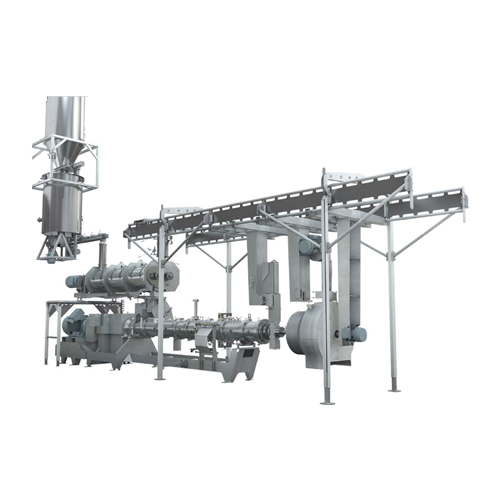

Twin screw extruder for pet and aquatic feed

Achieve exceptional cooking precision with our twin screw extruder, designed to enhance product consistency and expand ingredient possibilities through innovative steam injection and reduced mechanical energy dependency.

Processes Complex Food and Feed Formulations

The Thermal Twin Twin Screw Extruder from Wenger revolutionizes the production of textured vegetable proteins, meat analogs, and diverse aquatic feeds through its enhanced steam injection capabilities. Utilizing angled steam injector ports, it ensures up to four times more steam is evenly distributed, achieving a 14:1 thermal to mechanical energy ratio, crucial for consistent cooking processes. Ideal for applications like soy protein chunks and pet kibble with fresh meat inclusion, it efficiently handles various formulations with reduced wear and energy costs. The machine supports a range of capacities, controlled through a PLC system, allowing seamless integration into automated production lines. Available in stainless steel for food safety compliance, it minimizes maintenance with a hygienic design featuring minimal seams and dust-tight structures. Customize this extruder with ancillary equipment like the High Intensity Preconditioner to optimize hydration and mixing, supported by Wenger’s robust engineering network.

Benefits

- Reduces energy costs by harnessing thermal energy for cooking.

- Achieves higher ingredient incorporation, enhancing product formulation flexibility.

- Minimizes maintenance with a hygienic, easy-to-clean design.

- Supports continuous operation with precise automation and control.

- Enhances product consistency and quality with even steam distribution.

- Applications

- Rte cereals, Semi-moist treats, Hybrid products, Textured vegetable proteins, Sinking aquatic feed, Snacks, Pet food, Slow-sinking aquatic feed, Meat analogs, Protein crisps, Recirculating aquaculture system (ras) feeds, Filled treats, Traditional kibble, High fresh meat inclusion treats, Specialty aquatic feeds, Breadings, Dental treats, Floating aquatic feed

- End products

- Pea protein crisps, Beef jerky for pets, Slow-sinking tilapia feed, Chicken-filled dog treats, Cornflakes, Granola bars, Dental chews for dogs, Floating fish pellets, Ornamental fish feed, Plant-based burger patties, Bread crumbs, Protein-rich snack puffs, Kibble with salmon, High-protein ras fish diets, Soy protein chunks, Sinking shrimp feed

- Steps before

- Ingredient Mixing, Preconditioning, Hydration, Heating

- Steps after

- Cooling, Drying, Coating, Packing

- Input ingredients

- textured vegetable proteins, structured meat analogs, ingredients, protein crisps, breadings, meat slurries, liquids

- Output ingredients

- pet food, traditional kibble, semi-moist, high fresh meat inclusion, treats, floating feeds, sinking feeds, slow-sinking feeds, recirculating aquaculture system feeds

- Market info

- Wenger is known for its expertise in manufacturing extruders and dryers for pet food, aquatic feed, and food processing industries, renowned for reliability, innovation, and custom-engineered solutions worldwide.

- Steam Injection

- Up to 12% steam evenly distributed

- Energy Ratio

- 14

- Cooking Efficiency

- More than 90% cook

- Automation

- Automated Mixing Intensity Control

- Capacity

- Max 2400 kg/hr for TT-760

- 10,000 kg/hr for TT-3630

- Shaft Control

- Speed and rotational direction control

- Retention Time

- Wide range of capabilities

- Temperature Control

- Controls for temperature

- Moisture Control

- Controls for moisture

- Energy Source

- Thermal to Mechanical

- Steam Injection

- 4x more than standard

- Cook Level

- 90% cook

- Shear Reduction

- Low Shear

- Slurry Levels

- High Meat and Other Slurry Levels

- Wear Costs

- Lower compared to other twin screw systems

- Automation Level

- Automatic Mixing Intensity Control

- Enhanced Product Palatability

- No Change in Density

- Abrasion resistance

- Yes

- Biological compatibility

- N/A

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Varies

- Steam injector ports

- Angled, in direction of material flow

- Steam injection distribution

- Up to 12%

- Frame material

- Stainless steel

- Hygienic construction

- Minimal seams

- Design

- Dust-tight downspout

- Hygienic pneumatic hood

- Equipped with sampling port and sight glass

- Capacity

- Model TT-760

- Model TT-3630

- 10000 kg/hr