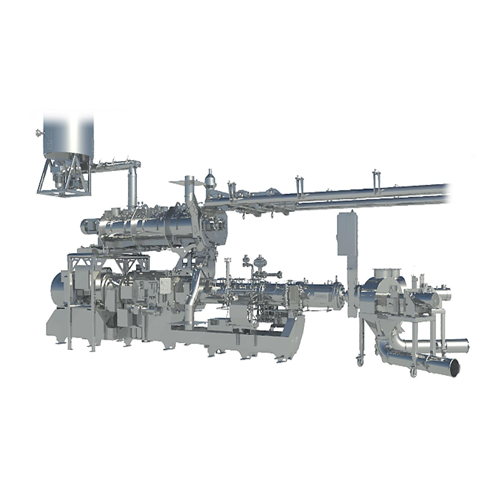

Extruder for aquatic feed production

Efficiently produce a wide range of aquatic and pet feed with precise control over pellet sizes and densities, ensuring optimal nutrition retention and water stability for demanding aquaculture environments.

Produces Consistent Aquatic and Pet Feed Pellets

The AquaFLEX™ Twin Screw Extruder, part of Wenger’s FLEX™ series, is engineered for manufacturers in the aquatic and pet feed industries requiring precise control over pellet size, density, and nutritional retention. This system employs twin screw technology to address the challenge of producing small-sized pellets that maintain high-density characteristics. The AquaFLEX™ excels at versatility, producing floating, sinking, and slow-sinking feed for a variety of species, including shrimp, salmon, and trout.

With the capability to process up to 13,000 kg/hr and pellet sizes ranging from 0.6mm to 10mm or more, the AquaFLEX™ combines high throughput with superior flexibility. Designed for automated, continuous operations, it integrates seamlessly into production lines, offering customization through Wenger’s High Shear Conditioner, High Intensity Preconditioner, and other supportive systems. By optimizing motor speeds, it ensures energy-efficient operation, while its stainless steel construction provides robust, corrosion-resistant durability. Ideal for facilities demanding high-volume, reliable feed production, this extruder ensures compliance with industry standards and supports easy maintenance with features like a CIP system for efficient cleaning processes.

Benefits

- Ensures consistent pellet quality with precise density control for optimal nutrition.

- Maximizes production efficiency with the ability to produce up to 13,000 kg/hr.

- Enhances energy efficiency through optimized motor control, reducing operational costs.

- Supports diverse production needs with flexible pellet size and type options.

- Simplifies maintenance and cleaning with integrated CIP system.

- Applications

- Textured vegetable proteins, Ingredients, Snacks, Pet food, Breadings, Aquatic feed, Meat analogs, Protein crisps, Breakfast cereals

- End products

- Pea protein crisps, Floating aquaculture pellets, Semi-moist pet treats, Pea-based meat analogs, Salmon feed, Protein-enriched breadings, Yellow tail tuna feed, Soy protein crisps, Dental pet chews, Slow-sinking aquaculture pellets, Trout feed, Traditional dry kibble, Cod feed, Cornflakes, Sea bass feed, High fresh meat inclusion pet foods, Granola, Wheat protein crisps, Soy-based meat analogs, Sinking aquaculture pellets, Muesli base flakes, Shrimp feed

- Steps before

- Ingredient Mixing, Preconditioning, Grinding, High Intensity Preconditioning, High Shear Conditioning

- Steps after

- Drying, Cooling, Coating, Packing, Water Stability Testing

- Input ingredients

- textured vegetable proteins, structured meat analogs, ingredients, protein crisps, breadings, RTE cereals, snacks, hybrid products, traditional kibble, semi-moist pet food ingredients, high fresh meat inclusion, floating feed ingredients, sinking feed ingredients, slow-sinking feed ingredients, RAS feed ingredients

- Output ingredients

- aquatic feed, pet food, floating pellets, sinking pellets, slow-sinking pellets, micro aquatic feeds, shrimp feed, salmon feed, trout feed, sea bass feed, cod feed, yellow tail tuna feed

- Market info

- Wenger is known for its expertise in manufacturing extruders and dryers for pet food, aquatic feed, and food processing industries, renowned for reliability, innovation, and custom-engineered solutions worldwide.

- Maximum Capacity

- 13, 000 kg/hr. (AFX-3000)

- Pellet Size Range

- 0.6mm to 10mm+

- Product Density Control

- Precise control of piece density and uniformity

- Water Stability

- Up to 7 hours (shrimp feed)

- Floating and Sinking Feed Production

- Floating, slow sinking, and sinking products

- Motor Size

- 300-600 HP (AFX-3000), 150-600 HP (AFX-600)

- Twin Screw Technology

- Yes

- Ingredient and Formula Flexibility

- Maximum level of ingredient and formula flexibility

- Nutrient Retention

- Excellent nutrient retention

- Screw Technology

- Twin Screw

- Pellet Size Range

- 0.6mm to 10mm+

- Operation Mode

- Batch / Continuous

- Flexibility of Feed Type

- Floating, Slow Sinking, Sinking

- Die Configuration

- Dual Die Assembly

- Customization Levels

- High - Customer Specific Needs

- Water Stability

- Up to 7 hours

- Automation Level

- PLC / SCADA Capable

- Product Density Control

- Precise

- Density/particle size

- 0.6–10 mm

- Nutrient retention

- High

- Water stability

- Up to 7 hours

- Control panel type

- PLC-controlled

- Integration with other systems

- High Shear Conditioner, High Intensity Preconditioner

- Die configuration

- Diverse die options for pellet size customization

- Customization for ingredient flexibility

- Wide range of ingredient use

- Customization for product type

- Floating, slow-sinking, sinking feeds