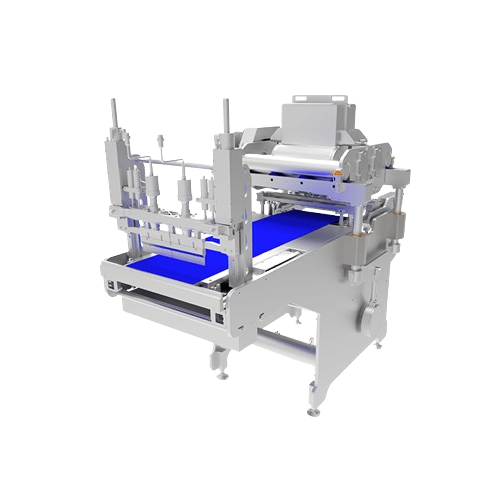

Cookie dough wirecut machine

Achieve precise control and flexibility in shaping a wide variety of cookies and bars with this cutting-edge wirecut machine, designed to streamline your production line with rapid and accurate cuts even for complex multi-color or filled products.

Cuts and Forms Cookies, Bars, and Snacks

The WCX Wirecut Machine from Reading Bakery Systems offers an unparalleled level of versatility and control for industrial bakeries and snack production lines. Engineered with servo-controlled positional accuracy, it enables precise wire positioning and stroke adjustments, allowing for diverse product formats, such as filled cookies and multi-color bars. Capable of executing up to 300 cuts per minute, this machine excels in maintaining consistent piece weight and production throughput. Its seamless integration into existing dough handling systems is facilitated by an intuitive touchscreen interface, further enhancing operational efficiency. The WCX is designed for easy sanitation with removable components, ensuring compliance with rigorous food safety standards. This equipment is ideal for producing items like chocolate chip cookies, protein bars, and pet treats, and it supports continuous, high-speed, automated production environments.

Benefits

- Enhances product consistency and quality with accurate cutting and forming.

- Increases production capacity with up to 300 cuts per minute.

- Minimizes labor costs through automated recipe settings and quick changeovers.

- Ensures food safety with easy-to-clean, removable components.

- Facilitates diverse product offerings, including filled and multi-color items.

- Applications

- Pet treats, Cookies, Baked goods, Multi-color products, Snacks, Bars, Filled cookies, Frozen dough

- End products

- Dog biscuits, Filled pastries, Granola bars, Fruit-filled cookies, Chocolate chip cookies, Red velvet cookies, Almond butter cookies, Oatmeal raisin cookies, Rice crackers, Rainbow spritz cookies, Cat treats, Gluten-free cookies, Vegan snack bars, Protein bars

- Steps before

- Dough Mixing, Dough Handling, Dough Feeding

- Steps after

- Sanitation and Maintenance, Product Transfer, Packaging

- Input ingredients

- dough, frozen dough, multi-color dough, filled dough, encapsulated dough

- Output ingredients

- cookies, bars, filled bars, multi-color products, filled cookies, encapsulated cookies, pet treats

- Market info

- Reading Bakery Systems is renowned for its expertise in designing and manufacturing innovative industrial bakery equipment, particularly for snack food production, combining advanced technology and industry knowledge to enhance productivity and quality.

- Throughput Yield

- Up to 300 cuts per minute (cpm)

- Control System

- Servo-controlled

- Automation

- Touchscreen controls

- Product Capability

- Standard and filled bars, multi-color, encapsulated cookies

- Co-extrusion Capability

- Yes, with internal and external pump systems

- Automation level

- PLC / Touchscreen controls

- Batch vs. continuous operation

- Batch

- Changeover time

- Quick changeover

- Cleaning method

- Manual / Easy removable parts

- CIP/SIP

- Easy sanitation and maintenance

- Integrated cutting system

- Yes

- Throughput yields

- Up to 300 cuts per minute

- Cleanability

- Easy removal of components for sanitation

- Product capability

- Standard and filled bars, multi-color products, filled and encapsulated cookies, pet treats, frozen dough

- Control Panel Type

- Touchscreen

- Discharge Method

- Transfer Conveyor Frame

- Feed Method

- Hopper and Roll Assemblies

- Wirecut Stroke Length

- Adjustable

- Control panel type

- Touchscreen interface

- Integration possibilities

- Existing dough feeding system or turn-key automated dough handling system

- HMI type

- Touchscreen controls

- Servo control features

- Wire positioning, stroke length, and infinite cam profiles

- Optional attachments

- Ultrasonic cutting attachment

- Pump system type

- Internal and external pump systems