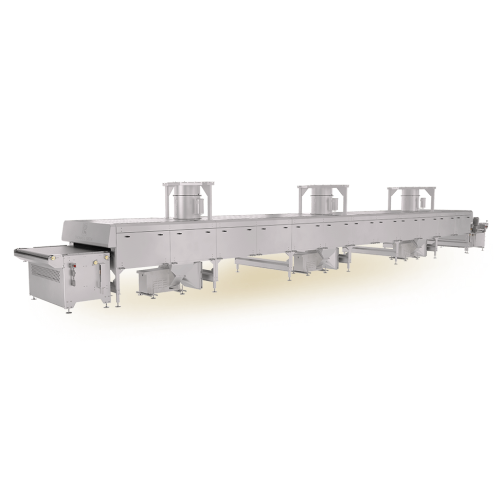

Ambient air cooler for bakery products

Efficiently cool fragile baked goods without causing distortion, using ambient air technology to ensure gentle handling and consistent temperature reduction.

Cools Bakery and Snack Products Efficiently

The Thomas L. Green Forced Air Ambient Cooling Conveyor is engineered for industrial bakeries and snack food producers seeking efficient product cooling without distortion. This modular system allows flexible installation and integrates seamlessly into continuous production lines, optimizing output. Its forced air mechanism quickly reduces internal product heat post-baking, ensuring high-quality finishes for items like pretzels, chips, and granola bars. Constructed with fresh air intakes for adjustable cooling, it supports high-speed operations while maintaining energy efficiency. Built to SafeShield Program standards, it ensures easy sanitation and operator safety. Fully customizable and compatible with Reading Bakery Systems’ control technologies, this equipment is a reliable choice for precise cooling needs.

Benefits

- Enhances product quality by preventing distortion during cooling.

- Modular design allows easy installation and integration into existing lines.

- Boosts energy efficiency with adjustable air intake controls.

- Promotes operator safety and sanitation through SafeShield standards.

- Supports high-speed production without compromising cooling effectiveness.

- Applications

- Cookies, Biscuits, Pet food, Snack foods, Crackers, Granola, Bakery products

- End products

- Granola bars, Popped snacks, Chips, Expanded snacks, Baked pet treats, Multi-crisp crackers, Biscuit layers, Pretzels, Fried potato rings

- Steps before

- Baking, Continuous Mixing, Dough Forming, Pretzel, Snack Extrusion

- Steps after

- Cooling, Packing, Product Inspection

- Input ingredients

- baked products, hot bakery products

- Output ingredients

- cooled products, ambient temperature bakery items

- Market info

- Reading Bakery Systems is renowned for its expertise in designing and manufacturing innovative industrial bakery equipment, particularly for snack food production, combining advanced technology and industry knowledge to enhance productivity and quality.

- Cooling method

- Forced Air Ambient

- Cooling efficiency

- Quick and efficient

- Installation

- Modular

- Air intake type

- Fresh air

- Working mechanism

- Forced Air Cooling

- Cooling control

- Adjustable Fresh Air Intakes

- Modular design

- Variable Widths and Sizes

- Product cooling time

- Immediate

- Airflow pattern

- Directed over Product

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance

- Stainless steel

- Footprint

- Modular, customizable sizes

- Cooling method

- Forced air cooling

- Construction

- Modular fashion

- Air intake location

- Top of the cooling chamber

- Discharge method

- Conveyor system

- Control panel type

- Custom designed

- Cooling chamber size

- Modular sizing available

- Cooling air intake

- Adjustable