Continuous mixer for wheat-based products

Achieve consistent dough quality with minimal variation using a continuous mixer designed for efficient integration in bakery and snack production lines, ensuring precise ingredient blending for diverse products while optimizing energy use and food safety standards.

Mixes and Kneads Wheat-Based and Snack Products

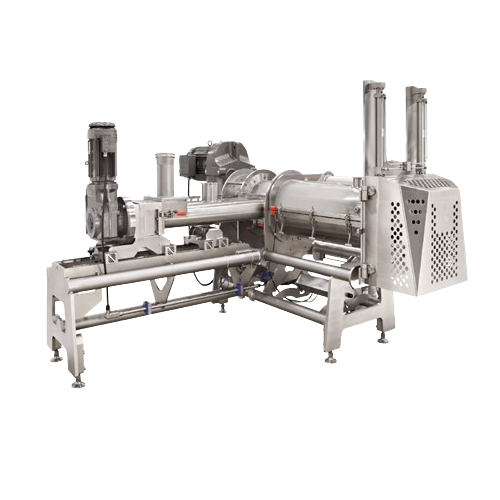

The EX Continuous Mixer from Exact Mixing is designed to optimize dough mixing and kneading for wheat-based and snack products. Utilizing interchangeable mixing elements within its clam-shell design, this mixer ensures gentle dough development without excessive heat, maintaining consistent quality across production lines. It’s ideal for applications ranging from bread doughs and cake batters to low viscosity mixtures like extruded snack pellets and pet food kibble.

With a processing capacity ranging from 100 to 10,000 kg/hour, the EX Continuous Mixer integrates seamlessly into automated production systems. Gravimetric, loss-in-weight metering paired with a closed-loop control system ensures precise ingredient mixing, enhancing product consistency and reducing waste. The EX Mixer operates with reduced energy consumption, making it efficient for large-scale food and bakery operations.

Constructed with FDA-approved materials, the mixer prioritizes food safety and easy sanitation, featuring washdown-in-place components and quick-disconnect sanitary connections. With fully automated control systems, the mixer supports real-time process monitoring and recipe-based operations, facilitating smooth integration into existing production environments while ensuring operator safety with emergency stop functions. Exact Mixing offers customization and engineering support to tailor the system to specific production needs.

Benefits

- Ensures consistent product quality by eliminating batch-to-batch variations.

- Minimizes operational costs with efficient energy use and automated ingredient metering.

- Enhances food safety with closed-system design and FDA-approved materials.

- Reduces maintenance time through easy-to-clean, quick-disconnect components.

- Supports high production capacities from 100 to 10,000 kg/hour for scalable operations.

- Applications

- Cookies, Biscuits, Snacks, Pet food, Low viscosity powder/liquid mixtures, Popped snacks, Wheat-based products, Crackers, Bakery products, Baked granola

- End products

- Soda crackers, Digestive biscuits, Granola clusters, Popped corn snacks, Cake batter, Bread dough, Low moisture pet kibble, Muffin mix, Extruded snack pellets

- Steps before

- Ingredient Pre-mixing, Dry Ingredient Metering, Liquid Ingredient Metering

- Steps after

- Dough Handling, Dough Forming

- Input ingredients

- wheat-based products, low viscosity powder, liquid mixtures, dry ingredients, liquid ingredients

- Output ingredients

- consistent dough, low moisture products, stiff products

- Market info

- Reading Bakery Systems is renowned for its expertise in designing and manufacturing innovative industrial bakery equipment, particularly for snack food production, combining advanced technology and industry knowledge to enhance productivity and quality.

- Capacity

- 100–10, 000 kg/hour

- Automation

- Fully automated

- Mixing shaft configuration

- Interchangeable mixing elements

- Ingredient metering

- Gravimetric, Loss-in-Weight

- Energy efficiency

- Reduced energy usage

- Sanitation method

- Wash down in place

- Control system interface

- Touchscreen control interface

- Safety features

- Interlocked access points

- Materials

- FDA approved materials

- Working mechanism

- Continuous mixing

- Integrated steps

- Pre-mixing, metering, mixing, discharge

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- Automated with touchscreen control

- Cleaning method

- Wash down in place

- Reduction in labor and energy costs

- Reduced

- Production rates

- 100 to 10, 000 kg/hour

- Sanitation principle

- Clamshell design for easy cleaning

- Cleanability

- Clam-shell design for easy sanitation and maintenance

- Corrosive resistance (e.g. acids)

- Only FDA approved materials are used in the product zone

- Mixing shaft configuration

- Interchangeable elements

- Mixing chamber design

- Clam-shell

- Sanitary access points

- Clamshell mixing chamber

- Production rate

- 100 to 10, 000 kg/hour

- Control panel type

- Touchscreen interface

- Automation level

- Fully automated operation

- Mixing shaft configuration

- Interchangeable mixing elements

- HMI Integration

- Custom designed control systems

- Clamshell design

- For easy sanitation and maintenance

- Ingredient Metering

- Gravimetric, Loss-in-Weight technology

- Emergency stop

- Buttons around the mixing system

- Recipe based controls

- Automated for all ingredient handling