Making Muesli

Find innovative production technology for making muesli and connect directly with world-leading specialists

Muesli, known as the adults’ cereal, is a loose mixture of rolled oats, whole grains, seeds, nuts, and dried fruits. Unlike granola, the muesli manufacturing process goes through rather simple steps. All of the ingredients are combined in the mixer without any specific cooking or baking process. This loose mixture is then packed individually, either in stand-up pouches, paper bags, paper tube and so on.

Tell us about your production challenge

The muesli manufacturing process - it’s all about choosing and mixing!

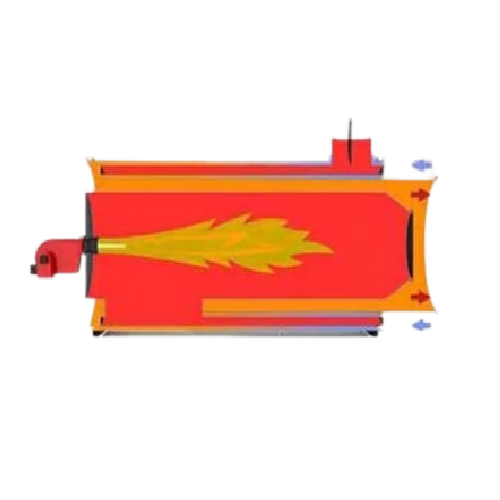

First, you need to find ingredients you would like to add to the combination of the loose mix; most often they are whole grain, oats, seeds, nuts, and dried fruits. Before mixing, ingredients such as oats and barley have to go through hulling process to separate the wheat from the chaff. The cereal also has to be cleaned based on weight – straw and chaff are lighter than cereal. A day before flattening, this cleaned cereal is soaked in water. Then, this soaked cereal goes into a bed with infrared burners – as known as a micronizer system – for 600 to 900°C for 10-15 seconds, so the cereal becomes softer for the flattening process. Then, you flatten the cereal with a strong roller and cooled it down to dry the extra moisture.

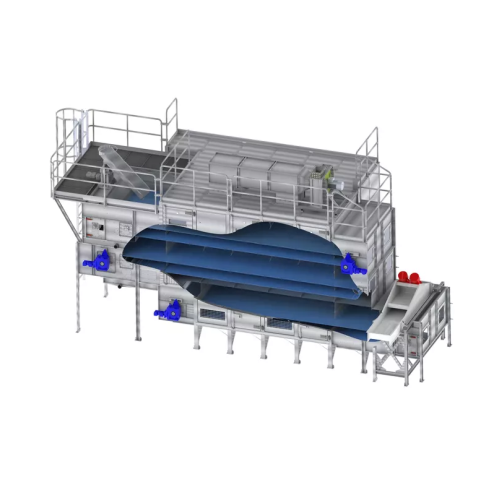

Then, combine all of these ingredients in the mixer. Without adding any oil or sweetener such as sugar and syrup, the batch goes through the mixing process. Usually, you need gentle mixing equipment for muesli that can preserve the shape and texture of the ingredients, and you have to mix them for a short period of time – from 10 to 30 seconds.

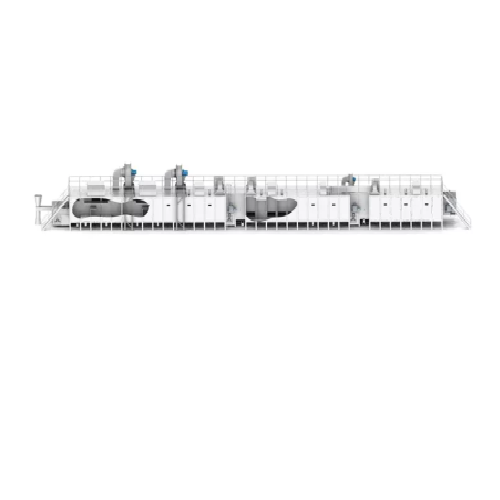

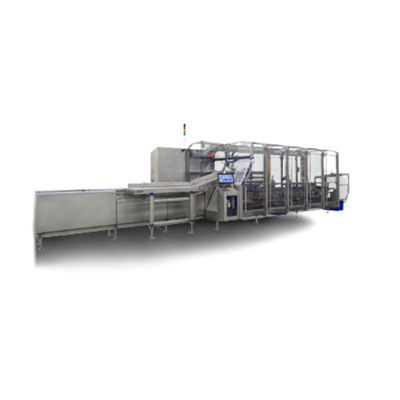

After the mixing, the loosely combined ingredients are transferred to a packaging machine, which packs the muesli in either paper bags or stand-up pouches. This process pertains to making plain muesli. However, muesli is often also combined with dried fruits such as apricots and coconut flakes. And, with nuts such as almonds and walnuts to give extra flavor. Muesli is a snack enjoyed on its own or mixed with yoghurt and fresh fruits.

Muesli vs. granola - baking or no baking?

To bake or not to bake, that is the question! The difference between muesli and granola lies in the production process of these two products. Simply put, muesli is a mix of rolled oats, whole grains, nuts, seeds, and dried fruits that is not cooked or baked, but in a natural form. On the other hand, granola is a mix of the similar ingredients as muesli, but oil and sugar are added to the baking process as these two additional ingredients allow the mixed batch to stick together better.

What is the best packaging for muesli?

Among three common packaging options of muesli – paper bag, paper tube, or Doypack (stand-up pouches) – it is proven that the Doypack is the best choice. According to a research, the moisture content and water activity of muesli in these three containers were varied after 9 months, showing Doypack with the highest percentage for both criteria. This demonstrates that the muesli packed in Doypack was dried out the least after a certain period. Also, evaluation of other criteria such as sensory evaluation microbiological parameters showed that Doypack was the best packaging solution for muesli.

Processing steps involved in muesli making

Which muesli technology do you need?

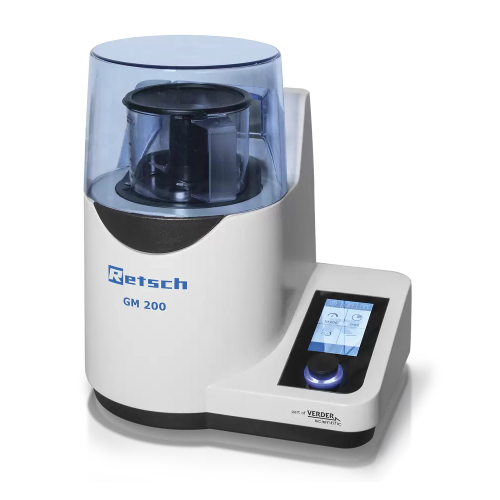

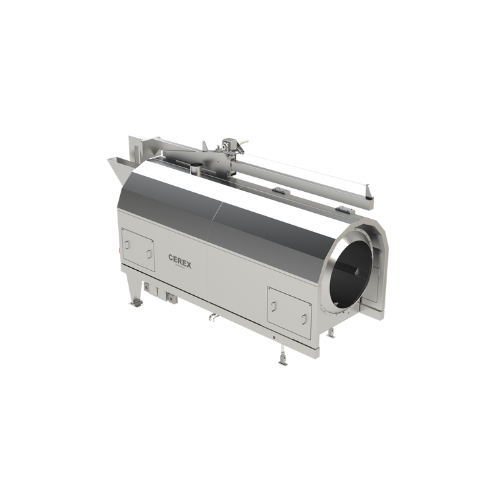

Cyclone mill for Nir analysis sample preparation

Ensure accurate NIR analysis by optimally preparing samples with efficien...

Ultra centrifugal mill for size reduction of soft and medium-hard materials

Achieve precise particle size reduction an...

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Industrial continuous heat treatment for dry ingredients

Optimize your production line with a continuous system that ensu...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

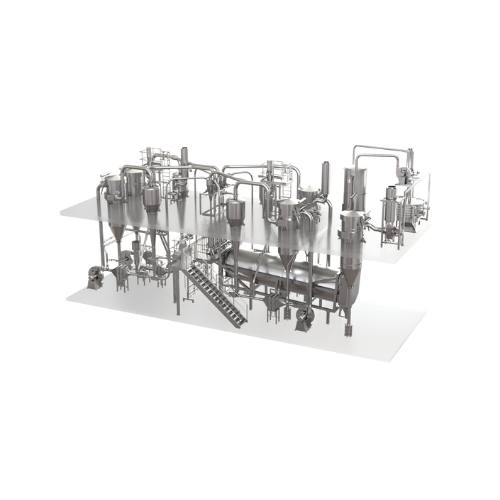

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Grain flow regulator for roller mills

Achieve consistent grain distribution and safeguard your roller mills from wear and c...

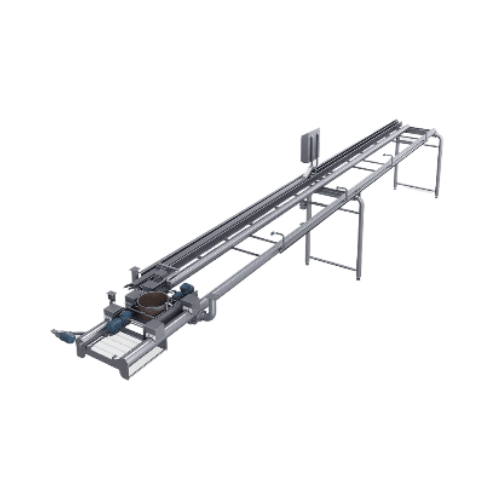

Chain conveyors for long-distance bulk material transport

Efficiently transport challenging bulk materials across long d...

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Vacuum dryer for powders and granules

Achieve precise moisture control for sensitive materials with a versatile vacuum dryi...

Roller press for fine-grained material compaction

Achieve optimal density and stability in your solid press agglomerates ...

High-speed hammer mill for continuous operation

Achieve precise particle size reduction with high-speed hammer milling, id...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

Powder flowability and compressibility analysis

Ensure accurate powder flowability and compressibility data with this adva...

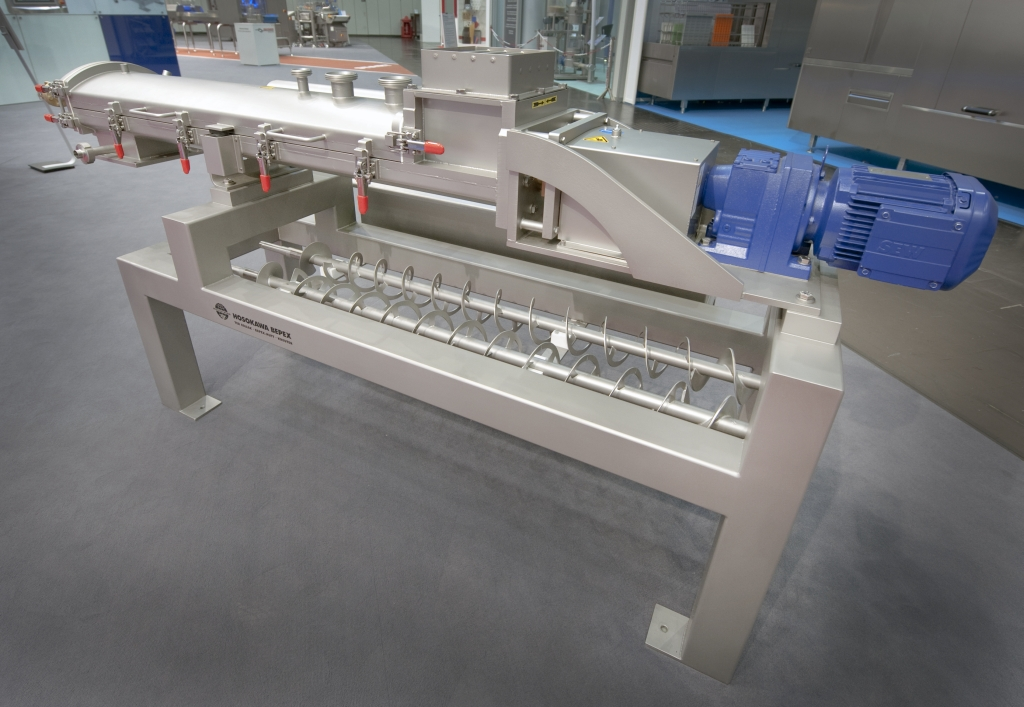

Industrial raw material mixer for complex recipes

Struggling with complex raw material mixtures? This advanced mixing sol...

Metal detection and weight verification system

Optimize space and boost inspection accuracy by combining metal detection a...

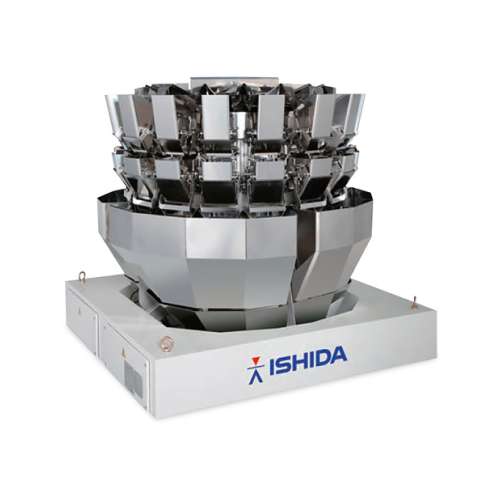

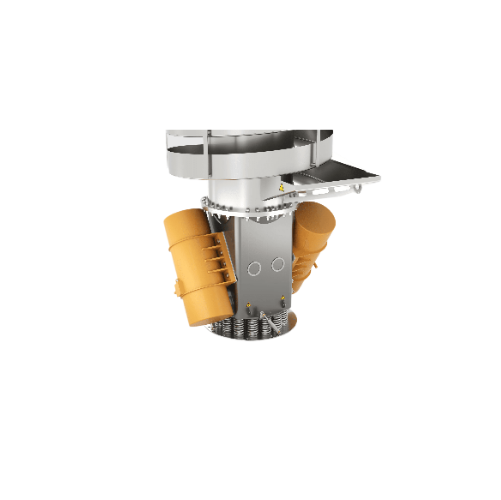

Blending multihead weigher for accurate component mixing

Achieve precise blending in high-speed operations with individua...

Carbon/nitrogen analyzer for organic samples

Optimize your lab’s efficiency with fast, reliable nitrogen and carbon ...

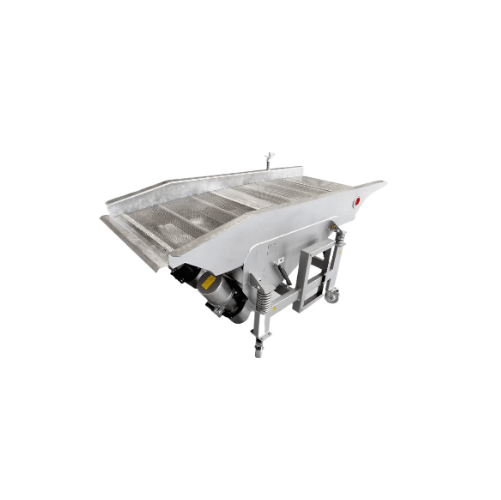

Vibration transport system for hygienic conveying of bulk goods

Optimize your production line with efficient and hygieni...

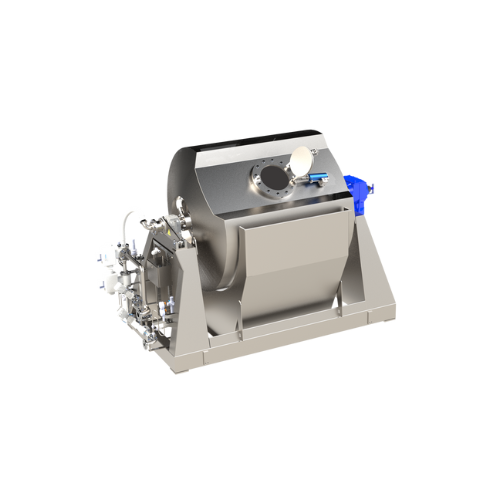

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

Product handling system for big bags and containers

Optimize your production line with a comprehensive system for transpo...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Industrial moisture and temperature control conditioner

Optimizing moisture absorption and temperature management, this c...

Horizontal screw loader for food processing

Optimize your production flow with a smooth-loading solution designed to effic...

High throughput twin screw extruder for low bulk density products

When handling low bulk density materials, achieving m...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Industrial 2-zone toaster for optimal cereal processing

Achieve precise toasting of cereals and seeds with the 2-zone toa...

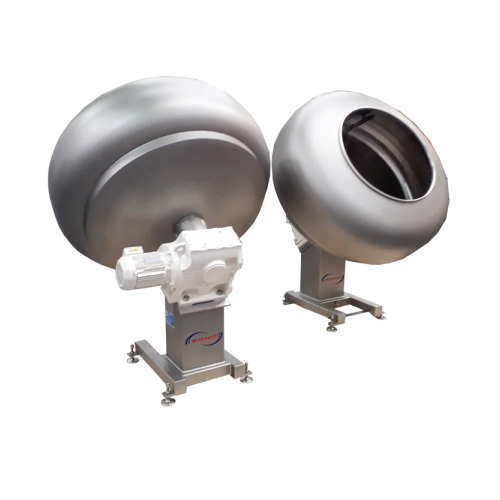

Industrial coating drum for breakfast cereals

Optimize your cereal production with a coating drum designed to enhance prod...

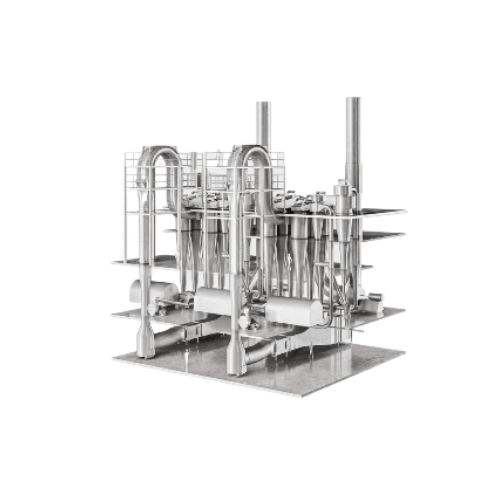

Coating dryers for breakfast cereal production

Achieve precise moisture control in coated cereal production with these mod...

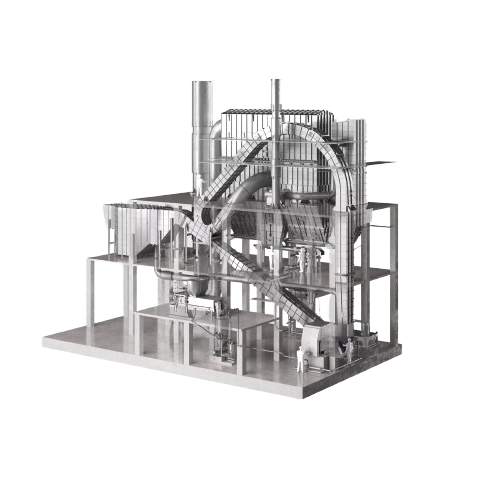

Multi-tier dryers for modern breakfast cereals

Optimize dry and cool cereal, nuts, and seed production with a compact modu...

Grain puffing system for breakfast cereals

Achieve precise and efficient grain expansion in breakfast cereals with this ad...

Rotary cooker for uniform steam heating in cereals production

Achieve consistent product quality in high-volume cereal p...

Grain scourer for wheat, durum, and rye

Enhance grain processing by efficiently removing impurities like dust, sand, and so...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

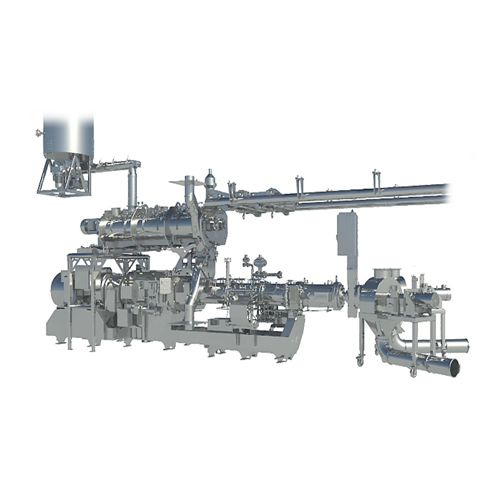

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Versatile steam distillation unit for laboratory applications

Achieve reliable analysis of complex samples with this ste...

Lab-scale twin screw extruder

Optimize your material testing and production efficiency with our versatile twin screw extrude...

Vertical forced feeder for extruders

Enhance your extrusion process with a vertical forced feeder designed for precise dosi...

Small twin screw extruder

Optimize your lab and pilot production with a versatile twin screw extruder, designed for precise ...

Gluten quality testing solution

Ensure optimal flour quality by rapidly assessing gluten properties, allowing you to refine ...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

Double shaft paddle mixer for solids and powders

Achieve unparalleled mixing precision for fragile and diverse materials w...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Automatic granular product weighing system

Effortlessly achieve precise fills for dry granular products and powders while ...

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle han...

Industrial powder sifter with sanitary compliance

Optimize your powder processing with this versatile sifter, ensuring pr...

Vacuum powder sampler for particle size distribution control

Ensure precise quality control with a vacuum powder sampler...

Vibratory spiral elevator for vertical transport

Achieve efficient vertical transport with precise temperature control, su...

Continuous motion packaging for short-cut pasta

Optimize your packing line with a high-speed solution designed for efficie...

Vertical packaging system for short-cut pasta and dry granular food

Streamline your packaging operations with a high-sp...

Vertical packaging system for fragile food products

Handle delicate food items like pasta nests and bakery products with ...

Intermittent motion packaging system for dry granular food

Achieve precision packaging for dry foods with an advanced sy...

Industrial cooling system for packaging temperature control

Achieve precise temperature control and maximize energy effi...

Batch standing mixer for dough preparation

Enhance your mixing precision with a batch standing mixer that optimizes paddle...

Dough distribution system for multiple mixing points

Ensure precise dough allocation across multiple production stages wi...

Industrial screw pump for dosing hard fillings

Enhance precision and efficiency in dosing hard fillings with a robust scre...

Industrial water cooling system for food products

Efficiently cool and convey food products with a system designed for un...

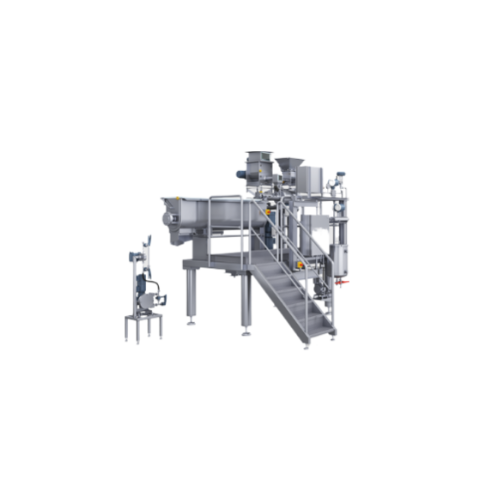

Automatic continuous mixer for dough preparation

Streamline your production line with a mixer that ensures precise dosing ...

Round die washer for pasta and snack production

Ensure impeccable hygiene with a specialized washer that streamlines die m...

Industrial ring dryer for efficient particle processing

Control particle size and drying efficiency with precise recircul...

Flash dryer for industrial moisture removal

Optimize your production with rapid moisture removal, efficiently transforming...

Screw belt mixer for dry materials

Achieve uniform mixing of bulk dry materials with variable speed control, ensuring preci...

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed...

Extruder for aquatic feed production

Efficiently produce a wide range of aquatic and pet feed with precise control over pel...

Coating and enrobing system for pet foods and treats

Achieve precise coating and flavoring of various food and feed produ...

High intensity preconditioner for textured vegetable proteins

Optimizing your production with precise moisture control a...

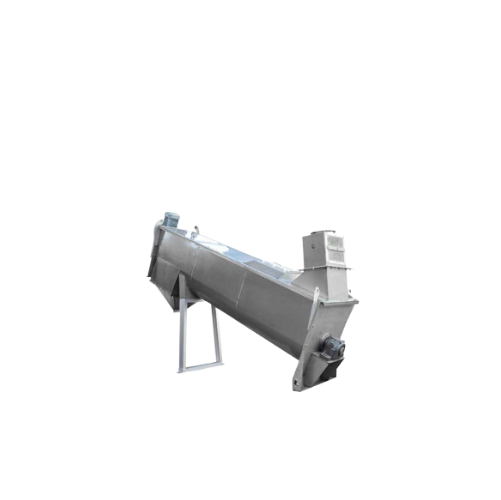

Trough screw conveyor for flour mills

Optimize your flour processing with efficient material handling, precisely designed f...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

High capacity vertical conveying for grains and cereals

Ensure efficient vertical transport of bulk materials like cereal...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Double deck roller mill for grain milling

Achieve superior milling results with increased efficiency and hygiene in proces...

Industrial extraction scale for accurate material weighing

Ensure precise ingredient proportions in your milling operati...

Bucket elevator for grain and powder products

Efficiently transport bulk materials like grain and powder vertically with p...

Inclined intensive dampener for grain processing

Ensure consistent moisture levels for optimal grain processing and enhanc...

Blower for vertical and horizontal grain transport

Efficiently transport grains, legumes, and flour both vertically and h...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

Modular linear packing system for granular products

Streamline your packing operations with a versatile system that integ...

Linear weigher for dry free flowing powder

Optimize your packaging line with precise weighing for free-flowing granular pr...

Cooking extruders for continuous food processing

Optimize your extrusion processes with cooking extruders designed for con...

Thermal conditioning for improved meal flow and starch digestibility

Ensure optimal meal flow and starch digestibility ...

High-capacity pre-cleaner drum for grain silo storage

Optimize your pre-cleaning process with a high-capacity drum that e...

Industrial hammermill for fine grinding applications

Elevate your milling efficiency with hammermills designed for precis...

Agricultural cleaner-separator for grain processing

Optimize your grain processing with a versatile cleaner-separator eng...

Mobile circulating dryer for agricultural products

Optimize your drying processes with a mobile circulating dryer, design...

Grain dryer with air circulation system

Enhance efficiency and product quality with our versatile grain dryer, designed to ...

Stationary grain dryer with biturbo system

Optimize your drying processes with a system that efficiently manages air flow ...

Low-emission belt drying systems for timber industry

Optimize moisture control and energy efficiency in drying processes ...

Industrial air heater for agriculture and industry

Optimize energy efficiency and maintain high air quality in your produ...

Belt dryer for timber industry

Optimize moisture removal and ensure consistent drying in your production line with advanced ...

Layer dryer for food and pet food applications

Optimize drying efficiency with multi-layer technology that minimizes space...

Belt dryer for food and pet food products

Optimize drying processes with customizable belt dryers, engineered to handle ro...

Belt dryer for sawdust

Optimize your drying process with advanced technology engineered for precise moisture reduction in div...

Hybrid dryer for agriculture and industrial applications

Achieve efficient moisture reduction in varied materials, from f...

Mobile belt dryer for sawdust and biomass

Efficiently reduce moisture in a variety of materials, from sawdust to cereal sn...

High-force texture analyser for precise measurement

Achieve unparalleled precision in texture analysis for high-force app...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Entry-level texture analysis system for Qc applications

Perfect for quality control labs, this portable system streamline...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Electrostatic drum flavouring for uniform coating

Achieve precise and uniform flavor distribution on snack products with ...

Z-conveyor for confectionery production

Ensure the gentle transport of delicate dry and granulated ingredients with a versa...

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

Industrial breadchips cutting solution

Achieve precise, high-speed slicing of bread-based strands into thin, uniform chips ...

Infrared dryer for breakfast cereals

Optimize your snack production with precise moisture control, energy-efficient infrare...

Top load Case Packer For Food Products

If you want to pack your food cartons, doy packs and pouches into regular cases, a s...

Intelligent Continuous Food Cartoner

Fully automated robotic packing solutions enable larger-scale food producers to pack a...

Hygienic vertical bagging machine

Hygienic bagging with a compact packing machine that can withstand the harshest wash down...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Dual channel plug diverter valve

Short switching times are often required when diverting or combining powder or granular sol...

Continuous caramel mixer

Mix your recipe’s ingredients in preparation for further processing. This is a continuous mixe...