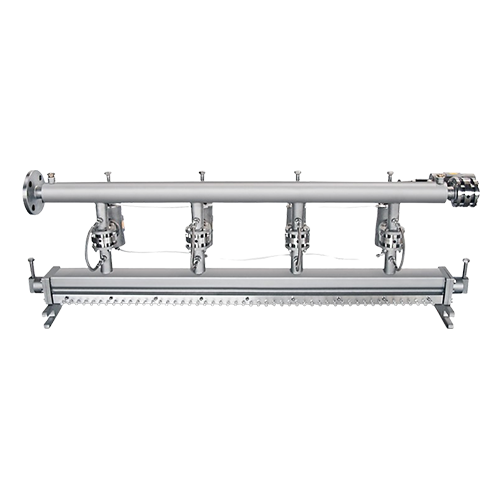

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Chocolate storage tanks for confectionery production

Optimize your confectionery production with state-of-the-art storage...

Sieving system for chocolate processing

Ensure product purity and consistency by seamlessly removing unwanted particles fro...

Decrystallization for tempered chocolate

Ensure your chocolate is perfectly smooth and free of fat crystals with an advance...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Precise metering system for dry confectionery ingredients

Achieve precise dosing of granular and dry ingredients like nu...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Manifold system for producing weight-accurate ropes of chocolate or fruit masses

Achieve precise weight and shape in c...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Forming system for cereal bars and nut mixes

Effortlessly transform diverse ingredients like cereals and nuts into precise...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Bucket sheeter for confectionery masses

Efficiently form thin, precise layers of flowable confectionery masses with ease, e...

Industrial spreading systems for sticky products

Effortlessly manage the spread of sticky confectionery products with prec...

Advanced cooling tunnel for confectionery production

Optimize your confectionery production with a cooling system that en...

High-precision biscuit sandwiching system

Efficiently align, fill, and sandwich high-speed biscuit rows while ensuring pre...

Single sigma arm bakery mixer

Streamline complex mixing tasks with precision using a mixer designed for optimal batch contro...

Ultra-compact case packer for consumer goods

Maximize efficiency on your production floor with a compact case packer desig...

Flowpacker for packaging products in flowpacks

Optimize your flowpack packaging line with a preconfigured solution that ac...

Flow-wrapping machine with quick format changeovers

Optimize your packaging flexibility with a flow-wrapping machine desi...

Infrared dryer for breakfast cereals

Optimize your snack production with precise moisture control, energy-efficient infrare...

High-accuracy moisture analyzer for lab weighing

Achieve precise and reproducible moisture content determination for diver...

Coffee capsule filling and sealing system

Boost capsule production efficiency and reduce downtime with a high-speed system...

Convenience and pet food filling solution

Optimize your production line with high-speed, hygienic filling of diverse food ...

Entry-level cereal bar making machine

Cereal and grain bars are increasingly popular, both as snack foods and as functional...

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

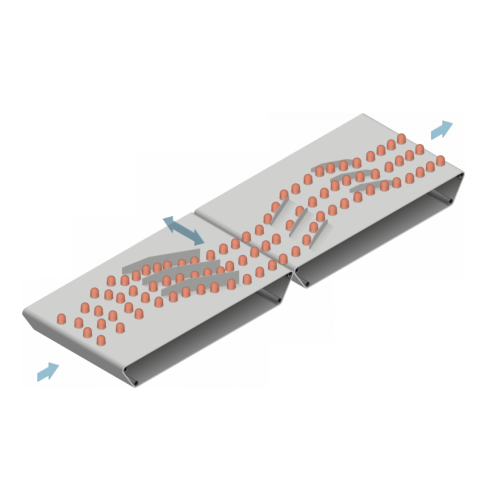

Strand forming machine for 2 masses

Form two-ingredient mixes into the shapes and layer combinations required for your fina...

Strand forming machine for 3 masses

Form three ingredient mixes into the shapes and layer combinations required for your fi...

Strand forming machine for creamy mixtures

Turn your ingredients mixture into strands and slabs for further processing int...

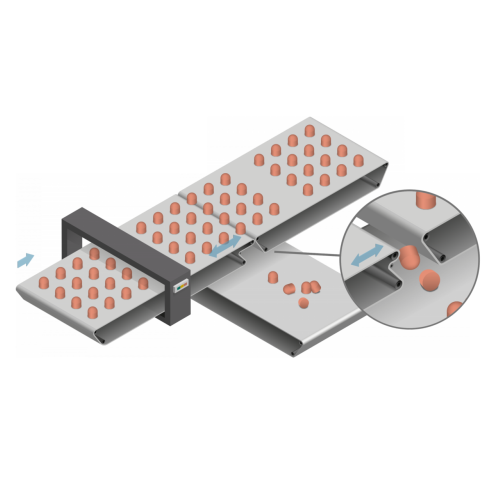

Strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other final product sha...

High-speed strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other fina...

Longitudinal strand cutting machine

Cut continuous slabs of your ingredient mix into spaced strands for further processing ...

Chocolate coating machine

Coat your product with chocolate or caramel. This is a chocolate coating machine born of many year...

Entry-level automatic cereal bar machine

Start up your manufacturing of cereal bars or produce smaller batches to test and ...

Slab forming machine

Turn the mixture of your ingredients, into continuous slabs for processing into bars, stands, or other s...

Strand forming machine

Form ingredient mixes into strands and slabs for further processing into bars, and other final product...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

Entry level cereal bar cutting table

The small-scale manual production of crunchy cereal bars, brittles, and similar produc...

Entry level cooker for cereal bar production

The creation of high-quality, flavourful crunch bars, brittles and similar pr...

Chocolate enrober for medium production capacities

Premium enrober for capacities from 100 to 500 Kg/h.

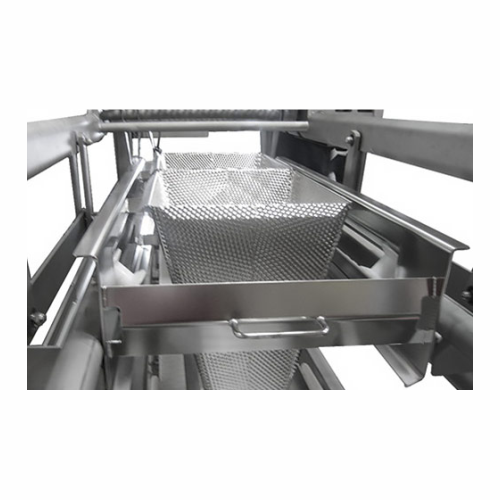

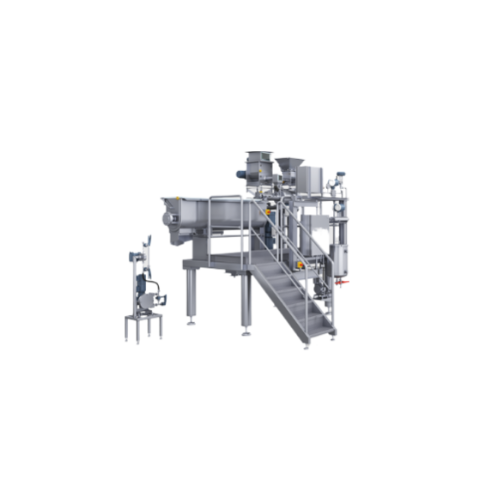

Granola batch mixer

The production of granola-based recipes requires careful ingredients handling to ensure optimum quality. ...

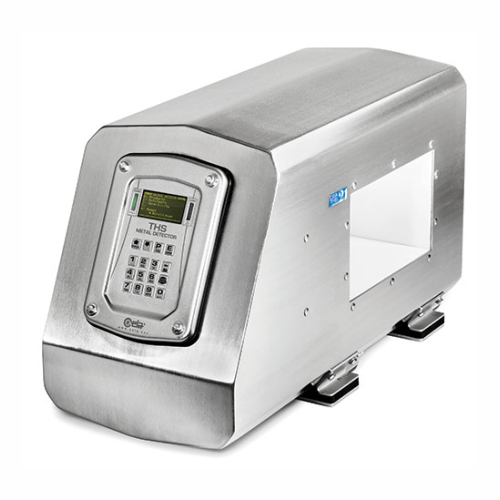

Metal detection system

The inspection system automatically determines the best frequencies to maximize sensitivity for both f...