Automated process management system for industrial extrusion

Optimize your production line with precise control and monitoring of extrusion processes, reducing waste and enhancing product consistency across various applications.

Monitors and Regulates Production Variables Continuously

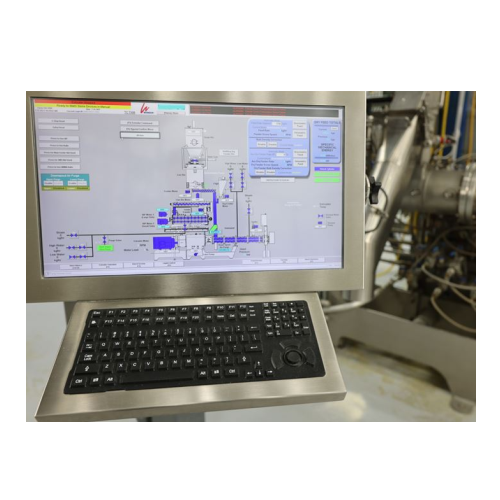

The Wenger Automated Process Management (APM) system is a comprehensive solution for precise control and monitoring in production environments. This system uniquely integrates control cabinets with Human Machine Interface (HMI) screens, allowing for real-time adjustment of processing conditions and continuous production management. Ideal for applications across food, pet food, and aquatic feed industries, it facilitates the production of various end-products such as veggie burgers, protein bars, and aquaculture diet pellets.

Processing at continuous and automated operations, the Wenger APM can handle solid, powder, granule, liquid, and slurry product types. It features pre-programmed software for startup, shutdown, and cleanout cycles, enhancing integration with existing systems. The system optimizes energy use and ensures safety through zoning control, crucial for maintaining operational standards and personnel safety during maintenance or adjustments.

Wenger APM supports data-driven decisions with advanced logging capabilities, tracking critical variables for traceability and energy management. It allows seamless installation with pre-wired and pre-plumbed modules, reducing commissioning time. Offering global support and customization, this system is engineered to meet stringent industry standards while providing flexibility for future upgrades.

Benefits

- Enhances product consistency and quality with real-time monitoring and control.

- Minimizes installation and commissioning time with pre-wired and pre-plumbed modules.

- Improves safety through integrated zoning to prevent unauthorized equipment operation.

- Facilitates data-driven decisions with comprehensive logging and traceability features.

- Increases flexibility with customizable processing conditions for diverse product applications.

- Applications

- Pet treats, Rte cereals, Hybrid products, Textured vegetable proteins, Sinking feeds, Snacks, Semi-moist pet food, Structured meat analogs, Industrial applications, Protein crisps, Slow-sinking feeds, Traditional kibble, Floating feeds, Breadings, High fresh meat inclusion, Recirculating aquaculture system (ras) feeds

- End products

- Hybrid snack mixes, Dog biscuits, Veggie burgers, Meat-infused kibble, Aquaculture diet pellets, Cornflakes, Granola clusters, Snack pellets, High-moisture dog food, Biodegradable packaging materials, Shrimp feed, Tilapia feed, Breadcrumb coatings, Soy meat substitutes, Dental pet chews, Ornamental fish feed, Salmon feed, Protein bars

- Steps before

- Ingredient Mixing, Preconditioning, Meat Injection

- Steps after

- Cooling, Coating, Drying, Packing, Data Logging

- Input ingredients

- textured vegetable proteins, structured meat analogs, ingredients, high fresh meat inclusion, various ingredient options

- Output ingredients

- protein crisps, breadings, RTE cereals, snacks, hybrid products, traditional kibble, semi-moist pet food, pet treats, floating aquatic feeds, sinking aquatic feeds, slow-sinking aquatic feeds, RAS feeds, specialty feeds

- Market info

- Wenger is known for its expertise in manufacturing extruders and dryers for pet food, aquatic feed, and food processing industries, renowned for reliability, innovation, and custom-engineered solutions worldwide.

- Automation

- APM (Automated Process Management)

- Control System

- ControlLogixTM from Allen Bradley

- Data Logging

- SQL database

- Remote Support

- Available

- Installation

- Pre-plumbed and pre-wired module

- HMI Interface

- Interactive, Real Time

- Density Control

- Requires Bulk Density System and Back Pressure Valve

- Mix Intensity

- Requires Mix Intensity Control

- Monitoring

- Extruder, Dryers, Liquid Levels, etc.

- Startup and Shutdown Sequences

- Automatic

- Temperature monitoring

- Critical points tracking

- Process Trending

- Real Time

- Zone Control

- Integrated Safety

- Automation level

- PLC / APM / SCADA

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP / Manual

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/Particle Size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- High / Moderate / Low

- Viscosity

- Low / Medium / High

- Foaming

- Yes / No

- Abrasiveness

- Yes / No

- Container size and shape

- Varies

- Agglomeration risk

- High / Medium / Low

- Control panel type

- HMI (Human Machine Interface)

- Compact footprint

- Pre-plumbed and pre-wired installation module

- Discharge method

- Automatic product fine-tuning and operator adjustment

- Control cabinets/panels

- Real-time extrusion process control

- Control Panel Type

- HMI with Shortcut Keys

- HMI Screen Features

- Alarm Handling, Formula Management, Trending

- PLC Integration

- ControlLogixTM from Allen Bradley

- Software Configuration

- Pre-programmed Sequences for Automatic Startup/Shutdown

- Remote Support Features

- Remote Access/Service

- Data Logging and Reporting

- Advanced Data Logging into SQL Database

- System Security Profiles

- Configurable

- Installation Module

- Pre-plumbed and Pre-wired

- Zone Control

- Integrated Safety with Zone Control

- Future Widget Additions

- Wenger APM Widgets (Optional)