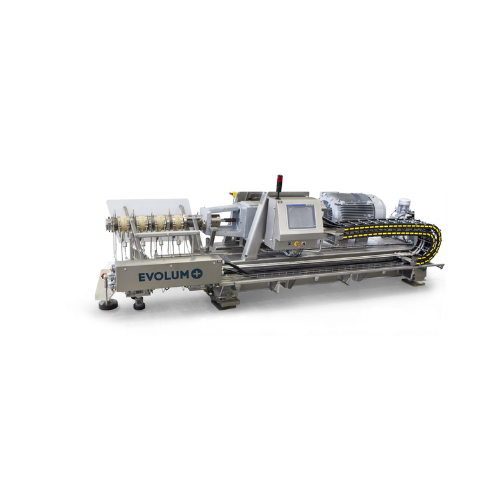

High-performance twin-screw extruder for food production

Enhance your production line efficiency and product quality with advanced twin-screw extruders designed to increase throughput and ensure optimal process control, delivering consistent results in diverse applications.

Processes and Extrudes Diverse Materials Efficiently

The EVOLUM+ Twin-Screw Extruder from Clextral revolutionizes extrusion for food, pet food, and bioplastic industries. Its advanced design provides up to 40% higher production volume, integrating seamlessly into your production line with a patented Advanced Thermal Control (ATC) system for precise temperature management. This equipment efficiently handles diverse applications from high-protein pet kibbles to compostable cutlery, with throughput capabilities reaching up to 23,000 kg/h. Its hygienic stainless steel construction supports CIP systems for easy maintenance and rapid recipe changeover. The extruder features a modular setup enhancing operational flexibility and process integration, making it ideal for continuous, high-speed operations in complex production environments.

Benefits

- Increases production volume by 40%, enhancing profitability and ROI.

- Optimizes operational efficiency with energy savings of up to 20%.

- Minimizes maintenance downtime through ergonomic design and easy access.

- Ensures consistent product quality with precise process control.

- Adapts to varied production demands, supporting a wide range of material applications.

- Applications

- Extruded snacks, Salty coatings, Bioplastics, Textured vegetable proteins, Aquatic feed, Biomass conversion, Co-extruded products, Premium pet food, Banknotes, Breakfast cereals, Sweet coatings

- End products

- Pelletized biomass fuel, Granola clusters, Frosted cereal coatings, Filled snack pillows, Cheese-flavored snack coatings, High-protein pet kibbles, Corn puffs, Fish pellets, Compostable cutlery, Soy protein isolate, Watermark-secure banknote substrate

- Steps before

- Heating, Hydrating, Mixing, Preheating, Premoistening, Pregelatinization

- Steps after

- Drying, Coating, Packaging, Cooling

- Input ingredients

- raw materials, dry mix product, starches, sweet fillings, savoury fillings, water

- Output ingredients

- extruded products, expanded snacks, co-extruded products, filled pillows, textured vegetable proteins, pet food kibbles, sinking aquatic feed, floating aquatic feed, glazed coatings, frosty coatings

- Market info

- Clextral is known for its expertise in twin-screw extrusion technology, providing innovative engineering solutions for food processing, pulp production, and specialty applications, building a solid reputation for high-quality, customer-customized equipment and reliable technical support.

- Production Volume Increase

- Up to 40%

- Energy Savings

- Up to 20%

- Process Stability Improvement

- Up to 70%

- Screw Diameter

- 25 to 145 mm

- Output Speed

- 50 to 20, 000 kg/h

- Preconditioner Volume

- 25L to 3000L

- Preconditioner Capacity

- 75L to 4500L

- Dryer Throughput

- 300 kg/h, 600 kg/h, 1200 kg/h

- Drying Energy Efficiency

- 90%

- Automation level

- PLC / SCADA / Advanced Thermal Control

- Batch vs. continuous operation

- Continuous

- CIP/SIP

- Easy clean design / CIP 121°C

- Cleaning method

- Manual / Washable CIP system

- Changeover time

- Quick access through hydraulic opening

- Energy efficiency

- Up to 20% savings

- Process flexibility

- Multiple torque/screw speed options

- System integration

- Co-extrusion kit integration

- Hygienic design

- Full stainless steel construction

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- High, designed for hygienic processing and food safety

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Foaming

- Control Available

- Container size and shape

- Adjustable

- Screw diameters

- 25 to 145 mm

- Material

- Stainless steel / Painted steel

- Compact footprint

- Plug, Play

- Ergonomic design

- Open profiles for full access

- Discharge method

- Direct hydraulic opening of barrels

- Construction

- Fully welded stainless-steel structure

- Barrel opening

- Patented hydraulic

- Control Panel

- PLC Fitsys+ V2

- HMI Type

- User-friendly multilingual interface

- Integration Flexibility

- Remote assistance service available

- Screw and Torque Speed

- Multiple options available

- AFC Device Customization

- Adjustable filling ratio and residence time

- Co-Extrusion Options

- Sweet or savoury fillings capability

- Preconditioner Capacity

- Variable output speeds and capacities

- Flexible Drying Requirements

- Multiple dryer models